You often see both clevises and shackles in rigging, lifting, and towing, but the main difference lies in their construction and specific applications. Clevises usually offer a fixed connection, while shackles provide removable links for greater versatility.

The global market for these fasteners is booming, with a projected value of $1.2 billion in 2025 and continued growth driven by industrial and construction demands.

When you compare shackles vs clevises, choosing the right one matters for safety and efficiency.

Safety Concern | Implication |

|---|---|

Improper setup | It can lead to dropped loads, damaged equipment, or serious injury. |

Overloading | It can cause failure and result in dropped loads, equipment damage, or injury. |

Under-strength rigging | The most significant cause of lifting accidents, leading to dangerous incidents. |

Key Takeaways

Clevises provide a fixed connection, while shackles offer removable links for flexibility in lifting and towing tasks.

Always inspect fasteners for damage before use. Regular checks prevent accidents and ensure safety during operations.

Choose the right fastener based on your application. Shackles are ideal for dynamic loads, while clevises suit stable connections.

Material matters! Stainless steel shackles resist corrosion, making them perfect for marine environments.

Understand load capacities and safety factors. Always select fasteners that exceed your actual load requirements.

Similarities of Clevises and Shackles

U-Shape and Function

You will notice that both clevises and shackles share a classic U-shaped design. This shape allows you to connect chains, ropes, or cables securely. The U-shape helps distribute force evenly across the fastener, which increases safety during lifting or towing.

Whether you work in construction, marine, or transportation, you rely on this design for stability and strength. The U-shape also makes it easy to attach and detach equipment, saving you time on the job.

Fastening Methods

When you compare shackles vs clevises, you see that both use a pin to close the open end of the U-shape. Clevises use a clevis pin, which you secure with a cotter pin. This setup handles shear loads well and makes installation straightforward. You can remove or replace the pin quickly, which is helpful in many applications.

Shackles, especially D shackles, use a screw pin or bolt. The D shackle design provides better load distribution, making it ideal for high-load tasks. High-strength steel construction allows shackles to handle significant tensile loads, which boosts safety and reliability in industrial settings.

Tip: Always check the pin and threads for damage before each use. A secure fastening method keeps your rigging safe.

Common Uses

You will find both clevises and shackles in many industries. Their versatility makes them essential for a wide range of tasks. Here are some of the most common uses:

Lifting operations, such as hoisting heavy equipment

Towing vehicles or trailers

Serving as tie-downs in cargo transport

Hoisting and pulling in construction or marine settings

Routine maintenance is important for both fasteners. Use this table to guide your inspection schedule:

Inspection Type | Description |

|---|---|

Initial Inspection | Conducted when purchasing new shackles or after alterations/repairs by a certified professional. |

Before Use Inspection | A visual check before each use to identify any distortions or damage; replace if necessary. |

Periodic Inventory Inspection | An annual review considering usage frequency, environmental conditions, and load nature. |

You should always inspect for deformation, surface damage, and the condition of the pin. Remove any damaged fasteners from service to maintain safety.

Shackles vs Clevises: Key Differences

Main Applications

When you compare shackles vs clevises, you notice that each fastener serves unique roles across industries.

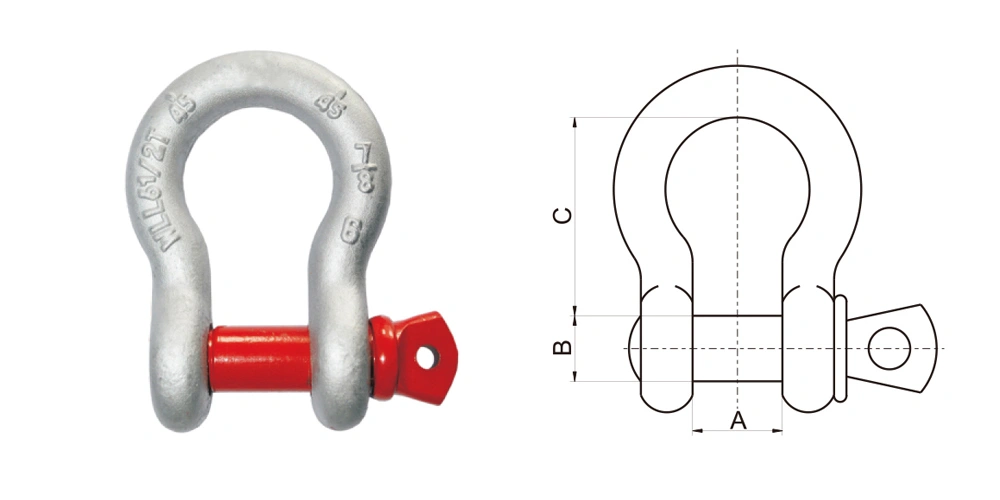

You often use shackles for lifting, towing, and rigging tasks that require frequent connection and disconnection. Powerful Machinery’s Stainless Steel Shackles and G209 Shackle work well in marine, construction, and transportation environments.

Clevises, on the other hand, provide a more permanent or semi-permanent connection. You see them in agricultural equipment, machinery linkages, and structural assemblies where movement is limited.

Application | Typical Use Case | Preferred Fastener |

|---|---|---|

Marine Rigging | Mooring lines, anchor chains | Stainless Steel Shackle |

Construction | Hoisting, load securing | G209 Shackle |

Machinery Linkages | Connecting rods, control arms | Clevis |

Towing | Vehicle recovery, trailer connections | Shackle |

You should always match the fastener to your application. This ensures safety and efficiency, especially when handling heavy loads or working in harsh environments.

Movement and Flexibility

Movement and flexibility set shackles vs clevises apart. Shackles allow for more movement because of their rounded shape and removable pin. You can rotate or pivot loads, which is essential in multi-leg sling setups or when you need to adjust angles during lifting.

The G209 Shackle, for example, handles loads from multiple directions, reducing the risk of side loading.

Clevises offer less flexibility. Their design keeps the connected parts in a fixed alignment. You use clevises when you want to limit movement and maintain precise control over the load’s direction. This makes them ideal for mechanical linkages or structural connections where stability matters more than adjustability.

Material and Strength

Material selection plays a critical role in the performance of shackles vs clevises. You find both fasteners made from steel, stainless steel, carbon steel, and alloy steel. Stainless steel stands out for its corrosion resistance, especially in marine or outdoor settings.

Powerful Machinery’s Stainless Steel Shackles and G209 Shackle use AISI 304 or 316 stainless steel, which ensures durability and long service life.

Here’s a comparison of common materials and their properties:

Material Type | Properties | Strength Rating |

|---|---|---|

Steel | High strength and durability, suitable for heavy loads | Grade 6 or A |

Stainless Steel | Corrosion resistant, good strength, ideal for outdoor/marine environments | Grade 6 or A |

Aluminum | Lightweight, lower load capacity compared to steel | N/A |

Carbon Steel | Strong, tough, economical, commonly used in rigging | Grade 6 or A |

Alloy Steel | Superior strength-to-weight ratio, used for demanding applications | Grade 8 or B |

Stainless steel is also a sustainable choice. It is 100% recyclable and does not emit harmful chemicals during production. Its durability means you replace it less often, which saves resources and reduces environmental impact.

Load capacity varies by application and material. The following table shows typical load capacities for different uses:

Application | Load Capacity (lbs) | Material | Corrosion Resistance | Safety Factor |

|---|---|---|---|---|

Marine Rigging | 7,000 | Galvanized Steel | Excellent | 4:1 |

Construction | 10,000 | Galvanized Steel | Good | 5:1 |

Mining | 15,000 | Galvanized Steel | Very Good | 6:1 |

Offshore Applications | 12,000 | Galvanized Steel | Excellent | 7:1 |

Heavy Lifting | 9,500 | Galvanized Steel | Good | 5:1 |

You should always check the strength rating and safety factor before selecting a fastener. This helps prevent accidents and equipment failure.

Pin Types

Pin type is another key difference in the shackles vs clevises debate. The pin secures the fastener and affects both performance and safety.

Shackles:

Screw pin shackles allow for quick connection and removal. You use them for temporary tasks, but they may loosen under vibration or torque.

Bolt, nut, and cotter shackles provide a more secure connection. You should use these for overhead lifting or long-term installations, as they resist accidental unscrewing.

Clevises:

Clevis pins can be threaded or unthreaded. Unthreaded pins use a cotter pin for security, while threaded pins may pose a risk if not installed properly.

You often see clevises in machinery where the connection needs to stay fixed but still allow for easy removal during maintenance.

Closure mechanisms also impact reliability. Latch mechanisms prevent accidental disengagement, which enhances safety during lifting. Screw-type clevis pins provide a secure attachment, making them reliable for heavy-duty applications.

Closure Mechanism | Description | Impact on Reliability |

|---|---|---|

Latch Mechanism | Prevents accidental disengagement | Enhances safety and reliability during lifting |

Screw-type Clevis Pin | Provides secure attachment | Ensures reliability in heavy-duty applications |

U-shaped Jaw and Pin | Quick and reliable attachment | Essential for consistent performance under load |

Tip: Always select the pin type that matches your application. For overhead lifting, choose a bolt, nut, and cotter shackle. For quick jobs, a screw pin shackle works best.

You also benefit from recent advancements in design and manufacturing. Modern shackles and clevises offer higher load capacities, better corrosion resistance, and easier installation. Powerful Machinery’s products meet international standards and use advanced materials for superior performance.

Choosing the Right Fastener

Identification Tips

You need to identify authentic and high-quality fasteners before every lift. Start by checking for clear markings on shackles, including manufacturer, rated load limit, and size. Inspect each fastener for signs of wear, elongation, or corrosion. If you see more than 10% wear or any cracks, remove the fastener from service.

Look for heat damage, such as discoloration or welding spatter. Always conduct regular inspections—initial, before use, and periodic inventory checks. Regulatory standards require shackles to have legible identification markings and prohibit use without them.

The American Society of Mechanical Engineers (ASME) sets standards for rigging hardware, especially under B30.26 for shackles.

Tip: Discard any shackle with a lost or damaged pin. Never substitute parts, as the pin and body are designed as a matched set.

Sizing and Specs

Selecting the right size and specifications ensures safety and stability. Use this table to match fastener features to your rigging needs:

Factor | Description |

|---|---|

Angle of Loading | Shackles are rated for loads applied in line; angles over 45° reduce capacity. |

Rigging Configuration | The setup affects the size and type of shackle or clevis needed. |

Safety Margin | Choose a working load limit (WLL) higher than your actual load. |

Environmental Conditions | Extreme temperatures or corrosive environments require specific materials and sizes. |

Proper sizing prevents common failure modes like material fatigue and overloading. Select high-quality materials with good fatigue resistance, such as Powerful Machinery’s stainless steel shackles and G209 Shackle. Always follow the manufacturer’s instructions for installation.

Shackle vs Clevis: When to Use Each?

You must consider application, load, and environment when choosing between shackles vs clevises. Use shackles for lifting, towing, and multi-leg sling setups where frequent connection and disconnection are needed. Clevises work best for machinery linkages or structural assemblies that require a fixed connection.

Always calculate load capacities accurately and consider environmental factors. Train personnel in proper rigging techniques and maintain clear communication during operations. Regular inspections and compliance with safety standards help prevent accidents and ensure reliable performance.

Conclusion

You see that clevises and shackles share a U-shaped design, but each serves different roles in rigging. Clevises work best for stable, single-axis connections, while shackles handle heavy loads and dynamic forces.

Feature | Clevises | Shackles |

|---|---|---|

Shape | U-shaped fitting | Metal loop with a removable pin or bolt |

Purpose | Easy attachment and detachment | Designed for heavy loads and dynamic forces |

Load Handling | Stable alignment along a single axis | Handles significant weight safely |

Material | Aluminum or steel | Heavy-duty metals |

Use Cases | Cable systems, suspension setups | Lifting, rigging operations |

Choosing the right fastener protects your team and equipment. Powerful Machinery provides certified, high-quality shackles and rigging hardware for demanding environments.

When selecting rigging hardware, always check material strength, load type, and labeling. Follow updated industry standards for safety and reliability. Regular inspections and compliance with ASME or OSHA guidelines help you maintain safe operations.

FAQ

What is the main difference between a clevis and a shackle?

You will notice that a clevis usually creates a fixed connection, while a shackle offers a removable link. Shackles work best for lifting and rigging. Clevises often serve in machinery or structural assemblies.

How do you choose the right size shackle or clevis?

You should check the working load limit and match it to your application. Always inspect the diameter, pin type, and material. Refer to manufacturer specifications for guidance.

Are stainless steel shackles suitable for marine use?

Yes, you can use stainless steel shackles in marine environments. Their corrosion resistance protects against saltwater and harsh weather. Powerful Machinery’s stainless steel shackles perform well in these conditions.

How often should you inspect shackles and clevises?

You need to inspect before each use and perform a detailed check at least once a year. Look for wear, cracks, or deformation. Remove any damaged fasteners immediately.