A sheave block is a mechanical device that uses a grooved wheel, called a sheave, to guide rope or wire for lifting heavy loads. You often see sheave blocks in construction because they help move materials safely and efficiently.

Understanding how to use a sheave block correctly prevents accidents and damage. Many safety incidents happen when workers select the wrong block, overload it, or skip inspections.

Common Safety Incidents Related to Sheave Blocks |

|---|

Selecting a block not rated for the load |

Improper setup or weak anchor points |

Using worn or damaged snatch blocks |

Overloading the snatch block beyond its rated capacity |

Failing to inspect the block before each use |

Using damaged or worn ropes, hooks, or shackles |

Attaching the block to a weak or unstable anchor point |

Neglecting to monitor the operation during lifting or pulling |

Allowing the rope to twist or slip out of the sheave groove |

Ignoring unusual noises or visible signs of stress during use |

Powerful Machinery offers certified sheave blocks that help you avoid these risks and ensure safe lifting every time.

Key Takeaways

A sheave block uses a grooved wheel to guide rope or wire, making it easier to lift heavy loads safely.

Choose the right type of sheave block based on your lifting needs, such as single, double, or triple blocks for different load capacities.

Always inspect sheave blocks before use to prevent accidents. Look for wear, damage, and ensure proper setup.

Regular maintenance, including lubrication and secure fittings, extends the life of your sheave block and ensures safe operation.

Select certified sheave blocks that meet industry standards for safety and performance, especially in demanding environments.

Sheave Block Basics

What Is a Sheave Block?

You often see a sheave block in places where heavy lifting happens. This device uses a grooved wheel, called a sheave, to guide a rope, cable, or wire. The main job of a sheave block is to help you lift or move heavy loads with less effort.

Note: Sheave blocks are not just single wheels. You can find them in different forms, such as single, double, or even triple blocks. Each type helps you handle different lifting tasks.

According to engineering and rigging handbooks, you can describe sheave blocks as:

Systems that use multiple pulleys (sheaves) to boost lifting capacity and efficiency.

Devices that come in several types, including single, double, triple, or quadruple blocks.

Tools commonly used in rigging, working with cables, belts, or ropes to lift loads.

You will find sheave blocks in construction, marine, and industrial settings. Their strong construction makes them perfect for tough jobs.

How Sheave Blocks Work?

A sheave block works by changing the direction of force and reducing the amount of effort you need to lift a load. When you pull on the rope, the sheave turns, letting the rope move smoothly. This action spreads the weight across the sheave and the block, making lifting easier and safer.

The more sheaves you have in a block, the greater the mechanical advantage. This means you can lift heavier loads with less force. For example, a double sheave block lets you split the load between two wheels, which reduces the strain on each part.

Here is a simple comparison of how much force you need with different lifting devices:

Lifting Device | Mechanical Advantage | Force Required (compared to load) |

|---|---|---|

Sheave Block (4 Pulleys) | 4:1 | 25% of the load weight |

Simple Pulley | 2:1 | 50% of the load weight |

Crane | Varies | Depends on configuration |

You can see that using more sheaves in a block means you use less force to lift the same weight. This makes sheave blocks a smart choice for many lifting jobs.

Sheave Block vs Pulley Block

You might wonder if a sheave block and a pulley block are the same thing. While both use a wheel to guide a rope or cable, they have some key differences in construction and use.

Feature | Sheave Blocks | Pulley Blocks |

|---|---|---|

Load Capacity | Designed for heavy-duty lifting | Typically used for lighter tasks |

Application | Suitable for dynamic jobs and vertical lifting | Ideal for static lifts |

A sheave block is built for tough, heavy-duty lifting. You use it when you need to move large or heavy items, especially in construction or marine work. Pulley blocks, on the other hand, are better for lighter loads and simple tasks. The construction of a sheave block is usually stronger, with more attention to safety and durability.

When you choose between these two, think about the weight you need to lift and the type of job. If you need to handle heavy loads or want a tool that can take on tough conditions, a sheave block is the better choice.

Types of Sheave Block

Single, Double, and Triple Sheave Blocks

You will find several types of sheave blocks in industrial settings. Each type helps you handle different lifting tasks.

Single sheave block: You use this block for basic lifting and pulling. It changes the direction of the rope or cable.

Double sheave block: This block, often called a block and tackle, lets you lift heavier loads with less force.

Triple sheave block: You use this block when you need to lift very heavy loads efficiently. It has three sheaves, which spread the weight and reduce the effort needed.

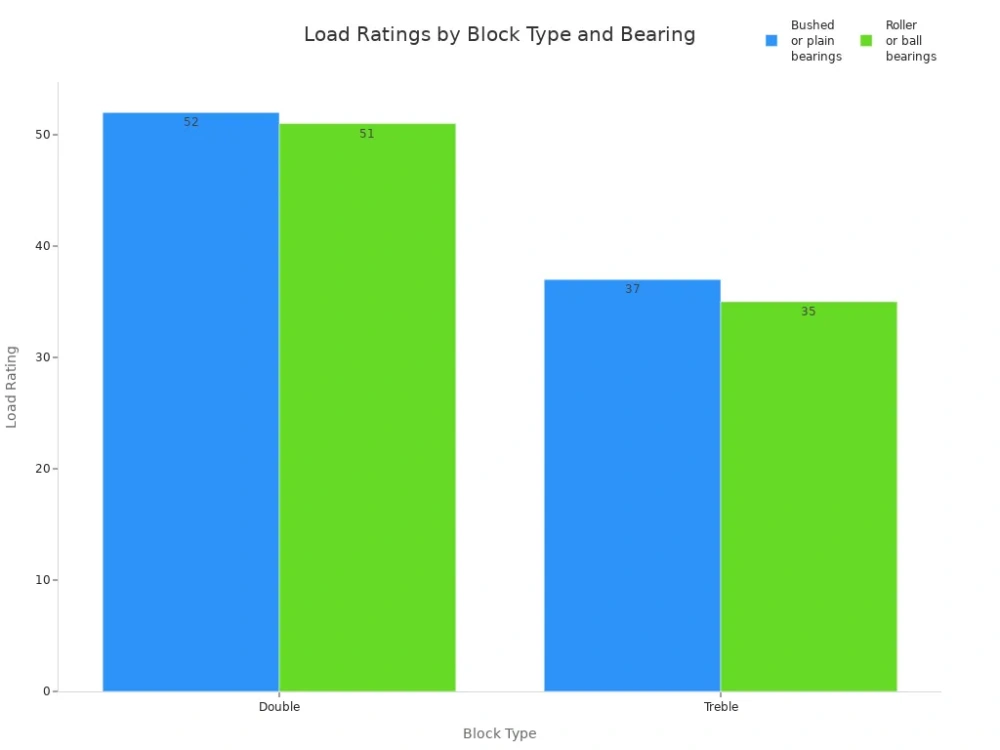

Here is a table showing typical load ratings for double and triple sheave blocks with different bearing types:

Type of block | Number of sheaves | Bushed or plain bearings | Roller or ball bearings |

|---|---|---|---|

Double | 2 | 52 | 51 |

Triple | 3 | 37 | 35 |

You can see that the number of sheaves and bearing type affect the load rating. This helps you choose the right block for your lifting job.

Specialized Sheave Blocks

Some sheave blocks are designed for unique environments or special tasks.

Snatch block: You use this block with winches to pull ropes, especially in offshore work.

Cable block: This block helps you lay cables and prevents sagging during construction.

Travelling block: You see this block in drilling operations, where it moves up and down in the derrick.

Construction block: This block is built for rigging and lifting at construction sites.

Specialized blocks may use advanced materials or designs. For example, Series 800 sheaves feature heavy-duty aluminum frames and custom-machined wheels for specific cable diameters. Instrumented sheaves support oceanographic instruments and use lightweight aluminum and galvanized steel for durability.

Product Type | Features |

|---|---|

Series 800 Sheaves | Heavy-duty aluminum frame, stainless steel hardware, custom-machined Nylatron wheel for cable diameter. |

Instrumented Sheaves | Used as fairleads and cable supports for oceanographic instruments, with lightweight aluminum and galvanized steel construction, snatch block configuration for easy cable handling. |

Material-Specific Sheave Blocks

You will find blocks made for certain rope or cable materials.

Manila block: Made of forged steel, this block resists salt water and lifts heavy cargo.

Nylon block: You use this block with synthetic ropes for pulling and lifting.

Wire rope block: This block helps you lift or lower heavy loads and change direction smoothly.

When you select a block, consider the rope or cable type and the environment. Powerful Machinery’s Pulley & Blocks product range covers all major types of sheave blocks. You get options for single, double, and triple sheaves, as well as snatch, cable, and construction blocks.

These products meet or exceed industry standards like ASME B30.26, ISO 9001, CE, and OSHA. Powerful Machinery tests each block for load limits and safety, giving you reliable performance in tough conditions.

Tip: Always check certifications and load ratings before using any block for lifting. This ensures safety and compliance with industry standards.

Sheave Block Construction

Key Components

When you look at a sheave block, you see several important parts working together to make lifting safe and efficient. Each component has a specific job in the lifting process. Here is a table that shows the main parts and what they do:

Component | Function |

|---|---|

Hook | Connects the block to the lifting equipment |

Strap | Keeps the rope or cable in place |

Shell | Protects the sheave |

Sheave | Acts as a pulley for lifting |

Pin | Allows the sheave to rotate |

Swallow | Opening between the sheave and shell |

Breech | Bottom opening of the shell |

These parts help you distribute weight evenly, change the direction of the rope, and reduce friction. You get smoother movement and less wear on your equipment.

Materials and Finishes

The materials used in sheave blocks play a big role in their strength and durability. Most high-quality blocks use an alloy mix of iron and steel. This combination gives you excellent durability, high strength, and less friction during lifting. Some blocks also include carbon and silicon to make them even tougher.

Powerful Machinery uses only premium materials for its sheave blocks. You benefit from cast iron and steel construction, which stands up to heavy loads and harsh environments. The finishes protect against rust and corrosion, so your block lasts longer and stays safe to use.

Design for Safety and Performance

Safety is always a top priority when you use sheave blocks. Modern designs include features like smooth sheave grooves to prevent rope damage and close-fitting guards to keep the rope in place. You also find guards on the bottom block to stop ropes from getting tangled when the block touches the ground.

Some advanced blocks have adjustable groove diameters. This feature lets you control the lifting process better and reduces the risk of sudden load shifts. Lubrication points or sealed bearings keep the sheave turning smoothly, which means less maintenance and more reliable performance.

Powerful Machinery follows strict industry standards for every block. You can trust that each sheave block meets or exceeds safety requirements, giving you peace of mind during every lift.

Industrial Applications and Lifting Uses

Construction and Marine

You see sheave blocks at work every day on construction sites and in marine environments. In construction, nylon blocks help you pull, lift, and reeve heavy loads. These blocks make it easier to move materials to higher floors or across large areas.

Wire rope blocks play a key role in crane operations, letting you lift or lower heavy loads safely and efficiently. On construction sites, you often need to change the direction of a rope or cable, and a sheave block makes this possible with less effort.

In marine applications, manila sheave blocks stand out. Made from forged steel, these blocks resist salt water and handle heavy cargo. You use them to load and unload ships, move equipment on docks, or manage anchor lines. The durability of these blocks ensures safe lifting operations even in harsh sea conditions.

Tip: Always inspect your sheave blocks before each use to prevent accidents and keep your lifting capacity at its best.

Mining and Power

Sheave blocks also play a vital role in the mining and power industries. In mining, you use them to lift ore, equipment, and other heavy loads from deep shafts. The blocks guide the wire ropes and help you control the movement of materials.

In power line work, sheave blocks support the installation and maintenance of cables. You rely on them to handle the weight and tension of power lines during lifting applications.

These industrial applications demand strong, reliable equipment. Sheave blocks from Powerful Machinery meet strict safety standards, giving you confidence in every operation.

Custom Solutions and Standards

Every lifting job is different. You may need a custom block for a unique application or a certified product for a specific industry. Powerful Machinery offers custom-engineered sheave blocks to fit your exact needs.

The company’s products carry certifications like ISO9001, TUV Rheinland, and OSHA, ensuring they meet or exceed global safety standards.

When you choose Powerful Machinery, you get more than just a product. You gain a partner with deep expertise in industrial lifting operations. The team helps you select the right sheave block for your application, so you can work safely and efficiently every time.

Selection and Maintenance

Choosing the Right Sheave Block

You need to consider several factors when making a selection for your lifting application. Start by checking the weight capacity rating. This tells you the maximum load the block can safely handle. Always match the block’s capacity to the heaviest load you plan to lift.

Next, look at rope compatibility. The rope must fit the sheave groove properly to prevent damage and ensure smooth operation. Rounded sheave edges help reduce friction and protect the rope.

Here is a quick guide to help you compare important criteria:

Criteria | Description |

|---|---|

Durability | Choose a block that withstands your work environment and lifting demands. |

Design Features | Look for features like adjustable grooves for different rope sizes. |

Type of Block | Select the right type, such as snatch or double sheave, for your task. |

Powerful Machinery’s Pulley & Blocks line offers a range of options with robust construction and custom solutions. You can find blocks designed for specific ropes, environments, and lifting needs.

Safety and Compliance

You must follow safety regulations to protect workers and equipment. Sheave blocks should have smooth, defect-free grooves to prevent rope damage. Guards keep the rope in place and stop it from slipping out.

Lubrication points or sealed bearings help the sheave turn smoothly. The table below shows key safety standards:

Regulation | Description |

|---|---|

1910.179(h)(1)(i) | Sheave grooves must be smooth and free from defects. |

1910.179(h)(1)(ii) | Guards must guide the rope back into the groove if it can unload. |

1910.179(h)(1)(iii) | Bottom blocks need guards to prevent ropes from fouling on the ground. |

1910.179(h)(1)(v) | All running sheaves must have lubrication means or sealed bearings. |

Maintenance Tips

Regular maintenance keeps your sheave block safe and reliable. Inspect pins, axles, and fittings for wear. Check side plates for deformation and make sure all nuts and bolts stay secure. Lubricate moving parts based on how often you use the block and the environment.

Store your block in a dry place to prevent corrosion, especially if you work in humid or marine areas. Always check the fit of the rope in the groove and test the safety latch before each use. Following these maintenance protocols helps extend the life of your equipment and ensures safe lifting every time.

Conclusion

You improve safety and efficiency when you understand the types, construction, and selection of sheave blocks. Regular maintenance helps you meet industry safety standards:

Routine inspections help you spot wear, corrosion, or defects early.

Good maintenance prevents accidents and equipment failures.

Choose certified Pulley & Blocks from Powerful Machinery for reliable lifting solutions in any industrial setting.

FAQ

What is the difference between pulley blocks and a block and tackle?

Pulley blocks are single units with one or more sheaves. You use a block and tackle when you combine multiple pulley blocks to increase lifting power. This setup lets you lift heavier loads with less effort.

How do you choose the right pulley blocks for your job?

You should check the load rating, rope compatibility, and environment. Select pulley blocks that match your lifting needs. Always inspect the block before use to ensure safety and reliability.

Can you use pulley blocks in marine environments?

Yes, you can use pulley blocks in marine settings. Choose blocks made from corrosion-resistant materials. Inspect them regularly for signs of rust or wear. Proper care helps you maintain safe lifting operations on ships and docks.

How often should you inspect pulley blocks?

You should inspect pulley blocks before each use. Look for worn sheaves, damaged hooks, and loose pins. Regular checks help you prevent accidents and extend the life of your equipment.

What are sheave blocks and pulley combinations used for?

You use sheave blocks and pulley combinations to change the direction of force and reduce lifting effort. These setups work well in construction, mining, and marine industries. They help you move heavy loads safely and efficiently.

Tip: Always follow manufacturer guidelines when using pulley blocks. Proper use keeps your lifting operations safe.

Inspection Checklist for Pulley Blocks |

|---|

Check Sheave Grooves |

Inspect Hooks |

Test Pins and Axles |

Examine Side Plates |