You achieve safe cable installation when you know how to use wire pulling grips correctly. Selecting the right grip for your cable project matters. Powerful Machinery provides certified pulling grips trusted by professionals worldwide. Choosing the correct grip offers several benefits:

You prevent cable damage and electrical failures.

You minimize physical strain, increasing cable longevity.

You meet safety standards and make installation easier.

This guide helps you work confidently with wire pulling grips, using proven tools from Powerful Machinery.

Key Takeaways

Choose the right pulling grip size for your cable to ensure a secure hold and prevent damage during installation.

Inspect cables for defects before installation to avoid costly mistakes and ensure reliable performance.

Use steady, controlled force when pulling cables to minimize stress and prevent damage.

Always wear personal protective equipment (PPE) to safeguard against potential hazards during cable installation.

Conduct post-installation checks to verify cable integrity and document the installation for future reference.

What Is a Pulling Grip?

A pulling grip is a specialized tool that helps you install or remove cables safely and efficiently. Think of it as a strong, flexible mesh sleeve that wraps around a cable, much like how a finger trap grips your finger.

When you pull on the grip, it tightens around the cable, holding it securely without causing damage. This tool ensures you can guide cables through conduits, ducts, or overhead spaces with control and confidence.

How Pulling Grips Work?

You rely on a pulling grip to hold cables firmly during installation. The design uses a mesh pattern that tightens as you pull, distributing force evenly along the cable. This prevents stress points and reduces the risk of cable damage.

Many grips feature swivel or flexible eyes, which help you navigate bends and prevent twisting. Some models include breakaway eyes that release tension if you exceed safe limits. Engineers select materials and weave patterns to maximize strength, flexibility, and durability.

The grip’s structure spreads the load, so you avoid stress concentrations that could harm the cable.

The main functions and design features include:

Securely holding cables during pulls or removals

Adapting to different cable types and installation scenarios

Using features like swivel eyes, flexible eyes, and breakaway eyes for safety and versatility

Types of Pulling Grips

You can choose from several types of pulling grips, each suited to specific tasks. The table below outlines common types and their best uses:

Grip Type | Description | Effective Scenarios |

|---|---|---|

Single-Eye Mesh Grips | Pulls cables, wires, or ropes | General cable pulling tasks |

Double-Eye Mesh Grips | Eyes on both ends for repositioning | Handling a wide range of cable sizes |

Single Eye Multi Cable Pulling Grips | Lays three single cables at once | Pulling multiple cables simultaneously |

Pulling Grips with Anti-twist Device | Prevents damage to delicate fiber optic cables | Fiber optic installations where tension control matters |

Open Ended Cable Pulling Grips | Joins or pulls two cable ends together | Elevator cable replacement, trenching, mining |

Powerful Machinery Product Features

Powerful Machinery’s Pulling Grip stands out for its robust construction and versatility. You benefit from a high-strength, flexible mesh made from galvanized steel, which resists corrosion and handles tough environments. The grip comes in multiple sizes, fitting a wide range of cable diameters.

Its lightweight design makes handling easy, while the mesh distributes pulling forces evenly to protect your cables. You can trust this tool for both indoor and outdoor projects, knowing it meets strict international safety standards.

Tip: Choose the right size and type of pulling grip for your cable to ensure a secure hold and smooth installation.

How to Use Wire Pulling Grips?

Preparation and Cable Inspection

You start every cable installation by preparing your workspace and inspecting your wire. This step helps you avoid problems later. Examine the cable for any signs of damage. Look for nicks, cuts, or abrasions on the insulation. Even small defects can lead to electrical failures or short circuits.

Environmental factors like moisture or contamination can weaken insulation. If you notice any damage, replace the wire before you begin.

Common cable defects to check:

Damage to insulation

Signs of moisture or contamination

Nicks or cuts from previous handling

Stretched or kinked sections

You also need to confirm that your wire matches the specifications for your project. Powerful Machinery’s Pulling Grip accommodates a wide range of cable diameters, so select the right grip size for your wire. Gather your tools, including gloves and safety glasses, and clear the area of obstacles.

Tip: Careful inspection prevents costly mistakes and ensures your wire performs as expected during installation.

Attaching the Pulling Grip

You attach the pulling grip to your wire by sliding the mesh sleeve over the cable end. Make sure the grip covers enough length to hold the wire securely. Powerful Machinery’s Pulling Grip features a flexible mesh and a loop for easy attachment to your pulling equipment. Avoid attaching the grip to damaged sections of wire.

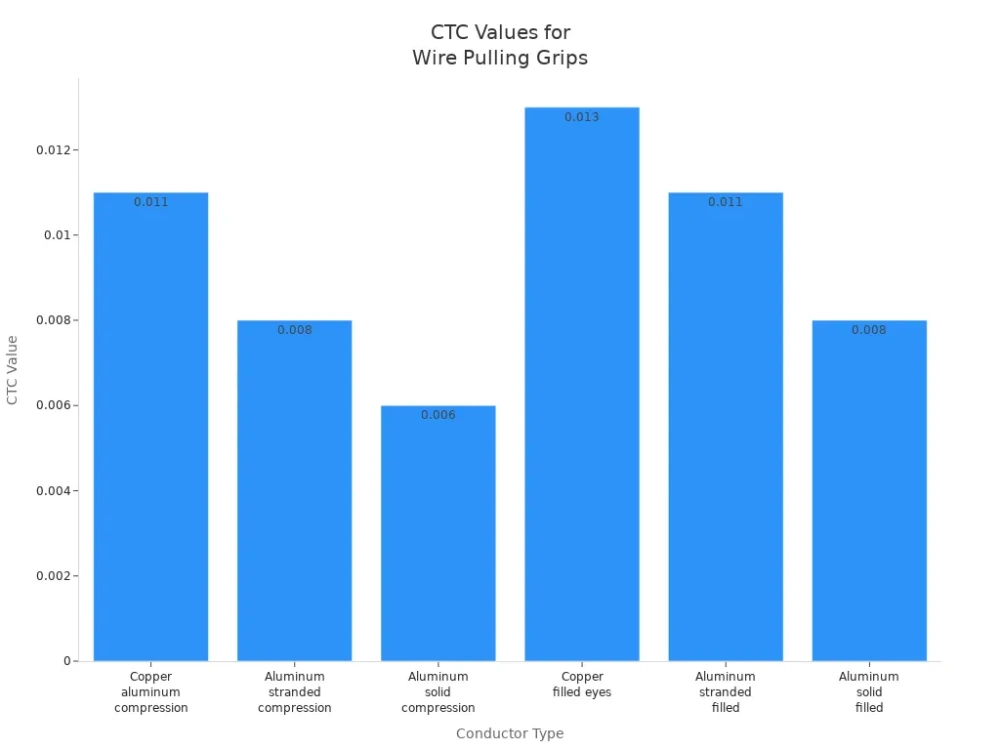

When you attach the grip, pay attention to tension limits. Exceeding recommended tension can damage your wire. Use the following table to determine the maximum pulling tension for different conductor types:

Conductor Type | CTC Value | Maximum Pulling Tension Formula |

|---|---|---|

Copper conductor with aluminum compression eyes | 0.011 | Tmax = CTC x CA x N |

Aluminum stranded conductor with aluminum compression eyes | 0.008 | Tmax = CTC x CA x N |

Aluminum solid conductor with aluminum compression eyes | 0.006 | Tmax = CTC x CA x N |

Copper conductor with filled eyes | 0.013 | Tmax = CTC x CA x N |

Aluminum stranded conductor with filled eyes | 0.011 | Tmax = CTC x CA x N |

Aluminum solid conductor with filled eyes | 0.008 | Tmax = CTC x CA x N |

You calculate the maximum allowable tension using the formula above. For most cable grips, do not exceed 1,000 lbs of pulling force. Powerful Machinery’s grips are engineered to distribute force evenly, reducing the risk of slippage or damage.

Note: Always attach the grip to the strength members of the wire, not the jacket, to prevent stretching or breaking.

Pulling Technique

You begin pulling wires by applying steady, controlled force. Avoid jerking or sudden movements. Powerful Machinery’s Pulling Grip helps you maintain a secure hold and reduces stress on the wire. Follow these best practices for safe and efficient installation:

Best Practice | Description |

|---|---|

Proper cable tension | Prevents damage during installation by avoiding excessive pulling forces. |

Cable pull calculations | Minimizes potential damage by determining appropriate cable sizes and routing. |

Reducing bends | Lower side wall bearing pressure, crucial for maintaining cable integrity. |

Adequate slack | Leaving 20-30 feet of slack ensures easier handling and reduces installation tension. |

Specific tensile ratings | Indicates the maximum allowable cable tension, which is crucial for safe installation. |

You should leave 20-30 feet of slack at the end of the pull. This makes handling easier and reduces tension on the wire. Plan your route to minimize bends and avoid pulling against tight corners. Excessive force can cause cracks, kinks, or breaks in the wire. Never pull on the cable jacket; always use the strength members.

Common mistakes to avoid:

Using too much force

Pulling on the jacket instead of the strength members

Dragging the wire against sharp bends or other cables

Safety Alert: Have a safety plan in place and check your equipment before starting. Stay aware of your surroundings to prevent accidents.

Post-Installation Checks

You finish the installation by inspecting the wire and the entire run. Look for signs of damage, such as cracks, kinks, or burned jackets. Make sure the wire follows the planned route and that the minimum bend radius is maintained.

Powerful Machinery’s Pulling Grip helps prevent damage, but you must verify the integrity of the installation.

Issue Description | Impact |

|---|---|

Cables pulled in two directions from a common mid-point can cause significant damage. | Damage to cables can lead to complications and increased costs for installers. |

Installation cable damage can lead to customer dissatisfaction and project delays. | Hidden damage may affect the power supply and communications after installation. |

Minimum bend radius not adhered to can cause damage to armoured cables. | Exceeding tension and pressure limits can lead to cable failure. |

You should test the wire for continuity and insulation resistance. Address any issues immediately to avoid future problems. Document the installation for future reference.

Tip: Post-installation checks protect your investment and ensure reliable performance.

By following these steps, you will master how to use wire pulling grips for safe cable installation. Powerful Machinery’s certified products give you confidence in every project.

Safety Tips for Using Pulling Grips

Personal Protective Equipment

You protect yourself and your team by wearing the right personal protective equipment (PPE) during cable installation. Always use safety gloves to prevent cuts and abrasions from wire mesh or cable ends. Safety glasses shield your eyes from debris and accidental cable snaps.

For larger projects, consider using hard hats and steel-toed boots to guard against falling objects and heavy equipment. Powerful Machinery recommends PPE for every installation, reinforcing a culture of safety and compliance with international standards.

Tip: Inspect your PPE before each use. Replace damaged gear immediately to maintain maximum protection.

Preventing Cable Damage

You minimize cable damage by following proven techniques and using certified equipment. Powerful Machinery’s Pulling Grips distribute force evenly, reducing stress on the cable. To further protect your cables:

Use appropriate lubricants to reduce friction during pulls.

Ensure proper cable support throughout the route.

Select the correct grip size for your cable diameter.

Plan the cable route to avoid sharp bends and obstacles.

Before you start, inspect all pulling equipment for wear or damage. Apply lubricants suited to your cable type and conduit material. Avoid sharp bends, as these can cause stress and breakage. The table below highlights frequent causes of cable damage and how you can prevent them:

Cause | Explanation |

|---|---|

Bend Radius | Bending the cable too tightly can damage it; keep the minimum bend radius at least 20 times the cable diameter. |

Twisting Cable | Twisting stresses fibers; use a swivel pulling eye to prevent this. |

Use of Cable Ties | Tight cable ties can compress and harm fiber optic cables, leading to attenuation and breakage. |

Avoiding Common Mistakes

You avoid costly errors by following best practices and staying alert to common mistakes:

Overloading the cable puller—never exceed the maximum load capacity.

Selecting the wrong cable or rope—ensure compatibility with your pulling grip.

Setting up improper anchor points—use stable, secure setups.

Overlooking regular maintenance—check and maintain your equipment routinely.

Failing to train operators—make sure everyone understands safety protocols.

Safety Alert: Powerful Machinery’s certified products help you meet safety standards and reduce risks during every installation.

By following these safety tips, you ensure reliable cable installation and protect both your equipment and your team.

Troubleshooting and Special Scenarios

Pulling Pre-Terminated Cables

You face unique challenges when pulling pre-terminated cables. Connectors and terminations require extra care to avoid damage. Begin by planning your route. Avoid bends and obstacles that could strain the cable. Check the path for blockages and mark it clearly.

Use a pulling eye to distribute tension evenly across the fiber strands. This technique reduces the risk of connector damage. Select smooth-walled conduits to minimize friction. Adhere to the minimum bending radius to prevent signal loss.

Gather all necessary tools before starting the pull. Powerful Machinery offers custom pulling grips designed for pre-terminated cables, ensuring safe and efficient installation.

Tip: Always inspect connectors before and after installation to confirm integrity.

Handling Thin or Fragile Wires

Thin or fragile wires demand gentle handling. You should use a wire puller with a grip sized for delicate cables. Avoid excessive force during pulls. Apply cable pulling lubricants to reduce friction and tension. Manage environmental factors such as bend radius and cable thickness.

Lower pulling forces help prevent physical damage. Decreased sidewall pressure improves installation performance and cable longevity. Powerful Machinery can provide specialized grips for fragile wires, tailored to your project needs.

Steps for safe handling:

Select the correct grip size.

Apply lubricant to the cable.

Monitor tension throughout the pull.

Inspect wires after installation.

Solutions for Tight or Long Runs

Tight or long conduit runs present significant challenges. You can use tools like LB Wire Guide or Click-N-Fish Fish Sticks to guide cables through difficult spaces. All American Pull Buddy and Pullee help you pull wire through conduits with less effort. Wire Vortex Plus directs cables smoothly into boxes.

The Jimbo Wire Pull Bracket keeps wires organized during the pull. The Ferret Inspection Camera allows you to inspect tight spaces before fishing wire. Apply cable pulling lubricants to reduce friction and tension.

Understanding the coefficient of friction helps you minimize pulling tension, especially in bends. Powerful Machinery offers custom solutions for complex installations. Consult their experts for advice on specialized equipment.

Note: For long runs, leave adequate slack and monitor cable tension to prevent damage.

Conclusion

You achieve safe cable installation by following each step with care and using certified wire pulling grips. Powerful Machinery’s Pulling Grip offers key advantages:

Withstands breaking loads over three times the working load

Quick to fit and remove, lightweight, and reusable

Adds minimal diameter to the cable during pulls

Stay alert to potential hazards and solutions:

Potential Hazards | Possible Solutions |

|---|---|

Awkward postures | Adjust work height and use platforms |

Manual strain | Use mechanical pullers and spool rollers |

For complex projects, you benefit from expert tips:

Label both cable ends for troubleshooting.

Avoid sharp bends to protect cables.

Test cables before finalizing installation.

You ensure reliability and safety by choosing certified products and following best practices.

FAQ

How do you choose the right size pulling grip for your cable?

You measure the cable diameter before selecting a grip. Powerful Machinery offers grips in multiple sizes. Always match the grip size to your cable for a secure hold. If unsure, consult the product specifications or contact Powerful Machinery for expert advice.

Can you reuse a pulling grip after installation?

Yes, you can reuse Powerful Machinery’s pulling grips. Inspect the grip for wear or damage before each use. Clean the mesh and store it in a dry place. Reusing undamaged grips saves time and reduces costs.

What should you do if the cable gets stuck while pulling?

Stop pulling immediately. Check for bends, blockages, or excessive tension. Apply more lubricant if needed. Gently reverse the pull to free the cable. If the problem continues, consult a professional or Powerful Machinery for troubleshooting support.

Are Powerful Machinery’s pulling grips suitable for outdoor use?

Yes, Powerful Machinery’s pulling grips use galvanized steel for corrosion resistance. You can use them indoors or outdoors, even in harsh environments. Always inspect the grip before use to ensure safety and performance.

How do you maintain your pulling grip for long-term use?

Clean the grip after each project. Remove dirt and debris from the mesh. Store the grip in a dry, cool place. Regularly inspect for signs of wear or corrosion. Proper maintenance extends the life of your pulling grip and ensures safe operation.