You rely on wire rope maintenance to keep your operations safe and reliable. Industry research confirms that regular attention can help steel wire ropes last over 240,000 cycles, reducing fatigue and early failures.

The importance of wire rope maintenance stands out in demanding environments, where early inspection and proper care prevent wear and corrosion. Powerful Machinery puts safety and quality first, offering Steel Wire Rope engineered for high performance and longevity in your toughest applications.

Key Takeaways

Regular inspections of wire ropes can prevent accidents and extend their lifespan. Conduct daily visual checks and detailed monthly evaluations.

Choose the right core type for your wire rope. Steel cores offer strength for heavy loads, while fiber cores provide flexibility for lighter tasks.

Proper cleaning and lubrication are essential. Clean wire ropes before applying lubricant to prevent wear and corrosion.

Follow safe handling practices to avoid injuries. Always keep wire ropes straight, avoid dragging them, and never exceed their safe working load.

Recognize signs of wear and damage early. Replace wire ropes showing broken wires, significant corrosion, or deformation to maintain safety.

Wire Rope Maintenance Tips and Inspection

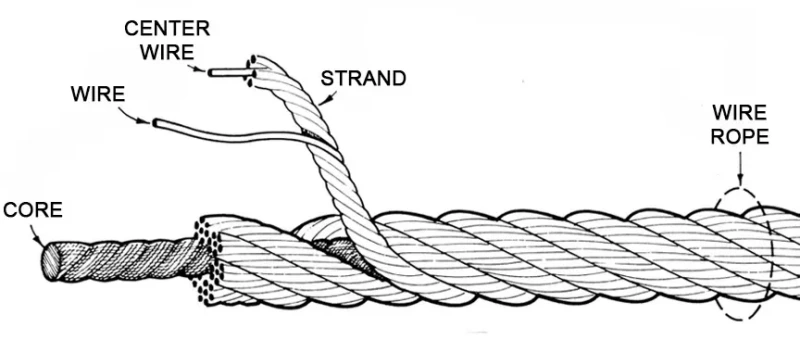

Understanding Steel Wire Rope Structure

You need to understand the structure of steel wire rope before you begin wire rope maintenance. Powerful Machinery’s Steel Wire Rope features a multi-layered design that delivers high tensile strength and durability. The rope’s core type plays a major role in its performance. The table below shows the two main core types and their impact:

Core Type | Characteristics | Performance Impact |

|---|---|---|

Steel Core (IWRC) | Rigid, high-strength structure; resists crushing | Higher tensile strength, better load-bearing, less flexible, ideal for heavy-duty use |

Fiber Core (FC) | Made from natural or synthetic fibers; flexible | Less strength, more flexible, absorbs shock, suitable for frequent bending applications |

Steel wire ropes with a steel core offer superior load-bearing capacity and resist deformation. Fiber core ropes provide flexibility and absorb shock, making them suitable for lighter tasks. Powerful Machinery recommends selecting the right core type for your application to maximize safety and reliability.

Pre-Use and Routine Inspection Steps

You should always perform thorough inspections before using steel wire rope. Routine checks help you spot problems early and prevent accidents. Powerful Machinery advises you to follow these maintenance tips for wire ropes to ensure optimal performance:

Conduct daily visual inspections to identify obvious damage such as cracked strands.

Measure the diameter of the rope at different strategic positions monthly or quarterly.

Evaluate the lay length of the rope regularly.

Assess the degree of corrosion present on the wire rope.

Inspect the most frequently stressed rope zones for wire breaks.

Measure groove diameters in the rope drive.

Evaluate the amount of lubricant on the rope surface.

You can use advanced inspection technology, such as Huisman’s Rope Vision system, for automated visual scans. This system uses high-speed cameras to provide a 360-degree view and measures parameters like lay length, diameter, and broken wires.

Automated inspections enhance reliability and safety, reduce downtime, and align with ISO 4309 standards.

Tip: Always record your inspection results. Keeping detailed logs helps you track changes over time and supports proactive wire rope maintenance.

Signs of Wear and Damage

You must recognize the signs of wear and damage to maintain safety and extend the lifespan of your wire rope. Powerful Machinery’s maintenance tips for wire ropes focus on early detection and timely action. The table below outlines common challenges and solutions:

Challenge | Description | Solution/Prevention |

|---|---|---|

Wire Breakage | Occurs due to fatigue, wear, or overload, compromising strength. | Replace broken sections or the entire rope to maintain integrity. |

Deformation | Alteration in shape, reducing strength and flexibility. | Regular inspections and replacement of deformed ropes. |

Corrosion | Deterioration from environmental exposure weakens the rope. | Regular cleaning and application of anti-corrosion agents. |

Slipping and Flower Knotting | Loss of grip on the drum/sheave, causing safety hazards. | Use specialized tools to re-tighten slipped or flowered sections. |

Wear | Rubbing against surfaces leads to reduced diameter and strength. | Conduct regular inspections and replace worn ropes timely. |

Twisting | Uneven stress distribution causes rotation and potential breakage. | Regularly inspect and address twisted wire ropes. |

You should look for broken wires, reduced diameter, corrosion, and deformation during wire rope maintenance. If you find any of these issues, follow Powerful Machinery’s maintenance tips for wire ropes and replace the rope or affected sections immediately.

Addressing problems early prevents accidents and ensures safe handling.

Note: Powerful Machinery’s Steel Wire Rope features a non-rotating design that helps prevent twisting and kinking, reducing the risk of damage during use.

You can overcome most wire rope maintenance challenges by following a structured checklist, using advanced inspection tools, and applying maintenance tips for wire ropes consistently. Regular inspections and prompt action keep your operations safe and efficient.

Cleaning and Lubrication Instructions

Cleaning Methods and Tools

You must clean the steel wire rope thoroughly before applying the wire rope lubricant. Contaminants act as abrasives and accelerate wear, while trapped moisture increases corrosion risk.

Cleaning also improves your ability to perform a detailed examination during routine inspections. Powerful Machinery’s Steel Wire Rope benefits from proper cleaning, which helps maintain its non-rotating design and high tensile strength.

Cleaning Method | Description |

|---|---|

Thorough Cleaning | Remove dirt, debris, and contaminants from the outer strands and valleys of the wire rope. |

Wire Rope Cleaner | Use a wire rope cleaner to ensure proper penetration of lubricant and enhance corrosion protection. |

Wire Brush and Petroleum Solvent | Clean the wire rope with a wire brush and compatible petroleum solvent if there are hardened lubricants or contaminants. |

Compressed Air or Steam Cleaner | Use compressed air or a steam cleaner for effective cleaning before relubrication. |

You can select from several cleaning tools:

Manual wire rope cleaning brush for small jobs.

Powered wire rope cleaning brush for industrial maintenance.

Cylindrical and round brushes for 360° cleaning.

Special-shaped brushes for unique rope geometries.

Routine inspections and regular equipment checks help you identify when cleaning is necessary.

Lubrication Types and Application

Proper lubrication is essential for extending the service life of steel wire ropes. You should use a wire rope lubricant that matches your application. Penetrating lubricants reach the core, protecting each strand and reducing internal wear. Coating lubricants seal the exterior, reducing corrosion.

Combination lubricants offer comprehensive protection. Petrolatum and grease types provide water resistance and help wash away contaminants. Vegetable oil-based lubricants are effective alternatives.

Type of Lubricant | Description | Purpose |

|---|---|---|

Penetrating | Contains petroleum solvent that penetrates the wire rope core. | Protects and lubricates each strand by leaving a thick film after evaporation. |

Coating | Seals the cable exterior from moisture and reduces corrosion. | Protects the outer surface from external friction. |

Combination | Uses both penetrating and coating lubricants. | Saturates the core and seals the outer surface for comprehensive protection. |

Petrolatum | Translucent with effective corrosion and water resistance. | Maintains consistency in colder temperatures but may drip off under heat. |

Grease (various) | Includes sodium, lithium, and aluminium complex soaps. | Provides excellent wear and rust resistance, and helps wash away abrasive contaminants. |

Vegetable Oil-based | Alternative to petroleum oils, effective in lubrication. | Offers similar benefits in terms of protection and lubrication. |

Proper lubrication reduces internal fatigue, slows corrosion, and maintains flexibility. You should apply wire rope lubricant after each cleaning and during routine inspections.

Scheduling Maintenance

You need to schedule regular equipment checks and examinations based on your environment and application. The table below shows recommended intervals:

Application | Maintenance Priority |

|---|---|

Marine (saltwater) | Frequent rinsing and corrosion checks |

Construction | Daily visual inspections and tension checks |

Elevators/hoisting | Monthly lubrication and testing |

Architecture | Annual cleaning and tension adjustment |

Environmental factors such as humidity and temperature affect your maintenance schedule. You should remove fiber-core ropes exposed to high heat and consult the manufacturer for metallic-core ropes in extreme conditions. Routine inspections and proper lubrication ensure your wire rope remains safe and reliable.

Tip: Always clean steel wire rope before applying wire rope lubricant. This practice supports effective examination and extends rope life.

Use and Maintenance: Handling and Storage

Safe Handling Procedures

You must handle steel wire rope with care to prevent injuries and equipment damage. Powerful Machinery recommends several best practices for safe handling.

Avoid dragging wire ropes across rough surfaces.

Prevent kinking or crushing by keeping the rope straight and untangled.

Never exceed the safe working load specified for your rope.

Inspect ropes regularly for visible damage, wear, corrosion, or distortion.

Lubricate ropes to reduce friction and protect against corrosion.

You should use professional tools when moving or installing wire rope. These tools help guide the rope and maintain its integrity. Always keep tension appropriate to avoid slack, which can lead to kinks or entanglement.

Tip: Proper handling reduces the risk of accidents and extends the lifespan of your steel wire rope.

Storage Guidelines for Steel Wire Rope

You need to store steel wire rope in a way that preserves its quality and performance. Powerful Machinery recommends spooling wire rope on a reel. This method prevents kinks and tangles.

Store the reel in a cool, dry, and well-ventilated area. Avoid exposure to corrosive substances and extreme temperatures. Elevate the base of the reel to prevent water damage.

After extended storage, inspect the rope for signs of corrosion or mechanical damage before use.

Storage Method | Benefit |

|---|---|

Spooling on a Reel | Prevents kinks and tangles |

Elevated Storage | Protects from water damage |

Dry, Ventilated Area | Reduces risk of corrosion |

Preventing Kinks and Damage

You can prevent kinks and mechanical damage by following a few simple steps.

Keep the rope under proper tension to avoid slack.

Place the wire rope correctly to prevent crossing and entangling.

Inspect the rope regularly and address any kinks immediately.

Use professional tools to guide the order of rope strips.

Choose high-quality wire rope materials for better durability.

You should always follow these use and maintenance guidelines to ensure your steel wire rope remains safe and reliable. Consistent attention to handling and storage protects your investment and supports efficient operations.

Safety and Replacement Guidelines

Identifying End-of-Life and Replacement Criteria

You must recognize when steel wire rope reaches the end of its service life to maintain safety and prevent accidents. Industry standards provide clear criteria for replacement. The table below shows the acceptable number of broken wires for different equipment types:

Equipment | Number of Broken Wires in Running Ropes (In One Rope Lay) | Number of Broken Wires in Standing Ropes (In One Rope Lay) |

|---|---|---|

Overhead and Gantry Cranes | 12 | Not Specified |

Portal, Tower, and Pillar Cranes | 6 | 3 |

Crawler, Locomotive, and Truck Cranes | 6 | 3 |

Derricks | 6 | 3 |

Base-Mounted Drum Hoists | 6 | 3 |

Floating Cranes and Derricks | 6 | 3 |

You should also look for other reliable indicators for replacement:

Broken wires exceeding limits.

Diameter reduction of 5% or more.

Advanced corrosion or rust.

Structural distortion or kinking.

Damaged end terminations.

Shock loading events.

Signs of internal core failure.

Rope condition over time, not just age.

Safety Practices During Operation

You need to follow strict safety measures during usage to protect workers and equipment. Powerful Machinery recommends these steps for safe wire rope handling:

Perform visual inspections for cuts, frays, or broken hardware before each use.

Check identification tags for load capacity and usage limitations.

Store wire ropes in clean, dry areas to avoid chemical exposure.

Remove damaged rigging hardware for examination.

Maintain detailed records of inspection dates, findings, and repairs.

International safety standards, such as ASME B30, guide inspection frequency and handling procedures. You should update records after every inspection or repair, including serial numbers and results. Powerful Machinery ensures all repair work meets safety standards and includes certification for every sling.

Tip: Always use proper tools and techniques for wire rope handling. This reduces the risk of injury and equipment damage.

Special Considerations for Hazardous Environments

You face unique challenges when handling steel wire ropes in hazardous environments like chemical plants or offshore platforms. You should increase inspection frequency and lubrication in areas with salt air or chemicals.

Non-destructive examinations help detect internal damage. Always follow manufacturer specifications for maintenance and compatibility.

You must train staff to inspect wire ropes properly and use the right instruments. Load tests help you assess performance and identify failures. Replace ropes that meet or exceed discard standards. Lubrication minimizes internal friction and prevents corrosion. Inspect for dry or cracked surfaces during regular checks.

Note: Consistent attention to handling and safety measures during usage ensures reliable performance, even in the most demanding environments.

Conclusion

You gain significant benefits by following a structured wire rope maintenance checklist. Regular care increases sling lifespan by 35% and reduces equipment downtime by 40%. Safety incidents drop to zero. When you use Powerful Machinery’s recommended practices, you see even greater results:

Improvement Aspect | Details |

|---|---|

Lubrication Impact | Regular lubrication reduces friction and prevents fatigue. |

Service Life Increase | Re-lubrication can extend wire rope life by up to 300%. |

Manpower Reduction | Automatic lubricators cut manual effort by up to 90%. |

Review your procedures often and train your team to keep safety and performance at their best.

FAQ

How often should you inspect steel wire rope?

You should inspect steel wire rope before each use and perform a detailed inspection monthly. High-frequency or critical applications may require weekly checks.

What is the best way to clean steel wire rope?

You can use a wire brush or a specialized wire rope cleaner. Remove dirt and old lubricant before applying new lubricant. Always clean the rope thoroughly for best results.

When do you need to replace wire rope?

Replace the wire rope when you see broken wires, severe corrosion, reduced diameter, or kinks. Follow industry standards for maximum broken wires per lay.

Can you use steel wire rope outdoors?

Yes, you can use steel wire rope outdoors. Powerful Machinery’s Steel Wire Rope resists corrosion and abrasion, making it suitable for harsh environments.

What lubricant should you use for wire rope maintenance?

Choose penetrating lubricants for internal protection and coating lubricants for exterior surfaces. Combination lubricants offer comprehensive coverage. Always match the lubricant to your application.