You need reliable solutions when handling demanding lifting or rigging tasks. Steel wire rope selection plays a critical role in ensuring safety and efficiency across many industries. Powerful Machinery brings over 20 years of expertise to help you choose the right product for your application.

You often encounter steel wire rope in tower cranes, hoisting equipment, elevators, suspension bridges, tension structures, and scaffolding systems. Matching construction to your project’s needs means you achieve optimal strength, flexibility, and durability, even in challenging environments.

Key Takeaways

Select a wire rope based on strength and flexibility to match your lifting needs. This ensures safety and extends the rope’s lifespan.

Always verify load ratings and tensile strength before use. This prevents accidents and ensures safe lifting operations.

Consider environmental factors like moisture and chemicals when choosing wire rope. This helps maintain durability and performance in harsh conditions.

Use a step-by-step checklist for wire rope selection. This simplifies the process and ensures you meet all application requirements.

Consult with experts like Powerful Machinery for tailored solutions. This enhances safety, efficiency, and performance in your projects.

Key Factors in Steel Wire Rope Selection

Choosing the right steel wire rope for your project requires careful consideration of several critical factors. You must evaluate strength, flexibility, safety, and environmental suitability to ensure optimal performance and longevity.

Strength and Flexibility

Strength determines the breaking load and breaking strength of the wire rope. You need to match the rope’s minimum breaking force to your application’s requirements. Flexibility plays a vital role in dynamic environments, such as winching or crane operations.

When you select a rope with the right bend-ability, you reduce wear and extend its lifespan. The following table summarizes the main characteristics you should assess during steel wire rope selection:

Characteristic | Description |

|---|---|

Strength | Minimum breaking force accepted by the wire rope industry. |

Reserve Strength | Relationship between the outer and inner wires’ strength. |

Resistance to Metal Loss and Deformation | Ability to withstand wear and shape changes. |

Crushing Resistance | Resistance to external pressure and distortion. |

Withstands repeated bending under stress. | |

Bend-ability | Ease of bending, influenced by construction and core type. |

Stability | Handling and working characteristics. |

You benefit from Powerful Machinery’s advanced steel wire rope designs, which offer superior flexibility and durability for demanding tasks.

Flexibility helps wire ropes withstand bending and dynamic loads.

The right level of flexibility improves durability and performance, leading to a longer lifespan.

Safety and Load Ratings

Safety is paramount in lifting and rigging operations. You must verify the rope’s load ratings and tensile strength to prevent accidents. The permitted tensile strength varies by wire diameter, as shown in the chart below:

Wire rope grades also affect strength ratings:

Rope Grade | Wire Tensile Strength Guide |

|---|---|

IPS (Improved Plow Steel) | 1570 to 1960 |

EIPS (Extra Improved Plow Steel) | 1770 to 2160 |

EEIPS (Extra Extra Improved Plow Steel) | 1960 to 2160 |

Powerful Machinery’s steel wire rope meets strict international standards, ensuring you achieve reliable breaking load and safety margins for every lift.

Environmental Considerations

Environmental factors influence the durability of steel wire rope. You must consider exposure to saltwater, chemicals, and weather conditions. Saltwater and corrosive chemicals accelerate metal degradation. Hot, humid climates also increase corrosion risk.

Powerful Machinery’s steel wire rope features high-quality steel and specialized finishes, providing excellent resistance to abrasion and corrosion.

Saltwater is highly corrosive in coastal environments.

Acids and bases cause wire rope corrosion.

Weather conditions, such as humidity and heat, affect rope longevity.

You can trust Powerful Machinery to deliver wire ropes that perform reliably in harsh environments, supporting your safety and operational needs.

Wire Rope Construction Basics

Components and Core Types

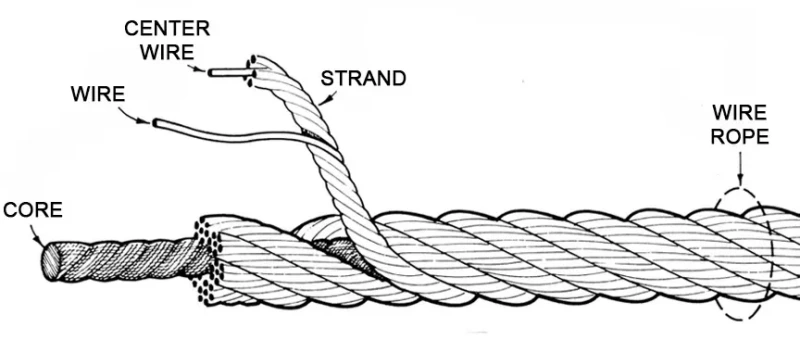

You need to understand the structure of steel wire rope to make the best choice for your project. Each rope consists of several main components. The number of wires and the number of strands determine the rope’s flexibility and strength.

The core supports the strands and influences the rope’s breaking load and durability. Powerful Machinery offers a wide range of wire rope construction options to suit your needs.

Component Type | Description |

|---|---|

Steel Wires | Form the strands of the rope. |

Strands | Wrapped around the core. |

Core | Supports and retains the strands; can be made of steel, fibre, or a combination. |

Core Types | FC (Fibre Core), WSC (Wire Strand Core), IWRC (Independent Wire Rope Core). |

The choice of core type affects flexibility and breaking strength. You can compare the main options below:

Core Type | Flexibility | Strength and Durability | Applications |

|---|---|---|---|

Fiber Core (FC) | High flexibility, ideal for bending | Lower strength, suitable for light-duty | Cranes, marine environments, flexible hoisting |

Steel Core (IWRC) | Moderate flexibility | Up to 15% higher breaking strength, superior resistance | Cranes, winches, mining, and construction |

Wire Strand Core (WSC) | Balanced flexibility and strength | Moderate strength, better resistance to elongation | Control cables, small winches, and mechanical systems |

Materials and Finishes

You must select the right material and finish for your steel wire rope selection. Powerful Machinery uses high-carbon steel for heavy-duty applications. Stainless steel wire rope offers excellent corrosion resistance for marine and offshore environments.

Galvanized wire rope provides extra protection against moisture and harsh weather. The finish impacts the rope’s breaking load and lifespan.

Material | Features | Applications |

|---|---|---|

Steel Wire Rope | High-carbon steel, excellent strength, durable, resistant to corrosion | Heavy-duty applications |

Stainless Steel Wire Rope | High-grade stainless steel, corrosion-resistant, durable | Marine and offshore applications |

Galvanised Wire Rope | Steel coated with zinc, corrosion protection, and durable | Marine, offshore, and harsh weather |

Copper Wire Rope | Highly conductive, corrosion-resistant | Electrical applications |

The finish you choose affects corrosion resistance. Stainless steel provides high protection in harsh settings. Galvanized finishes offer moderate resistance for outdoor use.

Finish Type | Corrosion Resistance Level | Suitable Environments |

|---|---|---|

Galvanized | Moderate | Outdoor use with occasional moisture |

Stainless Steel | High | Harsh environments like marine or chemical settings |

Strand Patterns and Lay Direction

Strand patterns influence flexibility and abrasion resistance. You should consider the strand patterns when selecting wire rope construction for your application. Powerful Machinery offers ropes with various strand patterns to match your needs. The lay direction affects handling and installation.

You must ensure ropes connected in series have the same lay direction. Mismatched lay directions can cause failures at terminations. The coiling direction on drums should match the lay direction to prevent excessive wear and malformation.

Connecting ropes with different lay directions can lead to catastrophic failures, especially at terminations.

The coiling direction on drums must match the lay direction to avoid excessive wear and malformation of the rope.

You can rely on Powerful Machinery’s expertise to guide you in choosing the right strand patterns and lay direction for your steel wire rope.

Steel Wire Rope Performance Factors

Flexibility vs. Abrasion Resistance

You face a critical decision when choosing between flexibility and abrasion resistance in steel wire rope selection. The construction type directly impacts these properties.

For example, ropes with larger outer wires offer more steel on the surface, which increases abrasion resistance but makes the rope stiffer. Ropes with smaller wires bend more easily, providing greater flexibility but wearing out faster in abrasive conditions.

Aspect | Larger Outer Wires | Smaller Wires |

|---|---|---|

Abrasion Resistance | More steel on the surface, better against wear | Wears out faster under abrasive conditions |

Flexibility | Stiffer, less flexible | More flexible, better for repeated bending |

You should also consider strand patterns. Lang lay ropes deliver high abrasion resistance and greater fatigue resistance, making them ideal for mining and heavy-duty lifting. Regular lay ropes resist crunching forces and provide moderate abrasion resistance.

Alternate lay ropes suit special applications where performance needs vary.

Wire Rope Construction | Characteristics | Abrasion Resistance |

|---|---|---|

Lang Lay | Greater fatigue resistance | High |

Alternate Lay | Special applications | Varies |

Regular Lay | Resistant to crunching | Moderate |

Fatigue and Durability

You must protect your steel wire rope from fatigue and premature failure. Mechanical stresses from overloading and improper installation weaken the rope. Cumulative damage builds up over time, reducing the rope’s breaking load and endurance.

Fatigue from repeated stress cycles lowers the rope’s lifespan. Environmental exposures, such as corrosion and temperature changes, also degrade the rope.

Mechanical stresses from overloading and improper installation practices can weaken wire ropes.

Cumulative damage accumulates over time, diminishing the rope’s strength.

Fatigue from repeated stress cycles reduces the rope’s endurance limit.

Environmental exposures such as corrosion and temperature fluctuations can lead to wire rope degradation.

The most common failure modes are fatigue and tensile overload. Factors that influence these failures include the diameter over which the rope bends, rope tension, frequency of bending, wear on the rope’s surface, corrosion, core collapse, local distortion, and temperature.

Specialized Features of Powerful Machinery Steel Wire Rope

You gain significant advantages when you choose Powerful Machinery steel wire rope for your operations. The non-rotating design minimizes twisting and kinking, which helps maintain stability and safety during lifting.

High abrasion resistance ensures the rope withstands tough conditions, extending its service life and maintaining a reliable breaking load. Corrosion resistance is another key feature. Galvanized wire ropes provide at least 50% better corrosion resistance than standard steel ropes.

Protective coatings like zinc and aluminum, or the use of stainless steel, enhance durability and prevent rust. Stainless steel offers exceptional strength and durability, which lowers maintenance costs and improves safety in challenging environments.

Tip: Selecting a wire rope with the right combination of flexibility, abrasion resistance, and corrosion protection ensures you achieve optimal breaking strength and breaking load for your specific application.

You can rely on Powerful Machinery’s expertise to guide you in steel wire rope selection, ensuring your equipment performs safely and efficiently in any environment.

Application Matching and Steel Wire Rope Selection Guide

Industry Applications

You must match wire rope construction to your industry’s demands. Each sector requires specific features for safety and efficiency. Construction projects need ropes with high breaking loads and flexibility for cranes and hoists. Marine operations demand corrosion-resistant ropes for saltwater exposure.

Mining sites rely on abrasion-resistant ropes for heavy load support and frequent bending. The oil and gas industry uses specialized wire ropes for extreme conditions and high breaking strength.

The following table highlights recommended steel wire rope constructions for the oil and gas industry:

Wire Rope Type | Key Features |

|---|---|

XLT4 | High strength-to-diameter ratio |

Starlift Xtra | Durable and crush-resistant |

Flex-X9 | High-density construction minimizes strand nicking |

Flex-X6 | Exceptional strength and stability |

You should select wire rope construction based on your project’s load requirements, environmental exposure, and operational cycles. Powerful Machinery offers a wide range of steel wire rope options, ensuring you achieve the right breaking load and durability for your application.

Environmental Suitability

You must consider environmental factors when making steel wire rope selection. Temperature changes, moisture, and chemicals affect rope performance and lifespan. Hot conditions cause steel wire ropes to expand, increasing tension and stress.

Cold temperatures make ropes brittle and inflexible, raising the risk of fractures. Polymer-coated ropes resist temperature extremes, enhancing safety and durability.

Temperature variations can cause steel wire ropes to expand and increase tension in hot conditions.

In cold temperatures, steel wire ropes can become brittle and inflexible, increasing the risk of fractures.

Polymer-coated ropes are designed to resist these temperature extremes, enhancing durability and safety.

You should also evaluate exposure to saltwater, acids, and bases. Galvanized and stainless steel wire ropes provide superior corrosion resistance for marine and chemical environments.

Powerful Machinery’s steel wire rope features advanced coatings and materials, ensuring reliable breaking load and long service life in harsh conditions.

Tip: Always match your steel wire rope selection to the environment. This practice prevents premature wear and ensures consistent breaking strength.

Step-by-Step Selection Checklist

You can simplify steel wire rope selection by following a clear checklist. This process helps you choose the right wire rope construction for your specific needs.

Define Application Requirements

Identify the type of load (static, dynamic, heavy load support).

Determine the required breaking load and breaking strength.

Assess Environmental Conditions

Check for exposure to moisture, chemicals, or extreme temperatures.

Select appropriate materials and finishes (galvanized, stainless, polymer-coated).

Choose Wire Rope Construction

Select a strand pattern and core type for flexibility or abrasion resistance.

Match rope diameter and configuration to equipment specifications.

Verify Safety and Compliance

Ensure ropes meet international safety standards.

Confirm load ratings and certifications.

Consult Powerful Machinery for Custom Solutions

Request tailored material selection for your environment.

Optimize strength for specific loads.

Adjust design for compact diameters or enhanced flexibility.

Ensure testing and certification for compliance.

Customization Aspect | Description |

|---|---|

Material Selection | Tailored to environmental conditions (e.g., corrosive, high-temperature). |

Strength Optimization | Ensures ropes are optimized for specific loads. |

Design Adjustments | Adjustments for industry-specific needs, such as compact diameters or enhanced flexibility. |

Testing and Certification | Ensures compliance with international safety standards. |

Note: Consulting with Powerful Machinery gives you access to expert guidance and custom-engineered steel wire rope solutions. You can achieve optimal breaking load, safety, and efficiency for any project.

You can rely on this checklist to make informed decisions and maximize the performance of your steel wire rope selection.

Conclusion

You improve safety and efficiency when you select the right wire rope construction.

The correct wire rope class boosts performance and equipment longevity.

Balancing wear resistance and flexibility supports safe lifting operations.

Compliance with standards and regular inspections increases reliability.

Powerful Machinery’s expertise helps you reduce downtime and maintenance costs:

Service Feature | Benefit |

|---|---|

Comprehensive inspections | Prevents costly failures |

Customized maintenance schedules | Minimizes disruptions |

Expert repairs | Optimizes equipment performance |

Proactive maintenance | Reduces unplanned downtime |

Consult Powerful Machinery for tailored solutions and use the checklist for best results.

FAQ

What is the main advantage of non-rotating steel wire rope?

You gain stability during lifting operations. The non-rotating design prevents twisting and kinking, which improves safety and extends the lifespan of your wire rope.

How do you choose the right wire rope for outdoor use?

You should select galvanized or stainless steel wire rope. These materials resist corrosion and abrasion, making them ideal for harsh weather and marine environments.

Can you request custom wire rope solutions from Powerful Machinery?

You can request custom-engineered wire rope solutions. Powerful Machinery tailors products to your project’s requirements, including material, diameter, and strand pattern.

What certifications do Powerful Machinery steel wire ropes meet?

You receive wire ropes that meet international standards, including ISO9001, TUV Rheinland, and OSHA. These certifications ensure safety and reliability for your operations.

How often should you inspect your steel wire rope?

You should inspect your wire rope before each use. Regular inspections help you identify wear, corrosion, or damage, which improves safety and prevents equipment failure.