Selecting the right wire rope core types is vital for both safety and performance in demanding industries. Each wire rope core offers unique features and applications:

Type of Core | Key Features | Applications |

|---|---|---|

Fiber Core (FC) | Lightweight, flexible, retains lubrication | Light-duty lifting, marine, flexible hoists |

Steel Core | Higher strength, crush and heat resistant | Cranes, winches, mining, high-load work |

Independent Wire Rope Core (IWRC) | Strong, resists deformation | Heavy lifting, offshore, construction |

Wire Strand Core (WSC) | Flexible with balanced strength | Control cables, pulleys, and mechanical systems |

Choosing the right steel wire rope core type can help you avoid exceeding safe wear or strength limits. Powerful Machinery delivers certified wire rope solutions trusted for critical lifting and rigging needs.

Key Takeaways

Choosing the right wire rope core type is crucial for safety and performance in various industries.

Fiber cores offer flexibility and are best for light-duty tasks, while steel cores provide strength for heavy loads.

Independent Wire Rope Cores (IWRC) are ideal for demanding jobs due to their high strength and durability.

Regular maintenance and inspection of wire ropes ensure safety and extend their lifespan.

Powerful Machinery provides certified wire rope solutions tailored to meet specific project needs.

Wire Rope Core Types Overview

What Is a Wire Rope Core?

You encounter wire rope core types in many industries. The wire rope core sits at the center of the wire rope. It supports the outer strands and helps the rope keep its shape. You find several types of wire rope cores, each designed for specific tasks. Fiber cores use natural or synthetic fibers for flexibility.

Steel wire cores offer extra strength and resist crushing. Independent wire rope cores (IWRC) use a separate wire rope as the core, giving maximum strength and durability. Wire strand cores (WSC) use a single strand of wire for balanced strength and flexibility.

These types of wire rope cores play a key role in how the wire rope performs under load.

Powerful Machinery stands out as a trusted provider of certified steel wire rope products. You benefit from their experience and commitment to quality. Here is why many professionals choose Powerful Machinery:

Evidence Description | Details |

|---|---|

Extensive experience in the industry | Powerful Machinery has a long-standing presence, showing reliability. |

Rigorous quality control processes | Quality is built into every stage of production. |

Comprehensive testing of products | Each batch undergoes chemical analysis and proof-load testing. |

Full traceability from production to shipment | Products are certified for safety and reliability. |

Positive customer testimonials | Customers praise the reliability and safety of the products. |

How Core Types Affect Performance?

You notice that the types of wire rope cores directly impact performance. The core determines how much load the wire rope can handle, how flexible it feels, and how well it resists crushing or heat. You select fiber cores for flexibility and light-duty tasks.

Steel wire cores work best for heavy loads and harsh environments. IWRC types provide the highest strength for demanding jobs. WSC types balance flexibility and strength for control cables and mechanical systems.

Recent advancements have improved wire rope core types:

Synthetic fiber cores, such as high-density polyethylene, increase strength-to-weight ratios and boost compression resistance.

Future wire rope technology will use advanced alloys and high-strength composites for greater resilience.

Wire rope cores now use various materials, including fiber for flexibility and IWRC for maximum strength, meeting different load needs.

You see that choosing the right wire rope core type ensures safety and efficiency. Powerful Machinery offers certified steel wire rope solutions that meet strict standards and deliver reliable performance for every application.

Types of Wire Rope Cores

Wire rope stands as a vital tool in many industries. You rely on its strength, flexibility, and durability for lifting, hoisting, and securing heavy loads. The core is one of the most important components of wire rope. It determines how the rope performs under different conditions.

You can choose from three main types: fiber core, independent wire rope core, and wire strand core. Each type offers unique features and benefits for specific applications.

Fiber Core (FC)

Fiber core wire rope uses natural or synthetic fibers at its center. You often see materials like sisal, hemp, or cotton yarn. This design gives the rope excellent flexibility and helps it retain lubrication. You find fiber core ropes in industries that need light-duty lifting and smooth operation.

Feature | Description | Common Industries |

|---|---|---|

Construction | Made from natural or synthetic fibers such as sisal, hemp, cotton yarn, etc. | Telecommunications, Agriculture |

Lubrication | It can store more lubricant, enhancing lubrication for the steel wire rope. | |

Load Suitability | Suitable for light loads and light-duty environments. |

Fiber core ropes offer several advantages. You get high flexibility, a good strength-to-weight ratio, and superior breaking load. These ropes also provide good fatigue life, which means they last longer under repeated bending.

Advantages of Fiber Core | Disadvantages of Fiber Core |

|---|---|

High flexibility | Lower crush resistance |

High strength-to-weight ratio | Lower strength than steel in some applications |

Superior breaking load | Cannot be used in high-heat environments |

Good fatigue life | N/A |

You should use fiber core wire rope when you need agility and smooth movement. These ropes work well in telecommunications, agriculture, and other general environments. Powerful Machinery offers steel wire rope with fiber core options for applications that require lightweight and flexible solutions.

Independent Wire Rope Core (IWRC)

The independent wire rope core, or IWRC, uses a separate wire rope as its core. This structure usually consists of a 6×7 wire rope with a 1×7 wire strand core, forming a 7×7 configuration. You benefit from higher tensile and bending breaking strength compared to fiber core ropes.

IWRC provides significant resistance to crushing and deformation.

An IWRC increases the strength of a wire rope by about 7% and its weight by 10%.

You get less flexibility, but much greater resistance to crushing.

IWRC contributes roughly 7.5% to the total strength of the rope.

You should choose IWRC for heavy-duty applications. It offers superior strength and durability over fiber core and wire strand core. You see IWRC in cranes, excavators, and drilling lines. These ropes handle high loads and harsh environments with ease.

IWRC gives you enhanced crush resistance, making it ideal for heavy-duty work.

The durability of IWRC suits industrial uses such as cranes and drilling lines.

Powerful Machinery supplies steel wire rope with IWRC for maximum strength and reliability. You can select configurations like 35W×7 or 18×19 for crane operations and other demanding tasks.

Wire Strand Core (WSC)

Wire strand core, or WSC, uses a single strand of wire at the center. This design gives you a balance between strength and flexibility. WSC provides high strength, structural stability, and outstanding crush resistance. You find WSC in ultra-heavy-duty lifting equipment and mechanical systems.

Type | Key Features | Advantages | Typical Applications |

|---|---|---|---|

Wire Strand Core (WSC) | High strength, structural stability, and outstanding crush resistance | Ultra-heavy-duty lifting equipment | Ultra-heavy-duty lifting applications |

Independent Wire Rope Core (IWRC) | High strength, heat, and crush resistance | Excellent resistance to compression and superior load capacity | Heavy-duty lifting equipment, e.g., bridge crane main hoisting ropes |

Fiber Core (FC) | Good elasticity, internal lubrication | Low cost, excellent flexibility | General environments, light to medium-duty use |

WSC offers higher tensile strength and better resistance to crushing forces than fiber core. It also tolerates heat well, making it suitable for high-temperature environments. However, you may notice that WSC is less flexible than other options.

Property | Description |

|---|---|

Tensile Strength | Significantly higher tensile strength, ideal for demanding applications. |

Resistance to Crushing Forces | Enhanced resistance, crucial for environments with crushing loads. |

Flexibility | Less flexible compared to other options, suitable for specific applications. |

Heat Tolerance | Greater tolerance to heat makes it suitable for high-temperature environments. |

You should use wire strand core wire rope in ultra-heavy-duty lifting and high-temperature environments. Powerful Machinery offers steel wire rope with WSC for these specialized needs.

Comparing Core Types and Maintenance

You must consider several factors when choosing a wire rope core. IWRC and WSC provide higher strength and crush resistance than fiber core. Fiber core gives you the most flexibility and is lighter in weight. Steel core ropes, including IWRC and WSC, last longer under heavy loads and resist heat better.

Performance Parameter | IWRC (Steel Core) | FC (Fiber Core) |

|---|---|---|

Tensile Strength | Very High | Medium |

Flexibility | Moderate | Very High |

Heat Resistance | Excellent | Weak |

Crush Resistance | Excellent | Poor |

Corrosion Resistance | Good (if galvanized) | Good (with lubrication) |

Weight | Heavier | Lighter |

Cost | Slightly higher | Lower |

Service Life (under heavy load) | Longer | Shorter |

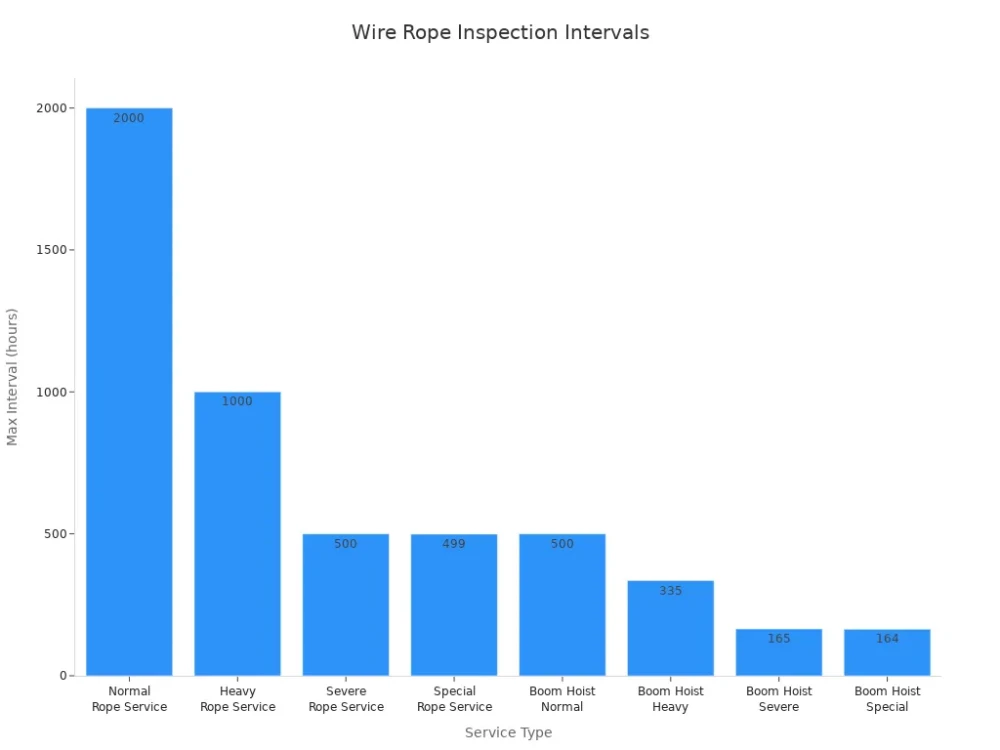

You need to maintain your wire rope to ensure safety and performance. Regular lubrication prevents corrosion and reduces friction. You should inspect your wire rope before and after each operation. Record any defects and address them quickly. Inspection intervals depend on service type.

Service Type | Inspection Interval |

|---|---|

Normal Rope Service | Not to exceed 12 months or 2,000 hours |

Heavy Rope Service | Not to exceed 6 months or 1,000 hours |

Severe Rope Service | Not to exceed 3 months or 500 hours |

Special Rope Service | Less than 500 hours |

Boom Hoist Normal | Not to exceed 3 months or 500 hours |

Boom Hoist Heavy | Not to exceed 2 months or 335 hours |

Boom Hoist Severe | Not to exceed 1 month or 165 hours |

Boom Hoist Special | Less than 165 hours |

Powerful Machinery offers a full range of steel wire rope configurations. You can select the right core type for your needs, whether you require maximum strength, flexibility, or a balance of both. Each product meets strict international standards for safety and performance.

You can trust Powerful Machinery to deliver reliable wire rope solutions for any industry.

Choosing Wire Rope Core Types

Factors for Selection

You need to consider several important factors when selecting wire rope core types for your project. The right wire rope core ensures safety and reliable performance. Here are the main points you should evaluate:

Strength must handle the maximum load with proper safety factors.

The wire rope should withstand repeated bending without wire failure from fatigue.

The wire rope core needs to resist abrasive wear.

The wire rope must endure distortion and crushing, also known as abuse.

You should also look at load capacity, flexibility, and environment:

Load Capacity: Check the maximum load your wire rope will support. Make sure the wire rope core type provides enough strength.

Flexibility: Decide how much flexibility you need. If your wire rope bends often, choose a core that allows for frequent movement.

Environment: Think about where you will use the wire rope. Outdoor or marine settings may require galvanized or stainless steel wire rope for corrosion resistance.

Tip: Always measure the wire rope diameter accurately. Use proper techniques for unreeling, installing wire clips, and cutting. Store your wire rope safely to prevent rust and damage. These steps help maintain safety and extend the life of your wire rope.

Application Recommendations

You can match wire rope core types to your specific needs by looking at their characteristics and costs. The table below helps you choose the best option:

Core Type | Characteristics | Suitable For | Cost Implication | Performance Characteristics |

|---|---|---|---|---|

Fiber Core | Enhances flexibility and elasticity, reduces internal friction and wear. | High-flexibility applications | Least expensive | Offers flexibility but lower strength |

Metal Core | Provides greater strength and resistance to crushing, less elastic but robust. | High-load scenarios | Middle-tier cost | Used in smaller diameters |

Hybrid Core | Combines fiber and metal for both flexibility and strength. | Dynamic environments like offshore winching | Most expensive | Best strength and structural stability |

You should use fiber core wire rope for tasks that need high flexibility, such as control cables or pulleys. Metal core wire rope works best for heavy lifting, cranes, and mining. Hybrid core wire rope is ideal for offshore winching and dynamic environments.

For outdoor or marine applications, choose galvanized wire ropes for rust protection. Stainless steel wire rope offers excellent corrosion resistance for marine and chemical settings. Marine wire rope is designed for strength and durability in harsh conditions.

Powerful Machinery provides custom-engineered steel wire rope solutions for many industries. Clients like Serenco UK, Cirque Du Soleil, and Costco trust Powerful Machinery for safety and reliability.

You can find wire rope for automotive, marine, entertainment, and industrial uses. Each wire rope core type meets strict safety standards and fits your project needs.

Conclusion

You see clear differences among wire rope core types. The table below highlights their best uses:

Feature | Fiber Core (FC) | Independent Wire Rope Core (IWRC) | Wire Strand Core (WSC) |

|---|---|---|---|

Strength and Durability | Lighter jobs | Heavy-duty, high-load tasks | General use |

Flexibility | Frequent bending | Less flexible | Moderate |

Resistance to Crushing | Susceptible | Excellent | Adequate |

To choose the right core, follow this checklist:

Match the core type to your load and environment.

Confirm certifications for safety.

Ask Powerful Machinery for custom solutions.

You improve reliability and efficiency when you select certified products and expert guidance.

FAQ

What is the main difference between IWRC and fiber core wire ropes?

You get higher strength and crush resistance with IWRC. Fiber core gives you more flexibility and better lubrication retention. Choose IWRC for heavy loads. Use a fiber core for light-duty tasks.

How do I know which wire rope core type to choose?

You should consider load, flexibility, and environment. For heavy lifting, pick IWRC or WSC. For frequent bending, select a fiber core. Always check your application needs before you decide.

Can I use steel wire rope outdoors?

Yes, you can. Powerful Machinery’s steel wire ropes resist corrosion and abrasion. You should choose galvanized or stainless steel options for the best outdoor performance.

Does Powerful Machinery offer custom wire rope solutions?

Yes! You can request custom-engineered wire rope solutions. Powerful Machinery tailors products to your project’s requirements and meets strict international safety standards.