You rely on load testing for lifting equipment to ensure that your operations meet strict industrial safety standards. Load testing verifies the strength and reliability of lifting equipment under real-world conditions. Regular testing plays a vital role in reducing accidents, meeting OSHA regulations, and keeping your workplace safe.

Companies that prioritize load testing often avoid costly penalties and minimize operational disruptions. Powerful Machinery provides certified solutions that help you maintain high compliance rates and protect your team.

Key Takeaways

Load testing ensures lifting equipment meets safety standards and can handle expected loads, reducing the risk of accidents.

Regular load testing helps identify weaknesses in equipment, ensuring worker safety and compliance with regulations like OSHA.

Different types of load tests, such as proof and dynamic load tests, serve unique purposes to verify equipment performance under various conditions.

Documenting load tests and inspections is crucial for compliance and helps track the condition of your lifting equipment over time.

Using certified equipment and qualified personnel for load testing enhances safety and reliability in lifting operations.

Load Testing for Lifting Equipment: Definition and Purpose

What Is Load Testing?

You need to understand load testing for lifting equipment before you can ensure workplace safety and compliance. Load testing is a process where you apply a specific load to a structure or lifting device to verify its strength and performance. This test helps you determine if your equipment can safely handle the loads it is designed for.

Load testing is a process that involves applying a load to a structure or lifting equipment. A proof load test is a subset of the load test. It helps determine the load-bearing capacity of a structure or equipment.

You will encounter several types of load testing in your operations. These include:

Proof load testing

Dynamic load testing

Water bag testing

Dead weight testing

Static load testing

Load cell testing

Non-destructive testing

Each method serves a unique purpose. For example, proof load testing confirms that your hoist or crane can bear a specific weight without permanent deformation. Dynamic load testing checks how your equipment performs under moving loads.

Static load testing evaluates the ability of your lifting equipment to hold a load steadily. These tests help you meet industry standards and prevent unexpected failures.

Load testing is a critical process that ensures the safety and performance of lifting equipment. You apply specific loads to assess the equipment’s load-bearing capacity, which is vital for compliance with standards.

When you perform a load test, you gain confidence that your equipment will operate reliably during lifting tasks.

Why Is Load Testing Necessary?

You must conduct load testing for lifting equipment to protect your team and your business. The primary objectives include:

Ensuring safety by identifying weaknesses or deficiencies in the equipment.

Verifying load limits and functionality under extreme conditions.

Assessing structural integrity to prevent potential failures or accidents.

Maintaining compliance with safety regulations and industry standards.

Enhancing the reliability and longevity of the equipment through regular testing.

When you perform load testing, you reduce the risk of equipment failure during lifting operations. This process ensures worker safety and meets safety standards set by governing bodies like OSHA, ASME, or CSA. You also confirm that your equipment remains reliable and efficient, allowing it to perform its intended tasks.

The risks you mitigate through load testing include:

Risk Type | Description |

|---|---|

Structural Weaknesses | Load testing helps identify cracks, worn-out welds, and loose bolts in the crane’s structure. |

Lifting Capacity Verification | Ensures cranes can safely lift expected loads, preventing accidents due to overloading. |

Safety Features Evaluation | Tests the effectiveness of safety features like limit switches and overload protection devices. |

Regulatory Compliance | Demonstrates adherence to safety standards, avoiding legal issues and penalties. |

Lifespan Extension | Prevents minor issues from escalating, optimizing maintenance, and reducing wear and tear on components. |

You benefit from load testing because it reduces workplace injuries. Mechanical assistance from ergonomic lift systems lowers the physical effort required from workers. This reduction helps prevent muscle fatigue, which often leads to poor lifting techniques and injuries.

Overhead lifting technologies eliminate ergonomic strains, minimizing manual handling and the risk of accidents.

You can further improve safety by implementing training programs that emphasize safe lifting techniques. These programs can reduce injury rates by up to 50% in some industries.

The NIOSH Lifting Equation helps you calculate safe lifting limits, considering factors like weight and frequency. A recent study reported a 35% reduction in lifting injuries after following NIOSH guidelines.

Load testing for lifting equipment is not just a regulatory requirement. It is a proactive step you take to ensure safety, reliability, and compliance in your workplace. When you invest in regular load testing, you protect your team, your equipment, and your reputation.

When Is a Load Test Required?

Installation and Commissioning

You must perform a load test before you use any new lifting equipment. This step ensures that your crane, hoist, or overhead lifting device meets all safety and load testing requirements. During installation and commissioning, you need to:

Arrange for a qualified individual to inspect and certify the equipment.

Make sure your employer organizes the inspection and maintains proper certification.

Follow the Workplace Safety and Health Act and Codes of Practice set by the Ministry of Manpower.

Complete load testing for lifting equipment before initial use.

Keep written reports of the load test and inspection results for the equipment’s lifespan.

OSHA and ASME standards require you to test new, reinstalled, altered, or repaired cranes and hoists with a load between 100% and 125% of the rated capacity. The Crane Manufacturers Association of America also recommends a load test at least once every four years, with documentation available for review.

Note: You should always have test reports ready for appointed personnel. This practice helps you meet regulatory requirements and ensures safety from the start.

After Repairs or Modifications

You need to conduct a load test after any major repairs or modifications to your lifting equipment. This process confirms that the equipment can handle its rated load safely before returning to service. Industry guidelines state:

Perform proof load tests after significant modifications or repairs.

Test new cranes before initial use and every four years after that.

Test uncertificated cranes at initial certification and every four years.

If equipment remains out of service for six months or more, complete an examination equal to initial certification, including a proof load test.

This approach helps you identify any issues that may have developed during repairs or downtime. You protect your team and maintain compliance with load test requirements.

Periodic Testing Intervals

You must schedule regular load testing to keep your lifting equipment in top condition. The frequency depends on the type of equipment, usage, and service conditions. Industry standards recommend:

Every six months, Complex lifting equipment, such as cranes, should undergo a thorough inspection.

Annually: Most hoists and slings require an annual examination.

Every two to four years: Equipment used less frequently may be tested every two to four years, based on advice from a competent person.

Monthly to quarterly: Overhead crane systems in severe service conditions need more frequent inspections.

You should also perform load testing after any major upgrades, repairs, or accidents. Keeping up with these intervals ensures your overhead lifting operations remain safe and reliable.

Tip: Document every inspection and load test. This record-keeping supports compliance and helps you track the condition of your equipment over time.

Types of Load Testing

Static Load Test

You use a static load test to check the structural and mechanical integrity of your lifting equipment. In this test, you gradually apply a fixed load—usually 125% of the rated capacity—to your hoist, crane, or overhead lifting device. You hold this load for 10 to 20 seconds, following OSHA and ANSI standards.

This process helps you spot any permanent deformation or weaknesses before you put the equipment into service. Static load testing for lifting equipment gives you confidence that your equipment meets load test requirements and can handle real-world demands.

Dynamic Load Test

A dynamic load test goes a step further by simulating actual working conditions. You attach test weights to your crane or hoist and then operate the equipment through its full range of motion. Here’s how you conduct a dynamic load test:

Position the crane over the test area.

Attach the test weights to the hook.

Lift, lower, and move the load across the span of the crane.

Monitor the control systems, brakes, and stability during these movements.

Record all data and observations for your inspection records.

This method ensures your equipment performs safely and reliably during overhead lifting operations.

Proof Load Test

You perform a proof load test to verify both the load capacity and the structural integrity of your lifting equipment. In this test, you apply a load that exceeds the maximum working load, creating a safety margin. This step helps you prevent failures and ensures compliance with safety standards.

A proof load test involves applying a controlled force for a set time using hydraulic cylinders and load cells. This approach gives you a clear picture of how your equipment handles stress.

Operational Load Test

An operational load test checks how your equipment performs under real-world conditions. You simulate actual lifting tasks by applying known weights and moving them at different angles and speeds. The table below shows what you evaluate during an operational load test:

Test Aspect | What You Check |

|---|---|

Load Capacity | Can the crane or hoist lift its rated load safely? |

Mechanical Function | Do all parts operate smoothly under stress? |

Deformation | Does the equipment show any signs of bending? |

Safety Devices | Do limit switches and brakes work as intended? |

This process helps you meet load testing requirements and follow best practices for overhead crane and hoist safety.

Break Load Test

A break load test pushes your equipment to the point of failure. You use this test to determine the maximum load your lifting device can withstand before breaking.

You rarely perform this test on equipment in service, but it is vital for design validation and meeting strict standards. Break load testing helps you understand the true limits of your lifting equipment and ensures you meet all requirements for safety and reliability.

Standards for Load Testing

OSHA and ASME Guidelines

You must follow strict OSHA and ASME guidelines when you conduct load testing. These organizations set the foundation for safety standards in the lifting industry. OSHA requires you to inspect rigging before each shift, never use untagged gear, and remove damaged slings immediately.

You must also proof-test custom lifting accessories to 125% of their rated load before use. ASME standards, such as B30.9, B30.10, B30.26, and B30.20, cover everything from sling fabrication to hook inspection and hardware marking. The table below summarizes the main OSHA and ASME requirements:

Source | Guideline | Details |

|---|---|---|

OSHA | Inspect rigging before each shift | Rigging equipment must be inspected before use and removed if defective. |

OSHA | Never use untagged or illegible gear | Equipment must show its identification and rated load. |

OSHA | Loads must not exceed the manufacturer’s rated capacity. | |

OSHA | Remove damaged slings immediately | Specific criteria for the removal of wire rope slings. |

OSHA | Proof-test special or custom accessories | Must be proof-tested to 125% of rated load before use. |

ASME B30.9 | Frequent + periodic inspections for slings | Covers fabrication, use, inspection, testing, and maintenance. |

ASME B30.10 | Inspect hooks for throat opening, twist, and wear | Initial inspection required for new or altered hooks. |

ASME B30.26 | Design factor and markings for hardware | Must meet construction, marking, inspection, and use provisions. |

ASME B30.20 | Mark, inspect, and operate below-the-hook devices | Devices must carry visible ratings and identification. |

You can trust Powerful Machinery’s lifting equipment because each product is designed and tested to meet or exceed these requirements.

CSA and International Standards

You also need to consider CSA and other international standards when you select lifting equipment. CSA standards, such as CSA B167, set guidelines for cranes, hoists, and related devices in Canada. International standards like ISO9001 and ISO14001 ensure quality management and environmental responsibility.

Powerful Machinery’s products carry certifications from TUV Rheinland, EURO CERT, EAC, and other global bodies. These certifications show that your equipment meets the highest safety and performance benchmarks worldwide.

CMAA Specifications

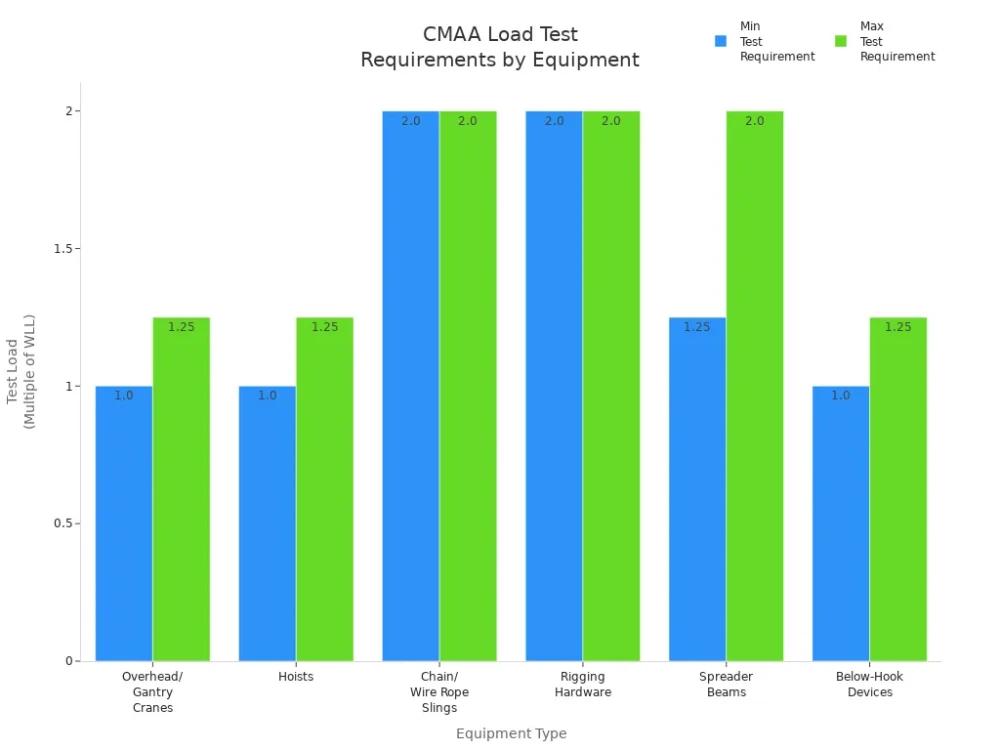

CMAA specifications provide detailed guidance for industrial lifting equipment. You must load test overhead and gantry cranes at 1.0 to 1.25 times their working load limit (WLL), and hoists at similar levels.

Chain and wire rope slings require testing at 2.0 times WLL. The chart below compares minimum and maximum load test requirements for different equipment types:

CMAA Specification 78 requires you to keep written reports for the entire lifespan of your equipment. Powerful Machinery supports you with full documentation and certified test results for every product. You can rely on these records to prove compliance and maintain a safe workplace.

Tip: Always verify that your lifting equipment carries proper certification and documentation. This practice helps you meet safety standards and pass inspections with confidence.

Load Testing Procedures

You must follow a structured process to ensure your lifting equipment meets industry standards and delivers reliable performance. Each step in the load testing procedure plays a critical role in maintaining safety and compliance. Here is how you can approach each stage with confidence.

Pre-Test Inspection

Start with a thorough inspection before you conduct any load test. This step helps you identify potential issues and ensures the equipment is ready for testing. Follow these best practices:

Review the original design drawing and manufacturer recommendations.

Check that previous test reports and inspection certificates are available.

Perform a full visual inspection. Look for surface corrosion, bent or deformed sections, and worn connection points or lugs. Confirm that all markings, such as serial numbers, safe working load (SWL), and CE tags, are clear and legible.

Make sure the test site is safe. Set up exclusion zones and place proper signage to keep unauthorized personnel away.

You protect your team and equipment by addressing these points before moving forward.

Test Load Preparation

Prepare your test loads with precision to guarantee accurate results. Always follow the manufacturer’s guidelines for load testing procedures and intervals. Use certified test weights that have been calibrated and verified for accuracy. This step is essential for maintaining the integrity of your results.

You should also inspect the test weights and lifting equipment before and after the test. Look for any signs of damage or wear. Certified technicians often use calibrated weights or hydraulic testing systems to apply controlled loads.

This approach allows you to monitor the equipment’s structural response, mechanical function, and safety components in real time.

Tip: Engage qualified professionals for test load preparation. Their expertise ensures that every aspect of the process meets regulatory requirements and industry standards.

Test Execution

Execute the load test with careful attention to detail. Adjust the equipment for environmental factors such as wind, ice, or snow. Never exceed the rated capacity of your lifting device. Verify the weight of the load using recognized industry sources or calculations.

If the load exceeds 75% of the maximum rated capacity, confirm the load weight before you proceed. During the test, operate the equipment as you would in normal conditions. Monitor all movements and control systems closely. Record your observations and any anomalies for later review.

Safety Alert: Always keep unauthorized personnel clear of the test area during execution. Use barriers and warning signs to enforce this rule.

Post-Test Inspection

After the load test, conduct a detailed inspection to assess the condition of your equipment. Focus on critical components such as gripping surfaces, welds, pins, and latches. Check for any structural or mechanical changes that may have occurred during testing.

Use a combination of visual inspections, welding checks, nondestructive tests, and magnetic particle inspections. Make sure all key identifiers, including the working load limit (WLL), remain legible and securely attached. Document your findings for traceability and compliance.

Documentation and Certification

Proper documentation validates your load testing process and supports regulatory compliance. You should maintain the following records for each piece of lifting equipment:

Document Type | Description |

|---|---|

Manufacturer’s Certificate | Confirms the equipment was manufactured to the required standards and includes essential information such as manufacturer details and compliance with relevant standards. |

EC Declaration of Conformity | Certifies that the equipment meets European safety standards and must accompany the item when supplied. |

Report of Thorough Examination | Issued after a thorough examination, this report ensures the equipment is safe for use and meets all necessary legal requirements. |

Keep these documents organized and accessible. They provide proof of compliance during audits and inspections.

By following these procedures, you ensure that your lifting equipment remains safe, reliable, and compliant with industry regulations. Powerful Machinery’s certified solutions and commitment to best practices help you achieve the highest standards in every load test.

Safety in Load Testing

Qualified Personnel

You must rely on qualified personnel to ensure safe and effective lifting operations. Only trained and certified individuals should conduct load tests. Certification confirms that your team understands engineering, performance, and safety standards.

You need to assign specific roles, such as Lift Director and Crane Operator, to people who have completed the required training. Regular inspections and refresher courses help your team stay current with best practices. In the United States, OSHA sets the requirements for personnel hoists.

In Canada, CSA Z185 outlines the standards for lifting equipment. ASME provides detailed guidelines for crane operator training and safety procedures.

Tip: Always verify credentials before assigning critical tasks. This step reduces the risk of accidents and ensures compliance with industry regulations.

Certification ensures compliance with safety standards.

Only trained, certified, and designated personnel should operate lifting equipment.

Specific roles require defined training and qualifications.

Regular inspections and refresher training are essential.

Equipment Certification

You must use certified equipment for every load test. Certification helps you identify potential failures before they cause harm. Engineers use these tests to understand equipment limitations and set safe operating parameters.

By determining the safe working load limits, you ensure that your lifting equipment can handle expected loads without risk. Certified equipment gives you confidence that your operations meet industry standards and protect your workforce.

Certified equipment prevents accidents by revealing weaknesses.

Load testing establishes safe working limits.

Certification ensures your equipment operates within safe parameters.

Risk Management

You need a strong risk management plan for every lifting operation. Start with a thorough risk assessment to identify hazards. Develop a detailed lift plan that includes load calculations and movement paths. Assign clear roles and responsibilities to each team member for effective communication.

Maintain your equipment with regular inspections and use only proper lifting accessories in good condition.

Risk Management Steps | Description |

|---|---|

Risk Assessment | Identify hazards before operations |

Lift Plan | Outline load calculations and movement paths |

Role Assignment | Ensure clear communication |

Maintenance | Schedule regular inspections |

Accessory Check | Use only approved, safe accessories |

You create a safer environment by following these steps and prioritizing safety in every aspect of your lifting operations.

Industry Organizations and Resources

CMAA, HMI, MMA Roles

You depend on industry organizations to set the standards that keep your lifting operations safe and efficient. The Crane Manufacturers Association of America (CMAA), Hoist Manufacturers Institute (HMI), and Monorail Manufacturers Association (MMA) play key roles in shaping best practices for overhead lifting.

These organizations publish technical documents and guidelines that help you maintain high safety and performance levels.

CMAA, HMI, and MMA provide clear guidelines and specifications for overhead lifting applications.

You can access nearly 100 published documents that address different aspects of overhead lifting, including design, inspection, and maintenance.

CMAA Specification 78 outlines standards for load testing, ensuring that cranes and hoists can safely perform their intended functions.

This specification includes detailed procedures for verifying a crane or hoist’s ability to handle its rated capacity.

You benefit from guidance on pre-operational checks, periodic inspections, and the importance of using certified technicians for all services.

By following these standards, you create a safer workplace and ensure your lifting equipment meets regulatory requirements.

Training and Safety Initiatives

You need proper training to operate lifting equipment safely and perform effective load testing. Industry organizations offer specialized programs that build your skills and prepare you for real-world challenges. The table below highlights key training and safety initiatives available to professionals in the lifting industry:

Training Initiative | Description |

|---|---|

Lifting and Rigging Safety Training | Gain practical skills in lifting fundamentals, load estimation, and hazard identification. |

Emergency Response Awareness | Learn how to handle emergencies effectively during lifting operations. |

Risk Assessment Training | Understand how to identify and mitigate risks associated with lifting equipment. |

You improve safety and reduce risks by participating in these programs. Regular training ensures you stay updated on the latest industry standards and best practices. You also build confidence in your ability to manage complex lifting operations and respond to emergencies.

Tip: Choose training programs recognized by leading industry organizations. This approach helps you meet compliance requirements and supports a culture of safety in your workplace.

Powerful Machinery: Reliable Lifting Equipment

Product Features and Advantages

You want equipment that delivers consistent performance and safety during every load test. Powerful Machinery’s lifting solutions offer a range of features that support your industrial needs. The table below highlights the key advantages you gain when you choose these products:

Feature | Description |

|---|---|

Portability | Lightweight and foldable design lets you transport equipment to remote sites easily. |

Easy Handling | Minimal manpower needed for setup; you can prepare the system quickly with just a water source. |

Precision & Control | Gradual filling and real-time monitoring give you accurate load testing results. |

Cost-Effectiveness | Reusable equipment and water as the main material keep your operational costs low. |

Safety Features | Built-in safety components and controlled loading reduce risks during testing. |

Versatility | Adaptable for many applications, including crane, davit, and beam testing across industries. |

You benefit from equipment that adapts to different environments and supports a wide range of applications.

Certified Solutions for Industrial Load Testing

You need confidence that your hoist and rigging hardware meet the highest safety standards. Powerful Machinery provides certified solutions for industrial load testing. Every product undergoes rigorous testing and carries certifications from recognized organizations.

You can trust that each component meets or exceeds international standards, including ISO9001 and TUV Rheinland. This commitment to certification ensures your lifting operations remain compliant and reliable.

Value for Safety and Efficiency

You improve safety and efficiency when you invest in specialized lifting equipment from Powerful Machinery. Properly certified equipment, operated by trained personnel, creates a strong safety foundation and helps prevent accidents.

You see efficiency gains as these solutions often reduce project timelines and crew requirements. Regular maintenance and inspection keep your equipment in top condition, minimizing downtime.

Innovative technologies, such as IoT sensors and remote operation systems, further enhance operational safety and productivity. Proof load testing ensures your equipment performs reliably under real-world conditions.

Tip: Choose equipment that supports both safety and efficiency to maximize the value of your investment.

Conclusion

You protect your team and assets when you schedule regular load testing for lifting equipment. This practice ensures safety, supports compliance, and extends equipment life.

Following industry standards and working with qualified professionals keeps your operations reliable.

If you want dependable results, choose Powerful Machinery’s certified lifting equipment for your next project.

FAQ

What is the difference between proof load testing and break load testing?

Proof load testing checks if your equipment can handle a specified load safely. Break load testing determines the maximum load your equipment can withstand before failure. You use proof load tests for regular inspections. You reserve break load tests for design validation.

How often should you perform load testing on lifting equipment?

You should follow industry standards. Most equipment requires annual or biannual testing. High-use or critical equipment may need more frequent tests. Always consult the manufacturer’s recommendations and local regulations for your specific schedule.

Why do you need certified test weights for load testing?

Certified test weights ensure accuracy and compliance. You reduce the risk of errors and meet regulatory requirements. Using uncertified weights can lead to inaccurate results and safety hazards.

Does Powerful Machinery provide documentation after load testing?

Yes, you receive full documentation and certification with every load test. This includes test reports, certificates of conformity, and inspection records. You can access these documents for audits or regulatory reviews.