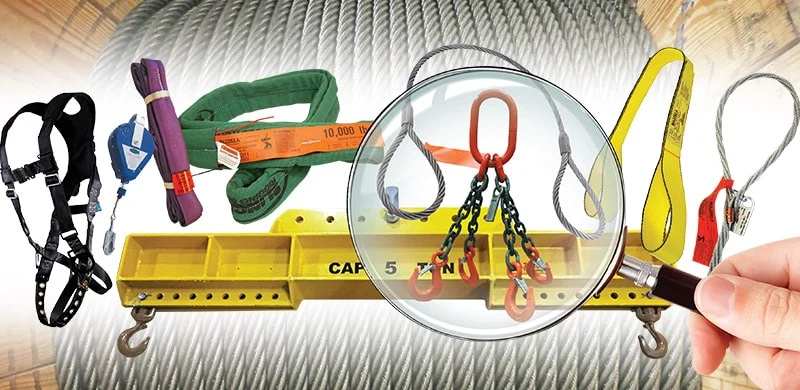

You rely on lifting and rigging equipment safety to keep every lift safe and controlled. A rigging equipment repair checklist helps you catch problems before they become hazards. Regular inspection and repair prevent accidents and keep your operations running smoothly.

Faulty rigging equipment contributes to 27% of load drops in workplaces. Using a checklist allows you to spot control system failures, maintain precise lifts, validate safety systems, and identify issues early. You protect yourself, your team, and your business by following a structured repair process.

Key Takeaways

Regularly inspect rigging equipment to catch issues early. This practice prevents accidents and protects your team.

Follow OSHA and ASME standards for compliance. Adhering to these guidelines ensures safety and legal protection.

Document every inspection and repair. Good recordkeeping supports audits and maintains equipment safety.

Consult professionals for complex repairs. Expert services ensure compliance and reduce risks associated with faulty equipment.

Why Lifting and Rigging Equipment Safety Matters?

Safety and Accident Prevention

You play a critical role in lifting and rigging equipment safety every time you operate lifting gear. Regular inspection and repair help you prevent accidents and injuries. Many failures happen because of improper sling use, worn or damaged gear, or lack of training.

You can avoid these risks by checking your equipment before each lift. When you identify worn or damaged rigging early, you protect your team and your property from costly damage. You also reduce the chance of dropped loads and workplace injuries.

Tip: Always train your crew to recognize the signs of wear and improper use. This step strengthens your safety culture and keeps everyone alert.

Compliance with Industry Standards

You must follow strict safety standards to meet legal and industry requirements. OSHA and ASME set clear rules for lifting and rigging equipment safety. These standards cover inspection, proof testing, and operator training. The table below highlights key requirements:

Standard | Description |

|---|---|

ASME B30.20 | Sets design, inspection, and documentation rules for lifting equipment. |

OSHA 29 CFR 1926.251 | Makes ASME standards legally binding and outlines rigging equipment requirements. |

Compliance | Requires proof testing, regular inspections, and proper training for all lifting operations. |

Powerful Machinery leads the industry with certified products and services. You can trust their solutions to meet or exceed international safety standards.

Cost Savings and Sustainability

You save money and resources by maintaining lifting and rigging equipment safety. Early detection of minor issues lowers repair costs and prevents major breakdowns. Well-maintained equipment uses less energy and lasts longer.

You also avoid expensive downtime and keep your projects on schedule. A proactive maintenance program supports your sustainability goals by reducing waste and extending equipment life.

Reduced downtime means you keep production moving.

Lower repair costs protect your budget.

Energy savings add up over time.

Reducing Downtime

You want less downtime and more efficient lifting operations. Timely repair and maintenance keep your equipment in top condition. This approach reduces the risk of sudden breakdowns and operational halts.

Proper rigging maintenance also increases the lifespan of your gear and boosts overall safety. When you invest in regular care, you ensure smooth, uninterrupted lifting activities.

Powerful Machinery stands behind every product with international certifications and a commitment to safety, quality, and reliability. You can rely on their expertise to keep your lifting operations compliant and efficient.

Rigging Equipment Inspection and Repair Process

A structured repair process ensures your lifting operations remain safe, compliant, and efficient. You must follow each step carefully to identify issues, carry out repairs, and verify that your rigging equipment meets all safety standards. Powerful Machinery uses certified procedures and advanced quality controls at every stage.

Here’s how you can approach the inspection and repair process for your rigging gear.

Receiving and Logging

You start by receiving the rigging equipment and logging it into your maintenance system. This step creates a traceable record for every piece of gear. You capture details such as serial numbers, equipment type, and the reason for service.

Accurate logging helps you track maintenance history and ensures no item is overlooked.

Tip: Always record the arrival condition and any visible defects. This information supports future audits and compliance checks.

Detailed Inspection

You conduct a thorough inspection to uncover both visible and hidden damage. Use visual checks and, when necessary, disassemble components to reveal internal wear. The table below outlines recommended inspection techniques and frequencies for common rigging items:

Equipment Type | Inspection Frequency | Additional Notes |

|---|---|---|

Shackles | Before each use | Must follow ASME B30.26 regulations; consult a skilled rigger if unsure. |

Slings | Daily or shift in normal conditions | Inspect upon arrival; periodic inspections by a competent person are required. |

Wire Rope Slings | Daily or shift in normal conditions | Similar to slings, periodic inspections by a competent person are required. |

Turnbuckles | Daily visual checks; yearly by a surveyor | Must be disassembled every 4 years for hidden damage inspection. |

You should always involve a qualified inspector for periodic checks. This step ensures you catch issues that could compromise safety.

Identifying Damage

You need to identify all types of damage during the inspection. Look for common problems such as cuts, tears, corrosion, and deformation. The table below summarizes frequent damage types found in rigging equipment:

Type of Damage | Description |

|---|---|

Damage to Slings | Slings can be damaged, ripped, or covered in dirt or grease, affecting their usability. |

Damage to Synthetic Slings | Cuts, tears, UV degradation, and chemical exposure are common issues. |

Damage to Wire Rope | Broken wires, corrosion, and deformation require immediate removal from service. |

Damage to Rigging Hardware | Deformations, cracks, nicks, or gouges can compromise safety. |

You must document every defect and decide if the equipment is safe to repair or needs replacement.

Repair or Replacement

You determine whether to repair or replace the rigging equipment based on the severity of the damage. Use these criteria to guide your decision:

Visible damage and deterioration, such as fraying, kinking, or corrosion, require replacement to maintain safety.

Malfunctioning or outdated hardware that does not comply with current safety standards must be replaced.

Missing or unreadable identification tags mean you cannot confirm load limits or inspection dates, so replacement is necessary.

Corrosion or rust, especially if pitting is present, weakens the equipment and calls for replacement.

Deformation and stretching indicate the equipment cannot hold rated loads and should be retired.

Failing inspections means the equipment does not meet safety requirements and must be removed from service.

You should always use certified parts and follow manufacturer guidelines when repairing rigging equipment. Professional services, like those from Powerful Machinery, ensure repairs meet international standards and keep your team safe.

Testing and Quality Assurance

After repairing rigging equipment, you must verify its safety and performance through rigorous testing. The quality assurance process includes:

Visual inspection to check for damage, verify welds, and confirm all markings.

Functional inspection to ensure smooth operation of lift and lower attachments.

Proof load tests to confirm the equipment can handle rated loads.

Breaking force and elongation tests to validate strength and flexibility.

You should only return equipment to service after it passes all required tests. Testing and repairing with certified procedures guarantee compliance with OSHA and ASME standards.

Documentation and Return

You must document every step of the repair process. Good recordkeeping includes:

Initial inspections for new, altered, modified, or repaired rigging equipment before returning to service.

Documentation for chain and metal mesh slings, below-the-hook lifting devices, and load indicating devices.

Periodic inspection records, noting the condition of each component.

Monthly inspection logs for below-the-hook lifting devices, regardless of usage.

Maintenance history for each kit, including IDs for ropes, pulleys, carabiners, and slings.

Details of defects found and corrective actions taken.

Note: Standardized documentation helps you maintain compliance, supports audits, and ensures traceability across all job sites.

You should always return equipment to service only after completing all documentation and confirming compliance with safety standards. Partnering with a professional service provider like Powerful Machinery streamlines the repair process and guarantees the highest level of safety for your lifting operations.

Common Rigging Equipment Damage and Removal Criteria

You must recognize the most frequent types of damage and understand when to take equipment out of use. Following OSHA and ASME standards protects your team and ensures your rigging operations remain compliant.

Below, you will find the main categories of equipment, their typical damage, and clear removal from service criteria.

Hooks: Deformation and Latch Issues

Hooks face high stress and can develop serious problems. Use the table below to guide your inspection and removal from service decisions:

Damage Type | Removal Criteria |

|---|---|

Missing or illegible manufacturer’s identification | Removal from service |

Excessive pitting or corrosion | Removal from service |

Cracks, nicks, or gouges | Removal from service |

Wear exceeding 10% of the original section dimension | Removal from service |

Deformation from the original plane | Removal from service |

Increased throat opening by more than 5% | Removal from service |

Inability to lock | Removal from service |

Damaged latch | Removal from service |

Evidence of heat exposure | Removal from service |

Unauthorized alterations | Removal from service |

Twisted more than 10° | Removal from service |

Cracked or defective | Removal from service |

Loss of 10% or more of the cross-sectional area | Removal from service |

Web Slings: Knots and Tag Problems

Web slings are vulnerable to knots and identification issues. You must remove them from service if you find:

Knots anywhere in the sling

Missing or illegible identification tags

Chain Slings: Gouges and Wear

Chain slings require careful inspection for damage. Follow these steps for removal from service:

Inspect for nicks, gouges, and excessive wear.

Remove if wear exceeds 10% of the original cross-section.

Take it out of service if you find pitting or cracks.

Ensure a competent person checks for defects regularly.

Wire Rope: Kinks and Broken Wires

Wire rope can develop kinks from improper handling. You must remove the wire rope from service immediately if you see kinks or a significant number of broken wires. These signs indicate the rope cannot safely support loads.

Shackles and Eye Bolts: Bends and Cracks

Shackles and eye bolts must be removed from service if you observe:

Criteria for Removal | Description |

|---|---|

Shackles | Bent, twisted, distorted, stretched, elongated, cracked, or broken components |

Eye bolts | Bent, twisted, distorted, stretched, elongated, cracked, or broken components |

Lifting Devices: Homemade or Non-Rated

Never use homemade or non-rated lifting devices. These devices do not meet safety standards and can cause severe accidents. Always consult a certified manufacturer or rigging specialist for proper equipment.

Synthetic Shackles: Damage and Compliance

Synthetic shackles must meet compliance standards. Remove them from service if you find cuts, abrasions, chemical damage, or if they lack proper certification.

For certified inspection and repair, consult Powerful Machinery. Their expertise ensures your equipment meets all safety and compliance requirements.

Inspection Frequency and Recordkeeping

OSHA and ASME Requirements

You must follow strict guidelines for equipment inspection to ensure safety and compliance. OSHA and ASME set clear rules for how often you need to check your rigging gear:

Inspect all lifting and rigging equipment daily or before each use. A competent person should perform this check.

Complete a periodic inspection at least once every 12 months for all equipment.

If your equipment operates under severe conditions, inspect it monthly or quarterly.

For special service equipment, a qualified individual must decide the inspection frequency within 12 months.

These requirements help you catch problems early and keep your team safe.

Periodic and Condition-Based Inspections

You should not rely on a single inspection type. Combine periodic and condition-based inspections for the best results. Schedule regular checks based on time, such as monthly or yearly. Add extra inspections if you notice unusual wear, damage, or if the equipment has been exposed to harsh conditions.

This approach helps you respond quickly to changes in equipment condition and prevents unexpected failures.

Tip: Use a checklist to guide every equipment inspection. This practice ensures you do not miss any critical steps.

Importance of Documentation

You need accurate records for every equipment inspection. Good documentation proves you follow safety standards and supports your compliance during audits. Record the date, inspector’s name, findings, and any repairs or replacements. Keep these records organized and accessible for every piece of rigging gear.

Powerful Machinery can help you set up inspection schedules and maintain proper documentation. Their support makes it easier for you to stay compliant and ready for any safety review.

Professional Repair Services by Powerful Machinery

Certified Expertise and Quality

You want your lifting operations to run smoothly and safely. Powerful Machinery stands out as a trusted provider of certified rigging solutions. The company holds international certifications, including ISO9001, TUV Rheinland, and OSHA.

You can rely on their wide product range, which covers lifting chains, wire ropes, hooks, shackles, and custom-engineered fittings. Every repair follows strict quality standards. You benefit from expert workmanship that ensures each component meets or exceeds industry requirements.

When you choose Powerful Machinery, you receive reliable service and high-performance equipment for every project.

Ensuring Compliance and Safety

You must meet safety regulations and maintain detailed records for every repair. Powerful Machinery uses a structured process to guarantee compliance. Their technicians complete essential training in rigging selection, inspection techniques, load ratings, and safe handling.

You can see their commitment to safety in their documentation practices:

Essential Training Topics | Documentation Practices |

|---|---|

Rigging selection | Record inspection dates and findings |

Inspection techniques | Track rigging identifications |

Load ratings and limits | List inspector credentials |

Safe handling and hazard awareness | Note actions taken |

Storage and maintenance |

You receive clear records for every repair, including inspection results and corrective actions. This approach helps you pass audits and keeps your team safe on every lift.

When to Consult Professionals?

You should consult professionals for any complex repair or when you need to ensure compliance with OSHA and ASME standards. If you find severe damage, missing identification, or uncertainty about equipment safety, reach out to Powerful Machinery.

Their team uses advanced testing and certified procedures to restore your rigging gear. You save time and reduce risk by trusting experts with your most critical repairs. Powerful Machinery supports you from initial inspection to final documentation, so you can focus on safe and efficient lifting operations.

Tip: Never compromise on safety. Choose professional repair services to protect your team and your investment.

Conclusion

You protect your team and assets when you follow a structured repair checklist for lifting and rigging equipment. Regular inspections and timely repairs reduce accidents and support compliance with OSHA and ASME standards.

Certified professional services, such as those from Powerful Machinery, deliver proven safety outcomes. Review the table below to see how a checklist supports safety and accountability:

Feature/Benefit | Description |

|---|---|

Verification of current load test certificates | Ensures certificates are up-to-date and valid. |

Provides documented evidence of equipment safety | Offers peace of mind and supports due diligence. |

Supports liability protection | Provides crucial evidence in the event of an accident. |

Industry case studies show that mistakes in rigging can lead to costly incidents. Prioritize safety and compliance by implementing your checklist and scheduling regular inspections.

FAQ

How often should you inspect your rigging equipment?

You should inspect your rigging equipment before each use and schedule a thorough inspection at least once every 12 months. If you use equipment in harsh environments, increase inspection frequency to monthly or quarterly.

What are the most common signs of rigging equipment damage?

Look for these signs:

Frayed or broken wires

Bent or deformed hooks

Missing identification tags

Excessive corrosion or rust

Tip: Remove any damaged equipment from service immediately.

Can you repair rigging equipment yourself?

You should only perform minor maintenance if you have proper training. For complex repairs or when safety is uncertain, always consult certified professionals like Powerful Machinery. This ensures compliance with safety standards.

Why is documentation important for rigging equipment repairs?

Documentation provides proof of inspection, repair, and compliance. It helps you track equipment history, supports audits, and protects your team by ensuring only safe gear returns to service.