You rely on the chain hoist safety factor to protect yourself and your team during lifting operations. This ratio compares the maximum load a chain hoist can handle to the safe working load, helping you reduce risks and meet industry requirements.

Powerful Machinery designs certified lifting solutions that prioritize safety, giving you confidence in every lift.

Key Takeaways

Understand the chain hoist safety factor. It compares the maximum load a hoist can handle to its safe working load, ensuring safety during lifting operations.

Choose chain hoists with the right safety factor. This reduces the risk of accidents and extends the lifespan of your equipment.

Follow industry standards for safety. Always check the working load limit and select hoists that meet or exceed international safety certifications.

Conduct regular inspections and maintenance. This practice helps catch issues early and keeps your lifting equipment safe and reliable.

Avoid common mistakes when selecting hoists. Respect load limits, perform inspections, and follow manufacturer guidelines to ensure safe lifting.

Chain Hoist Safety Factor Explained

What Is a Safety Factor?

You need to understand the chain hoist safety factor before you select or operate any lifting equipment. This concept forms the foundation of safe lifting practices. Leading engineering standards define the chain hoist safety factor as:

The ratio between the maximum load a hoist can lift before it fails and the rated load it is designed to lift under regular conditions.

A built-in margin that ensures the hoist can manage unexpected events, such as sudden impacts or overloads, without failing. This protects both your equipment and your team.

When you see a chain hoist safety factor listed on a product, you know the manufacturer has tested the hoist to handle much more than its rated working load. This extra capacity acts as a buffer, giving you peace of mind during every lift.

Why Safety Factor Matters in Lifting?

You face unpredictable challenges in every lifting operation. The chain hoist safety factor plays a critical role in keeping your worksite safe and your equipment reliable. By choosing a hoist with the right safety factor, you reduce the risk of accidents and equipment failure.

The safety factor enhances the reliability and lifespan of chain hoists by incorporating essential safety mechanisms and high-quality materials. These features help prevent accidents and minimize wear and tear, ensuring that the hoists can endure the demanding conditions of industrial environments.

Powerful Machinery understands the importance of the chain hoist safety factor. The company designs and manufactures certified, high-performance lifting chains and hoists that meet or exceed international standards.

You can trust Powerful Machinery’s products to deliver consistent strength, durability, and safety in every application. When you select a chain hoist from Powerful Machinery, you invest in equipment that protects your team and your operation.

Industry Standards and Working Load Limit

Safety Factor Calculation for Chain Hoists

You need to understand how manufacturers determine the safety factor for chain hoists before you trust any lifting equipment. The safety factor calculation uses two main variables: breaking strength and working load limit.

The breaking strength represents the maximum load a chain can handle before it fails. The working load limit is the maximum load you should apply during normal operations.

The formula for calculating the working load limit is:

Working Load Limit (WLL) = Minimum Breaking Strength (MBS) / Design Factor (Safety Factor)

Manufacturers use this formula to set a safe limit for each chain hoist. You should always check the working load limit on the product label or technical documentation. This limit helps you avoid exceeding the chain’s strength and ensures safety during lifting.

Powerful Machinery tests every chain hoist to verify the breaking strength and sets a clear working load limit based on international standards.

Typical Values and International Standards

You must follow industry standards to maintain safety and reliability in lifting operations. Organizations such as OSHA, ISO, and ASTM set strict requirements for chain hoists. These standards specify the minimum safety factor and working load limit for different chain grades.

The table below shows typical working load limits and safety factors for common chain grades:

Chain Grade | Typical Working Load Limit (WLL) | Safety Factor |

|---|---|---|

Grade 30 | Varies, lower strength | N/A |

Grade 43 | Varies, moderate strength | N/A |

Grade 70 | Higher strength for transport | N/A |

Grade 80 | Suitable for overhead lifting | 5:1 |

Grade 100 | 25% stronger than Grade 80 | 5:1 |

You should select chain hoists that meet or exceed these standards. Powerful Machinery’s chain hoists use high-tensile steel and advanced manufacturing processes to deliver superior strength and durability.

Every product carries certifications from organizations such as ISO9001, TUV Rheinland, and OSHA. These certifications confirm that the working load limit and safety factor comply with international requirements.

When you choose a chain hoist from Powerful Machinery, you invest in equipment that meets the highest safety standards. You protect your team and your operation by relying on certified products with proven strength and a clearly defined working load limit.

Choosing the Right Chain Hoist by Powerful Machinery

Matching Safety Factor to Application

You must select the right chain hoist for your lifting operation to ensure safety and efficiency. Start by reviewing the key criteria that affect your decision. The table below outlines the most important factors you should consider when choosing a chain hoist with the correct safety factor:

Criteria | Description |

|---|---|

Load Capacity | Determine the maximum load the chain hoist can safely lift. |

Environmental Influences | Assess conditions like corrosive or explosive atmospheres that may impact performance. |

Safety Standards | Follow international safety standards such as ASME and ISO for compliance and safety. |

Maintenance Regimen | Plan for regular maintenance to extend the life and reliability of the hoist. |

Total Cost of Ownership | Evaluate long-term value, not just the initial purchase price. |

You should also consider the environment where you will use the chain hoist. Different settings require different safety factors and materials. For example:

The ASME HST-2-1999 standard recommends using chain hoists in temperatures from 0° F to 130° F.

If you work in extreme cold or heat, you may need to de-rate the capacity or select special materials.

Construction, manufacturing, and marine environments each have unique demands on lifting chains and chains.

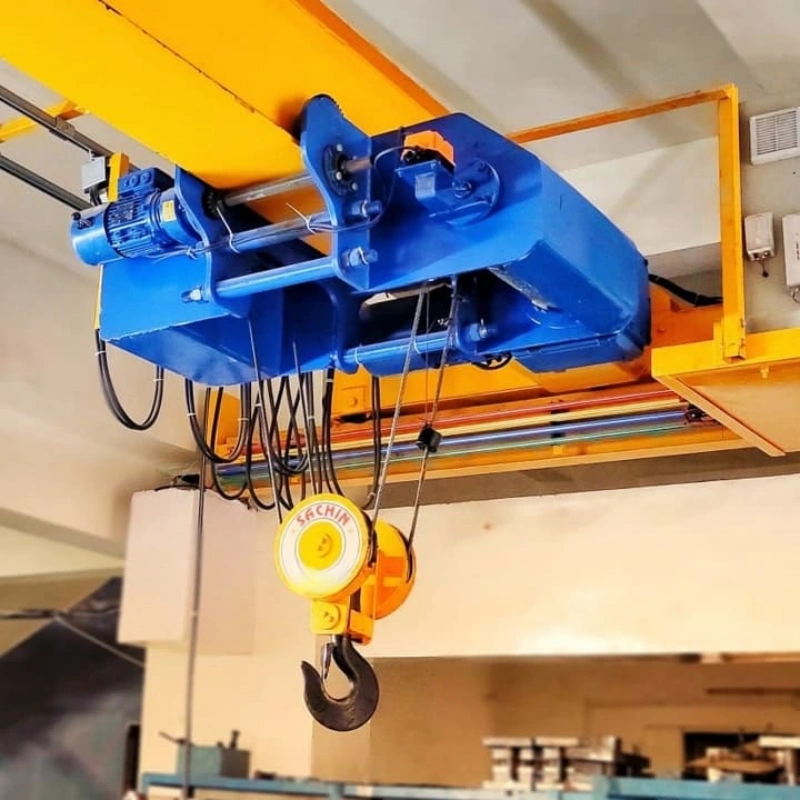

Powerful Machinery offers a full range of certified chain hoist solutions, including manual chain hoist and electric chain hoist models. You can find lifting chains and chains designed for heavy lifting in any environment. Each product meets strict international standards and provides reliable performance for your toughest jobs.

Avoiding Common Selection Mistakes

You can prevent costly errors by following best practices when choosing a chain hoist. The most frequent mistakes include:

Overloading the chain hoist. Always respect the safe working load and never exceed the rated capacity.

Ignoring regular inspections. Check your lifting chains and chains before every use to ensure they are in good condition.

Improper rigging. Secure the load with the correct lifting chains and hardware to maintain balance and safety.

Inadequate maintenance. Lubricate chains and replace worn parts to keep your chain hoist ready for heavy lifting.

Using the wrong chain hoist for the job. Match the chain hoist, lifting chains, and chains to the load weight, lifting height, and environment.

Ignoring manufacturer guidelines. Follow all instructions from Powerful Machinery to maximize safety and performance.

You can trust Powerful Machinery to provide high-quality chain hoist products and lifting chains for every application. The company’s certified chains and advanced engineering help you achieve safe, efficient, and reliable heavy lifting every time.

Safe Use and Maintenance of Lifting Chains

Inspection Practices for Chain Hoists

You must follow strict inspection routines to maintain the safety factor of your lifting equipment. Start by cleaning the chain hoist before each inspection. This step helps you spot any damage or wear. Focus on the inner links, looking for bent or broken links, chemical damage, and proper lubrication.

Daily or shift inspections help you catch problems early and prevent accidents.

You should also schedule periodic inspections. Use the table below to determine the right interval based on your service level and load requirements:

Service Level | Definition | Recommended Timing |

|---|---|---|

Normal | Less than 65% of the rated load and used 15% of the time or less | Annual |

Heavy | Greater than 65% of rated load and/or used more than 15% of the time | Every 6 months |

Severe | Non-standard conditions: High or low temperatures, outdoor and/or salt water exposure, caustic environment, etc. | Quarterly |

Monthly detailed inspections reveal issues that daily checks might miss. Consistent inspection practices build safety awareness and reinforce safety protocols for your team.

Maintenance Tips to Preserve Safety Factor

You can extend the life of your lifting equipment and preserve the safety factor with proper maintenance. Follow these steps:

Inspect your chain hoist regularly and repair or replace damaged parts immediately.

Lubricate chains, wire ropes, and moving components to reduce friction and prevent rust.

Clean all lifting equipment after every use to remove dirt and chemicals.

Rotate your equipment to distribute wear evenly.

Store gear in a dry, clean area to prevent corrosion.

Use padding or edge protectors when lifting sharp materials.

Follow manufacturer guidelines for periodic servicing.

Neglecting these steps increases the risk of accidents, reduces load-bearing capacity, and can lead to financial loss. Powerful Machinery’s certified chain hoists offer reliable performance and require minimal maintenance.

You benefit from high-strength materials and advanced engineering that meet global standards. This commitment to quality ensures your lifting equipment remains safe and dependable, even in harsh environments.

Conclusion

You play a vital role in workplace safety by understanding and applying the correct chain hoist safety factor.

Up to 60% of lifting accidents result from improper hoist use or skipped inspections.

Overloading remains the leading cause of hoist failure and injuries.

Certified chain hoists from Powerful Machinery offer overload protection, enclosed gearing, and compliance with OSHA and ASME standards.

Ignoring working load limits can lead to dropped loads, damaged property, and serious injuries.

Regular inspections and ongoing training help you prevent accidents and maintain a safe environment.

Prioritize certified equipment, routine checks, and adherence to safety standards for every lift.

FAQ

What is the difference between the working load limit and breaking strength?

You should know that the working load limit is the maximum safe load for regular use. Breaking strength is the point at which the chain fails. Always use the working load limit for a secure lifting operation.

How often should you inspect your chain hoist?

You need to inspect your chain hoist before each use. Schedule detailed inspections monthly and follow the manufacturer’s recommendations for periodic checks. Regular inspections help you spot wear and prevent accidents.

Can you use a chain hoist outdoors?

You can use a chain hoist outdoors if it is rated for harsh environments. Choose models with corrosion-resistant materials. Store your equipment properly after use to extend its service life.

What certifications should you look for in a chain hoist?

You should look for certifications like ISO9001, OSHA, and TUV Rheinland. These certifications show that the chain hoist meets international safety and quality standards.