IWRC stands for Independent Wire Rope Core. When you choose IWRC wire rope, you select a product with a steel core that boosts strength and structural stability. You need to understand IWRC because your decision impacts safety and long-term performance.

In industries like construction and mining, improper selection often causes mechanical wear, corrosion, and even catastrophic failures. You can prevent injuries and financial losses by choosing the right wire rope for your application.

Key Takeaways

IWRC stands for Independent Wire Rope Core, which enhances strength and stability in wire ropes.

Choose IWRC wire rope for heavy lifting and harsh environments to ensure safety and durability.

Regular maintenance and inspections of wire rope are crucial for extending its lifespan and ensuring safety.

IWRC wire rope offers superior resistance to crushing and corrosion compared to fiber core ropes.

Always verify certifications like API 9A and ISO when selecting wire rope for critical applications.

IWRC Wire Rope Meaning

What Does Iwrc Wire Rope Stand For?

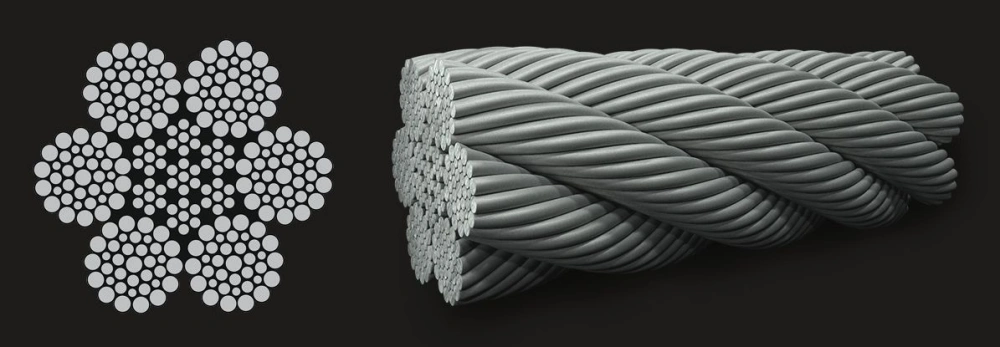

You encounter the term IWRC wire rope when you need a product with maximum strength and reliability. IWRC stands for independent wire rope core. This core consists of a separate steel wire rope placed at the center of the main rope.

The steel core supports the outer strands and increases the rope’s load-bearing capacity. You rely on this design for demanding lifting, hoisting, and rigging tasks. IWRC wire rope delivers superior performance in environments where safety and durability matter most.

IWRC Wire Rope Definition

You define IWRC as a wire rope with a steel wire rope core instead of a fiber or strand core. The independent wire rope core acts as the backbone of the rope, providing enhanced structural integrity. You benefit from higher tensile strength, better resistance to crushing, and improved stability under heavy loads.

IWRC wire rope maintains its shape and function even in harsh conditions. You choose this type when you need a rope that withstands repeated stress and extreme environments.

Powerful Machinery manufactures steel wire ropes with IWRC construction for industries that demand certified quality. You trust Powerful Machinery because the company meets strict standards such as API 9A and ISO Certification.

These certifications guarantee that every wire rope meets international requirements for safety, strength, and reliability.

Tip: You should always check for certifications like API 9A and ISO when selecting IWRC wire rope for critical applications.

IWRC vs Other Core Types

You compare IWRC to other core types to find the best solution for your project. The core determines the rope’s mechanical properties and suitability for specific tasks. IWRC wire rope uses a steel core, while fiber core ropes use natural or synthetic fibers. Wire strand core ropes feature a single strand of steel wires.

The following table highlights the differences between core types:

Core Type | Material | Strength Comparison | Resistance to Crushing | Applications |

|---|---|---|---|---|

IWRC | Steel | Up to 15% higher | Superior | Cranes, winches, mining, and construction |

Fiber Core | Fiber | Baseline | Lower | General applications |

Wire Strand Core | Steel | Moderate | Moderate | Smaller diameter ropes |

You notice that IWRC wire rope offers up to 15% higher strength and superior resistance to crushing. You select this core for cranes, winches, mining, and construction projects. Fiber core ropes provide more flexibility but less strength. Wire strand core ropes suit smaller diameter applications.

You also consider mechanical properties when choosing a core:

Property | IWRC (Steel Core) | Fiber Core (FC) |

|---|---|---|

Strength and Durability | Higher tensile strength, better load-bearing capacity | Less strength, suitable for lighter applications |

Flexibility | Less flexible, better for heavy-duty use | More flexible, ideal for applications requiring frequent bending |

Resistance to Crushing | Excellent resistance to crushing and deformation | Susceptible to crushing, better for single-layer applications |

Weight | Heavier due to the steel core | Lighter, easier to handle |

Environmental Resistance | Performs well in harsh environments, including high temperatures | Better for corrosive environments when paired with galvanized or stainless wires |

You choose IWRC wire rope when you need higher strength, durability, and resistance to crushing. You select fiber core ropes for lighter loads and applications that require frequent bending. You rely on Powerful Machinery’s steel wire ropes for projects that demand certified quality and proven performance.

Certifications: Powerful Machinery Meets:

API 9A

ISO Certification

You ensure safety and reliability by choosing wire ropes from a manufacturer that meets these standards.

Characteristics of IWRC Wire Rope

Strength and Durability

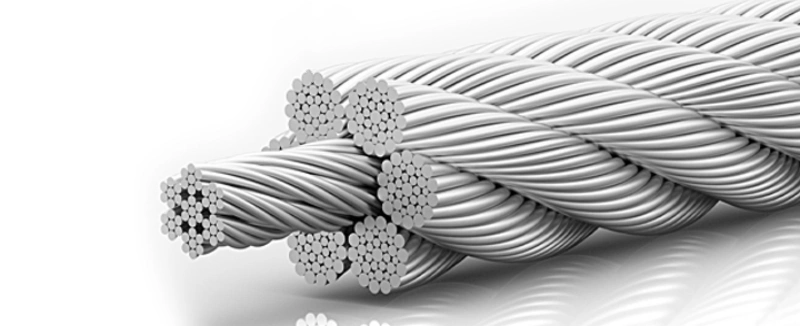

You rely on IWRC wire rope for its outstanding strength and durability. The construction features a steel core, which supports the outer strands and increases the rope’s breaking strength.

This design gives you a rope that withstands heavy loads and resists deformation. The characteristics of IWRC wire rope set it apart from fiber core alternatives. You can see the difference in breaking strength in the table below:

Rope Type | Rope Diameter (inch) | Nominal Strength (tons) |

|---|---|---|

IWRC (Steel Core) | 1 | 51.7 |

Fiber Core | 1 | 45.9 |

You notice that IWRC wire rope delivers higher breaking strength and a longer lifespan. The steel core distributes load evenly, which enhances fatigue life and durability. You benefit from these characteristics in demanding industries such as construction, mining, and marine operations.

Safety and Maintenance

You prioritize safety when selecting wire rope for critical applications. The characteristics of IWRC wire rope include a non-rotating design, which minimizes twisting and kinking during lifting. This feature reduces the risk of accidents and mechanical failures.

You should inspect steel wire rope before each use and perform a detailed inspection monthly. High-frequency applications may require weekly checks. Proper lubrication is essential to combat corrosion.

Wire rope lubricants push out moisture and block dirt, creating a protective barrier. In marine environments, you rinse the rope with fresh water after saltwater exposure and use marine-grade lubricants to maximize lifespan.

Maintenance Practice | Description |

|---|---|

Rinse with fresh water after saltwater exposure | This helps remove salt and prevent corrosion. |

Use marine-grade lubricants | These lubricants are designed to resist corrosion and protect the wire rope. |

Tip: Regular maintenance and inspection help you achieve a longer lifespan and maintain safety standards.

Corrosion Resistance

You need a wire rope that performs well in harsh environments. The characteristics of IWRC wire rope include excellent resistance to abrasion and corrosion. The steel core provides superior resistance compared to fiber core ropes, especially under abrasive conditions. You can compare corrosion resistance among wire rope types:

Wire Rope Type | Corrosion Resistance |

|---|---|

Stainless Steel | Excellent in moisture, saltwater, and acidic conditions. |

Galvanized | Moderate, particularly in dry or low-humidity environments. |

You choose IWRC wire rope for its ability to resist corrosion and maintain strength in tough conditions. This ensures a longer lifespan and reliable performance in construction, marine, and industrial settings.

IWRC Wire Rope vs Fiber Core

Performance Comparison

You need to compare the core types before you select the right wire rope for your project. IWRC wire rope and fiber core ropes each offer unique advantages. You see the main differences in flexibility, strength, and resistance to harsh conditions.

The table below highlights how these two core types perform in heavy lifting and industrial applications:

Aspect | Steel Core Wire Rope (IWRC) | |

|---|---|---|

Flexibility | Excellent, bends easily | Less flexible, needs a larger bending radius |

High-Temperature Resistance | Poor fibers can break down | Excellent, steel withstands heat |

Load Capacity | Lower, for light-to-medium loads | Higher, ideal for heavy lifting |

Crush Resistance | Poor, deforms under pressure | Excellent, resists crushing and impact |

Self-Weight | Light reduces equipment load | Heavy increases mthe echanical load |

You notice that IWRC wire rope delivers higher performance in demanding environments. It handles greater loads and resists crushing, which is essential in construction and mining. Fiber core ropes offer more flexibility and lighter weight, but they cannot match the strength and durability of IWRC.

Cost also plays a role in your decision. The following table outlines the cost implications:

Core Type | Cost Implication |

|---|---|

Fiber Core (FC) | Least expensive, flexible, lower strength |

Wire Strand Core (WSC) | Moderate cost, used for smaller diameters |

Independent Wire Rope Core (IWRC) | Most expensive, best strength, and stability |

You invest more in IWRC, but you gain superior performance and safety for critical lifting tasks.

When to Choose IWRC?

You should choose IWRC when your application demands maximum strength and reliability. This core type excels in high-temperature, high-pressure, and heavy-load environments. You find IWRC especially valuable in construction, mining, and marine operations where safety cannot be compromised.

The table below shows when IWRC outperforms fiber core:

Feature | IWRC | Fiber Core |

|---|---|---|

Strength | Higher strength | Lower strength |

Resistance to Crushing | Better resistance | Poorer resistance |

Heat Resistance | More effective in high temps | May dry out in high temps |

Recommended Conditions | High temperature, heavy pressure | Not recommended for these conditions |

You rely on IWRC wire rope for lifting heavy loads, working in extreme temperatures, or operating in environments where crushing and deformation are risks. You choose a fiber core only when you need flexibility and handle lighter loads.

Tip: Always inspect your wire rope for signs of wear, deformation, or corrosion. Regular checks help you maintain safety and extend the service life of your equipment.

Applications of Wire Rope with IWRC

Industrial Applications

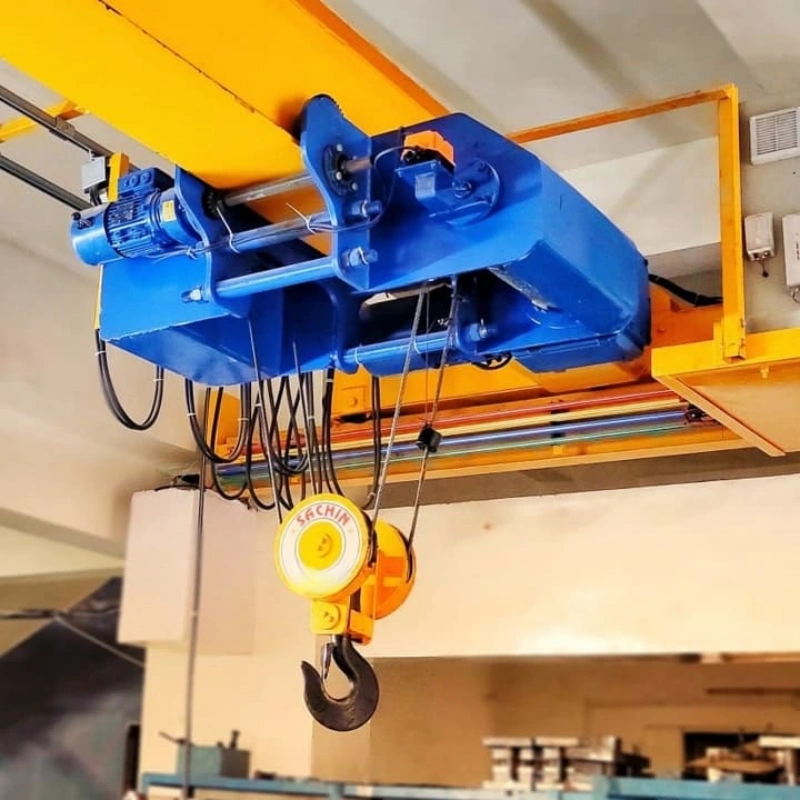

You see IWRC wire rope used in the world’s toughest industries. Construction sites depend on it for lifting heavy steel beams and concrete panels. Mining operations use it to hoist ore and equipment from deep underground.

Marine and offshore platforms rely on IWRC for mooring, towing, and cargo handling. You find this wire rope in transportation, manufacturing, and energy sectors as well.

The following table shows typical load capacities for different lifting configurations:

Sling Configuration | Load Capacity (lbs) | Load Capacity (kg) |

|---|---|---|

Vertical leg | 19,600 | 9,800 |

Choker | 14,400 | 7,200 |

Basket | 39,200 | 20,000 |

You choose IWRC wire rope when you need reliable lifting for cranes, winches, and hoists. Its strength and stability make it the preferred choice for demanding applications of wire rope.

Safety in Applications

You must prioritize safety in every lifting operation. IWRC wire rope meets strict international standards to protect workers and equipment. In marine and offshore applications, you follow guidelines set by organizations such as API, DNV, and ISO. The table below lists key safety standards:

Standard | Description |

|---|---|

API 9A | American Petroleum Institute standard for wire rope |

DNV-ST-E271 | Offshore containers and lifting sets |

ISO 10425 | Wire ropes for offshore mooring |

ABS, BV, or Lloyd’s Register certifications | Maritime compliance certifications |

You reduce risks by selecting wire rope that meets these standards. Regular inspections and proper maintenance further enhance safety during lifting and rigging.

Tip: Always verify certifications before using wire rope in critical applications.

Powerful Machinery Steel Wire Rope Applications

You trust Powerful Machinery steel wire rope for the most challenging lifting tasks. The non-rotating design prevents twisting, which increases safety and extends service life. You benefit from high tensile strength and resistance to abrasion and corrosion.

These features ensure reliable performance in construction, marine, and mining environments.

Powerful Machinery products carry certifications such as API 9A and ISO, so you know they meet or exceed global safety requirements. You can select from various configurations to match your specific lifting needs. When you choose Powerful Machinery, you invest in proven quality and peace of mind for all your applications.

Wire Rope Terms and Abbreviations

Wire rope specifications can seem complex when you first encounter them. You need to understand the main terms and abbreviations to select the right product for your lifting, construction, or industrial project. This glossary covers the essential wire rope terminology, including core types, grades, finishes, and safety ratings.

Core Types and Constructions

You find several core types in wire rope design. Each core affects the rope’s flexibility, strength, and durability. The table below summarizes the most common core types:

Core Type | Description |

|---|---|

Strand Core | Confined within stationary ropes, suitable for environments with severe crushing. |

Independent Wire Rope Core | Offers increased strength and resistance to crushing, recommended for severe loads, but is less flexible. |

Fiber Core | Made from plastic or sisal fibers, provides high-pressure resistance and durability. |

You often see constructions like Filler (F), Seale (S), Warrington (W), and Warrington Seale Core Construction (WS). These refer to how the strands are arranged. Powerful Machinery uses high-strength steel wires in its iwrc products to deliver a higher breaking load and reliable performance.

Grades and Finishes

Wire rope grades indicate the tensile strength grade and durability. You must choose the correct grade for your application to ensure safety and performance. The table below shows the most common grades:

Wire Rope Grade | Minimum Tensile Strength |

|---|---|

1770 | Specific value |

1960 | Specific value |

2160 | Specific value |

Grades directly impact the safe working load and working load limit. You also need to consider finishes. Galvanized wire rope offers moderate corrosion resistance, while stainless steel wire rope provides superior durability and minimal maintenance.

Type of Wire Rope | Corrosion Resistance | Durability |

|---|---|---|

Galvanized Wire Rope | Moderate; zinc coating can flake over time | Less durable in harsh conditions |

Stainless Steel Wire Rope | Superior; withstands harsh environments | Highly durable and requires minimal maintenance |

Safety Ratings and Other Terms

You must follow international standards for wire rope safety. Common ratings include ASTM A1023/A1023M-19, CSA G-4-15, EN 12385, and ISO 2408. These standards ensure your wire rope meets requirements for lifting operations lifting equipment regulations, and testing.

Key abbreviations you encounter include:

IWRC: Independent Wire Rope Core

FC: Fiber Core

SWL: Safe Working Load

WLL: Working Load Limit

ABF: Actual Breaking Force

MBL: Minimum Breaking Load

NDT: Non-destructive testing

LOLER: Lifting Operations Lifting Equipment Regulations

RCN: Rope Category Number

Tip: Always check the rope’s construction, tensile strength grade, and safety ratings before you begin any lifting or rigging operation.

You rely on these terms to specify wire rope for demanding projects in construction, mining, and marine industries. Understanding these abbreviations helps you select the right product and maintain safety during every operation.

Conclusion

You choose IWRC wire rope for its superior strength, durability, and safety in demanding environments. The table below highlights key advantages:

Advantage | Description |

|---|---|

Superior Strength | Handles heavy loads safely |

Durability | Resists wear and maintains shape |

Environmental Resistance | Performs well in harsh conditions |

You trust Powerful Machinery because their iwrc ropes meet ISO 9001:2015 standards, ensuring reliability and safety for your critical lifting needs.

FAQ

What does IWRC stand for in wire rope?

IWRC means Independent Wire Rope Core. You see this term when you need wire rope with a steel core for extra strength and stability in demanding applications.

When should you choose IWRC wire rope over fiber core?

You select IWRC wire rope for heavy lifting, high-pressure, or high-temperature environments. Fiber core works best for lighter loads and flexible applications.

How does Powerful Machinery ensure wire rope quality?

You trust Powerful Machinery because every wire rope meets strict international standards like ISO and API 9A. The company tests products for strength, durability, and safety.

Can IWRC wire rope resist corrosion?

You benefit from IWRC wire rope’s steel core, which offers excellent resistance to abrasion and corrosion. This makes it ideal for marine, mining, and outdoor use.