Knowing when to replace wire rope on a crane is crucial for maintaining safe and efficient operations. You should replace the wire rope on a crane immediately if you notice broken wires, significant wear, or any clear signs of damage during inspection.

Safety is paramount—OSHA mandates daily pre-shift checks, monthly reviews, and a comprehensive inspection by a qualified expert at least once every 12 months. Powerful Machinery provides certified wire rope and lifting solutions to help you meet these requirements.

Always use a practical checklist and follow industry guidelines to ensure your crane operations remain reliable and secure.

Key Takeaways

Inspect the wire rope regularly for broken wires, wear, and corrosion to ensure safety.

Follow the 10-2-1 rule for broken wires: replace if you find 10 broken wires in one lay or 2 in one strand.

Replace the wire rope if you notice significant diameter reduction or structural issues like kinks and birdcaging.

Document all inspections and findings to maintain compliance and enhance safety.

Always use certified wire rope and consult experts for inspections and replacements.

Key Signs to Replace Wire Rope

When you operate a crane, you must recognize the warning signs that show your wire rope needs replacement. Regular inspection helps you avoid accidents and keeps your lifting operations safe.

Powerful Machinery’s Steel Wire Rope offers high tensile strength and a non-rotating design, but even the best ropes need replacement when damaged. Use these key signs to guide your decision.

Broken Wires and the 10-2-1 Rule

You should check for broken wires every time you inspect your crane. Broken wires weaken the rope and increase the risk of failure. The 10-2-1 rule helps you decide when to replace the rope:

Condition for Replacement | Description |

|---|---|

10 Random Broken Wires | Replace if 10 randomly distributed broken wires are found in one rope lay. |

2 Broken Wires in a Strand | Replace if 2 or more broken wires are found in one strand within one rope lay. |

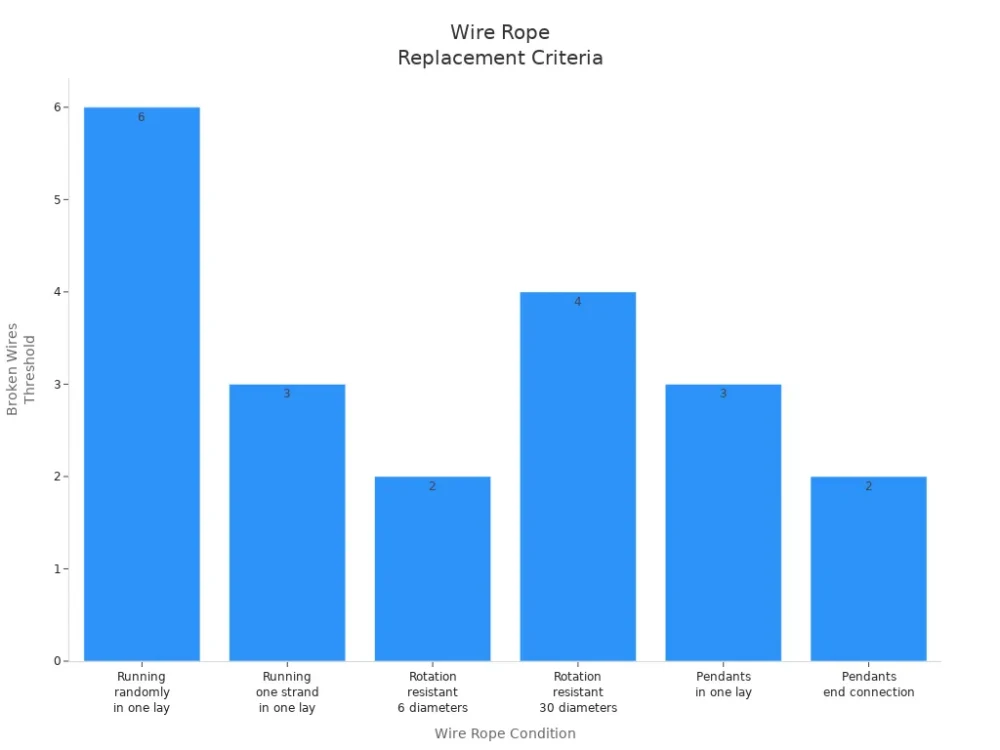

Industry standards also set strict limits for broken wires. The table below shows when you must replace wire rope based on the number of broken wires:

Condition | Number of Broken Wires Required for Replacement |

|---|---|

Running wire ropes | 6 randomly distributed in one rope lay |

3 broken wires in one strand in one rope lie | |

Rotation-resistant ropes | 2 randomly distributed in 6 rope diameters |

4 randomly distributed in 30 rope diameters | |

Pendants or standing wire ropes | More than 2 broken wires in one rope lie |

More than 1 broken wire in a rope lay at the end connection |

If you find broken wires that meet or exceed these limits, you must replace the rope immediately. Broken wires often appear after shock loading, overload events, or long-term use. Always count broken wires during your inspection and compare the results to these standards.

Diameter Reduction and Stretching

Wire rope diameter changes over time due to wear and stretching. You must measure the rope’s diameter regularly. If you notice a reduction greater than 1/3 of the wire’s diameter, replace the rope.

Most standards, such as ASME, ISO 4309, and OSHA, require replacement when diameter loss reaches between 3.5% and 9%. Core deterioration can cause rapid diameter reduction, so pay close attention to this sign.

Wire rope stretching also affects safety. Stretching reduces the rope’s strength and lifting capacity. If you operate near the crane’s maximum load, stretching increases wear and risk of failure.

The Working Load Limit (WLL) comes from dividing the Minimum Breaking Strength (MBS) by a design factor, usually 5:1. This safety margin protects you from unexpected rope failure. Regular checks help you maintain this margin and keep your crane safe.

Aspect | Impact on Lifting Capacity and Safety Margins |

|---|---|

Wire Rope Stretching | Reduces effective strength and lifting capacity |

Operating Near Capacity | Increases wear and risk of failure |

Safety Margins | Compromised due to stretching |

Corrosion, Rust, and Abrasion

Wear and corrosion shorten the life of the wire rope. You must look for signs of corrosion, rust, and abrasion during every inspection. Corrosive environments, lack of maintenance, and high humidity all speed up rust formation. Heavy corrosion weakens the rope and can cause sudden failure.

Cause of Corrosion | Impact on Service Life |

|---|---|

Corrosive Environments | Accelerates corrosion due to exposure to chemicals, saltwater, or industrial fumes. |

Lack of Maintenance | Trapped dirt and moisture speed up rust formation and metal loss. |

High Humidity | Promotes oxidation on steel surfaces, leading to rapid rust buildup. |

Exposure to corrosive environments leads to faster deterioration of wire ropes.

Inadequate maintenance allows for rust to form more quickly.

High humidity conditions contribute to oxidation and rust buildup.

If you see advanced corrosion or deep abrasion, replace the rope. Powerful Machinery’s Steel Wire Rope resists abrasion and corrosion, but you must still inspect it often. Wear and corrosion are common reasons for rope replacement in crane safety audits.

Kinks, Crushing, and Birdcaging

Structural distortion is another sign that you need to replace the wire rope. Look for kinks, crushing, and birdcaging. These problems damage the rope’s internal wires and reduce its strength.

Indicator | Description |

|---|---|

Kinks | Permanent bends that damage internal wires |

Birdcaging | Strands loosen and flare out due to the sudden release of tension |

Crushing | Flattening from improper winding or overloading |

Birdcaging is a severe form of distortion. It happens when the rope twists or its load is released suddenly. The strands unravel and expand, looking like a birdcage. Birdcaging is most common in rotation-resistant wire rope.

You must replace the rope immediately if you see birdcaging, kinks, or crushing. These problems lead to internal damage, loss of strength, and dangerous work conditions.

Tip: Always inspect the load chain and wire rope for signs of broken wires, wear, corrosion, and distortion before each shift. Early detection helps you prevent accidents and costly downtime.

Most frequently cited reasons for wire rope replacement in crane safety audits:

Broken wires exceeding acceptable limits

Significant diameter reduction

Advanced corrosion

Structural distortion or kinking

Damaged or improper end terminations

Shock loading or overload events

Possible internal core failure

Condition over time, not just age

Powerful Machinery’s Steel Wire Rope meets strict safety standards and offers reliable performance. You must still follow inspection guidelines and replace the rope when you see these warning signs. Safe crane operation depends on your attention to detail and commitment to regular maintenance.

How to Inspect Wire Rope for Safety?

Regular inspection is essential for crane safety and reliable operation. You must follow clear guidelines to ensure your wire rope remains in top condition. Powerful Machinery’s certified products come with detailed inspection instructions, making it easier for you to maintain high standards.

Visual Inspection Steps

You should always start with a thorough visual check. Follow these hoist inspection procedures to spot early signs of damage:

Prepare by cleaning the wire rope and making sure you have good lighting. Wear gloves so you can feel for any sharp protrusions.

Scan the entire length of the rope slowly. Focus on high-stress areas, such as near the drum or sheaves.

Measure the diameter at several points and compare each to the original size.

Count any broken wires. Use a spike or awl to gently separate strands if needed.

Check for proper lubrication. Adequate grease helps prevent corrosion and reduces friction.

For critical applications, consider advanced methods like electromagnetic or ultrasonic testing to find hidden flaws.

Tip: Consistent inspection and maintenance help you catch problems before they become serious.

Measuring Wear and Diameter Loss

You need to measure wear and diameter loss to judge the rope’s condition. Use calipers with wide flanks for accuracy. Measure at the widest point, from strand crown to strand crown. Take two measurements in the X-direction and two in the Y-direction, about one meter apart, and average the results.

Compare these numbers to the rope’s original diameter. If you see a reduction greater than one-third, replace the rope. Always compare worn sections to unworn ones to spot hidden damage.

Recording and Reporting Issues

Accurate records are vital for compliance and ongoing maintenance. Each inspection should include:

Rope identifier

Date of inspection

Inspector’s name

Points of deterioration found

Inspection Type | Frequency |

|---|---|

Comprehensive Inspection | Quarterly/Annually |

Documentation Review | During Inspections |

Operational Load Testing | As Required |

Keep signed reports for every periodic inspection. Document all findings and actions taken. This practice supports safety and meets industry guidelines.

Regular inspection and proper maintenance extend the life of your crane’s wire rope. Following these steps ensures you meet safety standards and keep your equipment running smoothly.

Immediate Actions When Replacement Is Needed

When you find a wire rope on your crane that shows signs of damage, you must act quickly to keep your team safe and your equipment in good condition. Powerful Machinery’s lifting equipment and certified wire ropes help you maintain high safety standards during every replacement.

Remove Damaged Wire Rope from Service

You should remove any damaged wire rope from service right away. The table below shows when you must take a rope out of use:

Condition for Taking Out of Service | Description |

|---|---|

Broken Wires | Six randomly distributed broken wires in one lay or three broken wires in one strand in one lay. |

Wear | Wear of one-third the original diameter of the outside individual wires. |

Damage | Kinking, crushing, bird caging, or any other damage resulting in distortion of the rope structure. |

Heat Damage | Evidence of any heat damage from any cause. |

Diameter Reduction | Reductions from nominal diameter exceeding specified limits based on rope size. |

Standing Ropes | More than two broken wires in one lay in sections beyond end connections, or more than one broken wire at an end connection. |

If you see any of these problems, stop using the crane until you replacethe wire rope with a certified product.

Replacement Checklist for Crane Operators

You need a clear checklist to guide you through safe replacement. Follow these steps:

Check for broken wires.

Inspect for corrosion, especially in high-stress areas.

Examine wear at contact points.

Identify any structural deformation, such as kinks or birdcaging.

Verify the rope is positioned correctly.

Confirm the lay direction matches the original.

Perform weekly or monthly detailed inspections.

Make sure the new wire rope matches the size, grade, and construction required by the manufacturer.

Review the test certificate to confirm a safety factor of 4.

Test the crane without a load to check lifting, lowering, brakes, and limit devices.

Tip: Always lubricate the new wire rope with a thin, penetrating lubricant to prevent internal friction and extend its life.

Training and Documentation

Proper training helps you spot problems early and handle replacements safely. You should take part in hands-on programs that cover real inspections, wear measurement, and replacement criteria. The table below outlines key training components:

Training Component | Description |

|---|---|

Real Inspections | Practice with real-life examples of wear or damage and documentation on checklists. |

Wear, Inspection, And Replacement Criteria | Learn to measure wear and decide when to replace. |

Hoist System | Practice switching out ropes and inspecting components. |

Wire Rope/Hooks | Understand different types and their uses. |

Keep detailed records of every inspection, replacement, and training session. This practice supports compliance and helps you maintain safe crane operations with Powerful Machinery’s reliable lifting solutions.

Conclusion

You must always prioritize safety and conduct regular inspections to know when to replace the wire rope on the crane. Key takeaways from industry cases show that missed inspections, lack of operator training, and ignoring corrosion can lead to serious failures.

You should follow these main criteria for when to replace the wire rope on a crane:

Replace if you see broken wires, significant wear, or any sign of corrosion.

Remove the rope if you notice kinks, birdcaging, or diameter reduction.

Involve qualified personnel for every inspection.

Feature | Powerful Machinery’s Certified Wire Rope |

|---|---|

Meets Safety Standards | Yes |

Resists Corrosion | Yes |

Long Service Life | Yes |

“Performing advanced inspections helps you determine when to replace wire rope on a crane, extend service life, and improve safety.”

You can trust Powerful Machinery’s certified products to help you decide when to replace wire rope on a crane and keep your crane operations safe. Schedule routine checks and consult Powerful Machinery for expert support.

FAQ

How often should you inspect wire rope on a crane?

You should inspect the wire rope on a crane before each shift. Monthly and annual inspections help you find hidden damage. Regular checks keep your lifting operations safe and prevent accidents.

What is the main reason wire rope fails on a crane?

Wire rope often fails on a crane because of broken wires, corrosion, or structural distortion. You must replace damaged rope quickly to avoid safety risks.

Can you reuse wire rope after removing it from a crane?

You should never reuse wire rope once you remove it from a crane. Old rope may have hidden damage. Always use new, certified wire rope for every replacement.

How do you choose the right wire rope for your crane?

You need to match the wire rope size, grade, and construction to your crane’s specifications. Check the manufacturer’s guidelines and use certified products for safe lifting.

What should you do if you find corrosion on your crane’s wire rope?

You must replace the wire rope if you see corrosion on your crane. Corrosion weakens the rope and increases the risk of failure during lifting operations.