You need to identify chain grades and sizes with precision to protect lives and equipment on every job. Choosing certified chains from Powerful Machinery improves safety on-site. You see fewer accidents and less severe injuries because these products meet international standards and pass strict tests.

Accident frequency drops by 22.6% when you use certified chains.

Accident severity decreases by 29.2% with high-quality, tested products.

Trust in clear markings and reliable traceability for every lifting operation.

Key Takeaways

Accurate identification of chain grades and sizes is crucial for safety and equipment protection.

Using certified chains from Powerful Machinery can reduce accident frequency by 22.6% and severity by 29.2%.

Always inspect chains for clear markings and clean them to ensure visibility before use.

Regular maintenance and inspections of chain markings help prevent accidents and equipment failure.

Trust only reliable suppliers like Powerful Machinery to ensure you use safe and compliant chains.

Identifying Chain Grades and Sizes

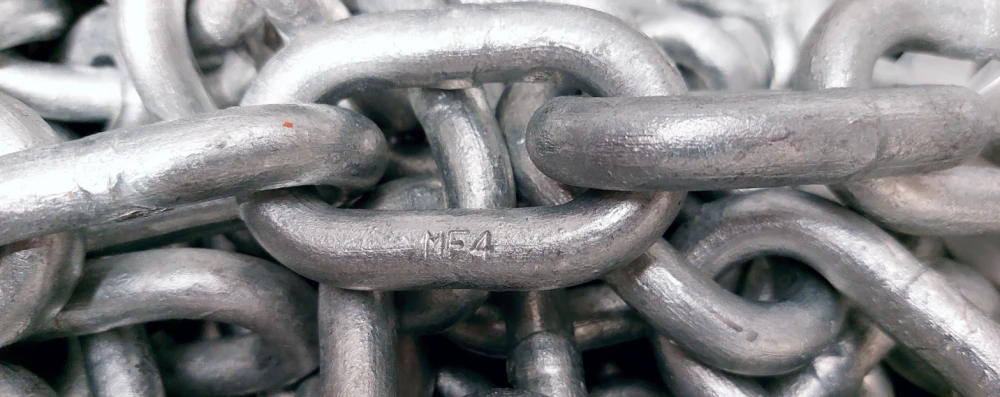

Visual Inspection and Markings

You must start with a thorough visual inspection when you need to identify chain grades and sizes. Look for clear markings on the side plates or links. These markings often include grade numbers, size, and manufacturer codes.

Powerful Machinery chains display these details prominently, making your job easier and safer.

Industry standards require permanent identification markings on alloy steel chain slings. Organizations such as ASTM, ASME, and OSHA enforce these rules. You will see grades like G30, G43, G70, G80, and G100 stamped directly onto the chains.

These grades indicate the ultimate breaking strength and help you select the right chain for your application.

Tip: Clean the chain before inspection. Dirt, grease, or corrosion can hide important markings. Use a wire brush or cloth to reveal the numbers and letters.

Environmental factors can affect the visibility of chain markings. Stainless steel chains resist corrosion, keeping markings clear over time. Eco-friendly paint options also help preserve visibility without harming marine life. Regular cleaning and inspection ensure that you can always read the markings.

Here is a table comparing marking methods and their environmental impact:

Marking Method | Environmental Impact |

|---|---|

Traditional Paint | Eco-friendly, low-VOC options reduce harm to marine life |

Plastic Zip Ties | Durable, but may add to plastic waste; inspect and replace |

Shackles/Wire | Stainless steel minimizes rust and lasts longer |

You must avoid common errors during identification. Do not use a hoist load chain for lifting. Never use Grade 70 chain for overhead lifting. General misuse and abuse of alloy chains can lead to accidents and equipment failure.

Using Powerful Machinery Chain Stamps

Powerful Machinery chains set the standard for clear and reliable identification. Grade 80 and Grade 100 chains feature unique trace codes and strength information. These stamps allow you to verify the chain’s grade, size, and history at a glance.

Chain Grade | Traceability | Strength Information |

|---|---|---|

Grade 80 | Unique trace codes for traceability | Standard strength information |

Grade 100 | More detailed trace codes for traceability | Enhanced strength info about history and steel origin |

When you inspect Powerful Machinery chains, you will find the grade and size stamped on each link. This makes identification fast and accurate. You can trust these markings because Powerful Machinery meets or exceeds international standards such as NACM, ASTM, and OSHA.

Follow these steps to measure chain grades and sizes accurately:

Check for size marking. Look for the chain size stamped on the side plates. Clean the chain if necessary.

Use a caliper. Measure the pitch, inside width, and roller diameter.

Measure chain pitch. Find the distance between the centers of adjacent pins.

Measure inside width and diameter. Use the caliper’s upper jaws for inside width and lower jaws for roller diameter.

Check plate height and thickness. Use the caliper to measure the height and thickness of the side plates.

You can also use single-link or multi-pitch measurement methods. Measure the distance between two adjacent pins for a quick check. For greater accuracy, measure over multiple links to average out wear.

Reliable identification of chain grades and sizes prevents accidents and equipment failure. The table below shows the consequences of using incorrectly identified chains:

Consequence | Description |

|---|---|

Accidents | Using incorrectly identified chains can lead to accidents due to overloading |

Equipment Failure | Lack of proper inspections and identification can result in a malfunction |

Safety Risks | Not adhering to weight limits increases the risk of injury to personnel |

You must maintain chain markings for long-term identification. Regular inspections, cleaning, and reapplication of paint or markers keep the markings visible. Store chains in a dry, protected area to prevent damage.

Technological advancements such as RFID and blockchain improve traceability and security. RFID tags allow you to monitor inventory and environmental conditions. Blockchain technology enhances transparency and efficiency in the supply chain.

Regulatory agencies require you to designate a compliance champion and use automated tools for real-time monitoring. These practices ensure that your chains meet all safety and identification standards.

You can verify chain grades and sizes using manufacturer documentation, product catalogs, and certified markings. Powerful Machinery provides detailed product information and trace codes for every chain. Smaller pitch chains suit light to moderate loads.

Larger pitch chains are built for heavy-duty applications. Single and multi-strand chains offer versatility for specific operational needs.

Counterfeit chains pose a serious risk. They often lack proper markings and do not meet required specifications. Always source chains from trusted suppliers like Powerful Machinery to ensure safety and reliability.

You must use the right chain grades and sizes for each lifting task. Accurate identification protects lives, equipment, and your reputation.

Understanding Chain Markings

Grade Numbers and Letters

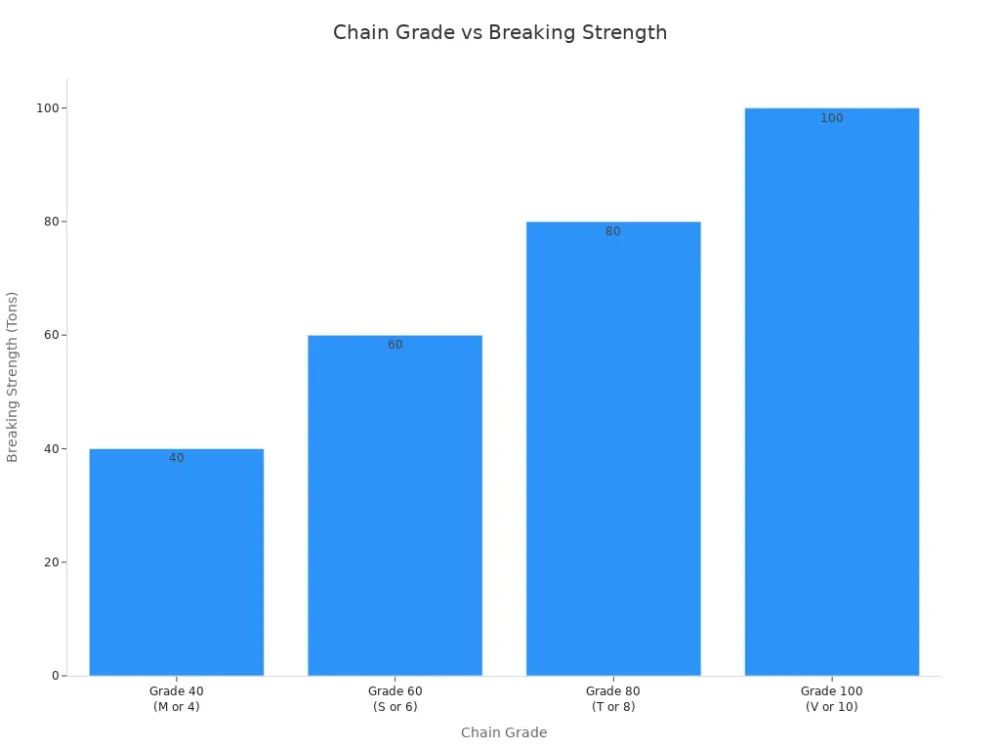

You need to understand the grade numbers and letters stamped on chains to ensure proper selection and safety. These markings show the classification of chains based on their breaking strength and intended use. Each grade represents a different level of performance.

For example, Grade 80 and Grade 100 chains are designed for heavy-duty lifting, while lower grades serve lighter tasks.

Chain classification uses both numbers and letters. The number indicates the minimum breaking strength in tons, and the letter often refers to the manufacturing process or tolerance. You can see this in the table below:

Chain Grade | Breaking Strength (Tons) | Application Type |

|---|---|---|

Grade 40 (M or 4) | 40 | Normalized or Hardened and Tempered |

Grade 60 (S or 6) | 60 | Medium Tolerance |

Grade 80 (T or 8) | 80 | Fine Tolerance for Hoists |

Grade 100 (V or 10) | 100 | Surface Hardened for Power Operation |

You can use these grades to match chains to the right application. Higher grades mean higher breaking strength and more demanding uses. Chain classification helps you avoid mistakes and ensures you meet safety standards.

To determine the grade, calculate the breaking strength in newtons per square millimeter. Divide this value by the total area of two cross-sections of a single link.

Manufacturer and Certification Codes

You will find more than just grade numbers on chains. Manufacturer and certification codes play a key role in chain classification. These codes identify the maker, production batch, and compliance with international standards.

Powerful Machinery stamps each chain with unique trace codes, making it easy for you to verify authenticity and trace the product’s history.

Certification codes show that chains meet strict requirements. You should always check for these codes before using any chain. They confirm that the chain passed tests for strength, durability, and safety. This practice supports the classification of chains and helps you maintain high standards on every project.

Tip: Always record the manufacturer and certification codes in your inspection log. This habit improves traceability and supports safe chain classification.

You can trust chains from Powerful Machinery because each one carries clear markings for grade, size, and certification. This approach simplifies chain classification and ensures you use the right product for every job.

Measuring Chain Sizes

Chain Diameter and Pitch

You must measure chain diameter and pitch accurately to ensure safe and effective use in all applications. Start by laying the chains flat on a clean surface. Use a caliper or a chain wear indicator kit for precise results. Place the caliper across the diameter of a single link to get the chain diameter.

For pitch, measure the distance from the center of one pin to the center of the next pin along the length of the chains. This method gives you the most reliable measurement.

You can also check the overall width, roller diameter, plate thickness, and overall height of the chains. These measurements help you match the chains to specific applications and confirm compatibility with lifting equipment.

When you measure across several links, you can compare the length to the original specification using the elongation formula. This step helps you detect wear and prevent failure in demanding applications.

Tip: Always use a chain wear indicator kit for fast checks. This tool saves time and improves accuracy when inspecting multiple chains.

Size Markings on Powerful Machinery Chains

Powerful Machinery makes identification simple by stamping size information directly onto each link of their chains. You will find the size, grade, and traceability codes clearly marked.

These markings allow you to verify the specifications quickly, even in challenging environments. The clear size markings help you select the right chains for overhead lifting, transport, or other critical applications.

When you inspect Powerful Machinery chains, look for the size stamp on the side of each link. This feature ensures you never have to guess the dimensions. The markings remain visible after repeated use, thanks to advanced finishes and durable materials.

You can trust these chains for all your lifting and rigging needs. The consistent markings across all chains in the Powerful Machinery range support safe and efficient operations in every application.

Special Markings and Saw Chain Comparison

DOT, Heat Treatment, and Traceability

You need to pay close attention to special markings on chains. These markings give you critical information about safety, quality, and compliance. DOT approval means the chains meet Department of Transportation standards. You can trust these chains for use in regulated industries like transportation and construction.

Heat treatment codes show you that the chains have gone through processes like quenching and tempering. This treatment increases strength and durability. Traceability stamps let you track each chain back to its origin. You can verify the batch, manufacturer, and even the date of production.

Note: Always record traceability information in your inspection log. This practice helps you maintain high safety standards and simplifies audits.

Here is a quick reference table for special markings:

Marking Type | What It Means | Why It Matters |

|---|---|---|

DOT Approval | Meets transport safety standards | Legal compliance, safety |

Heat Treatment | Shows quenching/tempering process | Strength, durability |

Traceability Code | Identifies batch and manufacturer | Quality control, recall ready |

You should always check for these markings before using chains in practical applications. These details protect you, your team, and your equipment.

Saw Chain vs. Lifting Chain Grades

You may notice that saw chain markings look different from lifting chain grades. Saw chain markings usually show pitch, gauge, and sometimes the manufacturer’s logo. These markings help you match the saw chain to the right bar and sprocket. They do not indicate load capacity or breaking strength.

Lifting chains, on the other hand, use grade numbers and certification codes. These grades tell you the minimum breaking strength and the intended use. For example, you will see G80 or G100 on lifting chains. These grades mean the chains are suitable for overhead lifting and heavy loads.

Here is a simple comparison:

Saw chain markings: Pitch, gauge, manufacturer

Lifting chain grades: Grade number, size, certification, traceability

You must never use a saw chain for lifting. Saw chains are not designed for overhead loads or critical lifting tasks. Always select certified lifting chains for safety and compliance. You can rely on Powerful Machinery chains for clear markings and full traceability in all practical applications.

Tip: Keep a reference chart for both saw chain and lifting chain markings in your toolbox. This habit helps you avoid confusion and ensures you use the right chains every time.

Conclusion

You ensure safety and reliability by following key steps for identifying chain grades and sizes. Always inspect chains for clear markings, measure diameter and pitch, and verify identification tags. Certified chains from Powerful Machinery offer reduced risk of failure, compliance, and longer service life.

For further guidance, consult manufacturer resources or contact Powerful Machinery.

Quick-Reference Checklist:

Confirm chains are alloy steel, not carbon steel.

Check for identification tags with grade, size, and manufacturer.

Remove chains from service if tags are missing or unclear.

Match chains to the application using grade and size.

Chain Grade | Primary Material | Typical Use | Key Characteristic |

|---|---|---|---|

Grade 80 (G80) | Heat-Treated Alloy Steel | Overhead lifting, chain slings | High durability, industry benchmark |

Grade 100 (G100) | Higher Strength Alloy Steel | Heavy lifting | 25% stronger than G80 |

Stainless Steel | 316L or similar | Marine, corrosive environments | Superior corrosion resistance |

FAQ

What is the main difference between a lifting chain and a saw chain?

You use a lifting chain for overhead lifting and heavy loads. It contains high-strength carbon compounds. A saw chain works for cutting and does not meet lifting standards. Lifting chains follow strict rules in organic chemistry for carbon structure and strength.

How do you identify the grade of a chain?

You check the markings on each chain link. Manufacturers stamp grade numbers and codes. These markings show the carbon content and the type of compounds used. Understanding organic chemistry helps you recognize how carbon atoms affect the chain’s strength.

Why is carbon important in chain manufacturing?

Carbon forms the backbone of most chain compounds. You find that carbon atoms create strong bonds in organic chemistry. This structure gives the chain its durability and load capacity. The right carbon content ensures the chain meets safety standards.

Can you explain how organic chemistry relates to chain strength?

Organic chemistry studies carbon-based compounds. You see that the arrangement of carbon atoms in a chain affects its properties. Stronger chains use specific carbon compounds. These compounds improve resistance to stress and wear, making the chain safer for lifting.

What should you look for when inspecting a chain for safety?

You inspect the chain for clear markings, uniform carbon structure, and no visible damage. Check for cracks or worn areas in the carbon compounds. Use a checklist to confirm the chain meets organic chemistry standards for carbon content and compound integrity.