If you have ever wondered what is tensile strength, you are not alone. Tensile strength tells you how much pulling force a material can handle before it breaks. The table below shows how experts define tensile strength:

Source | Definition |

|---|---|

ScienceDirect | Ratio of the maximum load a material can withstand without breaking to its original cross-sectional area. |

Fiveable | The maximum amount of tensile (pulling or stretching) stress a material can withstand before failure. |

You see tensile strength at work every day, from the steel in bridges to the fabric in seatbelts. Industries like aerospace, automotive, and construction rely on it to ensure safety and top performance. With the global focus on reliable materials, understanding tensile strength helps you make better choices in both daily life and industry.

Key Takeaways

Tensile strength measures how much pulling force a material can withstand before breaking, crucial for safety in construction and manufacturing.

Understand the three types of tensile strength: yield strength (permanent deformation), ultimate tensile strength (maximum stress before breaking), and breaking strength (total failure point).

Always check the tensile strength rating when selecting materials for load-bearing applications to ensure safety and reliability.

Tensile testing is essential for quality control, helping to confirm that materials meet industry standards and are safe for use.

Choosing materials with the right tensile strength protects lives and property, making informed decisions vital in engineering and construction.

What Is Tensile Strength?

Simple Definition

When you ask what tensile strength, you want to know how much force a material can handle when you pull on it before it snaps. Engineers define tensile strength as the maximum stress a material can withstand before breaking.

You see this property in action every time you use a wire rope, chain, or even a seatbelt. Tensile strength helps you understand how safe and reliable a material is for lifting, building, or securing loads.

Tensile strength at yield is the maximum stress a material can handle without permanent deformation. This means the material returns to its original shape after you remove the force. If you go beyond this point, the material changes shape and cannot recover.

In engineering, knowing what tensile strengthis helps you choose the right material for every job, from bridges to cranes.

Tip: When you select lifting equipment, always check the tensile strength rating. This ensures you get the safest and most reliable product for your needs.

Types of Tensile Strength

You will encounter three main types when you study what is tensile strength:

Feature | Yield Strength | Ultimate Tensile Strength (UTS) | Breaking Strength |

|---|---|---|---|

Definition | The limit before permanent shape change occurs. | The maximum stress before fracture/necking. | The point of total material failure. |

Behavior | Transition from Elastic to Plastic. | Occurs deep in the Plastic zone, just before failure. | Represents complete fracture. |

Design Priority | Critical for parts that must keep their shape. | Critical for safety buffers and limits. | Essential for evaluating load-bearing capacity. |

Typical Application | Structural beams, bolts, suspension springs. | Lifting cables, crash barriers, pressure vessels. | Safety equipment, lifting gear, load-bearing structures. |

Yield strength tells you when a material will start to deform permanently. You use this value when you design beams or bolts that must keep their shape under load.

Ultimate tensile strength measures the highest stress a material can withstand before it starts to break apart. You rely on this property for cables and barriers that must hold up under extreme conditions.

Breaking strength marks the point where the material fails. You need this value for safety equipment and lifting gear that must never break during use.

For example, when you design a steel beam for a building, you focus on yield strength to prevent bending. If you select an elevator cable, you look at the ultimate tensile strength to ensure it can handle heavy loads without snapping.

Powerful Machinery specializes in high-tensile products like lifting chains and wire ropes. These products meet strict international standards for tensile strength, yield strength, and breaking strength.

You can trust Powerful Machinery to deliver certified solutions for the construction, marine, and transportation industries. Every chain, hook, and wire rope undergoes rigorous testing to guarantee maximum performance and safety.

When you understand what tensile strength is, you make smarter choices for every project. You protect people, equipment, and structures by selecting materials with the right tensile strength for the job.

Importance of Tensile Strength

Everyday Uses

You encounter tensile strength every day, even if you do not realize it. When you cross a suspension bridge, the cables must withstand the weight of vehicles and people. The steel beams in buildings rely on tensile strength to prevent collapse.

Automotive seatbelts, elevator cables, and even packaging tapes all depend on materials that can resist pulling forces. If these products lack proper tensile strength, they may fail under stress, leading to safety risks.

Cables on bridges experience constant tension as vehicles pass.

Construction cranes use wire ropes with high tensile strength to lift heavy loads.

Automotive components, such as seatbelts and frames, require reliable tensile strength for passenger safety.

Packaging films and tapes need enough tensile strength to secure goods during transport.

Powerful Machinery supplies certified lifting chains, wire ropes, and rigging hardware designed for demanding environments. You can trust these products to deliver consistent tensile strength, ensuring safety and durability in construction, marine, and transportation sectors.

Note: Material durability and tensile strength are essential for product longevity and safety. High-performance materials help prevent accidents and reduce financial liabilities.

Role in Material Science

Tensile strength plays a central role in material science and engineering. You use tensile strength data to select the right material for each application. Engineers rely on tensile strength to perform stress analysis and determine safety factors.

This property guides decisions in aerospace, automotive, and civil engineering, where failure can cause catastrophic results.

Key Metric | Description |

|---|---|

Yield Strength | The stress at which a material begins to deform plastically. |

Ultimate Tensile Strength | The maximum stress a material can withstand while being stretched before failure. |

Ductility | The ability of a material to deform under tensile stress. |

Strain-Hardening | The increase in strength of a material as it is deformed plastically. |

Advancements in material science continue to improve tensile strength. For example, graphene and bamboo fiber composites offer exceptional strength and flexibility. These innovations allow you to choose sustainable materials that meet strict performance standards.

Understanding tensile strength helps you make informed decisions about material selection. You can evaluate which products will perform best under specific loads and conditions.

Powerful Machinery’s commitment to international standards and rigorous testing ensures that every product meets the highest requirements for tensile strength.

The importance of tensile strength extends from everyday products to advanced engineering projects. You protect lives, property, and investments by choosing materials with proven tensile strength.

Tensile Testing Methods

How Tensile Testing Works?

You use tensile testing to measure how much force a material can handle before it breaks. This process helps you understand the tensile strength of metals, plastics, and other materials. To start, you prepare a sample, often shaped like a dumbbell, from the material you want to test.

You then place the sample between two clamps in a tensile test machine. The machine pulls the sample apart at a steady speed while you watch for changes.

Here are the main steps you follow during a tensile test:

Prepare the sample with the correct shape and material.

Select the right grips for the tensile test machine.

Mark the sample to track how much it stretches.

Place the sample in the machine’s clamps.

Attach an extensometer to measure stretching.

Pull the sample until it breaks.

Record the results, including tensile strength and ductility.

Tensile testing plays a key role in quality control. You use it to check if materials meet industry requirements and to spot any defects. Manufacturers like Powerful Machinery rely on tensile testing to ensure every product meets strict tensile strength standards.

Their products undergo tests that follow international guidelines, such as ISO 6892-1 for metals and ASTM D638 for plastics.

Standard | Material Type | Key Properties Measured | Testing Conditions |

|---|---|---|---|

ISO 6892-1 | Metallic materials | Yield strength, tensile strength, and elongation | Room temperature (10°C to 38°C) |

ASTM A370 | Steel and alloys | Tensile strength, yield strength, and elongation | Various product forms, including bars and wires |

ASTM D638 | Plastics | Tensile strength, yield strength, and elongation | Standard dumbbell specimens, controlled conditions |

ASTM E21 | Metallic materials | Tensile strength, yield strength, and elongation | Elevated temperatures above 38°C |

ISO 527 | Plastics | Tensile properties of filled and unfilled plastics | Various conditions for reproducibility |

ISO 37 | Rubber materials | Tensile strength, elongation at break | Controlled environment, specific specimen shapes |

Interpreting Test Results

After you finish tensile testing, you look at the data to decide if a material is right for your project. You check several key values, such as yield strength, ultimate tensile strength, and elongation at break. These results help you compare materials and choose the best one for safety and performance.

Parameter | Significance | Interpretation |

|---|---|---|

Young’s Modulus | Measures material stiffness and rigidity. | Helps you know how much a material will stretch under force. |

Yield Strength | Shows resistance to permanent shape change. | Tells you if the material will keep its shape under load. |

Ultimate Tensile Strength | Maximum stress before failure. | Important for parts that must not break under heavy loads. |

Elongation at Break | Measures how much a material can stretch before breaking. | Higher values mean better flexibility and toughness. |

Reduction of Area | Shows how much the material thins before breaking. | Indicates the ability to absorb energy before fracture. |

You use tensile testing to confirm that products meet the highest standards. Powerful Machinery’s certified labs follow international tensile test methods and hold accreditations like ISO/IEC 17025:2017.

This ensures you get reliable results and safe, high-quality products. By understanding factors affecting tensile strength, you make better choices for every application.

Tensile Strength vs Tensile Stress

Key Differences

You may often hear the terms tensile strength and tensile stress used together, but they describe different concepts in material science. Tensile stress refers to the internal force per unit area that develops within a material when you apply a pulling force.

You calculate tensile stress using the formula σ = F/A, where F is the applied force, and A is the cross-sectional area. This value changes as you increase or decrease the load.

Tensile strength, on the other hand, is the maximum tensile stress a material can handle before it breaks. You do not calculate tensile strength with a formula; instead, you find it as the highest point on a stress-strain curve during a test. This value tells you the ultimate limit of a material’s ability to resist being pulled apart.

Term | Definition | Calculation Formula |

|---|---|---|

Tensile Stress | Internal force per unit area resisting being pulled apart. | σ = F/A |

Tensile Strength | The maximum stress a material can withstand before breaking. | Not applicable (max value) |

Tip: Always check both tensile stress and tensile strength when you select materials for safety-critical applications.

Related Properties

When you study tensile stress, you also encounter related properties like yield strength and ultimate tensile strength. Yield strength marks the point where a material starts to deform permanently under tensile stress. This value is crucial because it defines the limit of elastic behavior.

If you exceed the yield strength, the material will not return to its original shape.

Ultimate tensile strength represents the peak tensile stress a material can endure before breaking. This property is essential for ensuring structural integrity, especially in applications where safety is a top priority.

The engineering stress-strain curve helps you visualize how a material responds to increasing tensile stress, showing the transition from elastic to plastic deformation and finally to failure.

Understanding the relationship between stress and strain allows you to predict how materials will behave under different loads. You use the ultimate tensile load to determine the maximum force a component can safely handle.

By mastering these concepts, you make informed decisions about material selection and design, ensuring that your projects meet both performance and safety standards.

Real-World Examples of Tensile Strength

Common Materials Compared

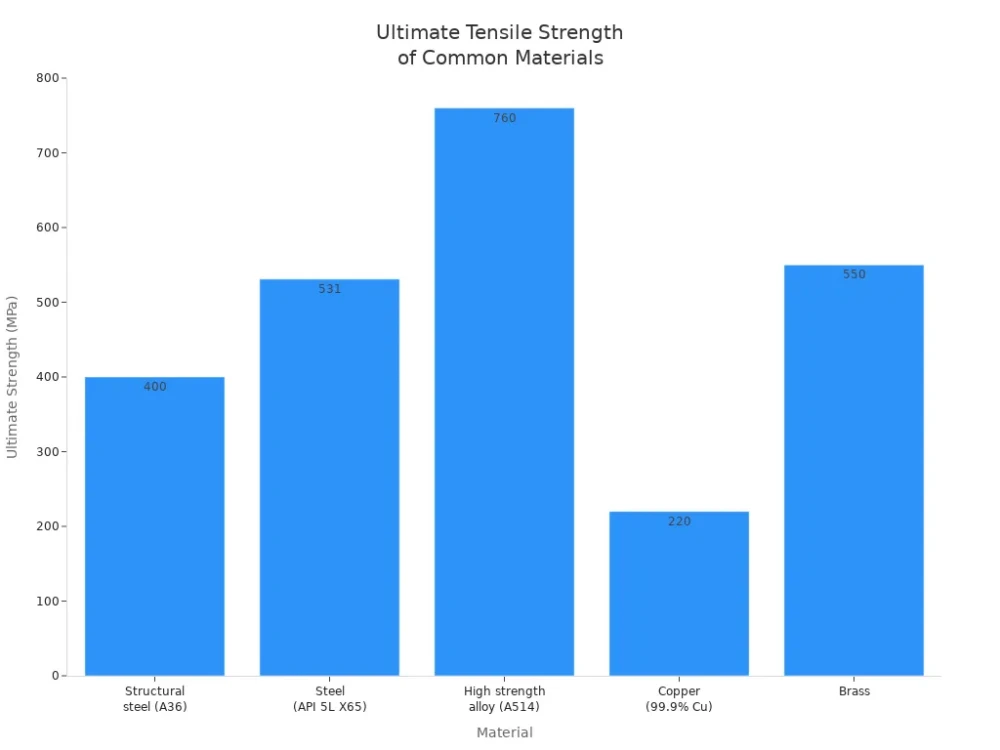

You often compare tensile strength when selecting materials for engineering projects. The table below shows typical values for common metals and alloys:

Material | Yield Strength (MPa) | Ultimate Strength (MPa) | Density (g/cm³) |

|---|---|---|---|

Structural steel (ASTM A36) | 250 | 400 | 7.8 |

Steel (API 5L X65) | 448 | 531 | 7.8 |

High-strength alloy (ASTM A514) | 690 | 760 | 7.8 |

Copper (99.9% Cu) | 70 | 220 | 8.92 |

Brass | 200+ | 550 | 5.3 |

You see that high tensile strength metals like ASTM A514 steel and brass offer much greater resistance to pulling forces than copper. The differences in tensile strength arise from factors such as alloy composition, wire pitch, and manufacturing processes.

For example, the pitch of copper wires and the friction between strands can change the mechanical properties and stress-strain behavior. When you optimize these factors, you improve the tensile strength and reliability of the final product.

Powerful Machinery in Action

You rely on tensile strength to make safe choices in industries like construction, marine, and transportation. Powerful Machinery manufactures lifting chains, wire ropes, and rigging hardware that meet strict international standards.

These products deliver outstanding performance in environments where safety cannot be compromised.

Shipbuilders use high-strength steel tested for tensile strength to ensure hulls withstand heavy loads and harsh conditions.

Mooring ropes made from synthetic fibers undergo repeated tensile tests to confirm they can handle cycles of stress without failure.

ASTM A131 EH36 steel, with tensile strength up to 90,000 psi, is a preferred choice for shipbuilding due to its durability.

Tensile strength guides your selection of materials for critical applications. You choose products with proven strength to protect lives and property. Powerful Machinery’s certified lifting solutions help you meet demanding safety requirements and achieve reliable performance in every project.

Tip: Always check the tensile strength rating before choosing materials for load-bearing or safety-critical tasks. This step ensures you select the right product for your needs.

Conclusion

Tensile strength shows you the maximum force a material can handle before breaking.

You should know the difference between yield, ultimate, and breaking strength for smart material choices.

Testing tensile strength in textiles, metals, and rubber helps ensure safety and durability.

Understanding tensile strength helps you select safe products for daily life and critical projects. Companies like Powerful Machinery guarantee reliability by inspecting raw materials, performing comprehensive tests, and maintaining full traceability.

Step | Description |

|---|---|

Inspection of Raw Materials | Careful examination before production. |

Comprehensive Testing | Chemical analysis, dimensional checks, and proof-load testing. |

Full Traceability | Tracking from production to shipment for certified products. |

If you want to learn more, explore resources that explain yield and tensile strength, or visit educational sites for deeper insights. What will you discover next in the world of material science?

FAQ

What is the difference between tensile strength and yield strength?

Tensile strength shows the maximum stress a material can handle before breaking. Yield strength marks the point where a material starts to deform permanently. You use both values to choose safe, reliable materials.

Why does tensile strength matter in construction?

You need materials with high tensile strength to build safe structures. Strong beams, cables, and fasteners prevent failures and protect lives. Engineers always check tensile strength when designing buildings, bridges, and cranes.

How do you test tensile strength?

You use a tensile testing machine. The machine pulls a sample until it breaks. You record the force and measure how much the material stretches. This test helps you confirm the material meets safety standards.

Can temperature affect tensile strength?

Yes, temperature changes can impact tensile strength. High heat often lowers a material’s strength, while cold can make some materials brittle. You must consider temperature when choosing materials for outdoor or extreme environments.