You need to know the typical pallet jack weight and load capacity before choosing equipment for your workspace. Manual models usually weigh between 150 and 180 pounds, while electric pallet jacks average around 570 pounds, with some models ranging from 275 to 1,329 pounds.

The table below shows the load capacities for different types:

Type of Pallet Jack | Load Capacity (lbs) | Best Use Case |

|---|---|---|

Manual pallet jacks | 3,000 – 5,500 | Small warehouses, retail spaces, or tight aisles |

Electric pallet jacks | 3,000 – 8,000 | Larger warehouses, distribution centers |

Heavy-duty pallet jacks | Up to 15,000 | Industrial warehouses, manufacturing plants |

Low-Profile Pallet Jacks | 3,000 to 5,500 | Specialized low-profile needs |

Weigh Scale Pallet Jacks | 4,400 to 5,500 | Applications requiring weight measurement |

Rough Terrain Pallet Jacks | 2,200 to 4,400 | Outdoor or uneven surface transport |

High-Lift Pallet Jacks | 2,200 to 3,300 | Lifting pallets to higher levels |

Specialized Width Pallet Jacks | 4,400 to 5,500 | Specific width requirements for certain pallets |

Understanding pallet jack weight and load capacity helps you prevent injuries and maintain workplace efficiency. Powerful Machinery delivers certified pallet jack solutions that meet strict safety and quality standards.

Key Takeaways

Understand the weight and load capacity of pallet jacks to choose the right equipment for your workspace.

Manual pallet jacks are ideal for lighter loads, while electric models excel in high-volume operations.

Always check the manufacturer’s specifications to avoid exceeding load limits and ensure safe operation.

Consider the specific needs of your workspace, such as surface type and load frequency, when selecting a pallet jack.

Regular maintenance and inspections are crucial for ensuring the longevity and safety of your pallet jack.

Types of Pallet Jacks

When you explore the types of pallet jacks available, you find three main categories: manual, electric, and specialty models. Each type serves a unique purpose in material handling and offers distinct advantages for your workspace.

Manual Pallet Jacks: Weight and Features

Manual pallet jacks remain the most common choice for small warehouses and retail environments. You operate these by positioning the fork arms under a pallet and pumping the handle to lift the load.

The weight of pallet trucks in this category usually ranges from 150 to 200 pounds for standard-duty models. Heavy-duty versions can weigh 250 pounds or more. Manual pallet jacks handle loads from 3,000 to 5,500 pounds, with fork lengths between 36 and 48 inches and a raised height of up to 8 inches.

Powerful Machinery’s manual pallet trucks feature robust steel construction, ergonomic handles, and polyurethane wheels. These design elements ensure durability and comfort, making them ideal for frequent use.

You benefit from minimal maintenance and reliable performance, especially when you need to move pallets in tight spaces.

Tip: Manual pallet jacks work best for light to medium-duty operations and require only basic upkeep.

Electric Pallet Jacks: Weight and Features

Electric pallet jacks offer a solution for high-volume operations. You use battery-powered controls to lift and move heavier loads, often exceeding 6,600 pounds. The weight of pallet trucks in this category can reach 570 pounds or more, depending on the model and battery size.

Electric models reduce operator fatigue and increase productivity, especially when you handle large or multiple pallets.

Common features include ergonomic controls, long battery life, and smooth lifting capabilities. For example, some electric pallet jacks provide a battery discharge indicator and a lift interrupt to protect the motor. You can expect travel speeds up to 3.6 MPH and advanced safety features.

Specialty Pallet Jacks: Overview

Specialty pallet jacks address unique material handling needs. You may encounter low-profile models for pallets with minimal clearance, wide or narrow fork jacks for non-standard pallet sizes, high-lift jacks for ergonomic workstations, and rough terrain jacks for outdoor use.

These types feature reinforced frames, larger wheels, and specialized designs to ensure safety and efficiency in challenging environments.

Type of Pallet Jack | Unique Features |

|---|---|

Low-Profile Pallet Jacks | Designed for low-clearance pallets, ideal for mixed operations and damage prevention. |

Wide or Narrow Fork Jacks | Specialized for handling pallets that do not fit standard sizes, enhancing safety and efficiency. |

High-Lift Pallet Jacks | Functions as both a jack and a workstation, raising loads to working height for ergonomic benefits. |

Rough Terrain Pallet Jacks | Built for outdoor use with larger wheels and reinforced frames, suitable for uneven surfaces. |

You can select from these types of pallet jacks to match your specific workspace requirements and improve overall efficiency.

Pallet Jack Weight and Load Capacity

Understanding pallet jack weight and load capacity helps you select the right equipment for your workspace. You need to match the weight of a pallet jack and its load capacity to your operational needs.

This section breaks down the typical ranges for manual pallet jacks, electric pallet jacks, and specialty models, so you can make informed decisions.

Manual Pallet Jack Weight and Capacity

Manual pallet jacks remain a staple in warehouses and retail environments. You often see these models weighing between 150 and 250 pounds. The weight of a pallet jack in this category depends on the steel construction and fork dimensions.

Most manual pallet jacks support load capacities from 2,000 to 5,500 pounds. You should never exceed these limits, as doing so risks hydraulic failure and structural damage.

Manual pallet jacks offer load capacities suitable for general warehouse operations.

The most common manual pallet truck models handle around 2,500 kilograms, which equals about 5,500 pounds.

Heavy-duty manual pallet jacks provide higher load capacity for demanding tasks.

Powerful Machinery’s manual pallet trucks feature robust steel frames, ergonomic handles, and polyurethane wheels. These design elements ensure you can move heavy loads safely and efficiently.

The manual hydraulic system allows you to lift and lower pallets with minimal effort. You benefit from a load capacity that meets industry standards, making these pallet jacks ideal for daily use.

Note: Always check the manufacturer’s specifications for pallet jack weight and load capacity before operating a manual pallet truck.

Electric Pallet Jack Weight and Capacity

Electric pallet jacks deliver enhanced performance for high-volume operations. You notice that the weight of a pallet jack in this category ranges from 400 to 700 pounds. The electric motor and battery system add significant weight compared to manual models.

Electric pallet jacks support load capacities from 3,000 to 8,000 pounds, making them suitable for larger warehouses and distribution centers.

Type | Weight (lbs) | Load Capacity (lbs) |

|---|---|---|

Manual Pallet Jacks | 150–250 | 1,000–5,500 |

Electric Pallet Jacks | 400–700 | 3,000–8,000 |

You operate electric pallet jacks using battery-powered controls. These controls reduce operator fatigue and increase productivity. Electric pallet trucks feature advanced safety systems, such as battery discharge indicators and lift interrupts. You can move heavier loads with less effort, which improves workflow efficiency.

Manual pallet trucks typically handle loads from 2,000 to 5,500 pounds.

Electric pallet trucks have weight capacities ranging from 3,000 to 8,000 pounds.

Electric pallet jacks offer consistent lifting power and smooth operation. You benefit from ergonomic controls and long battery life. The increased load capacity allows you to transport multiple pallets or heavier goods in one trip. Electric pallet trucks are essential for environments where speed and efficiency matter most.

Tip: Choose electric pallet jacks when you need to move heavy loads frequently or over longer distances.

Specialty Pallet Jack Load Limits

Specialty pallet jacks address unique material handling requirements. You find models designed for specific tasks, such as high-lift pallet jacks, low-profile jacks, and rough terrain jacks. The weight of a pallet jack in this category varies based on the frame, wheel size, and lifting mechanism.

High-lift pallet jacks are ideal for raising loads to heights between 20 and 32 inches.

These models create elevated workstations and help you stack inventory on shelves.

Standard pallet jacks work best for moving goods on the floor and loading shipments.

Heavy-duty pallet jacks provide maximum load capacity for industrial applications.

Specialty pallet jacks offer load capacities tailored to their intended use. High-lift pallet jacks support loads suitable for stacking and ergonomic workstations. Rough terrain models feature reinforced frames and larger wheels, allowing you to transport loads outdoors or on uneven surfaces.

You should always verify the pallet jack load capacity before using specialty equipment.

Alert: Using a pallet jack beyond its rated load capacity can lead to equipment failure and workplace injuries.

You improve safety and efficiency by matching the pallet jack weight and load capacity to your specific application. Powerful Machinery provides certified manual pallet trucks and electric pallet trucks that meet strict industry standards. You can rely on their products for consistent performance and durability in any environment.

Factors Affecting Pallet Jack Performance

Construction Materials and Design

You need to pay close attention to the materials and design of a pallet jack. High-grade steel provides strength and durability, making it ideal for heavy-duty applications. Pallet jacks made from steel can handle immense loads and resist impact during daily use.

Powder-coated steel increases corrosion resistance, which helps extend the lifespan of your pallet jack in industrial settings. Powerful Machinery uses robust steel construction and ergonomic handles to ensure reliable operation and operator comfort.

High-grade steel supports heavy loads and resists damage.

Powder coating protects against rust and wear.

Ergonomic design reduces fatigue and improves handling.

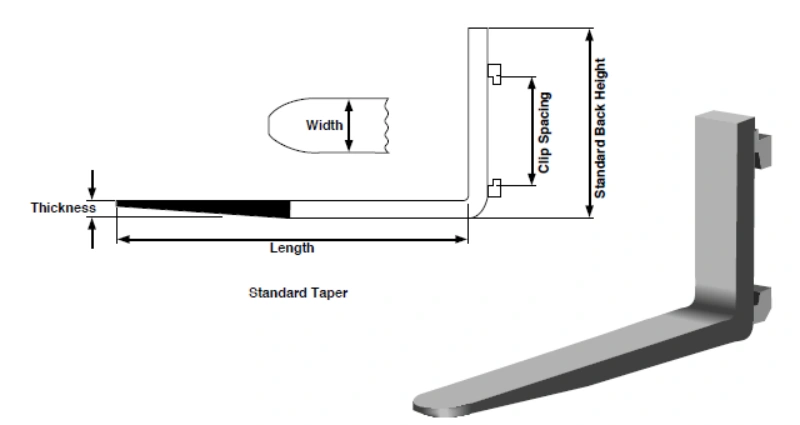

Fork Dimensions and Wheel Quality

Fork length and wheel quality play a major role in the stability and maneuverability of your pallet jack. Choosing the right fork length ensures safe transport and prevents tipping. Standard pallet sizes influence the required fork length, while uneven weight distribution can lead to instability.

Aspect | Impact on Load Capacity and Maneuverability |

|---|---|

Fork Length | Affects stability; too short can lead to tipping, while too long can obstruct movement in tight spaces. |

Weight Distribution | Proper fork length ensures even weight distribution, enhancing stability and safety during transport. |

Maneuverability in Aisles | Incorrect fork length can hinder navigation, increasing the risk of accidents in confined areas. |

Polyurethane wheels, featured on Powerful Machinery pallet jacks, offer excellent load-bearing capacity and protect floors from damage. Wheel quality affects how smoothly you move loads and how well the pallet jack performs over time.

Additional Features and Battery Size

Extra features and battery size impact the weight and operational time of electric pallet jacks. Larger batteries increase the overall weight, which can make maneuvering more difficult.

The battery’s capacity determines how long you can operate the pallet jack before recharging. You should consider these factors when selecting equipment for high-volume tasks.

Larger batteries add weight and may reduce maneuverability.

Higher battery capacity allows for longer operation between charges.

Surface Compatibility

Wheel material and design affect how well your pallet jack works on different surfaces. Nylon wheels suit smooth, even floors and offer chemical resistance. Polyurethane wheels provide superior traction and load-bearing ability on smooth surfaces. Rubber wheels absorb shock and perform better on rough terrain.

Wheel Material | Suitable Surfaces | Advantages |

|---|---|---|

Nylon | Smooth and even surfaces | Durable, chemical-resistant |

Polyurethane | Smooth and even surfaces | Excellent load-bearing, superior traction |

Rubber | Uneven surfaces | Shock absorption, better traction on rough terrain |

You should match the wheel type to your workspace for optimal pallet jack performance. These considerations help you avoid common issues like wheel wear, hydraulic failure, and fork damage, ensuring safe and efficient operation.

Safety Considerations for Pallet Jacks

Floor Load Limits and Durability

You must always consider the floor load limits when operating a pallet jack. Exceeding the recommended load-bearing capacity can damage floors and compromise operator safety. Use the following table to match your typical load weight with the right rated capacity and safety margin:

Typical Load Weight | Recommended Rated Capacity | Safety Margin | Usage Recommendation |

|---|---|---|---|

≤ 2,000 lbs | 2,200–2,400 lbs | +10–20% | Light warehouse handling and retail use |

2,000–4,000 lbs | 4,400–4,800 lbs | +10–20% | Standard palletized goods and general ops |

4,000–5,500 lbs | 6,000 lbs or above | +10–25% | Industrial and heavy-duty logistics |

Powerful Machinery’s pallet jacks are built for durability, ensuring reliable performance in demanding environments.

Operator Ergonomics and Handling

You reduce fatigue and improve safe handling by choosing pallet jacks with ergonomic features. These designs include adjustable handles and easy controls that help prevent back injuries. Electric models often have controls that minimize strain on your hands and wrists, allowing you to work longer without discomfort.

Ergonomic handles lower worker strain and support operator safety.

Easy-to-use controls help you maintain proper posture during operation.

Overloading Risks and Legal Standards

You face serious risks if you overload a pallet jack. Overloading can cause back and joint pain, equipment damage, and instability. Hydraulic leaks, cracked wheels, and bent frames are common results.

OSHA regulations require operators to be at least 18 years old and complete formal instruction. Pallet jacks fall under the Powered Industrial Truck Standard (1910.178). You should always push loads instead of pulling to prevent accidents.

Safety tips: Never exceed the rated load-bearing capacity. Always follow manufacturer guidelines and warehouse safety tips.

Maintenance and Inspection Tips

You keep your pallet jack in top condition by following regular maintenance practices. Clean the wheels often to avoid debris buildup. Inspect your equipment daily and perform monthly checks to catch issues early. Train your staff on proper maintenance protocols to ensure long-term safety.

Perform daily inspections for early repairs.

Maintain a clean workplace to enhance equipment longevity.

Keep wheels free of debris for smooth operation.

Powerful Machinery provides certified pallet jacks that meet international safety standards. You can trust their products for safe handling and reliable performance in any warehouse.

Safety tips: Regular inspections and proper training are essential practices for preventing workplace injuries and ensuring safe operation.

Choosing the Right Pallet Jack

Assessing Workspace and Surface Needs

You need to evaluate your workspace before selecting a pallet jack. Start by examining the layout and surface conditions. Consider the following factors to ensure you choose equipment that fits your environment:

Load Capacity: Identify the maximum weight you handle daily.

Lift Height: Determine how high you need to raise pallets.

Fork Dimensions: Check that the fork length and width match your pallet sizes.

Maneuverability: Measure aisle widths and turning spaces for smooth navigation.

Power Source: Decide if manual or electric models suit your workflow.

Environmental Conditions: Assess floor surfaces and temperature extremes.

Ergonomics and Safety Features: Look for designs that support operator comfort and safety.

Maintenance Requirements: Factor in long-term upkeep and repair costs.

Compliance and Certifications: Confirm the pallet jack meets industry safety standards.

Budget: Balance upfront costs with long-term value.

You improve efficiency and reduce risks by matching your pallet jack to your workspace. For example, polyurethane wheels work best on smooth floors, while reinforced frames suit rough terrain. Always check compatibility with existing equipment, such as shuttle racks and conveyor systems, to streamline operations.

Tip: Measure your aisles and pallet sizes before purchasing to avoid costly mistakes.

Matching Load Requirements and Frequency of Use

You must match your pallet jack to the weight and frequency of your material handling tasks. If you move lighter loads and use the equipment occasionally, manual pallet jacks offer a cost-effective solution. These models require minimal maintenance and suit smaller operations.

If you handle heavier loads or operate in a busy warehouse, electric pallet jacks deliver greater efficiency. You benefit from reduced physical strain and faster workflow. Regular use in large facilities often justifies the investment in electric models, which help prevent injuries and boost productivity.

Manual pallet jacks work well for infrequent use and lighter loads.

Electric pallet jacks excel in high-volume environments with heavier goods.

Frequent operations demand equipment that minimizes downtime and maximizes output.

You should also consider how your pallet jack integrates with existing warehouse systems. Fork length and lift height must align with your storage racks and conveyor systems for seamless handling.

Note: Choose a pallet jack that matches both your load requirements and your daily workflow to optimize performance.

Comparing Manual, Electric, and Specialty Models

You face several options when choosing the right pallet jack for your business. Each type offers distinct advantages and limitations. The table below compares manual, electric, and specialty pallet jacks to help you make an informed decision:

Type of Pallet Jack | Advantages | Disadvantages |

|---|---|---|

Manual Pallet Jack | Cost-effective, simple operation, reliable for lighter loads | Requires physical effort, less efficient for heavy loads |

Electric Pallet Jack | Increased efficiency, reduced physical strain, enhanced safety features | Higher initial cost, requires maintenance, reliant on electricity |

Specialty Models | Tailored for unique tasks (high-lift, rough terrain, low-profile), improved versatility | May have higher costs, specialized maintenance needs |

Manual pallet jacks suit small warehouses and retail spaces. Electric models fit large distribution centers and facilities with frequent, heavy lifting. Specialty pallet jacks address specific challenges, such as outdoor transport or handling non-standard pallets.

Alert: Always review the advantages and disadvantages of each type before making your final selection.

Powerful Machinery Pallet Trucks: Selection Guide

You can rely on Powerful Machinery to help you select the most suitable pallet truck for your needs. The company recommends a step-by-step approach:

Load Capacity: Assess the maximum weight your pallet truck must handle.

Terrain: Evaluate the surfaces in your facility, such as concrete, tile, or outdoor areas.

Construction Material: Choose materials that match your environment. Stainless steel works best in corrosive or wet conditions.

Fork Size: Ensure the forks fit your pallet dimensions. Adjustable forks provide flexibility for different loads.

Maneuverability: Look for features that allow easy navigation in tight spaces.

Powerful Machinery offers a wide range of certified pallet trucks, including manual hydraulic models with robust steel construction and ergonomic handles. You benefit from polyurethane wheels that protect floors and enhance maneuverability.

Custom-engineered solutions are available for unique requirements, ensuring compatibility with your warehouse equipment and operational needs.

Tip: Consult with Powerful Machinery’s experts to find a pallet jack that meets your load, terrain, and workflow demands. Visit their website for detailed product specifications and custom options.

By following these guidelines, you ensure that your pallet jack supports safe, efficient, and reliable material handling in any environment.

Conclusion

You improve workplace outcomes when you understand pallet jack weight and load capacity. This knowledge helps you prevent accidents, reduce physical strain, and streamline operations.

You avoid exceeding equipment limits and minimize risks by selecting the right pallet jack for your needs.

You gain long-term benefits such as cost savings, fewer product damages, and higher employee satisfaction.

Type of Pallet Jack | Certification Requirement |

|---|---|

Manual pallet jacks | No certification required, but training suggested |

Electric pallet jacks | Certification required under OSHA regulations |

You can trust Powerful Machinery for certified pallet jack solutions. For tailored support, consult an expert or visit the official website.

FAQ

What is the maximum weight a pallet jack can handle?

You can move loads up to 5,500 pounds with most manual models. Electric and specialty types support even higher capacities. Always check the manufacturer’s specifications before lifting heavy items.

How do you maintain a pallet jack for long-term use?

You should inspect the wheels and hydraulic system regularly. Clean debris from moving parts. Lubricate joints as needed. Schedule routine checks to prevent unexpected breakdowns.

Can you use a pallet jack on uneven surfaces?

You can use rough terrain models outdoors or on uneven floors. Standard pallet jacks work best on smooth, level surfaces. Choose the right type for your workspace to ensure safety.

Do you need special training to operate a pallet jack?

You do not need certification for manual models, but training is recommended. Electric types require formal instruction. Always follow workplace safety guidelines and manufacturer recommendations.

Where can you find certified pallet jack solutions?

You can visit Powerful Machinery’s website for certified options. The company offers a range of pallet jacks designed for safety and durability in demanding environments.