You see steel wire rope manufacturing as a process that transforms raw steel into a high-strength product through careful selection, precision engineering, and strict quality control. Material choice and advanced manufacturing steps play a key role in the durability and safety of wire ropes.

You rely on certified products from Powerful Machinery, trusted in industries such as drilling, offshore platforms, transportation, logging, and entertainment, where reliability and performance matter most.

Key Takeaways

Choose high-quality materials for steel wire ropes. Proper material selection ensures strength and durability in demanding environments.

Understand the importance of wire drawing and surface treatment. These processes enhance tensile strength and protect against corrosion.

Follow strict heat treatment methods to balance strength and flexibility. This step is crucial for ensuring the wire rope can handle heavy loads without breaking.

Select the right core type based on your application needs. Steel cores offer strength, while fiber and synthetic cores provide flexibility and corrosion resistance.

Maintain and inspect wire ropes regularly. Proper care extends the lifespan and ensures safety in all applications.

Steel Wire Rope Manufacturing Process

Material Selection and Wire Composition

You start the steel wire rope manufacturing journey by choosing the right materials. High-quality raw materials form the backbone of every reliable wire rope. Powerful Machinery uses both black metals and non-ferrous metals, each selected for its unique properties.

Black metals typically range from 0.14 to 10.00 mm in diameter, while non-ferrous metals can range from 0.01 to 16.00 mm.

Note: The chemical composition, physical properties, and surface quality of these materials directly impact the final product’s strength and durability.

You inspect every batch for chemical composition to ensure it meets strict requirements.

You check physical properties to guarantee the wire will perform under stress.

You examine surface quality to prevent defects that could weaken the rope.

The chemical makeup of the steel wires, including elements like carbon and zinc, plays a crucial role in performance. For example, corrosion can reduce the breaking force of the wire rope over time.

By selecting the right materials and monitoring their composition, you ensure the finished product stands up to harsh environments and heavy loads.

Wire Drawing and Surface Treatment

Once you select the materials, you move to the wire drawing stage. This process reduces the diameter of the metal rod and increases its tensile strength. You use several wire drawing techniques in wire rope production:

Single-die drawing for smaller diameters.

Multi-die drawing for fine wires, pulling the wire through a series of dies.

Wet drawing with lubricants for a smoother surface.

Dry drawing for specific materials.

Electroplated drawing, which coats the wire with a thin layer of metal before drawing.

Wire drawing is essential for achieving the uniformity and strength needed in steel wire rope manufacturing. You ensure each wire meets performance and safety standards.

Surface treatment follows wire drawing. Corrosion is a leading cause of wire rope failure, especially in marine or outdoor environments. You apply galvanization to provide sacrificial protection, slowing down material loss and extending service life.

Proper lubrication and corrosion inhibitors create barriers against moisture and saltwater, further enhancing durability. Powerful Machinery’s galvanized steel wire rope stands out for its exceptional corrosion resistance, making it ideal for marine and construction applications.

Heat Treatment for Quality and Performance

Heat treatment is the next critical step in the manufacturing process. You apply different heat treatment methods to optimize the wire’s mechanical properties:

Annealing relieves internal stresses and improves ductility.

Quenching increases hardness.

Tempering reduces brittleness after quenching.

Process | Effect on Tensile Strength |

|---|---|

Stress Relief | Lowers the yield strength to relieve shrinkage stress without changing the internal structure. |

Hardening | Increases internal stress, potentially reducing ductility and increasing brittleness. |

Tempering | Balances tensile strength and ductility while relieving internal stress. |

Re-crystallization | Restores ductility and lowers hardness, allowing for further working. |

You balance tensile strength and flexibility through careful heat treatment. This ensures the steel wire rope can handle heavy loads without breaking or becoming too brittle. Powerful Machinery follows international standards such as ISO 2408, ASTM A1023/A1023M-18, and EN 12385 throughout the process.

These standards guarantee that every steel core and galvanized steel wire rope meets the highest safety and quality requirements.

Tip: Always look for products with certifications like ISO 2408, EN 12385, and DIN 3060. These certifications show that the wire rope has passed rigorous testing and is suitable for critical applications.

By following these steps, you create steel wire ropes that deliver unmatched performance and reliability in demanding environments. Powerful Machinery’s expertise and commitment to certified materials ensure you receive products that meet or exceed global standards.

Wire Rope Construction and Core Types

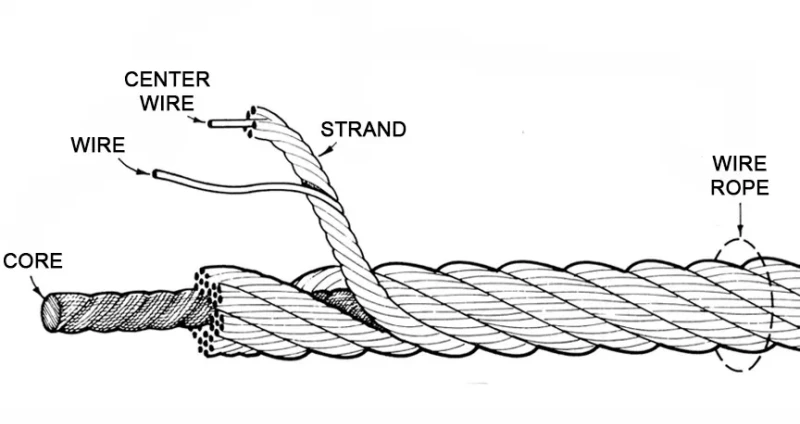

Strand Structures and Lay Methods

You encounter several strand structures during wire rope production. The composition of steel wire ropes often includes configurations like 6×19 and 6×37. The 6×19 construction uses six outer strands with 19 wires each, balancing abrasion resistance and strength.

The 6×37 construction features six strands with about 37 wires each, offering greater flexibility for applications that require smooth operation over sheaves.

You select strand structures based on the demands of your application. Parallel lay strands provide both strength and flexibility, making them popular for lifting and rigging. Spiral ropes, such as Powerful Machinery’s non-rotating designs, maintain load stability during crane operations.

Stranded ropes combine multiple layers around a core, delivering a balance between flexibility and rope durability.

Lay methods also influence performance. Regular lay ropes resist rotation and crushing, making them suitable for heavy-duty production environments. Lang lay ropes offer superior flexibility and abrasion resistance, ideal for applications involving frequent bending.

You choose the lay method that matches your load requirements and operational conditions.

Core Options: Steel, Fiber, Synthetic

The core composition plays a vital role in wire rope durability and load capacity. You can select from steel, fiber, or synthetic cores, each with unique advantages.

Core Type | Advantages | Disadvantages | Load Capacity | Fatigue Resistance |

|---|---|---|---|---|

High flexibility, good fatigue life | Lower crush resistance, not for high-heat | Lower | High | |

Steel Core | High strength, crush resistance, durability | Lower flexibility, poor bending deformation | Higher | Moderate |

Synthetic Core | Lightweight, corrosion-resistant, absorbs shock | Can sag, UV exposure risk, and higher cost | Moderate | High |

Steel cores deliver maximum strength and rope durability, supporting heavy loads in demanding production settings. Fiber cores provide superior flexibility and fatigue resistance, but you avoid them in high-heat environments.

Synthetic cores reduce handling effort and resist corrosion, making them suitable for specialized applications.

Closing and Final Assembly

You ensure rope durability and safety during the closing and final assembly phase. You store wire ropes in dry, ventilated areas to prevent corrosion. You check the rope diameter before installation to match equipment specifications. You follow proper unreeling procedures to avoid damage and keep wraps tight to prevent crushing.

You treat rotation-resistant ropes, like Powerful Machinery’s non-rotating models, with extra care to avoid core slippage. You secure the ends before cutting and use a cable snake with a swivel to prevent torque transfer. Skilled professionals handle installation, ensuring accuracy and adherence to safety standards.

Regular maintenance and inspection help you maintain rope durability and operational safety, especially when handling heavy loads.

Tip: Always follow industry standards for installation and maintenance. This practice extends the lifespan of your wire rope and ensures reliable performance in every application.

Coatings, Finishing, and Quality Assurance

Protective Coatings: Galvanized, PVC, Nylon

You rely on protective coatings to enhance the durability and longevity of steel wire rope. Powerful Machinery applies advanced coatings to meet the demands of harsh environments and extend service life. You select from several options, each offering unique benefits for specific applications.

Coating Type | Benefits |

|---|---|

Galvanization | Protects against rust by coating steel with zinc. |

PVC Coating | Provides abrasion resistance, moisture protection, UV resistance, and prevents wire fray. |

High-Quality PVC | Creates a barrier against corrosive elements, extending service life in harsh environments. |

You choose galvanized coatings when you need reliable rust protection. The zinc layer shields the steel from moisture and corrosive agents, making it ideal for marine, construction, and outdoor use. You select PVC coatings for flexibility and waterproofing.

PVC-coated wire rope resists abrasion, blocks UV rays, and prevents wire fray. This option works well for both indoor and outdoor tasks. Nylon coatings deliver higher abrasion resistance and durability, especially in environments with frequent movement or contact with rough surfaces.

PVC-coated wire rope is flexible and waterproof.

It is UV-resistant and cost-effective compared to nylon.

You use it for a wide range of applications, from lifting to security cables.

You compare coatings to match your needs for corrosion resistance and durability.

Coating Type | Corrosion Resistance | Longevity | Limitations |

|---|---|---|---|

Galvanized | Lower than stainless steel; can flake over time | Moderate | The zinc layer can wear off |

PVC | Excellent against moisture and chemicals; can degrade under UV | Moderate | Not suitable for high-heat applications; may hide internal corrosion |

Nylon | Higher durability and abrasion resistance; better performance in harsh conditions | Long-lasting | Can become brittle in extreme cold; slightly more expensive than PVC |

You select the right coating to maximize durability and ensure consistent performance in your environment.

Final Inspection and Quality Standards

You maintain strict quality control throughout the finishing process. Powerful Machinery follows international standards and uses rigorous inspection procedures to guarantee product reliability. You inspect every wire rope to confirm it meets safety and durability requirements.

You make sure all parts of the sling are visible and accessible.

You clean the sling to remove dirt and grease, improving the visibility of wires and fittings.

You examine the entire length, focusing on areas of wear.

You pay special attention to fittings and end attachments.

You check the worst section against OSHA and ASME criteria.

You keep records of inspections, including dates and conditions.

You dispose of rejected slings immediately.

You look for certifications from respected standards organizations. You check for markings or paperwork that prove compliance with necessary regulations. You engage with suppliers about their quality control processes to ensure every wire rope meets strict standards.

Powerful Machinery’s products carry certifications such as ISO9001, ISO14001, TUV Rheinland, EURO CERT, EAC, Geprüfte Sicherheit, OSHA, ASTM, China Classification Society, and Korean Register. These certifications confirm that you receive wire ropes with proven quality and durability.

Performance in Industrial Applications

You depend on steel wire ropes to deliver reliable performance in demanding industries. Powerful Machinery engineers wire ropes for offshore, mining, construction, and marine environments. You benefit from features that improve durability and operational efficiency.

Feature | Description |

|---|---|

Denser metallic structure | Enhances strength and reliability in demanding environments. |

Higher load-bearing capacity | Allows for smaller ropes with equal strength, beneficial in weight-sensitive applications. |

Smoother outer surface | Reduces wear on sheaves, increasing longevity in harsh conditions. |

Improved resistance to crushing | Ensures durability on drums, critical for operational efficiency. |

Higher Breaking Load | Stronger than conventional ropes, suitable for high-stress applications. |

Extended Service Life | Minimizes fatigue and wear, reducing downtime and maintenance costs. |

Superior Abrasion Resistance | Prevents premature wear, essential for environments like mining and offshore. |

Better Drum Winding Performance | Allows for tighter, more uniform winding, reducing operational issues. |

Versatility Across Applications | Suitable for cranes, elevators, and mining hoists, showcasing adaptability. |

You use wire ropes in mining for draglines and winches, where high load cycles and abrasive conditions demand maximum durability. You rely on wire ropes for offshore and marine operations, including mooring and subsea lifting, where compliance with industry standards is essential.

You choose wire ropes for construction and elevators, where safety margins and durability are critical.

You trust Powerful Machinery’s rigorous testing methods to verify durability and quality. You benefit from:

Magnetic Flux Leakage (MFL) to detect surface and internal defects.

Electromagnetic Testing (ET) to identify material degradation.

Ultrasonic Testing (UT) to find internal flaws.

Visual inspection for surface defects and wear.

Non-destructive testing to locate hidden damage.

Dimensional inspection to confirm size and tolerances.

Mechanical testing for strength and fatigue resistance.

You rely on comprehensive material testing, process controls, and dynamic load testing to ensure long-term durability. You verify environmental performance to confirm resistance to extreme conditions. You trust third-party verification and compliance with industry standards to guarantee quality.

Tip: Always select wire ropes with proven certifications and documented quality assurance. This practice ensures durability and reliable performance in every application.

Conclusion

You have seen how each step in steel wire rope manufacturing—from material selection to final inspection—ensures strength and reliability for critical applications.

Certified products from Powerful Machinery deliver enhanced safety, durability, and efficiency across diverse applications. When choosing wire rope, consider these factors:

Factor | Importance for Applications |

|---|---|

Application Needs | Match rope to specific applications |

Construction | Select for flexibility and strength |

Diameter and Strength | Ensure safe load handling in applications |

Material and Coating | Protect against corrosion in applications |

Environment | Adapt to temperature and chemicals |

Maintenance | Extend lifespan in all applications |

Store and maintain wire ropes properly to maximize performance in demanding applications.

FAQ

What makes steel wire ropes stronger than regular ropes?

You benefit from steel wire ropes because they use high-carbon steel and advanced engineering. The core wire and multiple strands deliver exceptional tensile strength. This design gives you higher strength, better durability, and improved safety compared to traditional ropes.

How do you choose the right core wire for your application?

You select a core wire based on your needs. Steel core wires provide maximum strength and tensile strength for heavy-duty lifting. Fiber cores offer flexibility. Synthetic cores resist corrosion. Always match the core wire to your load and environment for optimal performance.

Why is tensile strength important in wire ropes?

Tensile strength measures how much load steel wire ropes can handle before breaking. You rely on high tensile strength for safety and efficiency. Stronger wire ropes support heavier loads, reduce the risk of failure, and extend service life in demanding applications.

What is the difference between galvanized steel wire rope and stainless steel wire rope?

You use galvanized steel wire rope for corrosion resistance in marine or outdoor settings. The zinc coating protects the steel. Stainless wire ropes resist rust and chemicals, making them ideal for harsh environments. Both options offer high tensile strength and durability.

How do you maintain the strength and safety of steel wire ropes?

You inspect steel wire ropes regularly for wear, corrosion, and broken wires. Lubricate the core wire and strands to reduce friction. Store wire ropes in dry areas. Replace any rope that shows reduced tensile strength or visible damage to maintain safety and strength.