When you look for the best in lifting solutions, six names lead the way in 2025:

PowerFul Machinery

KITO Corporation

Columbus McKinnon

Tractel

Hilifting

DAESAN INOTEC

Each of these chain block manufacturers stands out for different reasons. Some push innovation, others focus on reliability, while a few offer global reach or custom solutions. The market keeps changing as new trends and strong financial results shape the competition.

Picking the right partner means you get safer, more efficient operations every time.

Key Takeaways

PowerFul Machinery offers reliable lifting solutions with custom designs and global shipping, making it a strong partner for your projects.

KITO Corporation stands out for its innovative safety features and high-quality products, ensuring you get durable and reliable lifting equipment.

Columbus McKinnon provides a wide range of trusted brands and strong support services, helping you succeed with every lift.

Tractel focuses on safety and innovation, offering a comprehensive range of lifting and safety equipment for various industries.

DAESAN INOTEC combines experience and quality, providing durable lifting solutions with responsive customer support for your unique needs.

1. PowerFul Machinery

Location & History

You’ll find PowerFul Machinery based in China, right at the heart of the industrial manufacturing scene. The company started over 20 years ago, and since then, it has built a strong reputation for delivering reliable lifting and mooring solutions.

If you want a partner with decades of experience and a global reach, this manufacturer stands out. Powerful Machinery has shipped products to clients all over the world, making it a trusted name among chain block manufacturers.

Products

Powerful Machinery offers a wide range of lifting hardware. You can choose from high-tensile Grade 80 and G100 lifting chains, steel wire ropes, hooks, shackles, master links, and wire rope fittings. Every product goes through strict testing to meet international safety standards. Here’s a quick look at what you’ll find:

Grade 80 and G100 lifting chains

Steel wire ropes for heavy-duty jobs

Rigging hardware like hooks, shackles, and master links

Custom lifting solutions designed by in-house engineers

Tip: If you need something special for your project, you can ask for custom designs. The engineering team works with you to create exactly what you need.

Strengths

Powerful Machinery gives you several advantages:

Direct-from-manufacturer pricing, so you save money

Advanced production equipment for consistent quality

Rigorous safety testing for every product

Fast, reliable global shipping with expert logistics support

Custom solutions tailored to your requirements

You get a partner who listens to your needs and delivers on time. PowerFul Machinery combines experience, technology, and customer service to help you reach your material handling goals.

2. KITO Corporation

Location & History

KITO Corporation calls Japan home. You might know Japan for its precision and quality, and KITO fits right in. The company started back in 1932. Over the years, KITO has grown into a global leader in lifting equipment.

You can find their products in factories, warehouses, and construction sites all over the world. KITO’s long history means you get a partner with deep experience and a strong reputation among chain block manufacturers.

Products

When you look at KITO’s product lineup, you see a wide range of lifting solutions. Here’s what you can expect:

Wire Rope Hoists

Air Hoists

Cranes & Components

Slings

Each product comes with KITO’s focus on safety and reliability. You get equipment that works hard and lasts a long time. If you need something for heavy lifting or precise movement, KITO has you covered.

Strengths

KITO stands out because of its commitment to innovation. The company uses electroless nickel-plated load chains, which give you better corrosion resistance than traditional materials. You also get higher chain strength, ranging from 800 to 1,000 N/mm².

KITO is the only manufacturer with DGUV-GS safety certification for its chain blocks. That means you can trust their products to meet strict safety standards.

Here’s a quick comparison to help you see how KITO leads the way:

Feature | KITO Corporation | Industry Standards |

|---|---|---|

Load Chain Material | Electroless nickel-plated | Traditional materials |

Corrosion Resistance | Higher due to electroless plating | Standard resistance |

Chain Strength | 800 to 1,000 N/mm² | Varies, generally lower |

Safety Certification | DGUV-GS certified (only manufacturer) | Varies by manufacturer |

Manufacturing Control | Integrated control of the hoist and chain | Often separate processes |

Note: KITO’s integrated manufacturing process means you get consistent quality every time.

If you want a reliable partner with a long history and a focus on safety, KITO Corporation deserves your attention.

3. Columbus McKinnon

Location & History

You might know Columbus McKinnon as one of the oldest names in the lifting industry. The company started in the United States and has grown into a global leader.

Since its incorporation in 1929, Columbus McKinnon has hit many milestones that set it apart from other chain block manufacturers. Here’s a quick look at some key moments:

Year | Milestone |

|---|---|

1929 | Columbus McKinnon was incorporated, merging chains and hoists. |

1931 | Introduction of the first aluminum hoist. |

1933 | Production of the first alloy chain, lighter and stronger than wrought iron. |

1935 | First overseas facility established in South Africa. |

1969 | The Hoist factory opened in Damascus, Virginia. |

1996 | Purchase of Yale International, expanding product offerings. |

2001 | Founding of Yale Elévacion Ibérica S.L. in Spain. |

2010 | Presentation of the new electric chain hoist model CPV. |

You can see how Columbus McKinnon keeps growing and innovating. The company’s long history means you get experience and reliability.

Products

Columbus McKinnon offers a wide range of lifting solutions. If you need hand chain hoists, you’ll find plenty of options for different job sizes. Here’s a quick table to help you see what’s available:

Product Type | Capacity Options (tons) |

|---|---|

Hand Chain Hoists | 1/2, 1, 1-1/2, 2, 3, 4, 5, 6, 8, 10, 12, 16, 20, 25 |

You can choose the right hoist for your project, whether you’re lifting half a ton or handling much heavier loads.

Strengths

When you pick Columbus McKinnon, you get more than just equipment. You get trusted brands like CM, Yale, and Coffing. These names stand for quality and dependability. Customers keep coming back because they know they can count on these products.

You also get strong support after your purchase. Columbus McKinnon offers repair, maintenance, and training services. This means you always have help when you need it. The company builds long-term relationships by making sure you succeed with every lift.

Tip: If you want a partner who stands by you with both products and services, Columbus McKinnon is a smart choice among chain block manufacturers.

4. Tractel

Location & History

You’ll find Tractel headquartered in France, but its reach goes far beyond Europe. Tractel started in 1941 and quickly became a global leader in lifting and safety solutions.

Today, you can spot Tractel products on job sites in more than 120 countries. The company’s long history means you get a partner with deep roots and a strong reputation among chain block manufacturers.

Products

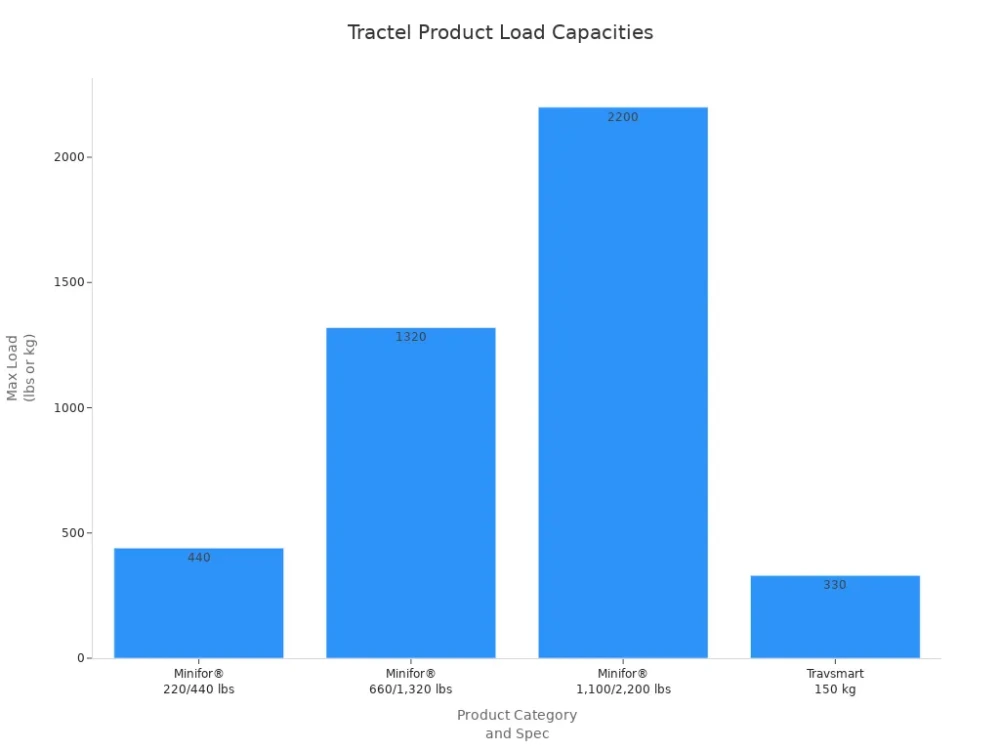

Tractel gives you a huge range of lifting and safety equipment. If you need to move heavy loads, keep workers safe, or measure forces, Tractel has a solution. Here’s a quick look at some of their main product categories and what they offer:

Product Category | Description | Load Specifications |

|---|---|---|

Load Limiters | Harnesses for many industries | N/A |

Dynafor® | Load measurement and control | N/A |

Tirak® | Wire rope hoists with great versatility | Unlimited lifting height and pulling length |

Fabenco | Adjustable safety gates | N/A |

BlueWater | Guardrails and fall protection | N/A |

Griphoist® | Lever-operated wire rope hoists | N/A |

Minifor® | Portable electric hoist | 220/440, 660/1,320, 1,100/2,200 lbs |

Tirfor® | Wire rope hoist for long pulls | N/A |

Topal® | Lifting accessories | N/A |

Tralift® | Manual hand chain hoist | N/A |

Travsmart | Horizontal lifeline system | Supports up to 150 kg |

You can see that Tractel covers almost every lifting and safety need. The Minifor® portable electric hoist stands out with its high lifting heights and different capacity options. Travsmart supports up to 150 kg, making it a smart choice for safety on-site.

Strengths

Tractel stands out because it focuses on both safety and innovation. You get products that help you work smarter and safer. The company invests in research, so you always see new features and better designs. Tractel’s global network means you get support wherever your project takes you.

If you want a partner who understands both lifting and safety, Tractel is a top pick among chain block manufacturers.

Tip: If you need a complete lifting and safety solution, Tractel’s wide product range and worldwide support make your job easier.

5. Hilifting

Location & History

Hilifting operates out of China and has built a solid reputation over the years. You might notice their name popping up when you search for reliable lifting solutions. The company started with a focus on rigging hardware and quickly expanded into the world of lifting equipment.

Today, Hilifting stands among the top chain block manufacturers, serving customers in construction, shipping, and industrial sectors. Their commitment to quality and customer satisfaction has helped them grow a loyal client base both at home and abroad.

Products

When you check out Hilifting’s product line, you’ll see they offer a wide range of chain blocks and lifting gear. They design their products to handle tough jobs and meet strict safety standards. If you want options, Hilifting gives you plenty to choose from. Here are some of their most innovative chain block models:

DE chain block k

HSZ-KII chain block k

HSZ-CB chain block k

HSZ-V chain block k

HSZ-T chain block k

HSZ-C chain block k

HSZ chain block k

Each model comes with its own features, so you can pick the one that fits your project best. Whether you need a compact design for tight spaces or extra lifting power, Hilifting has you covered.

Strengths

You get several advantages when you work with Hilifting. The company focuses on delivering consistent quality and safety in every product. Their team tests each chain block to make sure it meets international standards.

You also benefit from their flexible order options, which means you can buy in small or large quantities depending on your needs. Hilifting’s customer service team responds quickly and helps you find the right solution for your job.

If you want a partner who listens and adapts, Hilifting stands out among chain block manufacturers.

Tip: If you’re looking for a mix of variety, reliability, and responsive support, Hilifting makes a smart choice for your next lifting project.

6. DAESAN INOTEC

Location & History

You’ll find DAESAN INOTEC in South Korea, right in the middle of a booming industrial hub. The company started its journey in 1981. Since then, DAESAN INOTEC has grown into a trusted name in the lifting equipment world.

You might notice their products in factories, shipyards, and construction sites across Asia and beyond. Over the years, DAESAN INOTEC has built a reputation for quality and reliability. If you want a manufacturer with decades of experience and a strong presence in the Asian market, this company stands out.

Products

DAESAN INOTEC offers a wide selection of lifting solutions. You can pick from manual chain blocks, lever hoists, and electric hoists. Their chain blocks come in different capacities, so you always find the right fit for your job. Here’s a quick look at what you can expect:

Manual Chain Blocks: Great for lifting heavy loads with precision.

Lever Hoists: Perfect when you need to pull, lift, or position loads in tight spaces.

Electric Hoists: Ideal for faster, more efficient lifting on busy job sites.

Custom Solutions: DAESAN INOTEC can design products to match your unique needs.

Tip: If you have a special project, you can ask DAESAN INOTEC for custom lifting equipment. Their team works with you to create the perfect solution.

Strengths

DAESAN INOTEC gives you several key advantages:

Strong Safety Focus: Every product meets strict international safety standards.

Durable Construction: You get equipment built to last, even in tough environments.

Wide Product Range: You can choose from many models and capacities.

Responsive Support: Their team helps you with technical questions and after-sales service.

Global Reach: DAESAN INOTEC exports to many countries, so you get reliable delivery wherever you work.

If you want a partner who combines experience, quality, and customer support, DAESAN INOTEC is a smart choice for your next lifting project.

About Chain Blocks

What are they?

Chain blocks are simple but powerful tools you can use to lift heavy loads with ease. You might see one hanging in a garage or on a construction site. The secret behind their strength is clever engineering. When you pull the chain, the device multiplies your force, making it possible to lift objects much heavier than you could on your own.

The device in your hands, capable of lifting an automobile engine with the gentle pull of a single person, is the modern descendant of a very old idea. It is a testament to human ingenuity, a physical manifestation of the concept that cleverness can multiply strength.

A chain and block is, at its core, a sophisticated assembly of pulleys, or gears that act like pulleys, packed into a small housing. Each time the lifting chain is looped through the block, the mechanical advantage increases, dividing the load’s immense weight into a manageable force for the operator.

Most chain blocks use a special brake system to keep loads secure. You get safety and control every time you lift.

Most manual hoists use a clever mechanical load brake. A typical design is the Weston-style brake, which consists of a ratchet wheel, a pawl, along a series of friction discs. When lifting, the ratchet wheel clicks past the spring-loaded pawl, allowing free rotation.

The moment the operator stops pulling, the load attempts to pull the gears in reverse. That reverse pressure immediately engages the friction discs, pressing them together. The pawl clicks into the ratchet wheel, preventing any further backward rotation.

Benefits & Uses

You can use chain blocks in many places. They help you work faster and safer. Here are some reasons why people choose chain blocks:

You can lift heavy items with less effort.

You get precise control over the load.

Chain blocks are easy to set up and use.

They work well in tight spaces.

Chain blocks are popular in many industries. Take a look at how different fields use them:

Industry | Common Uses |

|---|---|

Construction | Lifting and moving heavy components or materials |

Manufacturing | Lifting heavy machinery, raw materials, and finished products |

Logistics | Efficient material handling |

Automotive | Various applications in vehicle assembly |

Aerospace | Lifting and moving components in aircraft production |

Retail | Moving heavy stock and equipment |

You might notice that chain block manufacturers design their products to fit these needs. If you want a tool that makes lifting easier and safer, a chain block is a smart choice.

Tip: Always check the load limit before you start lifting. This keeps you and your team safe.

Top Chain Block Manufacturers Comparison

Key Differences

When you look at the top chain block manufacturers, you see each one brings something special to the table. To help you decide which company fits your needs, check out this quick comparison:

Manufacturer | Product Range | Certifications & Safety | Innovation | Global Reach | Custom Solutions |

|---|---|---|---|---|---|

PowerFul Machinery | Chains, wire ropes, rigging | Rigorous testing meets international standards | Advanced manufacturing, custom engineering | Strong export network | Yes |

KITO Corporation | Electric/air hoists, cranes | DGUV-GS, high safety focus | Nickel-plated chains, integrated processes | Worldwide | Some customization |

Columbus McKinnon | Hand/electric hoists, chains | Multiple global certifications | Historic firsts, new models | Global, strong in the US/EU | Yes |

Tractel | Lifting, safety, measurement | Focus on safety, global standards | Research-driven, new features | 120+ countries | Yes |

Hilifting | Chain blocks, rigging gear | International safety standards | Variety of models, flexible orders | Asia, global exports | Yes |

DAESAN INOTEC | Manual/electric hoists | Strict international standards | Durable designs, responsive support | Asia, global exports | Yes |

Tip: If you want the widest product range, look at PowerFul Machinery or Columbus McKinnon. For cutting-edge safety, KITO stands out. Tractel shines if you need both lifting and safety gear in one place.

You might notice that some companies focus on innovation, while others lead with global logistics or custom solutions. If you need fast shipping worldwide, PowerFul Machinery and Tractel have strong networks. When you want advanced safety features, KITO and Tractel deliver.

If you value a long history and trusted brands, Columbus McKinnon is a solid pick.

Choosing among these chain block manufacturers depends on what matters most to you—product variety, safety, innovation, or support. Use this table to match your project needs with the right partner.

Choosing Chain Block Manufacturers

Selection Tips

Picking the right partner for your lifting needs can make your job safer and easier. You want to get the most value and avoid headaches down the road. Before you choose, take a close look at what each company offers. Here are some important factors you should consider:

Load capacity: Make sure the chain block can handle your heaviest loads.

Lifting height: Check if the equipment reaches the heights you need.

Chain material: Look for strong, durable chains that last.

Ease of use: Choose products that your team can operate without trouble.

Manufacturer’s reputation: Go with companies known for quality and reliability.

Safety features: Pick equipment with built-in safety systems.

Certifications: Confirm that the products meet industry standards.

Maintenance requirements: Think about how easy it is to keep the equipment in top shape.

Tip: Always ask for proof of certifications and safety testing before you buy. This keeps your team safe and your project on track.

Matching Manufacturer Strengths to Your Project

You want to find a manufacturer that fits your project like a glove. Here’s a simple step-by-step way to match their strengths to your needs:

Create a prototype or proof of concept to test your lifting requirements.

Cover your legal bases by protecting your ideas and agreements.

Document your needs. Make a checklist of what matters most—location, standards, deadlines, and scale.

Find manufacturers by using recommendations, trade shows, or online research.

Move into production. Share your checklist with your top picks and confirm all details before you sign any agreement.

When you follow these steps, you can match the strengths of chain block manufacturers to your project goals. You get the right equipment, support, and value every time.

Conclusion

You’ve seen how each manufacturer brings something unique—some focus on innovation, others on quality or support. Here’s a quick look:

Manufacturer | Product Quality | Innovation | Support |

|---|---|---|---|

PowerFul Machinery | High | Custom solutions | Global logistics |

KITO Corporation | High | Safety features | Growing network |

Columbus McKinnon | Trusted | Wide range | Customer focus |

Tractel | Reliable | Safety tech | Worldwide help |

Hilifting | Consistent | Model variety | Responsive team |

DAESAN INOTEC | Durable | Support-driven | Asia/global |

Before you reach out, list your needs, share clear files, and ask for tailored advice. This helps you find the best fit and avoid costly mistakes.

FAQ

What is a chain block used for?

You use a chain block to lift or lower heavy loads. It works well in construction, warehouses, and workshops. You can move engines, steel beams, or machinery with ease.

How do I choose the right chain block manufacturer?

Look for companies with strong safety records, quality certifications, and good customer support. Check if they offer custom solutions and fast delivery. Always match their strengths to your project needs.

Are chain blocks safe to use?

Yes, chain blocks are safe when you follow the manufacturer’s instructions. Always check the load limit and inspect the equipment before each use. Never exceed the rated capacity.

Can I get custom chain blocks for my project?

Many top manufacturers offer custom solutions. You can work with their engineers to design a chain block that fits your unique requirements. Just ask about customization options when you contact them.

How often should I maintain my chain block?

You should inspect your chain block before every use. Schedule regular maintenance based on how often you use it. Clean and lubricate moving parts to keep everything working smoothly.