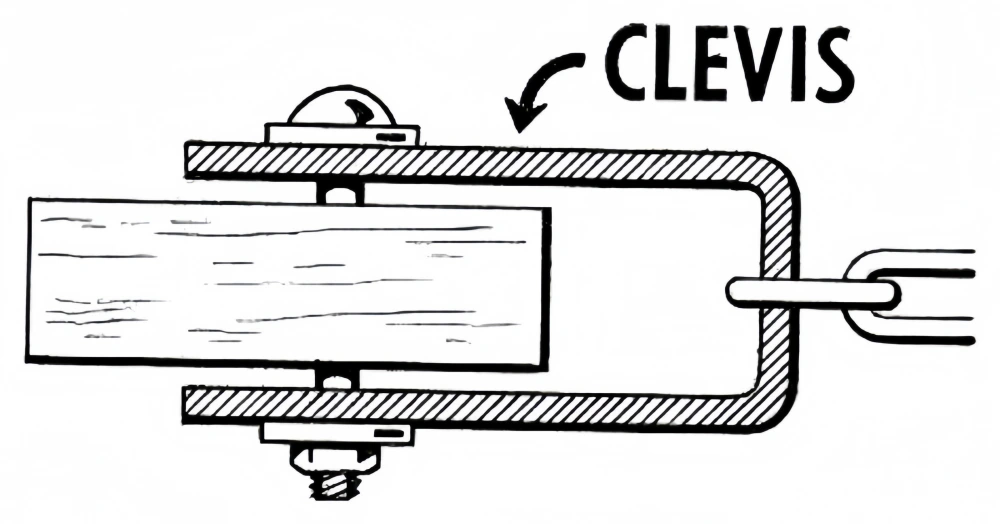

You often see a clevis as a U-shaped or forked mechanical component that connects two parts. This fastener uses a clevis pin and a secure retaining device to lock everything in place. Clevis fasteners give you the strength and adjustability needed for load control in many industries.

When you use clevis fasteners, you make sure machines, equipment, and structures stay safe and reliable. Industries such as automotive, construction, aerospace, and agriculture depend on clevis fasteners every day.

Industry | Global Market Size (USD) | Growth Rate (CAGR) | Year |

|---|---|---|---|

Automotive | N/A | N/A | N/A |

Industrial Machinery | N/A | N/A | N/A |

Aerospace | N/A | N/A | N/A |

Construction | N/A | N/A | N/A |

Agricultural Equipment | N/A | N/A | N/A |

Global Market Total | 634.1 million | 4.8% | 2033 |

Powerful Machinery stands as a trusted source for high-performance clevis and fasteners, delivering reliable solutions to meet demanding standards.

Key Takeaways

Clevis fasteners are essential for connecting parts securely in various industries, including automotive, construction, and aerospace.

Understanding the structure of a clevis, including its body, pin, and retaining mechanism, helps you choose the right fastener for your needs.

Selecting the appropriate material for clevis fasteners, such as stainless steel or alloy steel, ensures durability and resistance to harsh conditions.

Regular inspection and maintenance of clevis fasteners are crucial for safety and longevity, helping to prevent unexpected failures.

Powerful Machinery offers a wide range of high-quality clevis fasteners, including custom solutions, to meet the specific demands of different applications.

Clevis Fasteners Structure

Understanding the structure of a clevis helps you choose the right fastener for your needs. Each part of a clevis works together to create a secure and adjustable connection. Let’s break down the main components.

Clevis Body

The clevis body forms the foundation of the fastener. You see a U-shaped or forked design that cradles the connected part. This shape gives the clevis its strength and flexibility. Manufacturers use corrosion-resistant materials like hot-dip galvanized steel or malleable iron to make sure the clevis lasts in harsh environments.

The clevis body often includes pre-drilled mounting holes for easy installation. You can check the table below to see how each feature adds to the mechanical strength of the clevis.

Feature | Contribution to Mechanical Strength |

|---|---|

High mechanical strength | Withstands tensile and mechanical stress, preventing sagging or shifting of connected parts. |

Corrosion-resistant | Ensures long service life in tough conditions. |

U-shaped design | Provides solid support and flexibility. |

Pre-drilled holes | Allows quick connection with clevis pin and hardware. |

Versatile application | Fits many systems, making the clevis useful for new builds and repairs. |

Clevis Pin

The clevis pin acts as the main connector in the clevis assembly. You insert the clevis pin through the holes in the clevis body and the part you want to secure. The clevis pin must fit snugly to prevent movement. You often find clevis pins in different diameters and lengths to match various clevis sizes.

The clevis pin handles shear forces and keeps the assembly stable. You should always check the clevis pin for wear or damage before use.

Retaining Mechanism

The retaining mechanism keeps the clevis pin from slipping out during use. You have several options for retaining mechanisms, each with its own benefits. The table below shows common types and their effectiveness.

Retaining Mechanism | Description | Vibration Resistance | Ease of Use |

|---|---|---|---|

Cotter Pins | Inserted through the clevis pin’s end hole for high shear resistance. | High | Moderate |

R-clips | Quick to install, resistant to detachment. | Moderate | High |

Threaded Pin Locking | Uses nuts or tapped ends for secure clamping. | High | Moderate |

Ball-lock Pins | Spring-loaded balls for fast, positive locking. | High | High |

Quick-release | Easy insertion/removal, ideal for frequent use. | Moderate | Very High |

Tang and Mating Parts

The tang is the part that fits between the arms of the clevis. You insert the clevis pin through both the clevis and the tang to create a strong joint. The tang and clevis must match in size for a secure fit. You often see this setup in machinery, rigging, and lifting systems.

The clevis, clevis pin, and tang work together to handle heavy loads and allow for quick adjustments.

Tip: Always match the clevis pin size to the clevis and tang for maximum safety and performance.

Types of Clevis Fasteners

When you look at the world of clevis fasteners, you find a wide range of options. Each type serves a specific purpose and offers unique benefits. Understanding the different types of clevis fasteners helps you choose the right fastener for your project, whether you work in construction, transportation, or heavy industry.

Standard Clevis Pin

A standard clevis pin is the most common type you will see. This pin has a straight, cylindrical shape with a hole at one end. You insert the pin through the clevis and the tang, then secure it with a cotter pin or clip. Standard clevis pins work well in applications where you need a simple, reliable connection.

You often use them in agricultural equipment, machinery, and even playground structures. The straightforward design makes installation and removal easy.

Shouldered and Cotterless Pins

Shouldered clevis pins have a built-in shoulder that acts as a stop. This feature keeps the pin from sliding too far into the clevis. You should use shoulder pins when you want to control the movement of the fastener and prevent over-insertion. Cotterless pins, on the other hand, do not require a cotter pin or clip.

They use a spring-loaded ball or other mechanism to stay in place. Cotterless pins save you time during assembly and are ideal for situations where you need to remove and replace the pin frequently.

Threaded Clevis Bolt

A threaded clevis bolt combines the features of a bolt and a clevis pin. You see threads on one end, which allow you to secure the bolt with a nut. This design gives you a stronger, more permanent connection. Threaded clevis bolts are common in structural applications, such as bridges and heavy machinery.

You use them when you need extra holding power and vibration resistance. The threads keep the fastener tight, even under heavy loads.

Clevis Yoke and Rod Ends

A clevis yoke is a U-shaped fitting that attaches to rods, cables, or other hardware. You use a clevis yoke when you need to connect moving parts and allow for pivoting or rotation. Rod ends often pair with clevis yokes to create adjustable linkages.

You find these assemblies in steering systems, control linkages, and industrial machinery. The clevis yoke gives you flexibility and strength, making it a key part of many mechanical systems.

Note: You should always match the size of the clevis yoke and rod end to the load requirements of your application.

Bracket, Hanger, Hitch, Hook

You encounter several specialized clevis fasteners designed for specific tasks:

Clevis Bracket: This fastener provides a mounting point for rods or pins. You use clevis brackets in machinery frames and support structures.

Clevis Hanger: You see clevis hangers in piping systems. They support pipes and allow for movement due to expansion or vibration. Clevis hangers are essential in HVAC, plumbing, and fire protection systems.

Clevis Hitch: This type connects trailers or equipment to vehicles. You rely on clevis hitches for towing and agricultural work.

Clevis Hook: Clevis hooks, such as the Clevis Grab Hook and Clevis Slip Hooks from Powerful Machinery, offer secure load control in lifting and rigging. You use these hooks to attach chains or cables to loads.

Here is a comparison of Powerful Machinery’s Clevis Grab Hook and Clevis Slip Hook:

Feature | Clevis Grab Hook | Clevis Slip Hook |

|---|---|---|

Material | Forged, heat-treated steel | High-strength alloy steel |

Durability | Exceptional strength and durability | Stands up to heavy loads |

Corrosion Resistance | Zinc finish for protection | Corrosion-resistant coating |

Safety Features | Secure connection with bolt and cotter pin | Safety latch to prevent accidental disengagement |

Applications | Ideal for precise load control | Suitable for dynamic lifting applications |

You can trust these hooks for demanding jobs. The Clevis Grab Hook gives you firm control for load binding, while the Clevis Slip Hook offers a wide throat and safety latch for secure lifting.

Specialized and Custom Types

Some industries require specialized or custom clevis fasteners. In the automotive field, you find clevises in brake systems and suspension components. Agricultural machinery and sailboat rigging also use unique clevis designs. You can order custom clevis pins made to your specifications.

These custom fasteners come in inch or metric sizes, and you can request small batches or large production runs. Military and aerospace projects often need clevis fasteners built to strict standards.

Custom clevis pins can match your print or supplied drawings.

You can choose from different standards, including military and specialized options.

Small or large orders are available to fit your needs.

Threaded vs Unthreaded Clevis Pin

You need to decide between threaded and unthreaded clevis pins based on your application. Threaded clevis pins have threads at one end, allowing you to secure them with a nut. This design gives you a more permanent and vibration-resistant connection.

You use threaded pins in heavy-duty or high-vibration environments. Unthreaded clevis pins, on the other hand, rely on a cotter pin or clip for retention. They are easier to install and remove, making them ideal for applications where you need to disassemble the joint often.

Tip: Always select the right type of clevis pin for your project. Consider the load, frequency of removal, and safety requirements.

You now see that the different types of clevis fasteners each offer unique advantages. Whether you need a clevis yoke for a control linkage, a clevis hanger for pipe support, or a custom fastener for a specialized project, you have many options.

Powerful Machinery provides high-quality clevis fasteners, including Clevis Grab Hook and Clevis Slip Hooks, to meet the demands of any industry.

Clevis Fasteners Materials & Manufacturing

Common Materials

You find that the choice of material for a clevis affects its strength, durability, and resistance to harsh conditions. Manufacturers often use alloy steel, stainless steel, and titanium alloys for clevis fasteners. Alloy steel gives you high tensile strength and toughness, making it ideal for heavy-duty applications.

Stainless steel resists corrosion, so you can use it in marine or outdoor environments. Titanium alloys offer a lightweight option with excellent fatigue resistance. When you select a clevis hook for lifting or rigging, you benefit from these materials because they help prevent rust and wear.

Material Selection

Selecting the right material for your clevis fastener depends on several factors. You need to consider the environment, load requirements, and cost. The table below helps you compare important factors when choosing materials for clevis fasteners in corrosive or high-stress environments:

Factor | Description |

|---|---|

Strength requirements | Yield, ultimate, and fatigue strength matter for safety |

Environmental conditions | Corrosion resistance and temperature extremes affect performance |

Weight constraints | Lighter clevis fasteners improve handling and efficiency |

Cost and availability | Economic feasibility ensures project success |

Recommended materials | Alloy steels, stainless steel, and titanium alloys |

If you work in construction or the marine industries, you often choose stainless steel clevis hooks for their corrosion resistance. In high-stress environments, alloy steel clevis fasteners give you the strength you need.

Manufacturing Process

You see that the manufacturing process for clevis fasteners has evolved with technology. Advanced machining and automation improve the precision and reliability of each clevis. Manufacturers use forging, CNC machining, and heat treatment to create clevis hooks and other fasteners that meet strict standards.

Automation ensures consistent quality, especially for industries like aerospace and defense. Customization allows you to order clevis fasteners that fit your exact needs, whether you require a specific size or a unique design.

Advanced manufacturing increases precision and reliability.

Automation helps meet high-performance standards.

Customization lets you get clevis fasteners for niche applications.

Hardening and Surface Treatment

You want your clevis fastener to last as long as possible. Hardening and surface treatments play a key role in extending the lifespan of clevis hooks and other fasteners. Anodizing adds a protective layer that resists corrosion and gives a clean appearance.

Nitriding increases surface hardness, which helps your clevis handle heavy loads without wearing down. These treatments make clevis fasteners more durable and reliable, especially in demanding environments.

Anodizing improves corrosion resistance and appearance.

Nitriding boosts surface hardness for better wear resistance.

These processes extend the service life of clevis fasteners.

Tip: Always check for proper hardening and surface treatment when you select a clevis hook for critical applications.

Installation, Inspection & Maintenance

Installation Best Practices

You want your clevis fasteners to perform safely and reliably. Follow these installation best practices to get the best results:

Assess the maximum load your application will handle. Always consider the weight and mechanical stress on the clevis.

Check that the size and diameter of the connected parts match the clevis eye. This ensures a secure fit.

Evaluate the environment. Moisture and temperature can affect the material you choose for your clevis.

Confirm that your clevis is compatible with other hardware in your system.

Follow all industry standards and specifications for safety.

Choose a manufacturer known for accurate specifications and clear installation guidance.

Tip: Careful planning during installation helps prevent future problems and extends the life of your clevis fasteners.

Inspection Procedures

Regular inspection and maintenance keep your clevis fasteners in top condition. Use advanced methods to spot wear or damage before failure occurs. The table below shows some effective inspection techniques:

Inspection Method | Description | Effectiveness |

|---|---|---|

Advanced Image Processing | Uses high-resolution cameras and image analysis to detect defects. | High accuracy and efficiency |

Convolutional Neural Networks | Applies deep learning for automatic inspection. | Great improvement in defect recognition |

Edge Detection | Finds cracks and wear by identifying edges in images. | Useful for spotting cracks and surface damage |

Local Invariant Features | Extracts stable features under different conditions. | Enhances detection in varied environments |

SIFT with RANSAC | Locates specific clevis components precisely. | Effective for pinpointing locations |

2D Gabor Wavelet Transform | Uses wavelet analysis to detect small cracks. | Increases sensitivity for minor defects |

Maintenance Tips

You should clean your clevis fasteners regularly to remove dirt and debris. Lubricate moving parts to reduce friction and prevent rust. Replace any clevis that shows signs of wear, cracks, or deformation. Store unused fasteners in a dry, cool place to avoid corrosion.

Always use the correct tools when working with clevis fasteners.

Note: Consistent inspection and maintenance help you avoid unexpected failures and keep your equipment safe.

Professional Evaluation

Sometimes, you need a professional to check your clevis fasteners. Experts use advanced tools and methods to assess the condition of each fastener. They can spot hidden problems that you might miss.

Schedule regular evaluations, especially for critical applications or when you notice unusual wear. Professional advice ensures your clevis fasteners meet all safety standards and perform as expected.

Clevis Fasteners Applications & Selection

Industry Uses

You see clevis fasteners in almost every major industry. These fasteners help you connect, secure, and adjust parts quickly and safely. You find them in farm equipment, vehicles, ships, airplanes, and heavy machinery. The table below shows how different industries use clevis fasteners in real-world applications:

Industry | Applications |

|---|---|

Agriculture | Used in farm equipment like plows and harvesters for quick assembly and secure operation. |

Automotive and Transport | Employed in suspension systems, steering linkages, and trailer couplings to ensure safety and durability. |

Marine and Offshore | Utilized in boat rigging and offshore drilling equipment, providing corrosion resistance in harsh environments. |

Aerospace and Defense | Found in aircraft control systems and landing gear, meeting strict safety and durability standards. |

You rely on clevis fasteners because they make assembly and maintenance easier. In agriculture, you use them to attach plow blades or connect hydraulic cylinders. In transportation, you trust clevis fasteners to keep trailers and vehicles safe on the road.

Marine workers depend on clevis fasteners for rigging and mooring, where corrosion resistance is critical. Aerospace engineers use clevis fasteners in control systems, where safety and precision matter most.

Selection Criteria

Choosing the right clevis fastener for your application means looking at several important factors. You need to match the fastener to the load, environment, and frequency of use. Here are some key points to consider:

Load Capacity: Always check the working load limit. Make sure the clevis can handle the weight and stress of your application.

Material: Select stainless steel or galvanized steel for outdoor or marine environments. Use alloy steel for high-strength needs.

Size and Fit: The clevis pin and body must fit your equipment exactly. A loose or tight fit can cause problems.

Corrosion Resistance: If you work in wet or salty conditions, choose a clevis fastener with a protective coating.

Ease of Installation: Some applications require frequent assembly and disassembly. In these cases, use a clevis fastener with a quick-release or cotterless design.

Compliance and Certification: Make sure your clevis fasteners meet industry standards for safety and quality.

Tip: Always review your project requirements before selecting a clevis fastener. The right choice improves safety and extends the life of your equipment.

Powerful Machinery Solutions

Powerful Machinery gives you a full range of clevis fasteners designed for tough jobs. You get products that meet strict international standards and deliver reliable performance in demanding environments. The company understands that each industry faces unique challenges.

The table below shows how Powerful Machinery addresses these needs:

Challenge/Opportunity | Description |

|---|---|

Customization Demand | Increasing market demand for customized products to meet diverse industry needs. |

Technological Innovation | Advancements in AI, IoT, and automation are enhancing production efficiency and product quality. |

Growth in High-Performance Fasteners Demand | Rising demand in the automotive, aerospace, and construction sectors for high-performance fasteners. |

You can choose from a wide selection of clevis fasteners, including the Clevis Grab Hook and Clevis Slip Hooks. The Clevis Grab Hook gives you a secure grip for load binding and chain shortening. This hook works well in construction, mining, and cargo handling.

The Clevis Slip Hook features a safety latch and a wide throat, making it ideal for lifting and rigging in marine and industrial settings. Both hooks use high-strength steel and corrosion-resistant finishes, so you can trust them in harsh environments.

Powerful Machinery also offers custom solutions. If you need a special size or finish, you can work with their team to design a clevis fastener that fits your exact needs. Their products go through strict testing and certification, so you know you are getting safe and reliable fasteners for your application.

Upkeep and Longevity

You want your clevis fasteners to last as long as possible. The average lifespan of a clevis fastener depends on the material and the environment. The table below shows how long different types of fasteners can last under typical conditions:

Fastener Type | Average Lifespan |

|---|---|

Bright Fasteners | 25 – 60 Years |

Copper Fasteners | 65 – 80+ Years |

Galvanized Fasteners | 10+ Years |

Electro-galvanized Fasteners | 15 – 45 Years |

Hot-dipped Galvanized Fasteners | 35 – 60 Years |

Stainless Fasteners | 65 – 100+ Years |

To get the most out of your clevis fasteners, you should inspect them regularly. Clean and lubricate moving parts to prevent rust and wear. Replace any fastener that shows signs of damage or fatigue. Store unused clevis fasteners in a dry place. When you follow these steps, you help your equipment run safely and reduce the risk of failure.

Note: Regular upkeep and choosing the right clevis fastener for your environment will help you achieve the longest possible service life.

Conclusion

You rely on clevis fasteners to keep your equipment safe and efficient in many industries. When you choose the right clevis and maintain it well, you protect your team and your investment. Trusted brands like Powerful Machinery help you achieve top performance.

Reputable manufacturers use high-quality materials and accurate load ratings.

Reliable clevis fasteners reduce risks and improve productivity.

Choosing a trusted brand ensures your clevis meets strict safety standards.

Regular inspection and maintenance keep your clevis working longer. For custom solutions or expert advice, you can always consult Powerful Machinery.

FAQ

What are the most common questions about clevis fasteners?

You often want to know how to choose the right size, what materials work best, and how to install them safely. Many people also ask about the difference between a shackle and a clevis. These common questions about clevis fasteners help you make better decisions.

How do I know the difference between a shackle and a clevis?

You can spot the difference between a shackle and a clevis by their shape and use. A shackle usually has a rounded body and a removable pin. A clevis has a U-shaped body and uses a clevis pin for secure connections.

Why do industries use clevis fasteners so often?

You see clevis fasteners in many industries because they offer strong, adjustable connections. They make assembly and repairs quick. You can use them in construction, agriculture, marine, and transportation. These fasteners help you save time and improve safety.

Can I use the same clevis fastener for lifting and towing?

You should always check the load rating before using a clevis fastener for lifting or towing. Not every clevis is made for both jobs. Using the wrong type can cause accidents. Always follow the manufacturer’s guidelines for safe use.

Where can I find answers to more common questions about clevis fasteners?

You can visit trusted manufacturers like Powerful Machinery for expert advice. Their websites and support teams answer many common questions about clevis fasteners, including the difference between a shackle and a clevis, installation tips, and product selection.