When you use a block and tackle, you lift heavy objects with less effort by combining pulleys and rope. This system lets you trade force for distance. For example, with two pulleys, you only need half the force to lift the same load as you would with just one. The more pulleys you add, the easier lifting becomes.

Number of Pulleys | Force Required (pounds) | Percentage Reduction |

|---|---|---|

1 | 100 | 0% |

2 | 50 | 50% |

4 | 25 | 75% |

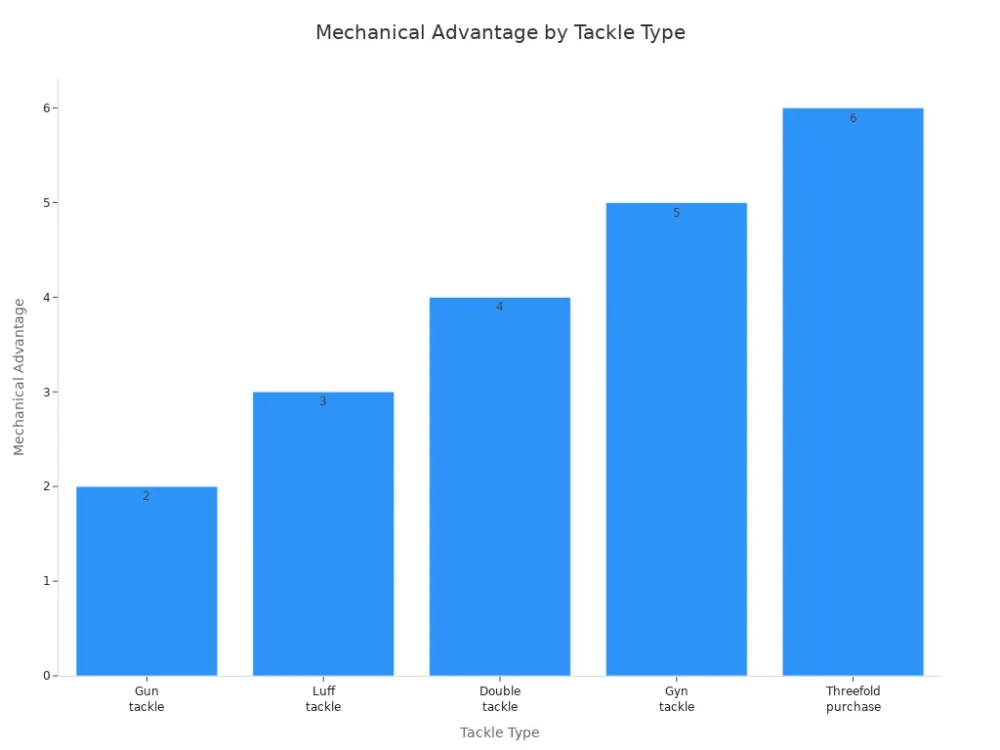

You might wonder how a block and tackle works compared to other lifting methods. The chart below shows that different setups give you more mechanical advantage, making lifting even large loads possible with your own strength.

Key Takeaways

A block and tackle system uses pulleys and rope to lift heavy loads with less effort, allowing you to trade force for distance.

Adding more pulleys reduces the force needed to lift a load, making it easier to handle heavy objects safely and efficiently.

Always inspect your block and tackle equipment before use. Check for wear, corrosion, and secure anchorage points to ensure safety.

Choose the right rope material based on your lifting needs. High-strength synthetic fibers resist wear, while steel cores handle heavy loads but require maintenance.

Block and tackle systems are versatile and used in various industries, including construction and marine, providing enhanced efficiency and safety.

What Is a Block and Tackle?

A block and tackle is a simple yet powerful lifting system. You use it to move heavy loads with less effort. This system combines two main parts: pulleys and rope. When you set up a block and tackle, you create a mechanical advantage that lets you lift more than you could with just your own strength.

Key Components

You need a few essential parts to build a block and tackle:

Block: This is the frame that holds one or more pulley wheels. You attach the block to a fixed point, like a beam or a hook.

Tackle: This is the rope or cable that runs through the pulleys. The type and thickness of the rope depend on the weight you want to lift.

Tip: Always choose a rope that matches the load and environment. High-strength synthetic fibers resist wear, while steel cores handle heavy loads but need regular care to prevent rust.

Here is a quick look at how different rope materials affect performance:

Rope Material | Performance Impact | Durability Impact |

|---|---|---|

High-strength synthetic fibers | Provides necessary tensile strength | High resistance to wear and tear |

Steel cores | Excellent load handling capabilities | Can be prone to corrosion if not maintained |

Rope diameter | Affects load distribution and flexibility | Thicker ropes generally offer more durability |

Construction | Impacts flexibility and handling | Different constructions can enhance longevity |

Basic Setup

To set up a block and tackle, you start by attaching the block to a secure anchor point. Next, you thread the rope through the pulleys in a specific pattern. The more pulleys you use, the easier it becomes to lift the load.

You pull on one end of the rope, and the pulleys multiply your force. This setup allows you to lift heavy objects safely and efficiently.

You will find block and tackle systems in many places. Workers use them in construction to move building materials. Shipbuilders rely on them to hoist sails and cargo.

Even in mining, these systems help lift minerals from deep underground. The block and tackle remains a trusted tool for anyone who needs to move something heavy with less effort.

How a Block and Tackle Works?

Force and Distance

When you want to understand how a block and tackle works, you need to look at the relationship between force and distance. The system uses pulleys to multiply your lifting power.

You pull on the rope, and the pulleys share the load. This means you can lift heavy objects with less force. The trade-off is that you must pull more rope to raise the load the same height.

The block and tackle system lets you use a smaller force to lift a heavier load by adding more pulleys.

You must pull extra rope to achieve the same lifting height, which shows the balance between force and distance.

When you use two pulleys, the weight splits equally. You need less force, but you pull twice as much rope.

If you add more pulleys, you increase the mechanical advantage. For example, a simple 3:1 setup means you can lift a 300-pound load with only 100 pounds of force. You trade distance for force, making lifting heavy loads possible with your own strength.

The more pulleys you use, the easier the task becomes, but you must manage more rope.

Tip: Always check the rope and pulleys before each use. Look for signs of wear or damage. Secure the anchorage points to strong, immovable structures. Training helps you understand how a block and tackle works and keeps you safe.

Powerful Machinery Pulley & Blocks

You need reliable equipment when you use a block and tackle for lifting heavy loads. Powerful Machinery offers a wide range of pulley and block solutions designed for industrial and marine environments. These products help you understand how a block and tackle works in real-world applications.

Requirement | Details |

|---|---|

Inspection Frequency | Inspect at least once a year. Some places require twice a year. |

User Inspection | Inspect before each use. Users must receive training. |

Documentation | Keep records of inspections and practices. |

Safety Factor | Use a minimum safety factor of 4:1. |

Material Standards | Use wood for shell plates; metal or synthetic for sheaves. |

Marking Requirements | Mark blocks with manufacturer, rated load, and rope size. |

Visual Inspection | Inspect before each shift. Written records not required. |

Periodic Inspection | Inspect at least once a year. Written records not required by B30.26. |

Powerful Machinery pulleys and block products meet strict safety standards. You find features like high-tensile steel construction, quick-release mechanisms, and permanent load markings. These features help you operate safely and efficiently.

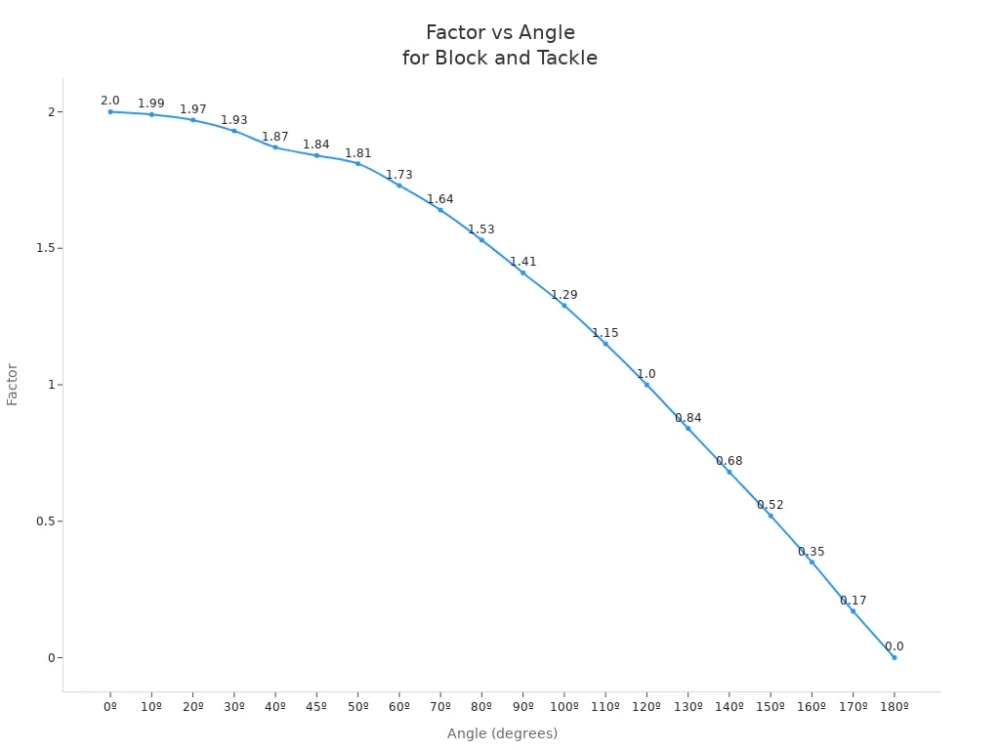

Environmental factors also affect how a block and tackle works. Humidity and temperature can change friction and wear in the pulley system. You should control operating conditions and inspect equipment regularly to maintain performance.

Check for wear, corrosion, or damage before each use.

Make sure anchorage points are secure and free from defects.

Train all users on proper procedures for ropes and anchorage points.

When you choose Powerful Machinery pulley and block products, you get durability, safety, and efficiency. You can use these systems in construction, marine, and industrial settings. The design reduces friction and increases lifting capacity, making your lifting tasks easier and safer.

Block and Tackle Rigging in Action

Real-World Uses

You see block and tackle rigging in many industries because it makes lifting safer and more efficient. In construction, you use these systems to move heavy materials, hoist equipment, and distribute loads evenly. This prevents damage to structures and keeps your worksite safe.

Here is a table showing common applications of block and tackle rigging in construction:

Application Type | Description |

|---|---|

Lifting Heavy Materials | Move concrete, steel beams, and other bulky items easily. |

Hoisting Equipment | Raise tools and machinery to higher floors or platforms. |

Load Distribution | Spread weight across supports to avoid structural stress. |

In marine settings, you use block and tackle rigging to hoist sails, lift anchors, and load cargo. Industrial sites rely on these systems for moving machinery, positioning large parts, and handling heavy loads in tight spaces. You can count on block and tackle rigging to provide control and safety in each of these environments.

Tip: Always check for certifications like CE, ASME B30, ISO 9001, and EN 13157 when choosing rigging equipment. These marks show that your block and tackle rigging meets strict safety and quality standards.

Product Examples from Powerful Machinery

When you need reliable block and tackle rigging, Powerful Machinery offers several solutions designed for tough jobs. The Snatch Block With Hook stands out for its 8-ton working load limit and 6-inch sheave diameter.

You can use it with ropes from 5/8″ to 3/4″, making it versatile for construction, logging, and industrial rigging tasks. Its heavy-duty build ensures durability on any job site.

The Snatch Block With Shackle matches industry standards with weight ratings from 5,000 to 20,000 pounds. You get the same strength and reliability as top products in the field.

The Red Snatch Block Shackle gives you a forged, heat-treated body and steel roller bearings for smooth operation. You can trust these blocks for repeated use in harsh conditions.

Powerful Machinery designs each pulley and block to meet or exceed global standards. You find features like permanent load markings and pressure grease fittings for easy maintenance.

These details help you use block and tackle rigging safely and efficiently, whether you work in construction, marine, or industrial settings.

Block and Tackle vs. Other Simple Machines

When you choose a lifting system, you often compare different simple machines. Each type has its own strengths and best uses. Understanding these differences helps you pick the right tool for your job.

Levers and Gears

Levers give you a way to lift or move objects by applying force at one end. You use a fulcrum as the pivot point. By changing the length of the lever arms, you can increase your lifting power. Levers work well for quick, direct lifts, but they have limits when you need to move very heavy loads over a distance.

Gears use interlocking teeth to transfer force and change speed or direction. You find gears in machines like winches and cranes. They can handle steady, controlled movements.

However, gear-based lifting mechanisms may not give you the same level of force amplification as a block and tackle. The block and tackle system uses multiple pulleys to create a mechanical advantage.

This setup redistributes gravitational forces, so you lift heavier loads with less effort. You also reduce strain on your body and improve safety.

Note: Gears require regular lubrication and precise alignment. If you want a system that is easy to set up and maintain, a pulley-based solution often works better for lifting tasks.

Hydraulics

Hydraulic systems use fluid pressure to move or lift objects. You see hydraulics in car jacks, forklifts, and heavy machinery. These systems can lift very heavy loads with smooth, steady motion. Hydraulics work well for tasks that need precise control and high force.

You may choose hydraulics for industrial settings where you need to lift massive weights. However, hydraulic systems need pumps, hoses, and regular maintenance. They can be more complex and expensive than a simple block and tackle.

Simple Machine | Best Use Case | Key Benefit | Typical Limitation |

|---|---|---|---|

Lever | Quick, direct lifts | Simple and fast | Limited range and power |

Gear | Controlled, steady movement | Precise force transfer | Less force amplification |

Hydraulic | Heavy, precise lifting | High lifting capacity | Complex, needs maintenance |

Block and Tackle | Versatile, heavy lifting tasks | High mechanical advantage | Requires more rope to pull |

When you compare these machines, you see that each has a place in lifting and rigging. The right choice depends on your needs, the load, and the environment.

Conclusion

You now know that a block and tackle lets you lift heavy loads with less effort by using pulleys and rope. This system gives you increased mechanical advantage, better efficiency, and more control. Here are some key benefits:

Benefit | Description |

|---|---|

Increased Mechanical Advantage | Less force is required to lift heavy loads, making it easier to move large items in industries like construction. |

Enhanced Efficiency | Provides smoother motion and reduces friction, leading to less wear on equipment and operators. |

Versatility in Application | It can be used across various industries, adapting to different load sizes and environments. |

Safety and Load Control | Better control over heavy loads reduces the risk of accidents, ensuring safer lifting operations. |

Cost-Effective Solutions | Often more affordable than other lifting devices while providing similar or superior performance. |

You find block and tackle systems in construction, marine, and industrial settings. When you choose Powerful Machinery’s certified products, you get reliable performance and safety. Understanding these systems helps you select the right gear and lift with confidence.

Knowing how a block and tackle works helps you make safer, smarter choices for every lifting task.

FAQ

How does a block and tackle pulley make lifting easier?

You use a block and tackle pulley to reduce the force needed to lift heavy loads. The system spreads the weight across multiple pulleys. You can see this effect clearly in a diagram that shows how the pulleys share the load.

Can I use a block and tackle pulley for vertical and horizontal lifting?

You can use a block and tackle pulley for both vertical and horizontal lifting. A diagram helps you plan the setup. You must secure the anchor points and check the rope path. This ensures safe operation in any direction.

Why should I check a diagram before setting up a block and tackle pulley?

A diagram shows you the correct way to thread the rope through each pulley. You avoid mistakes by following the diagram. This step helps you get the most mechanical advantage from your block and tackle pulley system.

What safety checks do I need before using a block and tackle pulley?

You should inspect the rope, pulleys, and anchor points. A diagram can remind you of each part to check. You must look for wear, corrosion, or damage. You keep your lifting tasks safe by following these steps.

How do I choose the right block and tackle pulley for my project?

You look at the load weight, rope type, and number of pulleys. A diagram helps you compare different setups. You select a block and tackle pulley that matches your lifting needs. Always check the product specifications before use.