You use a hand winch by turning a handle to pull or lift heavy objects. The winch multiplies your strength, making it easier to move things that would be too hard to lift alone.

Understanding the main parts and how the hand winch operation works helps you stay safe and get the job done right. When you learn how a hand winch functions, you protect yourself and your equipment.

Key Takeaways

A hand winch helps lift or pull heavy objects by turning a handle, making tasks easier and safer.

Key components of a hand winch include the drum, hand crank, gear system, and brake, each playing a vital role in operation and safety.

Regularly inspect and maintain your hand winch to ensure safe operation and extend its lifespan.

Choose a manual winch for portability and simplicity, especially in areas without electricity.

Always follow safety practices, such as checking the brake system and keeping bystanders clear during operation.

Hand Winch Operation Basics

What Is a Hand Winch?

A hand winch is a mechanical device that helps you lift or pull heavy objects by turning a hand crank. You often see hand winch operation in places like construction sites, workshops, or even on boats.

The main purpose of a hand winch is to make moving large loads easier and safer. You use manual winch models when you need to work without electricity or in remote locations.

Powerful Machinery is a trusted brand that supplies reliable hand winch solutions for many industries. Their GR Hand Winch and HWV Series Manual Winch are popular choices because they offer strong performance and safety features. These winches help you handle tough jobs with confidence.

You can find different types of winches in the market. Here are some common ones:

Manual winches: You operate these by hand. They work well for small-scale tasks.

Electric winches: These use electricity and are popular for off-road and recovery operations.

Hydraulic winches: These use hydraulic power and suit heavy-duty applications.

Pneumatic winches: These use compressed air and work in hazardous environments.

Industrial winches: These are designed for demanding jobs in various industries.

Specialty winches: These are made for specific uses like marine, mining, or ATV tasks.

How Does a Hand Winch Work?

Hand winch operation uses simple mechanical principles to help you move heavy loads. When you turn the hand crank, you rotate a drum that winds up a cable or rope.

The gear system inside the winch multiplies your force, so you can lift or pull much heavier objects than you could with your hands alone. The ratchet mechanism keeps the drum from unwinding by accident, which protects you and your load.

Here is a table that shows the main parts and their functions:

Component | Function |

|---|---|

Drum | Stores and controls the release of the cable or rope. |

Hand Crank | Applies torque to rotate the drum, enabling lifting or pulling of loads. |

Gear System | Multiplies the force applied, allowing for easier movement of heavier loads. |

Ratchet Mechanism | Prevents the drum from unwinding unintentionally, ensuring safety. |

When you use a manual winch like the GR Hand Winch from Powerful Machinery, you benefit from features such as a free-spooling drum and an automatic brake. These features make hand winch operation smoother and safer.

The HWV Series Manual Winch also offers a 360-degree hand crank and a self-locking brake system, which helps you control the load with less effort.

Hand winches come in different sizes and capacities. In industrial settings, you often see hand winches with load capacities ranging from 150 kg to 2000 kg. The material, gear ratio, and cable specifications all affect how much weight you can safely move.

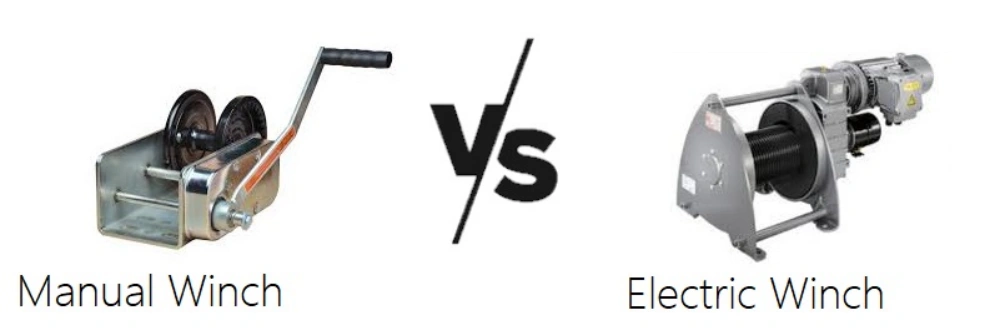

Manual Winch vs Electric Winch

You may wonder about the differences between manual winch and electric winch operation. Manual winch models require you to use physical strength to turn the hand crank.

This makes them ideal for lighter loads and situations where you need portability or do not have access to electricity. Electric winches use a motor to handle heavier loads quickly and with less effort.

Here is a table that compares the two types:

Feature | Manual Winches | Electric Winches |

|---|---|---|

Operation Mechanism | Requires physical cranking, labor-intensive | Motorized operation, faster handling |

Power and Load Capacity | Suited for lighter loads | Handles heavier loads efficiently |

Cost | Cheaper upfront, higher labor costs over time | Higher initial cost, saves time and effort |

Rope/Wire Management | Allows longer ropes, random winding | Guided rope systems, limited flexibility |

Applications | Best for light, infrequent tasks | Preferred for demanding scenarios |

Installation and Portability | More portable, less efficient | Often stationary, mounted on trailers/buildings |

Manual hand winches like those from Powerful Machinery give you flexibility and control. You can use them in places where electric winches are not practical. The GR Hand Winch and HWV Series Manual Winch are designed for easy hand winch operation, with features that help you work safely and efficiently.

Tip: Choose a manual winch when you need a portable solution or when you work in areas without electricity. Use an electric winch for larger, frequent tasks that require more power.

You now understand the basics of hand winch operation. You know what a hand winch is, how it works, and how manual winch models compare to electric winches. Powerful Machinery offers certified products that help you complete your tasks with safety and reliability.

Key Components of a Hand Winch

When you use a hand winch, you rely on several key components that work together to lift or pull heavy loads safely. Powerful Machinery designs each part with certified quality and high performance in mind.

You see these features in products like the GR Hand Winch and HWV Series Manual Winch, which include automatic brake systems, free-spooling drums, and robust steel frames. Let’s break down the main components so you understand how each one helps you operate your winch effectively.

Drum and Cable

The drum and cable form the heart of your hand winch. The drum stores the cable neatly and lets you wind or unwind it as you move a load. The cable connects your load to the winch and must be strong enough to handle the weight you plan to lift or pull.

Component | Function |

|---|---|

Drum | Stores the cable neatly and facilitates the lifting or pulling of loads. |

Cable | Connects the load to the winch and must be strong enough to handle the required weight. |

You can choose from different cable materials, each with its own benefits:

Galvanized steel resists corrosion and works well in tough environments.

Wire rope types like IPS or EIPS offer extra strength.

Synthetic ropes give you higher breaking points and lighter weight.

Steel cables provide durability and strength, especially for abrasive terrains.

Synthetic ropes are safer and lighter but need protection from UV and chemicals.

Natural ropes are eco-friendly but can absorb water and fray easily.

Steel winch cables are the industry standard because they last longer and handle rough conditions. Synthetic ropes work well if you want a lighter option, but you must watch out for damage from sunlight or chemicals.

Gear Mechanism

The gear mechanism multiplies your strength when you turn the handle. You find gear ratios like 1:10 in many hand winches. This means you turn the crank ten times for every single rotation of the drum.

The gear system lets you lift heavier loads with less effort, but it also slows down the lifting speed. You get more control and safety, especially when working with large objects.

Powerful Machinery uses high-strength gears in its winches to give you smooth and reliable operation. The HWV Series Manual Winch features a worm gear mechanism that reduces hand force and fatigue, making your job easier.

Handle and Crank

The handle and crank let you apply force to the winch. Modern hand winch handles include ergonomic features to keep you comfortable and safe. You might notice a molded urethane knob that feels good in your hand and improves your grip.

Some handles have an independent swivel between the knob and the handle, which helps keep your wrist in a natural position. This design supports better arm movement and lets you use more power with less strain.

The HWV Series Manual Winch from Powerful Machinery offers a 360-degree crank handle and a non-slip grip. These features help you maintain control and reduce fatigue during long tasks.

Brake System

The brake system is one of the most important components in your hand winch. The brake keeps the load secure and prevents uncontrolled movement. You find several types of brake systems in winches, including mechanical, hydraulic, dynamic, fail-safe, and electromagnetic brakes.

Mechanical brakes use friction to hold the drum in place. Fail-safe brakes engage automatically if power is lost, securing your load in emergencies. Electromagnetic brakes allow for smooth engagement and variable braking force.

Powerful Machinery’s GR Hand Winch and HWV Series Manual Winch include automatic brake systems. These brakes lock the drum when you stop turning the handle, so your load stays safe even if you let go. You get peace of mind knowing your winch will hold the load securely.

Safety Tip: Always check the brake before you start using your hand winch. A working brake system protects you and your equipment.

Ratchet and Housing

The ratchet mechanism keeps the drum from unwinding by accident. You rely on the ratchet to hold the load in place, especially when you pause during lifting or pulling. The ratchet adds another layer of safety to your hand winch operation.

The housing protects all the internal components from damage. You find housings made from stainless steel, aluminum, or polymer composites. Each material offers different durability benefits:

Material | Durability Benefits |

|---|---|

Stainless Steel | Ideal for marine and industrial applications. |

Aluminum | Lightweight and strong for off-road and automotive use. |

Polymer (Plastic Composites) | Suitable for lightweight applications in marine or high-moisture conditions. |

Powerful Machinery uses robust steel frames and optional cast iron drums in their winches. These features ensure your winch lasts longer and performs well in harsh environments.

When you understand the key components of a hand winch, you can choose the right model for your needs and operate it safely. Powerful Machinery focuses on certified, high-performance components to give you reliable lifting and pulling solutions.

Hand Winch Operation Steps

Pre-Use Safety Checks

Before you start using a hand winch, you need to make sure everything is safe and ready for operation. Always inspect the winch cable, hook, and slings for any signs of damage. Replace any worn or frayed parts immediately. Check the stability of the vehicle or structure you plan to use for lifting or pulling.

Make sure your anchor point can handle the working load limit. Keep others away from the area during winch operation. Use proper rigging techniques and unspool as much winch rope as possible when setting up. Never touch the winch rope or hook while someone else controls the winch.

Tip: Powerful Machinery recommends checking the brake system before each use to ensure it will hold loads securely.

Mounting and Setup

Proper installation is key to safe and efficient winch operation. Choose a sturdy mounting surface that can support the pulling capacity of your winch. Secure the winch with high-strength bolts and check that the handle has enough clearance for manual operation.

Install the cable or rope evenly onto the drum, leaving at least three turns to prevent slipping. Make sure the load attachment is secure and the winch is aligned with the direction of lifting or pulling.

Powerful Machinery winches, like the GR Hand Winch and HWV Series Manual Winch, feature ergonomic handles and multiple fixation points for easy installation. These user-friendly designs help you set up quickly and safely.

Using the Winch

When you operate the hand winch, turn the handle smoothly to wind the cable onto the drum. The gear mechanism multiplies your strength, making lifting and pulling heavy loads easier. Monitor the load during operation and avoid sudden movements.

The automatic brake system on Powerful Machinery winches engages when you stop cranking, holding loads securely. Always stay alert and keep your hands clear of moving parts.

Note: Manual operation gives you full control over the speed and direction of the winch, which is important for towing and recovery tasks.

Releasing and Storing

After you finish lifting or pulling, release the load slowly by turning the handle in reverse. Disengage the brake only when the load is stable. Make sure the cable is evenly wound onto the drum to avoid knots or tangles. Inspect the winch cable for damage before storing.

Lubricate moving parts every few months to prevent wear. Store the winch in a dry place to avoid rust and corrosion. Run the winch monthly to prevent moisture buildup and keep all functions working smoothly.

Tip: Regular maintenance and proper storage extend the lifespan of your winch and ensure safe holding and towing for future operations.

Applications and Advantages

Common Uses

You can use a hand winch in many industries and situations. The winch helps you lift, pull, and position heavy loads with ease. Here are some of the most common applications:

Construction and Rigging: You lift building materials, tension cables, and position equipment.

Agriculture and Farming: You pull stuck machinery, tension fence wires, and lift hay bales.

Marine and Boating: You launch boats, adjust sail lines, and secure cargo.

Off-Road and Vehicle Recovery: You pull vehicles out of mud or snow and assist with towing.

Industrial and Warehouse: You move heavy equipment and load or unload goods.

Home and DIY Projects: You lift heavy objects and organize storage.

Theater and Stage: You raise and lower stage props and lighting rigs.

Note: Powerful Machinery winches serve construction, marine, entertainment, transportation, and cargo handling industries. You benefit from their wide range of lifting and load capacity options.

Benefits of Manual Winch

Manual winches offer several advantages over powered alternatives. You get simple operation and reliable performance, even when electricity is not available. Here are the main benefits:

Simplicity: You operate the winch easily without complex mechanisms.

Portability: You move the winch to different locations as needed.

Cost-effectiveness: You save money compared to powered winches.

Reliability: You use the winch in any condition, regardless of power sources.

Lower cost: Manual winches are usually less expensive.

Dependable operation: You trust the winch to work in tough environments.

You choose a manual hand winch when you need flexibility and control. The winch gives you consistent lifting capacity and maximum lifting capacity for heavy loads in remote or off-grid locations.

Powerful Machinery Product Value

Powerful Machinery designs winches with durability, safety, and adaptability in mind. You get products that stand out for their heavy-duty construction and long-lasting finish. The winch features an anti-slip design and robust steel frames, which help you handle heavy loads safely.

Feature | Powerful Machinery | Competitors |

|---|---|---|

Heavy-Duty Construction | Yes | Varies |

Anti-Slip Design | Yes | Varies |

Long-Lasting Finish | Yes | Varies |

You benefit from certified products that meet international safety standards. The winch offers a range of lifting and load capacity options, so you can match the winch to your specific applications. Powerful Machinery winches provide maximum lifting capacity for demanding jobs, giving you confidence in every operation.

Tip: Choose Powerful Machinery winches for reliable operation, high lifting capacity, and proven durability in any industry.

Safety and Maintenance Tips

Essential Safety Practices

You protect yourself and your equipment by following certified safety practices during hand winch operation. Powerful Machinery recommends these steps to keep you safe:

Inspect your hand winch before each use. Look for damage or wear, especially on the cable.

Use the right equipment for your load. Never overload the winch.

Follow proper installation procedures. Mount the winch securely and check all components.

Wear gloves and safety glasses when you operate the winch.

Stand clear of the cable and keep your hands away from moving parts.

Engage the safety brake to prevent load slipping.

Keep bystanders at a safe distance during the operation.

Stop immediately if you hear unusual sounds and inspect the winch.

Maintain your winch regularly to ensure safe operation.

Tip: Certified safety standards from Powerful Machinery help you avoid accidents and keep your work environment secure.

Routine Maintenance

You extend the life of your hand winch by practicing regular maintenance. Start with routine inspections for cracks, corrosion, or loose fasteners. Clean the winch assembly to remove dirt and debris. Lubricate moving parts to reduce friction and wear.

Check the rope for damage and replace it if needed. Make sure all connections are tight and wiring is correct. Store the winch in a dry place to prevent rust. Regular maintenance practices help you avoid breakdowns and keep your winch ready for operation.

Note: Powerful Machinery provides detailed maintenance recommendations in their product manuals. You can find support and resources on their official website.

Troubleshooting

You may encounter issues during hand winch operation. Use this table to identify common problems and solutions:

Issue Type | Common Problems and Solutions |

|---|---|

Power supply issues | Battery drainage: Check connections and replace damaged parts. Insufficient power: Charge battery and upgrade wiring. |

Motor problems | Overheating: Allow cooling. Motor running but not turning: Inspect gears and replace worn parts. |

Cable or rope malfunctions | Fraying or snapping: Replace worn cables. Cable slippage: Adjust the brake or tension mechanism. |

Remote control issues | Fault wiring: Replace damaged connections. Weak signal: Stay within range and replace batteries. |

Corrosion and rust | Clean connections and apply protective coating. Inspect, clean, and use a rust inhibitor on the drum or gears. |

If you need help with troubleshooting or maintenance, visit Powerful Machinery’s official website for product support and expert advice.

Conclusion

You now know how a hand winch works and why each part matters for safe operation. Choosing certified products like those from Powerful Machinery gives you peace of mind. Products that meet ISO 9001 standards offer better safety and reliability.

Aspect | Description |

|---|---|

Certification Standard | ISO 9001 ensures quality and safety in manufacturing processes. |

Relevance to Winches | Critical for products where user safety is paramount. |

Always follow safety checks and regular maintenance to keep your winch working at its best.

FAQ

How do you choose the right hand winch for your job?

You should check the load weight, cable length, and mounting options. Powerful Machinery offers models with different capacities. Pick a winch that matches your task and environment.

Can you use a hand winch for both lifting and pulling?

Yes, you can use a hand winch for lifting and pulling. Always follow safety guidelines. Powerful Machinery winches work well for both applications in construction, marine, and more.

What maintenance does your hand winch need?

You need to inspect cables, lubricate gears, and clean the drum regularly. Replace worn parts quickly. Powerful Machinery provides maintenance tips in every product manual.

Why is an automatic brake important on your winch?

An automatic brake keeps your load secure when you stop cranking. You stay safe and prevent accidents. Powerful Machinery winches feature reliable automatic brakes for extra protection.