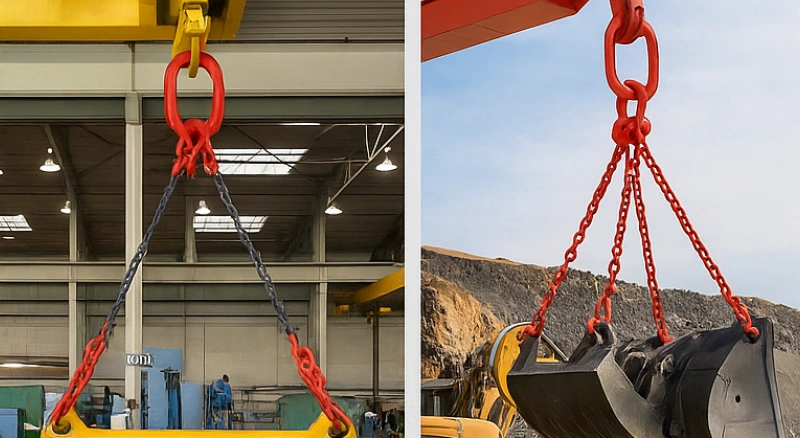

When you need to trust your equipment, Powerful Machinery’s G80 European Type Master Link stands out for its certified reliability and safety features. You see this master link at work in some of the world’s toughest industries. Check out how it’s used:

| Industry | Usage Description |

|---|---|

| Construction | Lifting large structures and materials |

| Offshore | Heavy lifting in marine environments |

| Manufacturing | Rigging applications in factories |

| Mining | Lifting heavy equipment and materials |

| Transportation | Moving heavy loads safely |

You get immediate peace of mind because every link is built to handle heavy loads, resist corrosion, and keep your team safe. That’s How the G80 European Type Master Link Ensures Your Lifting Safety every time you put it to work.

Key Takeaways

- The G80 European Type Master Link is made from high-strength forged alloy steel, ensuring durability and reliability for heavy lifting tasks.

- Each master link undergoes rigorous testing, including proof testing at 2.5 times its working load limit, guaranteeing safety and performance.

- Look for clear markings on the master link, including the working load limit and certification marks, to ensure safe usage and compliance with standards.

- Regularly inspect your master link for signs of wear or damage to maintain safety and extend its lifespan.

- Choosing the right size master link is crucial; it should be at least 20% larger than the crane hook for secure attachment.

What Is the G80 European Type Master Link?

Product Definition

When you look for lifting solutions, you want something that’s strong, safe, and easy to use. That’s where Powerful Machinery comes in. With over 20 years of experience, Powerful Machinery leads the way in manufacturing high-performance lifting chains, rigging hardware, and master links. The G80 European Type Master Link stands out as a top choice for professionals who need reliability on every lift.

Let’s break down what makes this master link unique. You get a welded oblong design made from forged alloy steel. Each link is stamped for easy identification and proof-tested at 2.5 times its working load limit. The safety factor sits at 4:1, so you know you’re working with a product built for tough jobs. It meets strict international standards like EN1677-4, making it suitable for overhead lifting, lashing, and towing.

Here’s a quick look at how it compares to other master links:

| Characteristic | Description |

|---|---|

| Design | Welded oblong design for single/multi-leg slings |

| Material | Forged alloy steel |

| Safety Factor | 4:1 |

| Proof Testing | 2.5x working load limit |

| Identification | Stamped with “G80” or “8” |

| Application | Overhead lifting, lashing, towing |

| Compliance | EN1677-4 (superseded DIN5688-3) |

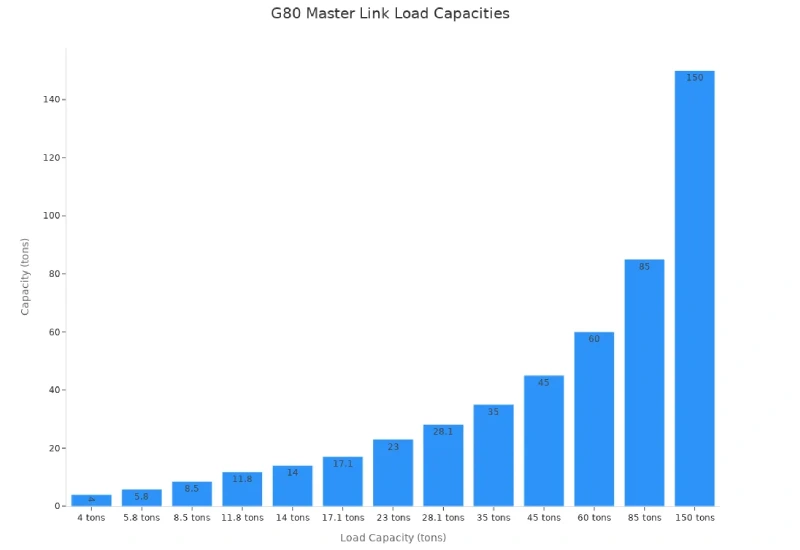

You can find G80 European Type Master Links in a wide range of load capacities. Whether you need to lift 4 tons or up to 150 tons, there’s a size for your job.

Role in Lifting Systems

You might wonder, “What does this master link actually do?” The answer is simple. The G80 European Type Master Link acts as the heart of your lifting system. You use it as the central connection point in multi-leg sling assemblies. This means it holds everything together, making sure the load spreads evenly across all sling legs. You get better stability and safety every time you lift.

When you choose Powerful Machinery’s master link, you’re not just picking a piece of hardware. You’re choosing a product that shows How the G80 European Type Master Link Ensures Your Lifting Safety, job after job. You can trust it to keep your team and your load secure, no matter the challenge.

How the G80 European Type Master Link Ensures Your Lifting Safety

High-Strength Alloy Steel

When you pick up a G80 European Type Master Link from Powerful Machinery, you hold a piece of equipment built for strength. The secret lies in the material. Each master link uses forged super alloy steel that goes through quenching and tempering. This process makes the steel tough and ready for heavy lifting. You can count on it to handle high tension and resist fatigue, even after thousands of lifts.

Here’s a quick look at what makes this steel special:

| Feature | Description |

|---|---|

| Material | Forged super alloy steel, quenched and tempered |

| Strength | High strength, passes tensile and fatigue tests |

| Coating | Powder plastic coating for durability |

| Testing | Individually tested at 2.5x working load limit, fatigue tested for 20,000 cycles |

You get more than just raw power. The powder plastic coating protects the master link from scratches and rust. This means you can use it in rain, saltwater, or mud, and it keeps working. That’s one way How the G80 European Type Master Link Ensures Your Lifting Safety every time you use it.

Tip: Always check the coating before each use. A good finish means your master link will last longer, even in tough environments.

Certified Safety Standards

You want to know your lifting gear meets the highest safety standards. Powerful Machinery makes sure every G80 European Type Master Link is certified by top organizations. These certifications prove that your master link is safe, reliable, and ready for the job.

Check out the certifications you get:

| Certification | Description |

|---|---|

| ISO9001 | Quality management system standard |

| CE | Conformity to European safety standards |

| SGS | Global leader in inspection, verification, testing, and certification services |

These certifications mean your master link follows strict rules for quality and safety. You can trust it for overhead lifting, rigging, and towing. When you see these marks, you know How the G80 European Type Master Link Ensures Your Lifting Safety is not just a promise—it’s a guarantee.

Note: Always look for certification marks on your lifting equipment. They show that your gear passed tough tests and meets international standards.

Load Testing and Markings

You never want to guess if your lifting gear is safe. That’s why Powerful Machinery tests every G80 European Type Master Link before it leaves the factory. Each link goes through proof testing at 2.5 times its working load limit. It also faces a fatigue test at 1.5 times the working load for 20,000 cycles. The breaking test pushes the link to four times its working load limit. Every link gets checked for cracks using magnaflux crack detection. You get a master link that’s 100% inspected and tested.

Here’s how the testing process works:

| Testing Parameter | Value |

|---|---|

| Proof Test | 2.5 times Working Load Limit |

| Fatigue Test | 1.5 times Working Load Limit for 20,000 cycles |

| Breaking Test | 4 times the Working Load Limit |

| Crack Detection | 100% magnaflux crack detection |

| Inspection | 100% individually inspected and tested |

You’ll also find clear markings on each master link. These markings show the working load limit, batch code, and certification. You can check them at a glance and know you’re using the right gear for the job.

Alert: Never use a master link without visible markings. Markings help you avoid mistakes and keep your team safe.

You get more than just a strong link. You get peace of mind. The combination of high-strength steel, strict certifications, and tough testing is How the G80 European Type Master Link Ensures Your Lifting Safety in every lift, every time.

- Protective finishes give you excellent corrosion resistance. You can use your master link in harsh environments without worry.

- The 4:1 safety factor means you have a big margin for error. You can trust your gear, even when the job gets tough.

When you choose Powerful Machinery, you choose safety, strength, and reliability. That’s How the G80 European Type Master Link Ensures Your Lifting Safety, no matter where you work.

Accident Prevention and Reliability

Secure Connections

You want every lift to feel safe and steady. That’s why the G80 European Type Master Link gives you secure connections every time. The design lets you attach multiple sling legs or chains without worry. You get a strong, welded oval shape that keeps everything in place. The large opening makes it easy to connect hooks or chains, even when you wear gloves.

Many customers trust this master link for big jobs. Ben Carter from Canada shared, “We use these master links on our construction sites. They never slip or twist, even with heavy steel beams.” You can see the difference when you use gear that holds tight and stays put.

Here’s what makes the design stand out:

| Feature | Description |

|---|---|

| Superior Strength and Durability | Made from high-quality alloy steel, ensuring reliability under heavy loads and harsh conditions. |

| Excellent Load Stability | Design allows secure attachment, minimizing load shifting and enhancing safety during lifting. |

| Enhanced Safety Features | Includes safety hooks and clear load capacity markings to prevent accidents and overloading. |

You get peace of mind because you know your load will not shift or fall. That’s a big part of How the G80 European Type Master Link Ensures Your Lifting Safety.

Wear and Fatigue Resistance

You want your lifting gear to last, even after hundreds of jobs. The G80 European Type Master Link uses special alloy steel that stands up to wear and tear. The powder-coated finish fights off rust and keeps the link looking new, even in rain or saltwater.

David Müller from Germany said, “We use these master links in our marine projects. They hold up against salt and rough weather. We trust them every day.” You can count on this master link to resist cracks, chips, and bending.

The master link goes through tough tests. Each one faces thousands of lifting cycles and gets checked for tiny cracks. You get a product that keeps working, lift after lift. When you use gear that resists wear and fatigue, you lower the risk of accidents and save money on replacements.

Tip: Check your master link for signs of wear before each use. A quick look can help you spot problems early and keep your team safe.

You see How the G80 European Type Master Link Ensures Your Lifting Safety by giving you secure connections and long-lasting strength. That’s why professionals around the world trust it for their toughest jobs.

Choosing and Maintaining Your Master Link

Selection Tips

Picking the right master link for your lifting job makes all the difference. You want to match the link to your equipment and the load you plan to move. Here’s a simple checklist to help you choose:

- Crane hook size and design: Always check the size of your crane hook. The master link should be at least 20% larger than the hook width. This gives you enough space for safe attachment.

- Weight of the load: Look at the working load limit (WLL) stamped on the master link. Make sure it matches or exceeds the weight you need to lift. Never guess—always check the numbers.

- Number of sling legs: Count how many legs your sling assembly needs. The master link must fit all the strands without crowding. If you use multi-leg slings, pick a link with enough room for each leg.

Tip: If you’re unsure about sizing or configuration, reach out to Powerful Machinery’s technical team. They can help you find the perfect match for your lifting setup.

Inspection and Maintenance

You want your master link to last and keep your team safe. Regular inspection and maintenance help you spot problems before they become serious. Start by looking for common signs of wear or fatigue. Nicks, gouges, and scratches on the surface can weaken the link. These injuries may shorten the life of your lifting gear and increase the risk of failure.

Set up a routine inspection before every use. Wipe down the master link and check for cracks, bends, or rust. If you see any damage, replace the link right away. Keep your master link clean and store it in a dry place when not in use. A little care goes a long way.

Alert: Never use a master link that shows signs of damage. Safety comes first—always inspect your gear and follow manufacturer guidelines.

You get more reliable lifts and fewer surprises when you choose the right master link and keep it in top shape. Powerful Machinery designs every link for easy maintenance, so you can focus on getting the job done safely.

You want lifting gear that keeps your team safe every time. Powerful Machinery’s G80 European Type Master Link gives you just that. Check out what sets it apart:

- Forged alloy steel, quenched and tempered for strength

- Individually proof-tested and fatigue-tested for reliability

- Safety factor of 4:1, meeting EN 1677-4 and other strict standards

- Clear Working Load Limit markings to prevent overloading

Choosing certified, tested equipment means you avoid accidents and meet industry regulations. When you trust your gear, you work with confidence and protect everyone on the job.

FAQ

How do you know if your G80 European Type Master Link is safe for overhead lifting?

Look for the working load limit stamped on the link. You should also check for certification marks like ISO or CE. If you see these, you know your master link meets strict safety standards.

Can you use the master link in wet or salty environments?

Yes! The powder-coated finish protects your master link from rust and corrosion. You can use it outdoors, in rain, or even in marine settings without worrying about damage.

What should you check before using your master link?

Always inspect for cracks, bends, or worn spots. Make sure the markings are clear. If you spot any damage, replace the link right away. Safety comes first!

How do you pick the right size master link for your job?

Check the size of your crane hook and the number of sling legs. The master link should be at least 20% bigger than the hook. If you need help, ask Powerful Machinery’s team for advice.

Do you need to maintain your master link regularly?

Absolutely! Wipe it clean after each use. Store it in a dry place. Regular checks help you catch problems early and keep your lifting gear working safely.

Conclusion

The G80 European Type Master Link is more than just hardware—it’s the core of safe lifting systems. Built from forged alloy steel, rigorously tested, and certified to international standards, it delivers durability, corrosion resistance, and dependable load control. Whether you work in construction, offshore, mining, or manufacturing, this master link ensures stability and security with every lift.

Choosing Powerful Machinery means choosing proven reliability, industry expertise, and products designed to protect your team and your load. It’s lifting safety you can trust, every time.