To install a wire rope thimble, you first shape the rope into a loop, insert the thimble snugly, and secure it with appropriate hardware. This process ensures safety by protecting the rope from abrasion and maintaining its strength.

The purpose of using a thimble is to keep the wire rope assembly reliable under heavy loads. You reduce friction and prevent kinks, which extends the lifespan of your wire rope.

Benefit | Impact on Lifespan |

|---|---|

Protection against wear | Reduces the rate of deterioration |

Prevention of kinks | Maintains rope integrity under tension |

Enhanced strength | Increases load-bearing capacity |

Reduced friction and abrasion | Extends the overall lifespan of the rope |

When you use wire rope thimbles, you prioritize safety and prolong the life of your equipment.

Key Takeaways

Always match the thimble size to your wire rope diameter for a secure fit and optimal load distribution.

Select corrosion-resistant materials, such as stainless steel, for marine or outdoor applications to prolong the lifespan of your wire rope assemblies.

Follow proper installation steps, including forming the eye and securing with clips or sleeves, to ensure safety and reliability.

Regularly inspect wire rope assemblies for signs of wear or damage to prevent failures and maintain performance.

Use quality products from trusted manufacturers to enhance durability and safety in demanding environments.

Wire Rope Thimbles Overview

Wire rope thimbles play a vital role in wire rope assemblies. You use them to reinforce and shape loops or eyelets at the ends of wire ropes. Thimbles provide abrasion resistance and protect against wire fatigue, especially at anchor points where stress is highest.

By preventing excessive bending and reducing direct contact between the rope and fittings, you help maintain the mechanical integrity of your wire rope assemblies. This is essential for demanding applications such as lifting, hoisting, and load securing.

When you choose the right thimble, you enhance durability, safety, and corrosion resistance in construction, marine, industrial manufacturing, and transportation.

Wire Thimble Types

You will find several types of wire rope thimbles designed for different types of wire rope assemblies. Each type offers unique benefits for specific environments and loads.

Type | Material | Applications |

|---|---|---|

Steel Thimbles | Galvanized/Stainless Steel | Marine, construction, high strength and durability |

Plastic Thimbles | Plastic | Lighter-duty rigging, cost-effective |

Bronze Thimbles | Bronze | Maritime, corrosion resistance |

Aluminum Thimbles | Aluminum | Racing boats, weight-saving |

Heavy-Duty Thimbles | Thick Steel | Industrial, extreme load-bearing |

Powerful Machinery’s Stainless Steel Thimble stands out for its corrosion resistance and robust construction. You can rely on it for marine, industrial, and construction settings where you need maximum protection and longevity.

Choosing the Right Thimble

You must select the right thimble for your types of wire rope assemblies by considering several factors. The environment, load requirements, and rope size all influence your choice.

Factor | Consideration |

|---|---|

Corrosion Resistance | Stainless steel offers high corrosion resistance. Galvanized steel is a cost-effective alternative. |

Load Requirements | Alloy steel handles maximum loads. Choose materials that will not fail under stress. |

When you select a thimble, match its size to your wire rope diameter for proper fit and load distribution. For vinyl-coated cables, account for the coating thickness. For example, a 5/16″ vinyl-coated cable with a 3/8″ diameter should use a 3/8″ wire rope thimble.

You should always check the specifications of your wire rope assemblies before making a selection.

Powerful Machinery offers a range of thimbles to suit different rope sizes and environments, ensuring you find the best fit for your needs.

Tip: Using a corrosion-resistant thimble like Powerful Machinery’s Stainless Steel Thimble increases the lifespan of your wire rope assemblies, especially in harsh or marine environments.

Wire Rope Thimble Installation

Tools and Materials

Before you install the thimble on the wire rope, gather all necessary tools and materials. Using the right equipment ensures safety and a secure connection. Here is what you need:

Wire rope cut to the required length

The correct size of thimble (choose from stainless steel thimbles, galvanized thimbles, or heavy-duty thimbles based on your application)

Wire rope clips or ferrule sleeves

Adjustable wrench or socket wrench

Crimping or swaging tool (for sleeves)

Tape measure

Safety gloves and eye protection

Tip: Always select the correct size of thimble for your wire rope diameter. This prevents slippage and ensures proper load distribution.

Installation Steps

Follow these steps to install the thimble on the wire rope safely and efficiently:

Prepare the Rope

Cut the wire rope cleanly. Remove any frayed ends. Slide the required number of wire rope clips or a ferrule sleeve onto the rope before forming the loop.From the Eye

Bend the end of the wire rope to create a loop. Place the thimble into the loop so the rope fits snugly around the outer groove.Position the Thimble

Make sure the thimble sits tightly in the loop. The rope should wrap evenly around the thimble’s groove. This step is crucial for preventing signs of wear and maintaining rope integrity.Secure with Clips or Sleeves

If you use wire rope clips, position the first clip as close to the thimble as possible. Tighten the nuts with a wrench. Add additional clips, spacing them 6-7 rope diameters apart. Tighten each clip to the recommended torque value for your cable size.

If you use a ferrule sleeve, slide it into place and compress it with a crimping or swaging tool. This creates a permanent, strong connection.Check Alignment

Inspect the assembly. The thimble should not move within the loop. The rope should grip the thimble tightly without gaps.Test the Installation

Apply a light load to the assembly. Check for movement, slippage, or signs of wear. If you notice any issues, re-tighten the clips or re-crimp the sleeve.

Note: Powerful Machinery’s stainless steel thimbles excel in marine and heavy-duty applications. Their corrosion resistance and robust design protect your wire rope from harsh environments and extend service life.

Feature | Description |

|---|---|

Marine and offshore applications | Used to protect wire ropes in mooring, towing, and lifting operations. |

Stainless Steel Thimble | Made from corrosion-resistant stainless steel, ideal for harsh marine environments. |

Prevents wire rope damage | Extends the lifespan of wire ropes by preventing damage to the wire rope eye. |

Using Clips and Sleeves

You can secure the thimble using either wire rope clips or sleeves. Each method offers unique advantages:

Feature | Wire Rope Clips | Sleeves (Ferrules) |

|---|---|---|

Function | Secures rope ends to create loops | Provides a permanent, crimped connection |

Installation | Requires proper spacing and torque | Needs a crimping/swaging tool |

Material | Forged steel, stainless steel, galvanized steel | Aluminum, copper, or stainless steel |

Applications | Loop creation, repairs, and general rigging | Permanent assemblies, heavy-duty thimbles |

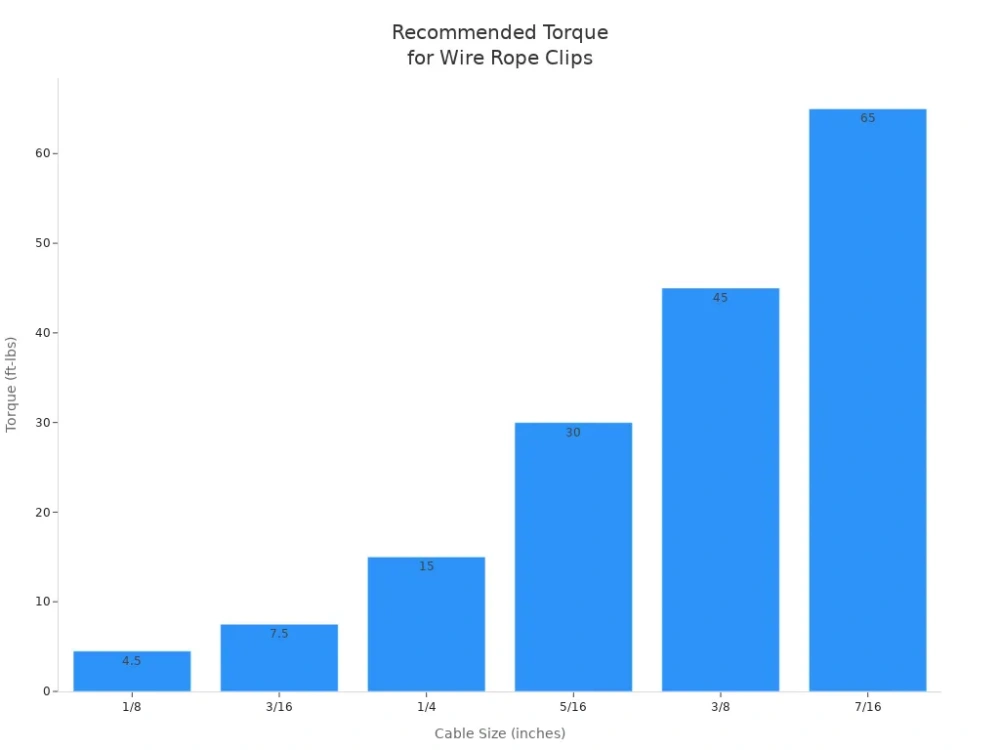

When you use wire rope clips, always follow the recommended torque values for your cable size. Proper torque prevents slippage and reduces signs of wear. Refer to the table below for guidance:

Cable Size (Inches) | Minimum Number of Clips | Amount of Rope Turnback (Inches) | Torque (ft-lbs) |

|---|---|---|---|

1/8 | 2 | 3-3/4 | 4.5 |

3/16 | 2 | 3-3/4 | 7.5 |

1/4 | 2 | 4-3/4 | 15 |

5/16 | 2 | 5-1/4 | 30 |

3/8 | 2 | 6-1/2 | 45 |

7/16 | 2 | 7 | 65 |

Safety Alert: Always wear gloves and eye protection when you install a thimble on a wire rope. Inspect for signs of wear after installation and before each use. Replace any components that show damage or corrosion.

You should choose stainless steel thimbles for marine or corrosive environments. Galvanized thimbles work well for general outdoor use. Heavy-duty thimbles provide extra strength for industrial lifting. Always match the correct size of thimble to your wire rope for optimal safety and performance.

Wire rope thimbles protect your assemblies from signs of wear and extend the lifespan of your equipment. When you follow these steps and use quality products from Powerful Machinery, you ensure reliable and safe operation in every application.

Maintaining Wire Rope Assemblies

Inspection Tips

You must inspect wire rope assemblies regularly to ensure safety and reliability. Begin by checking each component of a wire rope assembly, including the thimble, for signs of wear, corrosion, or deformation. Look for broken wires, kinks, or flattened areas.

Pay close attention to the thimble’s groove and the rope’s contact points. Use the following table to determine how often you should inspect your wire rope assemblies based on service conditions:

Service Condition | Inspection Interval |

|---|---|

Normal Service | Yearly |

Severe Service | Monthly to Quarterly |

Special Service | As recommended by a Qualified Person |

Regular maintenance and inspection of wire rope assemblies help you identify problems early and prevent failures.

When to Replace Components?

Replace any component of a wire rope assembly if you see visible damage, excessive corrosion, or deformation. Thimbles that show deep grooves, cracks, or rust compromise the integrity of the wire rope assembly.

In harsh environments, you should choose corrosion-resistant thimbles such as stainless steel. These thimbles offer several advantages:

Corrosion resistance protects against rust in marine or wet conditions.

Superior strength and durability handle heavy loads without bending.

Extended longevity reduces the need for frequent replacements.

Switch to a new thimble or rope if you notice any reduction in performance or safety.

Best Practices for Longevity

You can extend the lifespan of your wire rope assemblies by following best practices. Always use proper installation techniques and train operators on correct handling. Store wire rope assemblies in a clean, dry place to prevent contamination and corrosion.

Lubricate the rope to reduce friction and wear. The table below outlines essential maintenance steps:

Maintenance Practice | Description |

|---|---|

Regular Inspection | Identify issues early for timely repairs. |

Lubrication | Reduce friction and protect against corrosion. |

Proper Installation | Ensure correct setup for maximum longevity. |

Operator Training | Teach best practices for handling and maintenance. |

Proper Storage and Handling | Keep assemblies clean and dry to avoid damage. |

By following these steps, you maintain safety and performance standards for every component of a wire rope assembly. Powerful Machinery’s stainless steel thimbles provide added longevity and reliability, especially in demanding environments.

Conclusion

You ensure safety and long-lasting performance by following each step of wire rope thimble installation, from selecting the right size to regular inspection. High-quality thimbles prevent crushing and wear, extending the life of your assemblies.

Always match thimble size to cable diameter.

Choose corrosion-resistant materials for marine or outdoor use.

Consult manufacturers for specialized needs.

Material | Size Range | Finish | Ideal Use |

|---|---|---|---|

Stainless Steel | 2mm–36mm | Polished, galvanized | Marine, landscaping, outdoor |

Explore Powerful Machinery’s certified thimbles, trusted by industry leaders, for your next project.

FAQ

What size thimble should you use for your wire rope?

You should match the thimble size to your wire rope’s diameter. For coated cables, measure the total outside diameter. Always check manufacturer sizing charts to ensure a secure fit and optimal performance.

Can you reuse a wire rope thimble?

You should not reuse thimbles that show signs of wear, deformation, or corrosion. Always inspect thimbles before reuse. Replace any thimble that does not meet safety standards.

How do you prevent wire rope slippage during installation?

You must tighten wire rope clips to the recommended torque. Space clips correctly and use the right number for your rope size. Test the assembly under a light load before full use.

Why choose a stainless steel thimble for marine applications?

Stainless steel thimbles resist corrosion from saltwater and harsh weather. You gain longer service life and better protection for your wire rope in marine environments.

Tip: Always inspect your wire rope assemblies before each use to ensure safety and reliability.