To measure a shackle accurately, start by identifying the shackle type, then gather a measuring tape or calipers to check the diameter, pin size, inside width, and length.

Knowing how to measure a shackle correctly is crucial, as precise measurements help you avoid issues like improper contact with hooks, compromised rigging integrity, or exceeding safe working loads—each of which can lead to equipment failure or injury.

Always compare your results to Powerful Machinery’s certified sizing standards to ensure a safe and compatible fit.

Key Takeaways

Identify the shackle type before measuring. Bow shackles are best for multi-directional loads, while D shackles suit straight-line pulls.

Use digital calipers for precise measurements of the shackle body and pin diameter. Measuring tapes work well for overall length and inside width.

Always compare your measurements to Powerful Machinery’s certified sizing charts. A ±5% tolerance ensures a proper fit and safe operation.

Inspect shackles for wear, deformation, or corrosion before measuring. Clean shackles to ensure accurate results and maintain safety.

Select shackles that meet or exceed your load requirements. Certification is crucial for ensuring safety and reliability in demanding environments.

Shackle Types and Applications

Powerful Machinery stands as a global leader in certified lifting and rigging solutions. You can trust their products to deliver safety and reliability in demanding environments. Before you measure a shackle, you need to identify its type. This step ensures you select the right tool for your lifting or rigging task.

Bow Shackles and D Shackles

You will find that the most common types of shackles in the lifting and rigging industry are bow shackles and D shackles.

Bow shackles feature a rounded, bow-shaped design. This shape gives you more internal clearance, making them ideal for connecting multiple slings or handling loads from different directions.

D shackles, sometimes called Dee shackles, have a straight-sided design. They work best for single-leg slings and straight-line pulls. You should avoid using D shackles for side loads, as this can cause bending or failure.

Tip: Always match the shackle type to your application. Bow shackles suit multi-leg slings and complex rigging, while D shackles excel in linear load handling.

Specialty Shackles (G2150, G209, G210, G2130)

Powerful Machinery offers a full range of specialty shackles, including G2150, G209, G210, and G2130 models, as well as stainless steel screw pin D shackles. Each type meets strict industry standards for safety and performance.

Here is a quick overview of their specifications:

Specification | Details |

|---|---|

Size | 1/2″~4″ |

Working Load | 2 to 150 Tons |

Minimum Breaking Strength | 4 Times The Working Load Limit |

Certificates | ISO, CE, SGS, BV |

You must know the exact type before measuring, as each shackle has unique dimensions and load ratings. Using certified shackles from Powerful Machinery helps you reduce the risk of workplace injuries and equipment damage.

Proper identification and measurement support safe rigging practices and compliance with industry regulations.

Tools Needed to Measure a Shackle

Accurate measurement starts with the right tools. You need to select equipment that meets industry standards and delivers reliable results. Powerful Machinery recommends using certified tools to ensure your measurements align with product specifications.

Measuring Tape and Calipers

You should use a measuring tape to check the overall length and inside width of the shackle. This tool works well for larger dimensions and quick assessments. For precise measurements, especially when checking the diameter of the shackle body or pin, digital calipers are essential.

Calipers provide higher accuracy than measuring tapes, especially for smaller parts. Industry experts also suggest using advanced systems like the BroadWeigh load monitoring system for real-time load checks in rigging applications.

If you work with dynamometers, always match the shackle pin diameter to the device requirements. For example, a Crosby/Straightpoint 6.5T dynamometer needs a compatible Crosby G-2130 shackle for optimal performance.

Tip: Always use digital calipers for measuring pin and body diameters. Measuring tapes are best for overall length and width.

Tool | Best Use | Accuracy Level |

|---|---|---|

Measuring Tape | Length, inside width | Moderate |

Digital Calipers | Pin diameter, body diameter | High |

Load Monitoring System | Real-time load measurement | Very High |

Tips for Accurate Measurement

You can avoid common mistakes by following these guidelines:

Inspect the shackle for deformation, such as bending or twisting.

Check for surface damage, including nicks, cracks, or corrosion.

Make sure the pin and threads are clean and undamaged. Difficulty turning the pin signals a problem.

Confirm that the manufacturer’s markings and Working Load Limit (WLL) are clear and legible.

You should always measure at the widest points and record each dimension carefully. Clean the shackle before measuring to remove dirt or debris. Double-check your results against Powerful Machinery’s certified sizing charts for safety and compatibility.

Note: Accurate measurement protects you from equipment failure and ensures compliance with safety standards.

How to Measure a Shackle?

Accurate measurement is essential when you want to ensure safety and compatibility in lifting and rigging operations. You need to know how to measure a shackle correctly to match it with your equipment and meet industry standards.

Follow these steps to measure your current shackle and select the right replacement or new component.

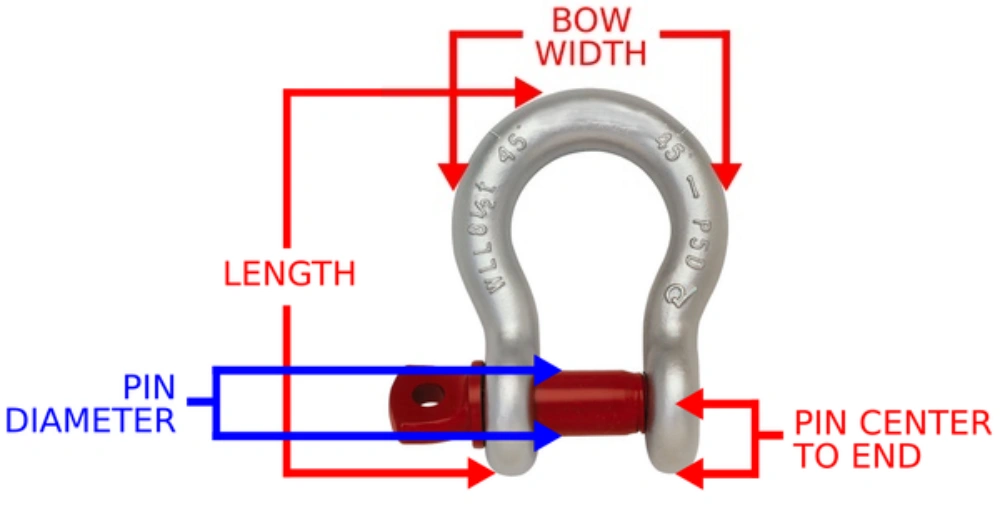

Measure Shackle Diameter and Pin Size

Start by identifying the main body diameter and the pin diameter. Use a digital caliper for the most precise measurement. Place the caliper jaws around the thickest part of the shackle body to record the diameter. Next, measure the diameter of the pin by placing the caliper across the widest part of the pin itself.

For Powerful Machinery’s G2150 and G209 shackles, you will find the body diameter and pin diameter listed in the product specifications. Always measure at the widest points to avoid underestimating the size.

Write down both measurements. These two values are critical for determining the working load limit and ensuring the shackle fits your rigging hardware.

Tip: Always double-check your measurements. Even a small error can lead to a mismatch or an unsafe connection.

Measure Inside Width and Length

After you measure the diameter and pin size, you need to check the inside width and length. Use a measuring tape for these dimensions.

To measure the inside width, place the tape across the inner sides of the shackle at its widest point. This tells you how much space is available for connecting slings, chains, or hooks.

For the inside length, measure from the inside top of the shackle (opposite the pin) down to the inside edge of the pin. This gives you the usable length for your connection.

You should compare these measurements to the sizing charts provided by Powerful Machinery. Each model, such as the G2130 or stainless steel screw pin D shackles, has specific dimensions that must match your application.

Measure a D Shackle

When you measure a D shackle, focus on its straight sides and narrow profile. D shackles, like Powerful Machinery’s stainless steel screw pin D shackles, are designed for straight-line loads.

Measure the body diameter using a caliper.

Measure the pin diameter at the widest point.

Measure the inside width between the straight sides.

Measure the inside length from the top of the shackle to the inside of the pin.

Record each measurement clearly. D shackles require precise sizing because they do not tolerate side loads well. Always match your measurements to the certified sizing chart to ensure a safe fit.

Measure a Bow Shackle (G209, G2150, G2130)

Bow shackles have a rounded body, which allows for multi-directional loading. When you measure a bow shackle, follow these steps:

Use a caliper to measure the thickest part of the bow for the body diameter.

Measure the pin diameter at its widest point.

Measure the inside width at the widest part of the bow.

Measure the inside length from the top of the bow to the inside edge of the pin.

Bow shackles from Powerful Machinery, such as the G209, G2150, and G2130, come with detailed sizing charts. Always compare your measurements to these charts before making a selection.

Note: Certified shackles undergo rigorous testing and certification. In the United States and Europe, organizations like ABS, DNV, Bureau Veritas, and Lloyd’s Register certify shackles for industrial and lifting applications.

Each shackle must pass proof load testing at twice the working load limit and undergo inspections such as ultrasonic and magnetic particle testing. Here is a summary of the main certification bodies:

Certification Body | Description |

|---|---|

ABS | Approved manufacturer for industrial applications |

DNV | Approved for lifting and mooring applications |

Bureau Veritas | Certification for quality management system |

Lloyd’s Register | Certification for heat treatment procedures |

NDT Testing | Ultrasonic and magnetic particle inspection |

Proof Load Testing | Conducted at 2x WLL with traceability to each shackle |

You should always select shackles that meet these standards. Powerful Machinery provides certified products that comply with these requirements, ensuring your measurements lead to safe and reliable choices.

Remember: When you know how to measure a shackle properly, you protect your team, your equipment, and your project. Always use certified sizing charts and select products that meet international standards.

Select the Correct Shackle Size

Compare Measurements to Standard Sizes

After you complete your measurement, you need to compare your results to the standard sizing charts from Powerful Machinery. Focus on the diameter of the shackle body, as this is the primary reference point in standard sizes.

You should check that your measured values for diameter, pin size, inside width, and length match the specifications listed in the sizing chart. If your measurement falls within ±5% of the standard dimension, you can proceed with confidence.

This small tolerance ensures that your shackle will fit properly and perform safely in your rigging setup.

Tip: Always use the most recent sizing chart from Powerful Machinery. Product updates may change standard dimensions or load ratings.

Measurement Step | What to Check | Acceptable Range |

|---|---|---|

Body Diameter | Matches the chart size | ±5% |

Pin Diameter | Matches the chart size | ±5% |

Inside Width & Length | Matches the chart size | ±5% |

If your measurement does not align with the chart, you should repeat the process to confirm accuracy. Never force a shackle that does not fit the standard. This step protects you from equipment failure and ensures compliance with safety standards.

Choosing the Right Powerful Machinery Shackle

Once you confirm your measurement, you can select the correct shackle size for your application. Review the product specifications for each Powerful Machinery shackle model. Each product page provides detailed sizing charts, working load limits, and certification details.

You should always choose a shackle that meets or exceeds your load requirements. Certification is critical. Only use shackles that display clear markings for working load limit and manufacturer identification. Powerful Machinery shackles meet international standards, giving you peace of mind in demanding environments.

Note: Never exceed the working load limit listed in the product specifications. Always select the correct shackle size based on your measurement and the intended load.

By following these steps, you ensure that your rigging setup remains safe, reliable, and compliant with industry regulations. Accurate measurement and careful comparison to standard sizes help you select the correct shackle size every time.

Common Measurement Challenges

Avoiding Errors

You may encounter several challenges when measuring a shackle. Mistakes often occur during field inspections, leading to inaccurate results or unsafe rigging.

The most common reasons for discrepancies include missing nuts on bolt-type shackles, excessive wear that reduces the original size by 10% or more, and visible corrosion or severe pitting. These issues can compromise the accuracy of your measurement and the safety of your lifting operation.

To help you avoid these errors, follow these best practices:

Select the correct shackle for the load and environment.

Always check the working load limit (WLL) marked on the shackle.

Inspect for wear, corrosion, or deformation before each use.

Ensure the pin is fully engaged and the load is evenly distributed.

Never overload the shackle or exceed its WLL.

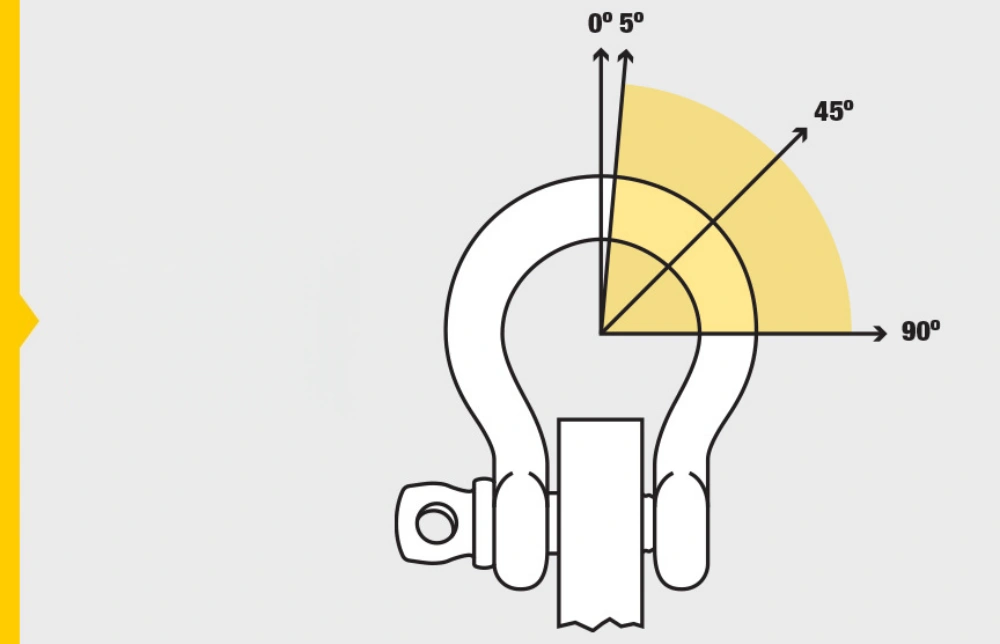

Account for the angle of lift to prevent exceeding capacity.

Environmental factors such as corrosion and wear can change the dimensions of a shackle over time. This degradation affects the accuracy of your measurement and may reduce the structural integrity of the equipment. You should always clean and inspect shackles before measuring to ensure reliable results.

Tip: Store and handle shackles properly, inspect them before and after use, and never use shackles with bent pins or deformed bodies. Avoid forcing or wedging shackles into position.

Ensuring Compatibility

You need to ensure that your measurement matches the certified tolerances for your application. Regular inspection and re-measurement help maintain compliance with safety standards. The recommended inspection frequency varies by standard:

Standard | Inspection Frequency |

|---|---|

OSHA/ASME | Annual thorough examination |

HSA (Ireland) | Minimum every 6 months |

ISO | 6-12 months typical |

Using certified products from Powerful Machinery gives you confidence in your measurement results. These shackles undergo rigorous testing and certification, so you can trust their reliability in demanding environments.

When you follow proper measurement and maintenance practices, you protect your team and equipment from unexpected failures.

Conclusion

Accurate shackle measurement keeps your rigging safe and your equipment performing at its best. You should always use Powerful Machinery’s certified shackles and consult sizing charts before making a selection. If you feel unsure about sizing or need a custom solution, try these steps:

Test the fit with your anchor chain before use.

Bring a few chain links to verify pin compatibility.

Always check for quality and compliance with standards.

Resource Type | Description |

|---|---|

Custom Solutions | Tailored options for unique project needs, including size or material. |

Customer Support | Expert help with questions and product selection. |

Installation Instructions | Step-by-step guides for proper shackle installation. |

Contact Powerful Machinery for expert advice or custom solutions to ensure every connection is safe and reliable.

FAQ

How do you know when a shackle needs replacement?

You should replace a shackle if you see visible wear, deformation, cracks, or corrosion. If the pin does not fit securely or the markings become unreadable, choose a certified replacement from Powerful Machinery to maintain safety.

What is the best way to measure a shackle for replacement?

Use a digital caliper for the body and pin diameter. Use a measuring tape for inside width and length. Always compare your measurements to the manufacturer’s sizing chart before ordering a replacement.

How to select the right shackle size for your application?

Check your load requirements and measure the connection points. Match your measurements to the sizing chart. Always choose a shackle with a working load limit that meets or exceeds your needs for safe operation.

Can you use a different shackle size as a replacement?

Never substitute a different size unless it matches all critical dimensions and load ratings. Using the wrong size can cause equipment failure. Always confirm compatibility with the sizing chart before making a replacement.

Why is certification important when choosing a shackle?

Certification ensures the shackle meets international safety standards. Certified shackles from Powerful Machinery undergo rigorous testing, so you can trust their performance in demanding environments.