To measure anchor chain size, you need to check the diameter of the chain link and the overall dimensions using precise tools. Accurate measurement is essential for keeping your vessel safe and ensuring your windlass functions properly.

Marine safety organizations emphasize that knowing how to measure anchor chain size and using the correct chain size prevents windlass malfunctions and safety hazards. Compatibility with ISO-standard chains is critical for smooth operation.

Key Takeaways

Use precise tools like calipers for accurate measurements of anchor chain diameter and dimensions. This ensures safety and proper windlass function.

Regularly inspect and maintain your anchor chain to prevent wear and corrosion. This practice helps maintain strength and reliability.

Always measure multiple links to identify discrepancies in size. Averaging measurements leads to a more accurate determination of the required chain size.

Understand international standards like ISO and DIN to ensure compatibility with your vessel’s equipment. This knowledge prevents costly mismatches.

Avoid common mistakes such as measuring the wrong part of the chain or ignoring wear. Recognizing these errors enhances the reliability of your anchoring system.

Tools to Measure Anchor Chain

Choosing the right tools helps you measure your anchor chain accurately and safely. You want to ensure that every measurement reflects the true size and condition of your equipment.

Calipers and Rulers

You can use several tools to measure an anchor chain. Calipers provide high precision and are ideal for checking the diameter of each link. Rulers and tape measures work well for basic checks, such as measuring the length and width of links or the total chain deployed.

The table below compares the accuracy of these tools:

Measuring Tool | Accuracy Level |

|---|---|

Calipers | High precision |

Rulers/Tape Measures | Suitable for basic checks |

Some mariners also use the ribbon method, wrapping a flexible ribbon around the link and then measuring the ribbon with a ruler. This method helps when you need to measure curved surfaces or hard-to-reach areas.

Powerful Machinery’s anchor chains feature clear markings, making your job easier. Marked chains let you quickly identify how much chain you have deployed, which is critical for safe anchoring. You will find painted increments or webbing tabs on these chains, providing clear visual indicators.

Unmarked chains make it difficult to gauge the amount of chain in use, which can lead to errors.

Preparing the Chain

Before you start measuring, take a few simple steps to ensure accuracy and safety:

Mark the anchor chain at regular intervals to help you gauge the scope.

Measure from the anchor fitting to the waterline for accurate depth calculations.

Wear gloves when handling the chain to protect your hands from injury.

Tip: Regular maintenance keeps your measurements accurate. Inspect each link for rust or damage, repair broken links, lubricate the chain, rinse off salt, and keep the anchor locker dry.

Using the right tools and preparation steps ensures you get reliable measurements every time.

How to Measure Anchor Chain Size?

Accurate measurement of your anchor chain is essential for safety and compatibility. You need to follow a systematic approach to ensure you select the right chain for your vessel and anchoring system. Here’s how to measure anchor chain size step by step:

Calculate your vessel’s displacement in metric tons. This figure represents the weight of water your vessel displaces and determines the strength requirements for your anchor chain.

Use a chain size multiplier. Industry standards recommend a multiplier between 1/8 and 1/6 of your vessel’s displacement. This helps you estimate the minimum diameter needed for your anchor chain.

Multiply your vessel’s displacement by the chain size multiplier. This calculation gives you the minimum diameter required for safe anchoring.

You should always check the manufacturer’s recommendations and marine engineering standards before making a final decision. Powerful Machinery’s studless and stud link anchor chains provide clear specifications and engraved size markings, making it easier for you to measure anchor chain size and ensure compliance.

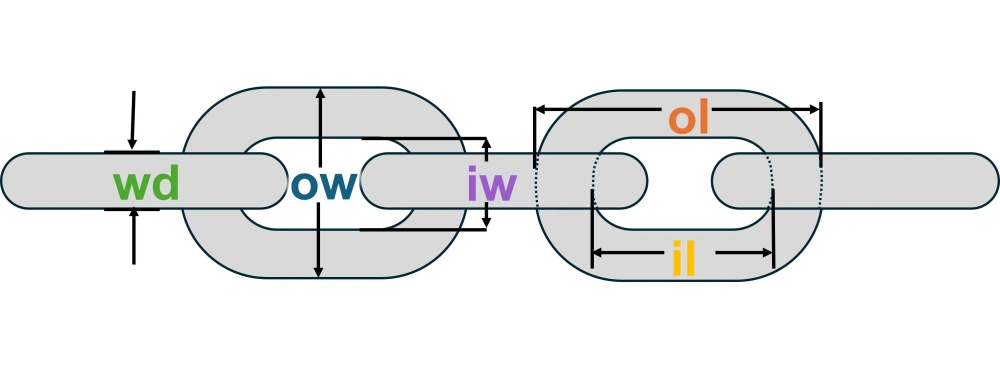

Measuring Link Diameter

To measure the diameter of your anchor chain, use a caliper for precision. Place the caliper across the thickest part of the chain link, which is known as the wire diameter. For example, if you have a 1/2-inch anchor chain, the wire diameter should measure exactly 1/2 inch.

Always measure at several points along the chain to confirm consistency. If your chain has engraved size markings, verify your measurements against these markings for accuracy.

Stud link anchor chains and studless anchor chains differ in design and measurement. The table below highlights the key differences:

Feature | Stud Link Anchor Chain | Studless Link Chain |

|---|---|---|

Design | Contains a stud in each link | No stud in the link |

Strength | Higher due to stud reinforcement | Lower, more flexible |

Weight | Heavier | Lighter |

Flexibility | Less flexible | More flexible |

Applications | Large vessels, offshore | Smaller vessels, recreational |

You need to measure the wire diameter for both types, but stud link chains may require you to measure around the stud for an accurate reading.

Measuring Link Length and Width

Measuring the length and width of each chain link is crucial for compatibility with your windlass gypsy. Use a ruler or caliper to measure from the outside edge to the opposite outside edge for both length and width. This ensures your anchor chain fits properly into the windlass and operates smoothly.

The table below shows common chain specifications and their compatibility with windlass gypsies:

Gypsy Number | Chain Specification | Rope Diameter | Rope Construction |

|---|---|---|---|

006 | 6mm ISO 4565, 1/4″ G40*, 1/4″ BBB | 12-14mm | 3 strand, 8 plait |

000 | 7mm ISO 4565, 1/4″ G40*, 1/4″ BBB | 12-14mm | 3 strand, 8 plait |

001 | 8mm DIN 766, 8mm ISO 4565 | 12-16mm | 3 strand, 8 plait |

002 | 10mm DIN 766, Campbell 3/8″ S4, 5/16″ G40 | 12-16mm | 3 strand, 8 plait |

003 | 10mm ISO, Campbell 3/8″ S3, Lewmar 9.5mm G40 | 16mm | 3 strand, 8 plait |

Note: Always measure the outside-to-outside dimensions for both length and width. This method helps you avoid windlass mismatch and ensures smooth operation.

Measuring Multiple Links

You should measure several links along your anchor chain, not just one. This practice helps you identify any minor discrepancies in link size, which can occur due to wear or manufacturing tolerances.

By averaging your measurements, you get a more precise determination of the required anchor chain size. This step is especially important when you need to measure the anchor chain for replacement or compatibility checks.

Powerful Machinery’s anchor chains often feature engraved size markings, which allow you to double-check your measurements and ensure you select the correct chain for your vessel. If you notice significant variation between links, consider replacing the chain to maintain safety and reliability.

Tip: Regularly inspect and measure your anchor chain, especially before long voyages or after heavy use. Consistent measurements help you maintain optimal performance and avoid costly mistakes.

By following these steps, you learn how to measure anchor chain size accurately and ensure your equipment meets industry standards. Whether you use a studless or stud link chain, precise measurement protects your vessel and guarantees compatibility with your anchoring system.

Anchor Chain Standards

Common Standards (ISO, DIN)

When you select an anchor chain, you need to understand the main international standards that define its dimensions and performance. The two most common standards are ISO and DIN. These standards help you ensure that your chain will fit your vessel’s windlass and meet safety requirements.

ISO and DIN 766 chains have different-sized links for some sizes of chain.

The dimensions of DIN and ISO chains are generally the same, except for a 10 mm difference in certain sizes.

ISO chains have greater tolerances compared to DIN chains, making them somewhat interchangeable.

You should always check which standard your vessel’s equipment requires. This step prevents costly mismatches and ensures smooth operation.

Why Standards Matter?

International standards do more than set measurements. They protect you, your crew, and your vessel by ensuring every anchor chain meets strict guidelines for design, manufacturing, and testing. When you use chains that comply with recognized standards, you reduce the risk of accidents and equipment failures.

Aspect | Description |

|---|---|

Standard Name | BS ISO 1704:2022 |

Purpose | Provides guidelines for design, manufacturing, and testing of anchor chains. |

Safety Enhancement | Reduces risk of accidents and failures in maritime operations. |

Equipment Compatibility | Ensures anchor chains are compatible with various marine vessels and anchor systems. |

Release Date | February 24, 2022 |

Document Length | 42 pages |

You can trust Powerful Machinery’s anchor chains because they comply with major international standards and hold certifications from leading organizations:

Certification | Description |

|---|---|

CCS | China Classification Society |

KR | Korean Register of Shipping |

GL | Germanischer Lloyd |

LR | Lloyd’s Register |

BV | Bureau Veritas |

RS | Russian Maritime Register of Shipping |

ISO9001:2008 | Quality management certification |

Tip: Always verify the certifications and standards before purchasing or installing a new chain. This practice ensures safety and compatibility for every voyage.

Common Mistakes When You Measure Anchor Chain

Measuring your anchor chain may seem straightforward, but many mariners make errors that can compromise safety and equipment performance. You need to recognize these common mistakes and learn how to avoid them.

Wrong Dimensions

You might measure the wrong part of the chain or use inaccurate tools. This mistake often leads to improper sizing, which affects how well your anchor holds. If you select the wrong size, your anchor may not grip the seabed, causing your vessel to drift.

Short chains prevent the anchor from reaching deep enough, while chains that are too long create unnecessary drag and instability.

Tip: Always measure the wire diameter at the thickest part of the link and confirm the length and width from outside edge to outside edge. Use calipers for precision.

The table below highlights frequent sizing errors reported in marine survey reports:

Mistake | Impact on Performance |

|---|---|

Measuring the wrong link dimension | The anchor fails to grip the seabed |

Using an incorrect chain standard | Chain jumps under windlass load |

Not checking the number of links | Fails Class Society Rules |

Ignoring Wear

You may overlook chain wear and corrosion, especially in the intergrip area. Even minor corrosion reduces the strength of your anchor chain and can lead to failure during heavy loads. Accurate measurements help you assess the residual strength and ensure your chain remains within safe limits.

Note: Regularly inspect and measure your chain diameter. Replace chains that show significant wear or corrosion to maintain safety.

Windlass Mismatch

Selecting a chain that does not match your windlass gypsy is a classic error. For example, the difference between DIN766 and ISO4565 10mm chains is about 2mm per link. This small gap causes the chain to jump under load, risking damage to your windlass and anchor system.

Chain Standard | Link Size | Windlass Compatibility Issue |

|---|---|---|

DIN766 | 10mm | May not fit ISO gypsy |

ISO4565 | 10mm | May not fit DIN gypsy |

Callout: Powerful Machinery offers product support and customization. You can consult their experts to select the correct chain size and standard for your vessel, ensuring compatibility and safety.

By understanding these mistakes and following best practices, you improve the reliability of your anchoring system and protect your vessel.

Conclusion

Measuring anchor chain size accurately protects your vessel and ensures smooth anchoring. Use calipers and follow manufacturer guidance for best results. Always check the diameter, pitch, and width of several links. Before installation, review this checklist:

Start with manufacturer guidance

Measure the diameter of the bar and wire

Measure ten links, outside edge to outside edge

Measure the pitch and width of each link

Compare eight links with the new chain links

Certified anchor chains from Powerful Machinery offer high strength, corrosion resistance, and excellent abrasion resistance. If you have questions, consult an expert for peace of mind.

FAQ

How often should you measure your anchor chain?

You should measure your anchor chain at least once a year. Check before long trips or after heavy use. Regular measurement helps you spot wear and ensures your chain remains safe and reliable.

What is the best way to clean and maintain your anchor chain?

Rinse your anchor chain with fresh water after each use. Dry it completely before storage. Inspect for rust or damage. Apply a rust inhibitor if needed. Proper care extends the life of your chain.

How do you know when to replace your anchor chain?

Replace your anchor chain if you see deep rust, worn links, or reduced diameter. If any link looks damaged or weak, replace the chain immediately. Never risk your vessel’s safety with a compromised chain.

How to choose your anchor chain for your vessel?

You should match the chain size to your vessel’s displacement and windlass requirements. Always check international standards and manufacturer recommendations. Consult experts if you have doubts about compatibility or safety.

Can you mix different types of anchor chains on one vessel?

Avoid mixing different types or sizes of anchor chains. Using chains with different standards or materials can cause uneven wear and equipment failure. Always use a single, certified chain type for best performance.