You must use a come-along safely and effectively to prevent serious accidents. Always check your equipment, follow proper technique, and stay alert. Many injuries result from improper use, including amputations, fractures, and back injuries. The table below highlights the most common incidents:

Type of Injury/Incident | Description |

|---|---|

Caught in Equipment | Workers can get caught or tangled in the winch or lines, leading to serious injuries or fatalities. |

Slips and Falls | Wet and slippery conditions near winches can cause falls. |

Amputation | Hands and fingers can be lost during the operation. |

You protect yourself and others by handling a come-along with care.

Key Takeaways

Always inspect your come-along winch for damage before use. This step ensures safety and reliability.

Secure the winch to a strong anchor point and attach the load properly. This prevents accidents during operation.

Wear appropriate safety gear, including gloves and safety glasses. Protecting yourself reduces the risk of injuries.

Follow safe operating procedures and avoid overloading the winch. This practice ensures safe and efficient use.

Perform regular maintenance on your come-along to extend its lifespan and maintain safety. Consistent care prevents equipment failure.

Come Along Winch Overview

What Is a Come Along?

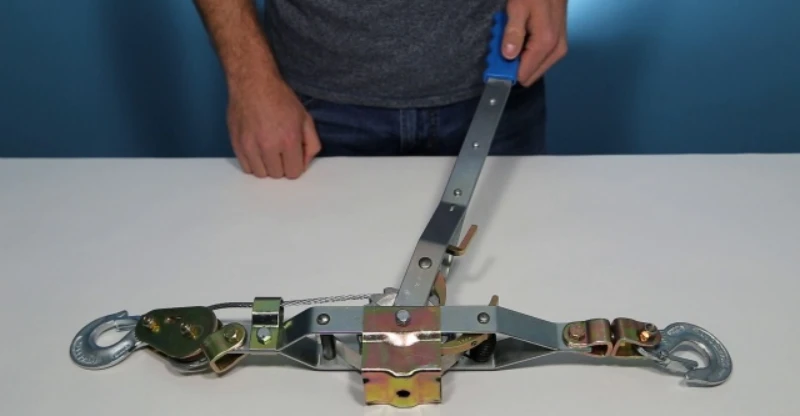

A come-along is a manual, hand-operated device that helps you pull, stretch, or move heavy objects. You use a ratcheting gear mechanism and a steel cable or strap to control the load. When you crank the handle, the cable tightens around a drum, pulling the load toward an anchor point.

This ratcheting action gives you precise control and prevents the load from slipping backward. Many people also call this tool a hand winch. The main parts include a ratchet lever, a drum with a steel cable or chain, and strong hooks for secure attachment.

When you use a cable come-along, you gain a mechanical advantage that makes moving heavy loads much easier.

Main Uses and Benefits

You can use a come-along winch in many settings, from construction sites to home garages. The table below shows common applications for different types of winches:

Type of Winch | Common Applications |

|---|---|

Air Winches | Mining, oil and gas, and marine settings |

Electric Winches | Industrial worksites, workshops, construction |

Hydraulic Winches | Heavy industrial use, energy infrastructure, marine |

Hand Winches | Davit cranes, boat trailers, farm sheds, and garages |

When you choose a come-along, you get several key advantages:

Portability: You can carry it easily to different locations.

Simple Operation: You do not need special training to operate a come-along.

Quick Setup: You can set it up fast, which helps in emergencies.

Powerful Machinery’s Come-Along Tool

Powerful Machinery offers a come-along tool that stands out for its strength and reliability. You benefit from a robust design, heavy-duty hooks, and an ergonomic handle that makes operating a come-along comfortable and safe.

The tool uses high-quality materials and a precise ratchet mechanism, so you can trust it for demanding jobs. Powerful Machinery’s products meet strict international standards, giving you peace of mind when you need to move or secure heavy loads.

If you want a certified, high-performance come-along, you can rely on Powerful Machinery’s expertise and proven track record.

How to Use a Come Along: Step-by-Step Guide

Inspection and Preparation

Before using a come-along, you must inspect the tool thoroughly. This step ensures your safety and the reliability of the equipment. Begin by preparing the come-along for use in a clean, well-lit area. Follow this step-by-step guide to inspection:

Visually inspect the come-along winch for any visible damage, corrosion, or deformation. Look for cracks, rust, oil leaks, and loose bolts.

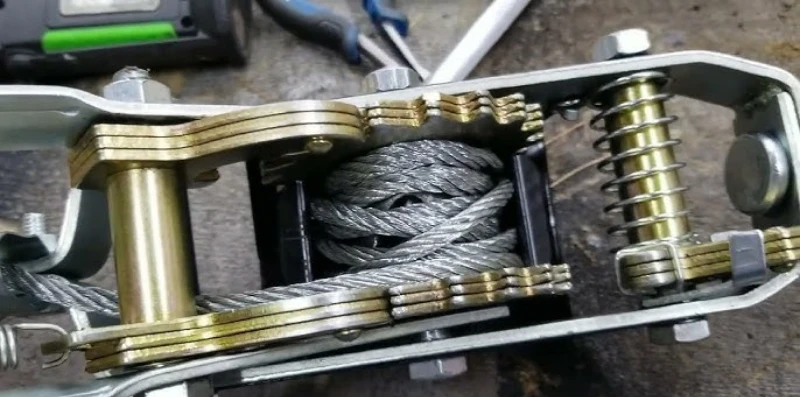

Check all mechanical parts, including the ratchet, brakes, and wire rope, to confirm they function properly.

Review the control systems and ensure all safety features, such as emergency stops, work as intended.

Test the tool under a controlled load to verify it can handle its rated capacity.

Check maintenance logs and inspection records to confirm the tool has been properly serviced.

When inspecting and maintaining the come-along, pay close attention to these common signs of wear or damage:

Fraying, kinks, or bulges in the wire rope.

Strange noises like grinding or squeaking during operation.

Discoloration or stiffness in the rope may indicate chemical contamination or shock load damage.

Cuts, flat areas, or open strands in the rope.

Excessive roughness or glossy spots that suggest heat damage.

Inspect the hooks for proper shape and any signs of bending or cracks.

If you notice any of these issues, do not use the tool. Report the problem to a qualified professional.

Tip: Always wear gloves and safety glasses during inspection to protect your hands and eyes from sharp edges or debris.

Attaching and Setting Up

Proper setup and operation techniques are essential for safely securing loads and achieving efficient load movement. Start by choosing a flat, stable surface for your work. Position the come-along winch so the cable runs straight between the anchor point and the load.

Avoid offline pulls, as they can increase stress on the tool and reduce pulling power.

Follow these steps for attaching the load and setting up:

Disengage the ratchet mechanism and spool out the wire rope, leaving a few wraps on the drum.

Attach the heavy-duty hook to a secure anchor point that can withstand the force of lifting heavy loads.

Connect the other hook to the load, ensuring it is stable and balanced.

Remove slack from the cable by gently pulling it tight.

Double-check all connections and make sure the hooks are fully engaged.

If you need extra pulling power, use a double-line pull. This technique reduces strain on the cable come along and improves control. Always plan your pull and use the right equipment for your specific applications.

Note: Powerful Machinery’s come-along tool features ergonomic handles and robust hooks, making setup easier and more secure.

Operating the Ratchet Mechanism

Once you have set up the come-along, you can begin lifting or pulling. The ratchet mechanism gives you precise control over load movement. To operate the ratchet:

Gradually engage the ratchet lever, applying steady force to the ergonomic handle.

Monitor the load as it moves, making sure it stays balanced and secure.

Avoid sudden jerks or rapid movements, which can cause the load to shift or the cable to snap.

If you hear unusual noises or notice inconsistent pulling, stop and inspect the tool before continuing.

Always use a secure anchor point and keep your hands clear of the cable and moving parts. The heavy-duty hooks and smooth ratchet action of Powerful Machinery’s come-along tool help you maintain control during lifting and pulling tasks.

Safety Reminder: Never exceed the rated capacity of your come-along winch. Overloading can lead to equipment failure and serious injury.

Safe Tension Release

Releasing tension safely is a critical part of using a come-along. Improper release can cause sudden movement and injuries. Follow these steps for a controlled release:

Locate the ratchet release lever and disengage the pawl to allow the ratchet to turn freely.

Maintain a firm grip on the handle to control the release of tension.

Slowly and steadily turn the handle, letting the cable coil back onto the drum.

Watch the cable as it winds, ensuring it does not tangle or snag.

Keep your hands and body away from the recoiling cable at all times.

After releasing the load, inspect the tool and store it in a dry, secure place. Regularly inspecting and maintaining the come-along extends its lifespan and ensures safe operation for future lifting tasks.

Pro Tip: Always plan your release before starting. Controlled tension release prevents accidents and protects both you and your equipment.

By following these steps, you can use a come-along winch safely and efficiently for lifting, pulling, and securing heavy objects in a variety of environments.

Safety Precautions and Common Mistakes

Essential Safety Gear

You must wear appropriate safety gear every time you operate a come-along. Personal protective equipment protects you from injuries and keeps you safe in hazardous environments. Make sure you and anyone nearby follow these guidelines:

Wear gloves to protect your hands from sharp edges and wire rope strands.

Use safety glasses to shield your eyes from flying debris or sudden cable movement.

Select clothing that fits the task and environment. Avoid loose sleeves or jewelry that could get caught.

Wear sturdy footwear with non-slip soles for better grip and stability.

Tip: Always check your gear before starting. Proper equipment can prevent most injuries.

Safe Work Practices

You improve safety and efficiency by following best practices when using a come-along. These steps help you avoid accidents and keep your equipment in top condition:

Get proper training and certification before operating a come-along. Understand the tool’s features and limitations.

Inspect and maintain your come-along regularly. Check for damage, wear, or corrosion before each use.

Calculate the load’s weight and compare it to the tool’s load capacity and weight ratings. Never exceed the pulling capacity.

Follow safe operating procedures. Keep a safe distance from the winch line and always wear appropriate safety gear.

Prepare for emergencies. Know how to stop the operation quickly and have a communication plan in place.

Note: Safe work habits protect you and your team from unexpected hazards.

Mistakes to Avoid

Many users make common mistakes that can lead to equipment failure or injury. You can prevent these problems by staying alert and following precautions:

Do not use too little winch rope or fail to use the full length. This can strain the tool and reduce efficiency.

Never overload the come-along. Always check the load capacity and weight ratings before starting.

Avoid misusing the tool for tasks it was not designed for, such as towing vehicles or lifting beyond its rated limits.

Do not ignore the forces involved in winching. Understand how much force you need and use the right tool for the job.

Stay clear of the winch line during operation. If the line snaps, it can cause serious injury.

Mistake | Consequence |

|---|---|

Using a winch not rated for the load | Equipment failure, loss of control over the load |

Failing to pre-tension the winch line | Increased risk of accidents and equipment damage |

Standing too close to the winch line | Serious injury if the line snaps |

Improper handling of winch lines | Potential for serious accidents and injuries |

Stay focused and follow all safety precautions to ensure a safe and successful operation.

Come Along Maintenance Tips

Proper maintenance keeps your come-along reliable and safe for every job. You extend the lifespan of your equipment and reduce the risk of failure by following a few essential routines.

Maintenance and Inspection Tips

Inspect the winch cable before and after each use. Look for kinks, fraying, or other damage that could cause breakage.

Keep the cable clean and dry. Dirt and moisture can lead to corrosion and weaken the cable come along.

Lubricate the gears regularly. Smooth operation prevents wear and ensures safe load movement.

Wind the cable evenly onto the drum. Uneven spooling can cause knots and tangles.

Run your come-along at least once a month. This practice prevents moisture buildup and keeps the internal parts lubricated.

Tip: Store your come-along in a dry, secure place to avoid rust and accidental damage.

Neglecting maintenance can lead to common issues such as power supply problems, cable malfunctions, or corrosion. You avoid these problems by staying consistent with your inspection routine.

Types of Come-Along Winches and Best Uses

Type of Winch | Best Use Cases | Description |

|---|---|---|

Manual Winch | Smaller loads, trailers, vehicles | Affordable, easy to install, hand-cranked or lever-operated |

Electric Winch | Heavy loads, large trailers, vehicles | Battery-powered, fast operation, ideal for frequent use |

Hydraulic Winch | Construction, mining, transportation | Most powerful, professional installation, handles extremely heavy objects |

Choose the right type for your specific needs to maximize efficiency and safety.

Practical Applications and Industry Expertise

You find come along winches in many industries. In construction, you lift heavy objects and align materials. Maritime crews use them for deploying anchors and handling equipment. Mining operations rely on them for hoisting minerals and machinery.

Emergency responders use portable winches for rescue operations. Powerful Machinery supports these practical applications with certified products and expert guidance, ensuring you get the right solution for your toughest jobs.

Conclusion

To use a come-along safely, you should always follow these steps:

Inspect the tool for damage before each use.

Secure it to a strong anchor point.

Attach the load and operate the handle with care.

Keep your body clear of the equipment and load.

You protect yourself and your team by wearing proper safety gear, planning your work, and performing regular maintenance. Choosing certified tools like Powerful Machinery’s Come Along Tool ensures quality, durability, and advanced safety features. Prioritize safety and consult professionals for complex tasks.

FAQ

What is the maximum load capacity of Powerful Machinery’s come-along tool?

You can safely handle loads up to 3 tons with Powerful Machinery’s come-along tool. Always check the load rating before each use to prevent overloading and ensure safe operation.

Can you use a come-along outdoors in harsh conditions?

Yes, you can use this tool outdoors. The durable construction and high-quality materials withstand tough environments, including rain and dirt. Always inspect the tool after exposure to harsh weather.

How do you maintain a come-along for long-term use?

Inspect the wire rope and hooks before and after each use. Lubricate the ratchet mechanism regularly. Store the tool in a dry place. Clean off dirt and moisture to prevent corrosion.

Is the wire rope on the come-along replaceable?

You can replace the wire rope if it shows signs of wear or damage. Always use a compatible replacement and follow the manufacturer’s instructions for installation.

What safety gear should you wear when operating a come-along?

Wear gloves to protect your hands, safety glasses for your eyes, and sturdy footwear for stability. Avoid loose clothing or jewelry that could get caught in the tool.