Safe use of lifting equipment begins with your commitment to safety, awareness of risks, and strict adherence to regulations. When you handle hoists, cranes, or slings, you face real dangers—contact with objects and overexertion cause a significant portion of workplace injuries.

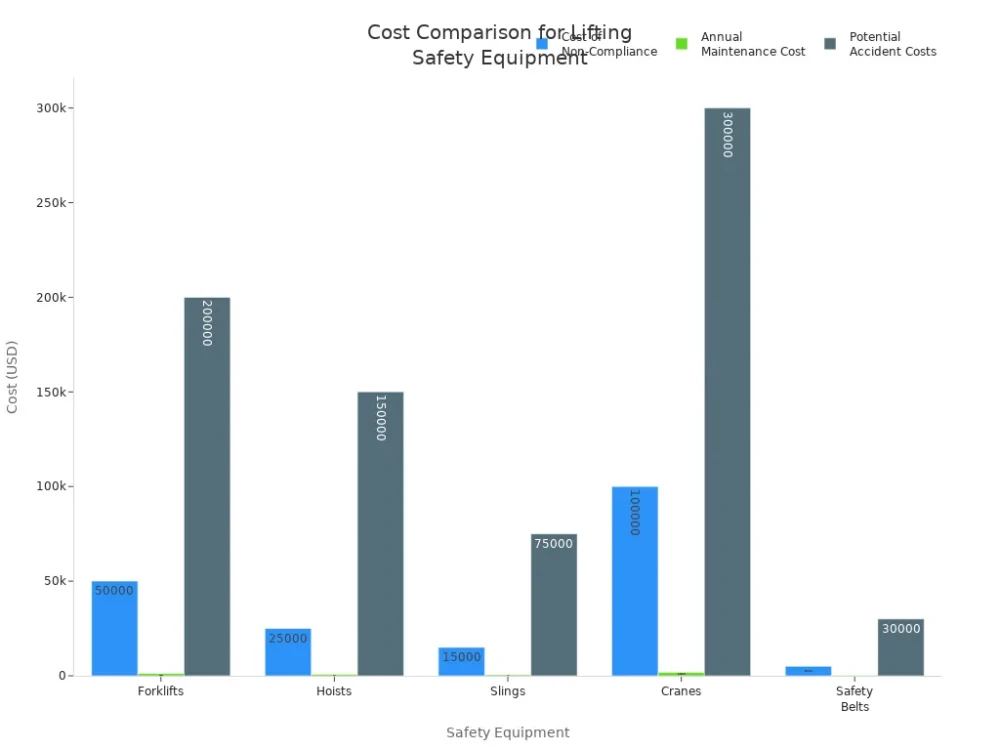

Ignoring safety not only risks serious accidents but also leads to costly downtime, medical bills, and legal issues.

Powerful Machinery delivers certified, high-performance solutions you can trust, supporting your goal to keep every lift secure and every worker protected.

Key Takeaways

Always inspect lifting equipment before use. Check for damage, wear, and ensure all safety systems function properly.

Match the load to the equipment’s rated capacity. Overloading can lead to serious accidents and injuries.

Wear appropriate personal protective equipment (PPE) to safeguard against workplace hazards during lifting operations.

Conduct a thorough workplace assessment to identify risks and ensure safe lifting procedures are in place.

Communicate clearly during lifting operations. Use standard signals and confirm instructions to prevent confusion.

Essential Safety Precautions for Lifting Equipment

Pre-Use Inspection

You must inspect lifting equipment before every use. This step helps you catch defects and prevent accidents. Begin by checking all slings for damage or wear. Examine shackles, eyebolts, and other rigging hardware for cracks or deformation. Make sure every piece of rigging equipment has a legible capacity tag.

Inspect load securing devices and tag lines for good condition. Confirm that you have the right rigging for the day’s lifts. Walk around the crane and look for leaks, loose bolts, or other hazards. Test each control function individually. Verify that all safety systems work as intended.

If possible, perform a light load test. Record your findings in the inspection log sheet. Brief your crew on the operational status of the equipment. Powerful Machinery designs products with clear capacity markings and robust construction, making inspections straightforward and reliable.

Inspect slings, shackles, eyebolts, and hardware

Check capacity tags and load securing devices

Test controls and safety systems

Record inspection results

Communicate equipment status to your team

Load Matching and Capacity

Matching the load to the equipment’s rated capacity is one of the most important precautions. You must identify the maximum rated capacity for your lifting machinery. Determine the load radius and boom length or angle. Consult the load chart to ensure the load weight stays within safe limits.

Use manufacturer specifications or a scale for accurate weight readings. If you estimate weight, calculate based on dimensions and material density. Accurate load determination prevents overloading and protects both workers and equipment.

Operating beyond rated capacity can cause catastrophic failures. For example, a 50-ton crane overloaded to 55 tons failed, injuring workers. Overloaded nylon slings have snapped, crushing workers.

Hydraulic cranes have tipped over when operators underestimated the load weight. These incidents show why you must always respect load limits and follow best practices for safe lifting.

Personal Protective Equipment

You need the right personal protective equipment to stay safe during lifting operations. Occupational safety standards require specific PPE for operators. The table below outlines the essential categories:

PPE Category | Description |

|---|---|

Foot protection | Protective boots and shoes to prevent injuries from falling debris and hazards. |

Head protection | Helmets or hard hats to protect against head injuries. |

Eye and face protection | Goggles, masks, and eyeglasses to safeguard against eye injuries. |

Fall protection systems | Lanyards, anchors, and harnesses to prevent falls from heights. |

Ventilation safety equipment | Gas masks and venting kits to ensure proper air quality in confined spaces. |

Hazardous Waste Operations PPE | Full-body protection for hazardous waste cleanup tasks. |

Occupational noise exposure PPE | Equipment to protect against harmful noise levels. |

You should always wear PPE that matches the hazards of your workplace. Powerful Machinery recommends using certified PPE with all lifting equipment to maximize safety.

Workplace Assessment

Assessing your workplace before lifting operations helps you identify risks and plan safe procedures. You must check that operators have proper training and authorization. Confirm that the load is compatible with the equipment and well-distributed.

Inspect lifting machinery and accessories before first use and at regular intervals. Evaluate ground conditions and look for hazards in pathways. PPE is mandatory when working at heights greater than 1.8 meters.

Factor | Description |

|---|---|

Operator Training | Workers must have the necessary training and authorization to operate lifting equipment safely. |

Load Weight Compatibility | Ensure the load is well-distributed and the equipment is suitable for the weight and shape. |

Regular Inspections | Lifting machinery and accessories should be inspected before first use and at specified intervals. |

Workplace Conditions | Assess risks in the workplace, including ground conditions and potential hazards in pathways. |

Personal Protective Equipment | PPE is mandatory when working at heights greater than 1.8 meters to ensure worker safety. |

You should also examine pathways for obstacles or slippery surfaces. Keep the area clean to reduce accident risks. Use proper footwear to prevent slips and falls. Powerful Machinery’s lifting equipment is engineered for stability and safety, supporting your efforts to maintain a safe workplace.

Avoiding Common Hazards

You face several hazards when using lifting equipment. Loads can crush workers if they move unexpectedly or fall due to improper slinging. Moving vehicles and collapsing structures pose risks, including cranes tipping over. Poor posture and repetitive tasks can cause musculoskeletal injuries.

Environmental factors like noise or slippery surfaces affect concentration and communication. Overhead electrical cables present serious dangers.

To avoid these hazards, follow these actionable steps:

Assess the task: Consider weights, distances, and heights.

Decide what can be lifted safely: Evaluate your capability and the environment.

Identify ways to reduce risk: Use mechanical aids if needed.

Re-arrange the task: Redesign tasks to avoid unnecessary lifting.

Assess the load: Break loads into smaller items or stabilize them.

Assess the environment: Clear obstructions and ensure safe pathways.

Plan tasks in advance: Collaborate and communicate with your team.

Use safe lifting techniques: Maintain good posture and lift with your legs, keeping the load close.

By following these safety precautions and best practices, you reduce the risk of accidents and injuries. Powerful Machinery’s commitment to quality and safety ensures that you have reliable equipment for every lift.

Best Practices for Safe Use of Lifting Machinery

Planning and Risk Assessment

You must start every lifting operation with careful planning and risk assessment. Identify everyone involved in the task. Analyze the job to find hazards. Score each risk by how likely and severe it is. Review your control measures before you begin. Inspect your lifting machinery before any activity.

Assess risks using a structured plan. Put your control measures in place and make sure everyone understands their role. When you learn from past incidents, you improve safety for future jobs. The Bureau of Labor Statistics reports that heavy machinery environments have the highest fatality rates.

Ongoing training and regular assessment help you prevent accidents and protect your team.

Identify all personnel involved

Analyze hazards and score risks

Review and implement control measures

Inspect equipment before use

Load Handling Techniques

You must use proper load handling techniques to ensure the safe use of lifting equipment. Select the right machinery for the job. Check that the loading area is level and clear. Secure the load with heavy-duty straps or chains.

Distribute weight evenly to avoid tipping. Inspect the unloading site for stability. Unload slowly and keep in contact with ground personnel. Only trained and certified workers should handle these tasks. Regular maintenance and inspections of your lifting machinery help you spot issues early and keep operations safe.

Choose suitable equipment

Secure and balance the load

Unload with care and communication

Involve trained personnel

Communication During Operations

Clear communication is vital during lifting operations. Use standard signals—verbal, hand, or radio—to direct actions. Assign one person to signal the operator. Confirm instructions before moving the load.

Keep eye contact when possible. Report any problems right away. If you feel unsure, stop the lift and review the plan. This approach reduces confusion and keeps everyone safe.

Use clear signals

Assign a single signaler

Confirm instructions

Stop if uncertain

Overload Protection Systems

Modern lifting machinery uses advanced overload protection systems to prevent accidents. These systems include load cells, limit switches, torque limiters, and electronic monitoring. Each device helps you stay within safe limits and protects both workers and equipment.

Type of System | Function |

|---|---|

Load Cells | Monitor force to ensure safe load limits |

Limit Switches | Stop the machinery at preset limits |

Torque Limiters | Disengage the load if the torque exceeds safe levels |

Electronic Monitoring Systems | Use sensors to alert operators to overload risks |

Powerful Machinery’s lifting equipment features robust overload protection, clear markings, and reliable construction. These features support your commitment to best practices and safety in every lift.

Regulatory Compliance for Lifting Equipment

Key Regulations Overview

You must follow strict regulations when you use lifting equipment. These rules protect workers and ensure safe lifting operations. Many countries use similar standards, but you should know the main ones:

Regulation/Standard | Description |

|---|---|

OSHA Regulations | Sets safety standards for lifting operations, including inspection and training. |

ASME Standards | Offers guidelines for safe operation and maintenance of lifting equipment. |

ISO Guidelines | Provides international standards for wire rope care and lifting safety. |

SOLAS Regulation | Requires safety checks for lifting appliances on ships. |

In the UK and Europe, the Lifting Operations and Lifting Equipment Regulations (LOLER) and the Provision of Work Equipment Regulations (PUWER) set the legal requirements for safe working loads and equipment use.

Powerful Machinery designs products to meet or exceed these international standards, giving you confidence in every lift.

Following lifting equipment regulations helps you avoid accidents, reduce downtime, and protect your team.

Equipment Marking and Documentation

You must keep your lifting equipment properly marked and documented. Regulations require you to display the working load limit clearly on each device. You also need to keep records that prove your equipment meets all legal requirements.

Document Type | Description |

|---|---|

Manufacturer’s Certificate | Proves the equipment can carry the rated working load limit. |

EC Declaration of Conformity | Confirms compliance with European standards. |

Report of Thorough Examination | Shows the equipment passed a full safety inspection. |

You should check that each piece of equipment has a visible tag with the rated load, manufacturer’s name, serial number, and other key details. If you repair or alter equipment, update the identification to show the repairer’s information. This process ensures you always know the safe working loads and the status of your gear.

Employer and Operator Responsibilities

You have important responsibilities under the lifting equipment regulations. As an employer, you must:

Make sure all lifting equipment is safe and strong enough for the job.

Appoint competent people to plan and supervise lifting operations.

Provide training for everyone involved.

Carry out risk assessments before each lift.

Arrange regular maintenance and inspections.

Keep records of all checks and repairs.

Operators must follow instructions, use equipment as intended, and report any problems right away. You must supervise every lift at a level that matches the task’s complexity and risk. By meeting these legal requirements, you create a safer workplace and avoid costly penalties.

Powerful Machinery supports your compliance efforts by supplying equipment that meets global standards and includes clear markings and documentation.

Inspection and Maintenance of Lifting Equipment

Routine Inspection Procedures

You must perform routine inspection procedures to keep lifting equipment safe and reliable. Start each shift with a visual check of hoists, chains, and clamps. Look for signs of wear, cracks, or corrosion. Use a safety inspection checklist to confirm that all moving parts work smoothly.

Record your findings and report any issues before using the equipment. Schedule regular inspections based on service conditions. For normal service, inspect yearly. In severe conditions, inspect monthly or quarterly. Qualified personnel should conduct annual inspections to meet safety standards.

Inspection Type | Frequency |

|---|---|

Periodic Inspection | Every 12 months (minimum) |

Severe Conditions | Monthly or quarterly |

Customized Schedule | As recommended by a qualified person |

Daily inspections by the operator help detect problems early and prevent equipment failure. Keep comprehensive records to support compliance and future improvements.

Maintenance Best Practices

You extend the life of lifting equipment by following maintenance best practices. Clean equipment regularly to remove dirt and debris. Lubricate chains and moving parts to reduce wear and prevent rust. Store equipment in dry, protected areas to avoid environmental damage.

Check hydraulic systems for leaks and maintain proper fluid levels. Train employees on correct usage to prevent damage and maximize longevity. Schedule preventative maintenance to catch issues before they become serious. Use high-quality spare parts and accessories for repairs.

Powerful Machinery offers maintenance support, including refurbishment and modernization services, to help you keep equipment in peak condition.

Tip: Regular maintenance checks and proper storage protect your investment and ensure safe operation.

Equipment-Specific Care (Hoists, Clamps, Chains)

You must care for each type of lifting equipment according to manufacturer’s guidelines. For hoists, always check load capacity and never exceed rated limits. Lubricate chains and moving parts often. Inspect hooks and lifting media before each shift.

For clamps, ensure the screw mechanism and safety lock work correctly. Confirm the clamp fits the beam securely. For chains, look for signs of stretching, corrosion, or broken links. Replace worn parts immediately.

Train personnel in proper operation and always lift loads vertically to avoid side pulls. Powerful Machinery’s products are designed for durability, making routine care straightforward and effective.

Check the load capacity before each use

Lubricate moving parts regularly

Inspect hooks, clamps, and chains for damage

Replace worn components promptly

Train operators in safe handling techniques

By following these inspection and maintenance steps, you protect your team and extend the life of your lifting equipment.

Lifting Equipment Training and Operator Competency

Training Stages and Certification

You must complete several steps to become a competent lifting equipment operator. The process begins with suitable training, where you learn how to operate machinery safely and understand workplace hazards. After you finish your training, you need to pass the written and practical exams to earn certification.

This certification and award prove that you meet industry standards and can handle lifting equipment responsibly. Your employer or supervisor will then evaluate your skills before you start working. These stages ensure you have the knowledge and ability to use lifting equipment safely.

Complete lifting equipment training to gain essential skills.

Pass certification exams to demonstrate your competence.

Undergo evaluation by your employer before operating equipment.

Powerful Machinery supports the importance of training by offering resources and guidance for proper training and certification. Their commitment helps you maintain high safety standards in every lift.

Ongoing Assessment and Re-Training

You must keep your skills sharp through ongoing assessment and re-training. OSHA regulations require you to undergo re-evaluation every three years. If your performance or knowledge falls short, you must complete additional training programs.

Employers have a continuous responsibility to assess your competence and ensure you follow safe practices. Regular refresher courses help you stay updated on new equipment and safety protocols. A culture of continuous learning encourages you to take ownership of your safety and seek improvement.

Regular training and assessment reduce workplace accidents and improve lifting techniques.

Health and Fitness Requirements

You need to meet health and fitness standards to operate lifting equipment safely. Employers should educate you on recognizing lifting hazards and using personal protective equipment. Training should cover equipment operation, communication protocols, and ergonomics.

You should avoid manual lifting above 35 pounds and use powered lifts or transfer aids instead. Refresh your training regularly and adjust tasks based on incident reports. These steps protect your health and ensure you work safely.

Requirement | Description |

|---|---|

Hazard Recognition | Learn to identify and reduce lifting risks. |

PPE Usage | Use protective gear for every lifting task. |

Ergonomics | Optimize workstations for safety and comfort. |

Powered Lifts | Use mechanical aids for heavy loads. |

Training Refresh | Update skills and knowledge regularly. |

Powerful Machinery encourages ongoing lifting equipment training and supports operator education to help you achieve safe and efficient lifting operations.

Conclusion

You achieve the safe use of lifting equipment by following strict safety precautions, adopting best practices, and maintaining regulatory compliance. Ongoing training and regular maintenance protect your team and equipment.

Investing in quality solutions from Powerful Machinery delivers proven results. The table below highlights key benefits seen in industry case studies:

Benefit | Description |

|---|---|

Cost Reductions | Simulation reduced crane operator training costs by over 60%, from $40,000 to $15,000. |

Enhanced Safety | Operators learn in a risk-free environment, lowering the chance of accidents. |

Improved Productivity | Efficient lifting solutions streamline work and minimize downtime. |

Choose reliable equipment and prioritize training to create a safer, more productive workplace.

FAQ

What safety checks should you perform before operating a forklift?

You need to inspect the forklift for leaks, tire damage, and faulty brakes. Check the forks for cracks. Test the horn and lights. Confirm the load capacity. Review the operator’s manual. Report any issues before you use the forklift.

How do you choose the right forklift for your workplace?

You must consider the load weight, lift height, and aisle width. Select a forklift that matches your material type. Review the manufacturer’s specifications. Ask your supervisor for guidance. Use a forklift that meets your workplace safety standards.

What personal protective equipment do you need when using a forklift?

You should wear a hard hat, safety shoes, and high-visibility clothing. Use gloves for better grip. Protect your hearing in noisy areas. Always wear a seatbelt when operating a forklift. Follow your company’s PPE policy for forklift operations.

How often should you maintain your forklift?

You need to perform daily checks before each shift. Schedule monthly and annual inspections. Clean and lubricate moving parts regularly. Replace worn components. Keep a maintenance log for every forklift. Proper care extends the life of your forklift.

What training do you need to operate a forklift safely?

You must complete forklift training from a certified instructor. Pass written and practical exams. Learn about load handling, workplace hazards, and emergency procedures. Refresh your skills every three years. Training helps you operate a forklift safely and efficiently.

Tip: Always follow your company’s forklift safety guidelines to prevent accidents and injuries.

Forklift Safety Tip | Description |

|---|---|

Inspect before use | Check the forklift for damage or defects |

Wear PPE | Use protective gear every time |

Follow load limits | Never exceed the forklift’s rated capacity |

Stay alert | Watch for obstacles and pedestrians |

Maintain regularly | Keep the forklift in top condition |