You want to know how to use the spring balancer safely, right? If you skip steps or ignore signs of wear, you can run into trouble. Overloading the device or mounting it the wrong way often leads to damage and injuries.

Not following manufacturer guidelines, poor maintenance, or using the balancer for the wrong tasks can cause unexpected failures. Powerful Machinery offers reliable spring balancers to help keep your tools secure and your workspace safe.

Key Takeaways

Always inspect your spring balancer before use. Check for safety latches, cable condition, and signs of wear to prevent accidents.

Mount your tool balancer securely using proper hardware. A stable setup reduces the risk of injuries and ensures smooth operation.

Adjust the tension according to your tool’s weight. Proper tension keeps your tool balanced and extends the life of the balancer.

Regularly maintain your spring balancer. Clean, lubricate, and inspect components to avoid costly repairs and ensure safety.

Avoid common mistakes like overloading or incorrect installation. Following guidelines helps keep your workspace safe and efficient.

What Is a Spring Balancer?

Spring Balancer Basics

You might wonder what makes a spring balancer so useful in your workspace. This device uses a coil spring to counterbalance the weight of your tools, making them feel almost weightless. You can move your tools up and down with little effort, which helps you work faster and with less strain.

Here’s a quick look at the main components of a tool balancer and how they work together:

Spring System: This is the heart of the device. It adjusts its tension to keep your tool balanced.

Steel Cable or Chain: This part holds your tool and connects it to the spring system.

Adjustment Mechanism: You use this to set the right height or load range for your tool.

Housing: This protects everything inside from dust and damage.

The working principle behind a spring balancer is simple. The adjustable spring inside creates an upward force that matches the weight of your tool. When you pull the tool down, the spring stretches, but it always wants to return to its original position.

This working principle lets your tool “float” in place, so you don’t have to lift or lower it every time you use it. The components of a tool balancer work together to keep your workspace safe and organized.

Here’s a table to help you see how a spring balancer functions:

Aspect | Description |

|---|---|

Definition | Uses a coil spring to counterbalance the tool’s weight for easy maneuverability. |

Mechanism | The robust spring provides a counterbalance, allowing effortless operation. |

Benefits | Improves ergonomics, boosts productivity, and reduces manual lifting. |

Tool Balancer Applications

You’ll find spring balancers in many industries. The working principle stays the same, but the tasks can change. In automotive assembly lines, you can use them to hold heavy tools above your workstation. In aerospace, they help you handle delicate parts with precision.

Manufacturing plants use them to keep tools handy and reduce worker fatigue. Construction sites rely on the components of a tool balancer to make lifting safer and easier.

Some common industries and their uses include:

Aerospace: Precision assembly tasks.

Automotive: Streamlining workflows on assembly lines.

Manufacturing: Improving efficiency and worker comfort.

Construction: Reducing strain during heavy lifting.

Engineering: Enhancing safety and productivity.

Powerful Machinery’s spring balancer stands out because of its rugged construction, unique cable drum design, and easy adjustments. You get a device that’s safe, reliable, and built for tough jobs.

How to Use Spring Balancer?

Learning how to use a spring balancer the right way keeps your workspace safe and your tools working smoothly. You want to avoid common mistakes and get the most out of your lifting equipment. Let’s walk through each step so you know exactly how to use a tool balancer from Powerful Machinery.

Inspect Before Use

Before you start, always check your tool balancer for safety and performance. You don’t want to risk using damaged lifting equipment. Here’s what you should look for:

Inspect safety latches. Make sure they lock and release as they should.

Check emergency stop mechanisms. Test them to confirm they work.

Look at the mounting points. They should be secure and free from movement.

Scan the cable for frays or broken strands.

Examine the spring for any signs of damage.

Search for cracks or corrosion on the housing.

Tip: If you spot any issues, don’t use the tool balancer until you fix or replace the damaged parts. Regular inspections help prevent accidents and keep your lifting equipment reliable.

Mounting the Spring Balancer

Mounting your tool balancer correctly is key to safe operation. You want your lifting equipment to stay secure and stable. Follow these best practices:

Use proper hardware. Heavy-duty bolts, clamps, or shackles rated for your tool’s weight work best.

Inspect the hanging point and accessories for rust, wear, or instability.

Position the tool balancer so your tools are easy to reach. This reduces strain and boosts efficiency.

Train everyone who uses the lifting equipment. Make sure they know how to use the spring balancer safely.

Always follow the manufacturer’s instructions for setup.

Note: A secure mount keeps your tool balancer working smoothly and protects your team from injuries.

Attaching and Adjusting Tools

Now you’re ready to attach your tools and adjust the settings. Matching the tool weight to the balancer’s capacity is crucial. If you overload your tool balancer, you risk damaging your lifting equipment and creating safety hazards.

Here’s a quick table to help you understand how to use a tool balancer with different weights:

Feature | Description |

|---|---|

Spring Force Adjustment Dial | Let’s you fine-tune tension for various tool weights |

Weight Capacity | 9-15 kg (19.8~33 lbs) |

Tool Weight | 3.61 kg (8 lbs) |

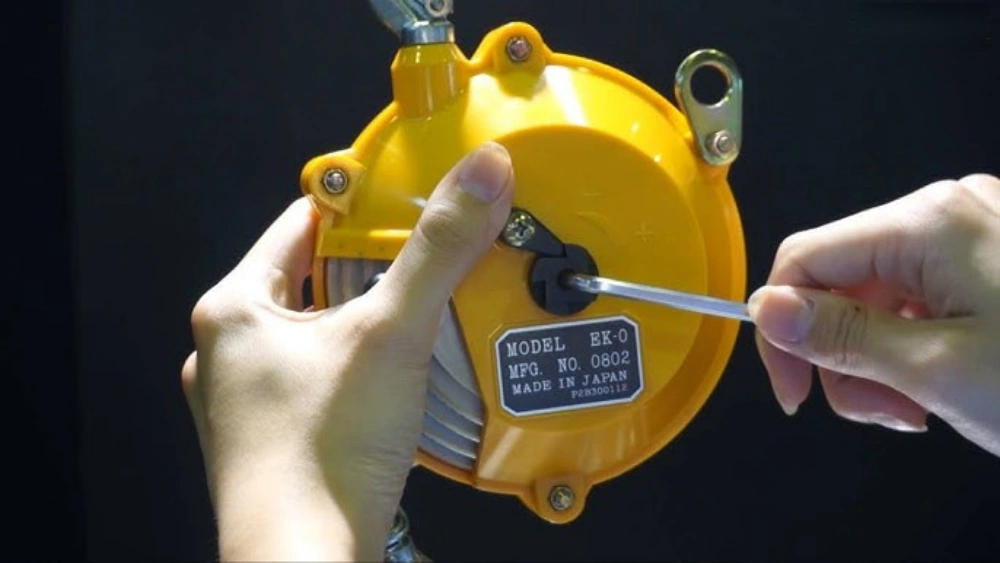

You can adjust the tension using the knob on the side of the tool balancer. The adjustable cable stop helps you set the right working height for your tool. Always check that the tool’s weight falls within the balancer’s rated capacity. This step is essential for safe and efficient lifting equipment use.

Tip: If you switch tools often, double-check the weight and readjust the tension each time. This keeps your tool balancer working at its best.

Testing the Tool Balancer

After installation, you need to test your tool balancer to make sure everything works as it should. Here’s a simple process you can follow:

Pull the tool down gently and let it return to its resting position.

Check if the tool “floats” at the desired height without drifting up or down.

Test the fall arrest device by simulating a sudden release. The tool should not drop.

Adjust the tension if the tool feels too heavy or too light.

Inspect the cable movement for smooth operation.

Confirm that all safety features, like the drum lock and emergency stop, work properly.

Make sure the tool balancer does not swing or twist during use.

Safety Alert: Never skip the testing step. It helps you catch problems before they lead to accidents or equipment damage.

Knowing how to use a spring balancer and how to use a tool balancer gives you confidence in your lifting equipment. You keep your workspace organized, your team safe, and your tools ready for action.

Common Mistakes with Spring Balancer

You want your tool balancer to work smoothly and safely, but small mistakes can lead to big problems. Let’s look at the most common errors people make and how you can avoid them.

Overloading the Tool Balancer

You might think your tool balancer can handle a little extra weight, but pushing it past its rated capacity causes trouble. Overloading leads to premature wear and tear. The tool balancer and the tool it supports both suffer.

Many users assume the device can handle more, but this increases the risk of mechanical failure. If you overload your tool balancer, you put your workspace and team at risk.

Tip: Always check the weight of your tool before attaching it. Stick to the manufacturer’s guidelines for safe operation.

Incorrect Installation

Setting up your tool balancer the wrong way can cause instability and accidents. Improper load capacity settings make your tools wobble or slip. Inadequate maintenance practices during installation can damage your tool balancer.

If your team doesn’t get proper training, they might mismanage the device, leading to safety hazards and inefficiencies.

Here’s a quick checklist for installation:

Confirm the mounting point is secure.

Set the load capacity to match your tool.

Train everyone who uses the tool balancer.

Skipping Regular Checks

You might feel tempted to skip inspections, but regular checks keep your tool balancer reliable. Annual inspections are required, and many workplaces enforce them with audits.

If you ignore these checks, you risk safety hazards and non-compliance with regulations. Neglecting maintenance can lead to unexpected downtime and costly repairs.

Alert: Create a schedule for inspections and stick to it. Regular checks help you catch problems early.

Improper Tension Adjustment

If you don’t adjust the tension correctly, your tool balancer won’t work as it should. Inadequate tension increases friction and corrosion, causing accelerated wear. Too much strain on the components leads to premature failure.

You might notice misalignment, decreased efficiency, or even total failure under load. The tool balancer loses its shape and energy storage, which affects performance.

Mistake | Consequence |

|---|---|

Wrong tension setting | Increased wear, misalignment |

Skipped adjustment | Tool instability, poor performance |

Take a moment to set the tension right every time you change tools. Your tool balancer will last longer and work better.

Spring Balancer Safety and Maintenance

Routine Maintenance Tips

You want your spring balancer to last and keep your workspace safe. Regular maintenance is the best way to make that happen. Start by inspecting all parts before each shift. Look for loose bolts, worn cables, or any signs of rust. Clean the housing and moving parts to prevent dust and grime from building up.

Lubricate the cable and spring as recommended by the manufacturer. Test the tension adjustment and make sure the tool floats smoothly. Always match the balancer to the tool’s weight and check that the safety latches and emergency stop work.

Here’s a quick checklist for your routine:

Inspect all components for wear or damage.

Clean surfaces and moving parts.

Lubricate according to manufacturer guidelines.

Test tension and load adjustments.

Check safety latches and emergency stops.

Keeping up with these steps helps you avoid costly repairs and keeps operator safety front and center.

Safety Features of Powerful Machinery Spring Balancer

Powerful Machinery builds spring balancers with advanced safety features. You get a fall arrest device that catches your tool if the spring breaks. The drum lock lets you change cables or tools securely.

A tension gauge makes it easy to set the right balance for each tool. These features help prevent accidents and keep your workspace organized.

Safety Feature | What It Does |

|---|---|

Fall Arrest Device | The stops tool drops if the spring fails |

Drum Lock | Secures cable and tool changes |

Tension Gauge | Shows you the current tension setting |

Secondary Support | Adds extra security for heavy loads |

When to Replace or Service?

You need to know when your spring balancer is ready for service or replacement. Watch for these signs:

The tool feels heavy or hard to lift.

The tool doesn’t stay at the set height.

You see gaps or rust in the spring.

The cable squeaks or moves unevenly.

The balancer struggles or stops mid-use.

If you notice any of these, stop using the device and call for professional service. Most spring balancers last over five years with regular care, but heavy use or harsh environments can shorten that time. Early detection of wear lets you fix small problems before they become big ones.

Regular maintenance saves money and keeps your equipment running smoothly. Emergency repairs cost more and can lead to unexpected downtime.

Conclusion

You want your spring balancer to work safely every time. Start with these quick steps before each use:

Inspect for wear or damage.

Check cable and spring tension.

Match the tool weight to the balancer.

Clean and lubricate moving parts.

Test safety latches and emergency stops.

Choosing a spring balancer with the right certifications keeps your workspace safe. Here are some you might look for:

Certification Type | Description |

|---|---|

ATEX-certified | Safe in explosive environments |

ESD-safe | Prevents static discharge |

Food-grade | For food processing and packaging |

Cleanroom | Minimal particle emission |

Pick a certified, reliable product like Powerful Machinery for the best results.

FAQ

How do you choose the right spring balancer for your tool?

You need to check your tool’s weight and pick a spring balancer with a matching capacity. Always look at the product’s rated range. If your tool is too heavy or too light, the balancer won’t work as intended.

Can you adjust the tension on a spring balancer?

Yes! You can turn the tension adjustment knob or dial. This lets you set the perfect balance for your tool. Always test the tool after adjusting to make sure it “floats” at the right height.

What should you do if the cable gets frayed or damaged?

Stop using the spring balancer right away. Replace the cable or call a professional for service. Using a damaged cable can cause accidents or tool drops.

How often should you inspect your spring balancer?

You should inspect your spring balancer before every shift. Look for signs of wear, loose parts, or damage. Regular checks help you catch problems early and keep your workspace safe.

Can you use a spring balancer outdoors?

You can use a spring balancer outdoors if it’s rated for outdoor environments. Always check the manufacturer’s guidelines. Keep the device clean and dry to prevent rust or damage.