You play a crucial role in maintaining ASME B30.20 lift magnet safety at your facility. Operator training, regular inspections, maintenance, and testing help you prevent accidents and meet regulatory requirements.

These practices keep your team safe and your operations compliant. Powerful Machinery provides certified products and solutions that support your safety goals every day.

Key Takeaways

Regular training for operators is essential. It reduces accidents and ensures safe handling of lifting magnets.

Always inspect lifting magnets before use. Look for cracks, wear, and missing labels to maintain safety.

Match the lifting magnet to the load type and material. This prevents unsafe lifting practices and enhances performance.

Follow ASME B30.20 guidelines for maintenance and testing. This keeps your equipment compliant and reliable.

Use certified lifting equipment to improve safety and efficiency. It helps meet industry standards and reduces risks.

ASME B30.20 Overview

Standard Scope and Coverage

You need to understand the full scope of ASME B30.20 to ensure safe lifting magnet operations. This standard covers a wide range of requirements that help you maintain safety and compliance in your facility. The table below outlines the key areas addressed by ASME B30.20:

Requirement Type | Description |

|---|---|

Definitions, scope, references | Covers the general framework and terminology used in ASME B30.20. |

General construction and installation | Guidelines for the proper construction and installation of lifting devices. |

Inspection and testing standards | Standards for the inspection and testing of lift magnets and other devices. |

Crane operator training and operation | Requirements for training operators to safely use lifting devices. |

General maintenance and training | Guidelines for the maintenance and training of personnel involved. |

Lifting magnet design requirements | Specific design criteria for lift magnets to ensure safety and functionality. |

Electrical component requirements | Standards for the electrical components used in lifting devices. |

Mechanical design requirements | Guidelines for mechanical aspects including rigging hardware and fasteners. |

Structural and connection design | Requirements for the structural integrity of lifting devices. |

Classification based on lifting capacity | Classifies devices according to their lifting capabilities. |

By following these requirements, you help your team meet industry certifications and maintain a safe work environment.

OSHA and BTH-1 Relationship

You must also recognize how ASME B30.20 interacts with other important standards and regulatory bodies. Here is how these relationships work:

OSHA recognizes ASME B30.20 specifications as a reference for inspections.

This recognition ensures that below-the-hook lifting devices are inspected according to established standards.

Compliance with these standards is essential for safety and regulatory adherence.

Both ASME B30.20 and ASME BTH-1 play a critical role in ensuring your lifting magnets meet OSHA compliance. You should always check that your equipment carries the proper certifications and is marked according to these standards. This approach helps you avoid regulatory issues and supports a safer workplace.

Types of Lifting Magnets

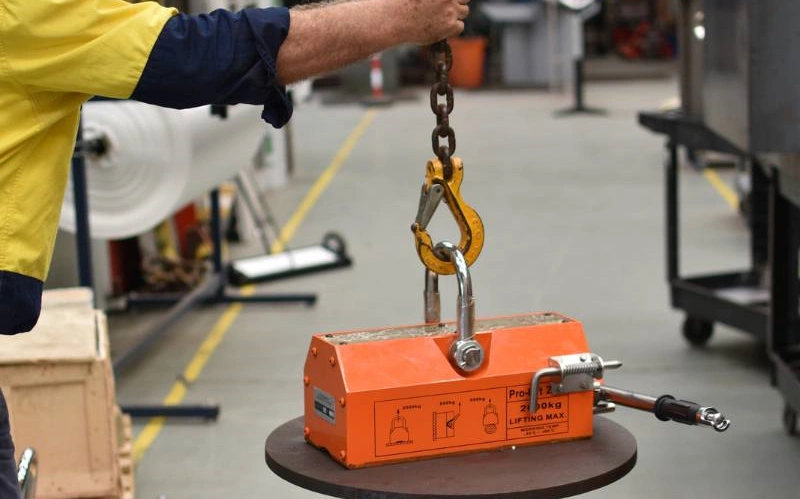

Permanent Magnet Lifters by Powerful Machinery

You can rely on permanent magnet lifters for safe and efficient lifting magnet operations. These devices use powerful Nd-Fe-B magnets and do not require electricity. This design makes them fail-safe during power outages.

You benefit from a tear-off force that is at least three times the working load limit, which adds an extra layer of safety. Permanent magnet lifters from Powerful Machinery offer a compact design and easy one-hand operation.

You can use them for close-proximity magnet lifting tasks in factories, docks, and warehouses. When you choose these lifters, you reduce the risk of dropped loads and improve workplace safety.

Electromagnets and Other Types

Electromagnets provide another option for lifting magnet applications. You can achieve higher lifting capacities and deeper magnetic fields with these devices. Electromagnets require a continuous power supply, so you must monitor for power failures.

Safety features like automatic warnings and backup systems help secure loads if the power fails. You may use electromagnets for proximity magnet lifting or remote operations, depending on your facility’s needs.

Other types, such as battery-powered magnets, also support various lifting magnet tasks, but you should always match the device to your specific application.

Close Proximity vs. Remote Operation

You must understand the difference between close-proximity magnet lifting and remote operation. The table below outlines the main types recognized by ASME B30.20:

Type of Lifting Magnet | Definition |

|---|---|

Close-proximity operated lifting magnets | A lifting magnet is used in such a fashion that the operator manually positions the lifting magnet on the load. |

Remotely operated lifting magnets | A lifting magnet that does not require the operator to be in proximity to the lifting magnet or its load. |

When you perform proximity magnet lifting, you face risks such as pinched fingers or crushed hands. You should never stand under a lifting magnet carrying a load.

Remote operation reduces some hazards, but you still need to assess the environment and train your team. Always follow ASME B30.20 standards for every lifting magnet operation.

ASME B30.20 Lift Magnet Safety Guidelines

Operator Training and Qualification

You must ensure that every operator handling a lifting magnet receives thorough training and proper qualification. ASME B30.20 lift magnet safety starts with knowledgeable personnel. Operators should understand how to position the lifting device, recognize load limits, and follow all safety guidelines.

Training programs must cover the correct use of lifting magnets, emergency procedures, and the importance of regular inspection and maintenance. Powerful Machinery supports your commitment to lift magnet safety by offering certified products and resources that align with industry standards.

When you invest in operator training, you reduce the risk of accidents and create a safer work environment.

Tip: Schedule refresher courses for your team to keep their skills sharp and up-to-date with the latest standards.

Load Limits and Material Suitability

You must always match the lifting magnet to the load and material type. ASME B30.20 lift magnet safety guidelines require you to consider several factors before every lift. The table below highlights what you need to check:

Factor | Description |

|---|---|

Material Thickness | Thicker materials allow for full saturation of the magnetic field, enhancing holding strength. |

Surface Condition | Clean surfaces without rust, paint, or oil to prevent air gaps that can reduce performance. |

Magnet Size and Rating | Must match the loads handled; oversizing can lead to operational difficulties, especially with thin materials. |

Design Factor | A minimum design factor of three-to-one is required, ensuring safety margins in lifting operations. |

Understanding Magnetic Interaction | Operators must recognize how different materials affect holding power to avoid unsafe lifting conditions. |

A lifting magnet rated for 800 pounds must achieve a breakaway pull test of at least 2,400 pounds on clean, flat steel. You should always derate magnets when lifting thin, dirty, or irregular steel. Misunderstanding load limits can lead to unsafe lifting practices and increase the risk of dropped loads.

Powerful Machinery’s certified lifting magnets are clearly marked with load ratings and designed to meet or exceed ASME B30.20 standards, supporting your lifting device safety program.

Environmental and Operational Risks

You face many environmental and operational risks when using a lifting magnet. ASME B30.20 lift magnet safety guidelines require you to assess the workspace before every lift. Dust, moisture, extreme temperatures, and poor lighting can all affect lifting magnet performance.

You must also consider operational risks, such as improper handling or decommissioning of magnetic lifting systems. Always follow established safety protocols and handle components with care to prevent accidents and equipment damage.

ASME B30.20 outlines inspection requirements, documentation procedures, and safety protocols for every stage of the lifting device lifecycle. Powerful Machinery’s products are engineered for reliability in demanding environments, helping you maintain lifting device safety even in challenging conditions.

Inspect the area for hazards before each lift.

Keep surfaces clean and dry.

Follow all decommissioning and maintenance procedures as outlined in the standards.

Electronic and Medical Device Precautions

You must take special precautions when operating a lifting magnet near electronic or medical devices. Strong magnetic fields can disrupt pacemakers, hearing aids, and sensitive equipment.

ASME B30.20 lift magnet safety guidelines recommend keeping a safe distance between the lifting device and any electronic or medical device.

Always post warning signs and inform your team about these risks. Powerful Machinery includes clear safety labels and documentation with every certified product, helping you communicate hazards and comply with safety guidelines.

Note: If you or your team members use medical devices, consult a qualified professional before working near lifting magnets.

By following these safety guidelines and using certified products from Powerful Machinery, you strengthen your lift magnet safety program and ensure compliance with ASME B30.20 standards. Regular inspection, maintenance, and testing keep your lifting operations safe and reliable.

Lift Magnet Safety Best Practices

Warning Labels and Manufacturer Support

You must always check for clear warning labels before using any lifting magnet. These labels alert you and your team to the presence of strong magnetic fields. Place warning signs next to the work area to caution anyone nearby.

Reliable manufacturers, such as Powerful Machinery, provide lifting magnets with proper warning labels already attached. You should also keep the manufacturer’s instructions and support information close at hand. This helps you follow the correct procedures and ensures you use the equipment as intended.

Place strong magnet warning labels near all lifting magnet operations.

Use only lifting magnets that arrive from the manufacturer with proper warning labels.

Keep manufacturer instructions available for reference.

Surface and Load Preparation

You need to prepare both the surface and the load before every lift. Clean, debris-free surfaces allow the magnet to grip the material securely. Dirt, rust, or oil can weaken the magnetic hold and increase the risk of accidents.

Proper surface preparation improves the effectiveness of the magnet and supports safe lifting. Always inspect the load and surface before starting any operation. This step is essential for both safety and successful lifting.

Remove dirt, rust, and oil from the load surface.

Check that the surface is flat and free from debris.

Inspect the load and magnet before each use.

Injury and Dropped Load Prevention

You can prevent injuries and dropped loads by following strict procedures. Only trained and authorized personnel should operate lifting magnets. Always read and understand the instructions before use. Inspection before and after each lift is critical.

Maintain a 3:1 safety factor for every lift. Stay clear of the load while it is in motion. Never stand under a suspended load. Pay attention to the load until it is safely placed. Use a spreader bar for large plates when needed. Move and lower the load gently to avoid sudden shifts.

Read all instructions before operating.

Allow only authorized personnel to use lifting magnets.

Inspect the magnet before and after each use.

Ensure a 3:1 safety factor for every lift.

Stay clear of the load during lifting.

Never stand under a suspended load.

Watch the load until it is safely placed.

Use a spreader bar for large plates.

Move and lower loads smoothly.

By following these best practices, you strengthen your safety program and reduce the risk of accidents. Regular inspection and proper maintenance keep your lifting magnets reliable and effective.

ASME Inspection Standards for Lifting Magnets

You must follow strict ASME inspection standards to keep your lifting operations safe and compliant. These standards outline inspection requirements for every stage of a lifting magnet’s use. By following these guidelines, you reduce the risk of equipment failure and protect your team.

Every Lift Inspection

Before you use a lifting magnet, you need to perform a visual inspection. This step helps you catch any obvious issues that could affect safety. You should check the magnet before and during each lift. Look for cracks, worn parts, or missing labels. If you find any problems, do not use the magnet until you fix them.

Inspection Type | Frequency |

|---|---|

Visual Inspection | Before and during each lift |

Frequent Inspection | As per defined intervals |

Periodic Inspection | As per defined intervals |

You should always follow the inspection requirements set by ASME B30.20. Powerful Machinery designs its lifting magnets to make these checks easy. Clear markings and robust construction help you spot issues quickly.

Frequent and Periodic Inspections

You need to understand the difference between frequent and periodic inspections. Frequent inspections happen daily or before each shift. You look for signs of wear, damage, or missing parts. Periodic inspections are more detailed and occur less often. The frequency depends on how you use the magnet.

Inspection Type | Frequency |

|---|---|

Initial | Before first use (new, modified, or repaired) |

Frequent | Daily or each shift before use |

Periodic | Annually (normal service) |

Monthly (severe service) | |

As recommended by a qualified professional |

You must document each inspection and keep records for reference. These records help you track the condition of your equipment and prove compliance with ASME inspection standards. Powerful Machinery supports your inspection program by providing clear guidelines and documentation tools.

Tip: Schedule periodic inspections based on your facility’s workload and environment. If you operate in harsh conditions, increase the inspection frequency.

Idle Magnet Inspection

When a lifting magnet sits idle for a long time, you must inspect it before returning it to service. This process ensures the magnet remains safe and ready for use. Follow these steps:

Inspect the lift magnet surface for rust or damage.

Check the handles and safety latches for smooth operation.

Assess the lifting ball or eye hook for wear.

Look for cracked housing, damaged welds, or loose bolts.

Verify that warning labels and capacity markings are present and readable.

Inspect all other parts for signs of damage.

Replace any missing or damaged parts.

Update warning labels and capacity markings if needed.

Conduct load testing to confirm performance.

You should never skip these inspection requirements. Powerful Machinery’s certified products come with detailed instructions to guide you through each step.

Inspection Documentation

Proper documentation is a key part of ASME inspection standards. You must record every inspection, including the date, findings, and any corrective actions. Keep these records organized and accessible. This practice helps you demonstrate compliance during audits and supports ongoing safety.

Use inspection checklists for consistency.

Store records in a secure location.

Review documentation regularly to spot trends or recurring issues.

Powerful Machinery offers support tools and templates to help you manage your inspection requirements. By maintaining accurate records, you ensure your lifting magnets stay in top condition and meet all safety and testing standards.

Note: Good documentation not only protects your team but also extends the life of your equipment.

By following these inspection requirements, you create a safer workplace and maintain compliance with ASME inspection standards. Powerful Machinery stands ready to support your inspection and testing needs with certified products and expert guidance.

Maintenance and Testing Protocols

Maintenance Program Essentials

You need a strong maintenance program to keep your lifting magnets safe and reliable. Start by scheduling regular maintenance for close-proximity magnet lifting devices. Clean all surfaces and check for rust or damage. Lubricate moving parts and inspect safety levers.

Replace worn components right away. Use standardized inspection checklists to make sure you do not miss any steps. A good maintenance program helps you catch problems early and avoid costly downtime.

Maintain detailed logs of all maintenance activities.

Use checklists for every inspection.

Document all component replacements.

Keep operator training records up to date.

Testing Requirements and Procedures

You must perform testing after any repair or major maintenance. Testing of repaired close-proximity magnet lifting devices ensures they meet safety standards before you return them to service. Always conduct a load test to verify the magnet’s holding power.

Follow the manufacturer’s instructions and ASME B30.20 guidelines for testing. Annual certifications help you prove that your equipment remains safe and compliant. Testing also includes checking warning labels and capacity markings for clarity.

Tip: Schedule testing after repairs, modifications, or any incident that could affect magnet performance.

Recordkeeping for Maintenance and Testing

Accurate recordkeeping supports your compliance with ASME standards. You should keep detailed records for every inspection, maintenance, and testing activity. Store these records in a secure location and review them regularly. The table below shows what you need to track:

Aspect | Details |

|---|---|

Inspection Frequencies | Guidelines on how often to inspect lifting magnets and related equipment. |

Documentation | Importance of maintaining records for compliance with ASME standards. |

Equipment Types | Includes shackles, hooks, hoists, and below-the-hook devices. |

You must also keep accurate records of load tests and annual certifications. Good documentation helps you spot trends, plan future maintenance, and show compliance during audits.

Removal and Repair Criteria

When to Remove from Service?

You must remove a lifting magnet from service when you notice any signs of damage, malfunction, or wear. Cracks in the housing, missing warning labels, or loose bolts signal immediate risk. If the magnet fails a load test or inspection, you should not use it.

Rust, corrosion, or bent hooks also indicate unsafe conditions. You need to act quickly to prevent accidents. Tag the magnet as “Out of Service” and inform your team.

Only trained personnel should handle the removal process. You protect your workplace by following these steps and keeping unsafe equipment away from daily operations.

Tip: Always tag and isolate any lifting magnet that does not meet ASME B30.20 standards. This step prevents accidental use and keeps your team safe.

Steps for Safe Repair and Return

You must follow strict procedures when repairing and returning a lifting magnet to service. ASME B30.20 outlines clear steps to ensure safety and compliance:

Disconnect all power sources. Lock out and tag the lifting magnet as “Out of Service.”

Relieve fluid pressure from all circuits before removing any components.

Assign only designated personnel to perform repairs and tests.

Use replacement parts that meet or exceed the original manufacturer’s specifications.

Inspect the lifting magnet after repairs. Follow the inspection guidelines in ASME B30.20 para. 20-3.3.4.

Maintain dated records of all repairs and replacements.

You must conduct operational tests on new or repaired lifting magnets. These tests verify that the magnet meets all safety standards.

Load tests are required for all new, altered, or repaired magnets. The rated load must exceed the maximum breakaway force.

Note: Keep detailed records of every repair and test. Accurate documentation helps you track equipment history and supports compliance during audits.

You ensure a safe return to service by following these steps. Powerful Machinery provides certified products and expert support to help you meet every requirement.

Product Value and Compliance

Powerful Machinery Permanent Magnet Lifter Advantages

You gain a clear advantage when you choose a Powerful Machinery permanent magnet lifter for your operations. These lifting magnets deliver consistent performance and help you meet strict safety standards.

The design ensures you can lift heavy loads without relying on electricity, so you avoid risks during power outages. You also benefit from a flexible tool that adapts to different shapes and sizes of steel, making it ideal for many industries.

Here is a quick look at what sets these lifting magnets apart:

Advantage | Description |

|---|---|

Safe and Reliable | Maintains a strong grip even if power fails, reducing accident risks. |

Flexible and Versatile | Handles a wide range of materials and shapes, supporting various lifting tasks. |

Environmental Protection | Operates without electricity, saving energy and lowering pollution. |

You can trust these lifting magnets to perform in demanding environments. The robust construction and clear labeling make every inspection easier and more effective. When you use certified below-the-hook lifting equipment, you show your commitment to workplace safety and operational excellence.

Value of Certified Lifting Equipment

Certified lifting equipment brings real value to your workplace. You reduce the risks that come with manual handling, such as back injuries or repetitive stress. Safe lifting magnet design follows ergonomic principles, which help your team work more efficiently and with fewer injuries.

Regular training and inspection routines keep your equipment in top shape and support compliance with industry regulations.

You improve productivity by using equipment that is easy to operate and maintain.

You lower the chance of accidents, which means less downtime and fewer costly repairs.

Certified operators and equipment help you pass audits and meet OSHA and ASME requirements.

By investing in certified lifting magnet solutions, you create a safer, more efficient workplace. You also extend the life of your equipment and protect your team from avoidable hazards.

Conclusion

You play a vital role in upholding ASME B30.20 lift magnet safety at your facility. This standard guides you through construction, operation, and inspection, helping you reduce risks and maintain compliance. Certified products from Powerful Machinery meet strict industry requirements, giving you confidence in every lift.

Regular training and maintenance programs support ASME B30.20 lift magnet safety.

Only qualified personnel should perform repairs and adjustments.

Keep accurate records of all inspection and maintenance activities.

Consult with industry experts or manufacturers to keep your safety program current and effective.

FAQ

What should you check during a lifting magnet inspection?

You need to look for cracks, worn parts, and missing labels. Always verify that the magnet operates smoothly. If you find any issues, remove the magnet from service until you fix the problem.

How do you ensure safety when using lifting magnets?

You must follow the manufacturer’s instructions and ASME B30.20 guidelines. Only trained personnel should operate lifting magnets. Always keep warning labels visible and never stand under a suspended load.

Can you use a permanent magnet lifter on thin steel plates?

You should avoid lifting thin materials with permanent magnet lifters. Thin steel reduces magnetic contact and holding power. Always check the material thickness before starting any lift.

How often should you perform maintenance on lifting magnets?

You need to schedule regular maintenance based on usage and environment. Daily checks and annual certifications help keep your equipment reliable. Always document each maintenance activity for future reference.

What is the best way to store lifting magnets when not in use?

You should store lifting magnets in a dry, clean area. Keep them away from electronic devices and moisture. Always inspect the magnet before returning it to service.