You use a geared trolley to move heavy loads smoothly along beams in factories, warehouses, and construction sites. This device supports safe and efficient material handling, helping you avoid unnecessary lifting risks. Making the right industrial trolley selection reduces workplace injuries.

For example, in large infrastructure projects, choosing the correct trolley can lead to a 30% drop in manual handling injuries, as shown below:

Impact Area | Statistic |

|---|---|

Reduction in manual handling injuries | 30% reduction reported in large infrastructure projects |

Powerful Machinery stands out as a trusted provider of certified lifting solutions. You can rely on their expertise and high-quality products to keep your operations safe and productive.

Key Takeaways

Geared trolleys help move heavy loads safely and efficiently, reducing the risk of manual handling injuries by up to 30%.

These trolleys use a hand chain and gears, allowing for smooth movement and precise control, making them ideal for industrial settings.

Choosing the right trolley based on load capacity and beam compatibility is crucial for safe operation and to avoid costly mistakes.

Powerful Machinery offers a range of high-quality trolleys that meet strict safety standards, ensuring reliability and durability in tough environments.

Regular maintenance and inspections are essential to extend the life of your geared trolley and ensure safe operation.

Geared Trolley Basics

Definition and Function

A geared trolley is a powerful device that helps you move heavy loads along a beam in factories, warehouses, and construction sites. You attach the trolley to an overhead track, such as an I-beam or H-beam.

The trolley uses a special gearing system that lets you move heavy items with less effort. You pull a hand chain or lever, and the gears inside the trolley help it roll smoothly along the beam.

You use geared trolleys for many important jobs in industrial settings. These trolleys make it easy to move heavy pallets, machines, and equipment across large spaces. You can also use them to lift and position items in high storage areas or to move parts between workstations.

Geared trolleys help you work safely and efficiently because they reduce the need for manual lifting and lower the risk of injury.

Tip: Geared trolleys are especially useful when you need to move loads over 500 kg or when you want to avoid risky manual handling.

Here is a table that shows the main functions of geared trolleys in your workplace:

Functionality | Description |

|---|---|

Material Handling | Lets you move loads smoothly along overhead tracks or beams. |

Heavy Load Management | Handles heavy objects and helps you use space more efficiently. |

Efficiency and Safety | Improves how quickly and safely you can move materials in your operation. |

Mechanism and Operation

You operate a geared trolley by pulling a hand chain. This chain turns gears inside the trolley. The gears then rotate the wheels, which move the trolley along the beam. This system gives you precise control over movement, even when handling very heavy loads.

You do not need to push or pull the load directly. Instead, the gearing mechanism does most of the work for you.

Here is a quick look at how the mechanism works:

Feature | Description |

|---|---|

Mechanism | You use a hand chain to turn gears that move the trolley wheels. |

Movement | The trolley moves smoothly and steadily along the beam. |

Load Capacity | Most geared trolleys can carry loads from 0.5 to 5 tons or more. |

Installation | You can adjust the trolley to fit different beam widths. |

Applications | You use geared trolleys in factories, warehouses, and construction. |

You get several advantages when you use a geared trolley instead of a push trolley:

You need less effort to move heavy loads.

You get smoother and more controlled movement.

You can handle much heavier loads, which is ideal for industrial work.

Powerful Machinery Product Overview

Powerful Machinery gives you a wide range of high-quality trolleys for your lifting needs. You can choose from several types, including the Geared Beam Trolley, Beam Trolley, and Push Beam Trolley. Each product is designed to help you move loads safely and efficiently.

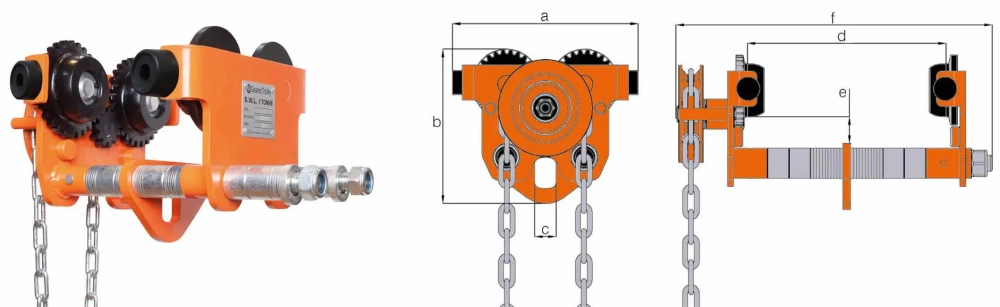

Geared Beam Trolley: This trolley uses a hand chain and gears for precise movement. You can adjust it to fit different beam sizes. It is perfect for heavy-duty lifting in factories and warehouses.

Beam Trolley: You use this trolley for manual movement along beams. It works well in places without power and is easy to install and maintain.

Push Beam Trolley: This trolley lets you move loads by pushing them along the beam. It is simple, reliable, and works in tight spaces.

Powerful Machinery tests every batch of trolleys to meet strict quality standards. The products comply with major certifications, such as ASME/ANSI B30.16, OSHA, and EU Directives (2006/42/EC). You can trust these trolleys to perform safely and reliably in your toughest jobs.

Note: Powerful Machinery also offers custom solutions, so you can get a trolley that fits your exact needs.

Key Features and Benefits

Load Capacity and Durability

You need a trolley that can handle the weight of your materials day after day. Geared trolleys offer impressive load capacities, ranging from 1/4 ton up to 20 tons. This wide range lets you choose the right trolley for your specific needs. You can find models that suit light tasks or heavy-duty lifting.

Geared trolleys stand out for their robust construction. Manufacturers use strong materials like steel and aluminum, which means these trolleys last for years even under tough conditions. Compared to other trolley types, geared trolleys require less maintenance and provide reliable performance over time.

Safety and Maintenance-Free Design

Safety is a top priority in any industrial trolley selection. Modern geared trolleys include features that help prevent accidents and keep your team safe.

Safety Feature | Description |

|---|---|

Locking Mechanisms | Prevents accidental movement during operation. |

Robust Construction | Ensures durability and stability, reducing the risk of failure. |

You also benefit from maintenance-free designs. Many geared trolleys use sealed bearings and modular parts. These features reduce downtime and lower operating costs. Some gearboxes and brakes can work for up to 10 years without service. This means you spend less time on repairs and more time getting work done.

Versatility and Space Optimization

You want equipment that adapts to your workspace. Geared trolleys offer adjustable frames that fit different I-beam widths. This flexibility allows you to use the same trolley across multiple facilities. The compact design works well in tight spaces, such as machinery bays or storage racks.

By moving loads overhead, you free up valuable floor space and reduce ground-level hazards. This makes your operation safer and more efficient.

Adjustable frames fit various beam sizes.

Compact footprint suits areas with limited headroom.

Overhead operation reduces floor congestion and improves safety.

Suitable for retrofit projects where space is limited.

Powerful Machinery Advantages

When you choose Powerful Machinery, you get more than just a trolley. You receive products that meet strict international certifications, including ISO9001, TUV Rheinland, and CE marking. Every trolley undergoes rigorous testing to ensure safety and reliability.

Powerful Machinery also offers custom solutions, so you can match your trolley to your exact requirements. Their commitment to quality, safety, and customer support makes them a trusted partner for your industrial trolley selection.

Tip: Choosing a certified and durable trolley from a reputable provider like Powerful Machinery helps you maximize productivity and minimize risks in your workplace.

Industrial Trolley Selection Guide

Assessing Load and Beam Compatibility

You need to start your industrial trolley selection by checking the load and beam compatibility. This step helps you avoid common mistakes and ensures safe operation. You must look at the actual load, not just the static weight. Consider dynamic forces and always apply a safety factor.

Duty cycle classifications tell you how often and how hard the trolley will work. This affects how long your equipment lasts. You also need to measure the beam specifications. Make sure the trolley fits the beam type, whether it is an I-beam or an H-beam. Measure the flange width and thickness to guarantee a proper fit.

Factor | Description |

|---|---|

True Load Requirements | Assess the actual load considering dynamic forces, not just static weight. Apply a safety factor to ensure equipment can handle unexpected stresses. |

Duty Cycle Classifications | Understand how often and how hard the trolley will work, which affects its thermal and mechanical endurance. |

Beam Specifications and Compatibility | Ensure the trolley fits the beam type (I-beam vs. H-beam) to prevent instability and wear. Measure flange width and thickness to ensure proper fit and structural integrity. |

Mistakes in industrial trolley selection often happen when you ignore these factors. Side-loading puts extra stress on the trolley and beam. Overloading can cause permanent damage. Modifying trolleys to fit non-standard beams is risky and can lead to mechanical failures.

Over-torquing adjustment rods may result in uneven pressure and shorten the trolley’s lifespan.

Tip: Always check the manufacturer’s guidelines before making adjustments. Never modify a trolley to fit a beam it was not designed for.

Mistake | Description |

|---|---|

Side-loading | Pulling the load from the side rather than lifting it vertically can cause undue stress and failure. |

Overloading | Exceeding the weight capacity can lead to permanent damage and increased risk of failure. |

Modifying the trolley | Altering the trolley for non-standard beams can lead to mechanical failure and void warranties. |

Over-torquing | Over-tightening adjustment rods can cause bending and uneven pressure distribution, shortening lifespan. |

Safety Features and Material Quality

You want your trolley to keep your team safe and last for years. Look for advanced safety features that reduce the risk of workplace accidents. Precise load positioning lets you place heavy items exactly where you need them. This reduces mishandling and accidents.

Trolleys that reduce manual effort help prevent injuries and improve efficiency. Extremely durable designs withstand harsh conditions and keep your operation running smoothly.

Safety Feature | Benefit |

|---|---|

Precise Load Positioning | Enables exact placement, reducing the risk of mishandling and accidents. |

Reduces Manual Effort | Less physical strain on operators, enhancing safety and efficiency. |

Extremely Durable | Withstands harsh conditions, ensuring reliable performance and safety. |

Material quality matters in industrial trolley selection. You should choose the right material for your environment and application. Standard steel works for general use. Stainless steel resists corrosion in food processing or chemical plants.

Galvanized steel is best for outdoor use. High-quality steel handles heavy-duty, long-term industrial work. Aluminum alloy offers sturdy, corrosion-resistant performance.

Material Type | Application |

|---|---|

Standard Steel | General applications |

Stainless Steel | Corrosive environments like food processing |

Galvanized Steel | Outdoor use |

High-Quality Steel | Heavy-duty, long-term industrial use |

Aluminum Alloy | Sturdy, corrosion-resistant materials |

Note: Powerful Machinery offers trolleys in a range of materials, including stainless steel and high-tensile alloys, to match your specific needs.

Comparing Geared, Beam, and Push Trolleys

You need to compare different trolley types to make the best industrial trolley selection. Geared trolleys use a gearing mechanism and handle heavier loads. You get better control and reduced manual effort, which is ideal for long distances and industrial lifting.

Manual push trolleys have a simpler design. You operate them by pushing, so they suit lighter loads and short distances. Beam trolleys move along beams and require secure tightening. They can carry significant loads but may pose safety risks if not used correctly.

Trolley Type | Mechanism | Load Capacity | Performance Characteristics | Applications |

|---|---|---|---|---|

Geared Trolley | Equipped with a gearing mechanism | Heavier loads | Reduced manual effort, better control, suitable for longer distances | Industrial lifting, heavy loads |

Manual Push Trolley | Operated manually | Up to 10 tonnes | Simpler design, suitable for lighter loads, less control | Light material handling, short distances |

Beam Trolley | Moves along beams | Varies | Requires secure tightening, can be unsafe if improperly used | Beam traversing, general lifting |

Geared trolleys: Best for heavy loads and precise movement.

Manual push trolleys: Good for lighter loads and simple tasks.

Beam trolleys: Useful for general lifting, but require careful installation.

Tip: Match the trolley type to your application. For heavy-duty lifting, choose a geared trolley. For basic material handling, a push or beam trolley may be enough.

Powerful Machinery Selection Tips

You can make your industrial trolley selection easier by following these practical tips from Powerful Machinery:

Choose a trolley that can safely carry your maximum expected load. Always check both static and dynamic load ratings.

Select materials based on your environment and how often you use the trolley. Steel works for heavy-duty jobs. Stainless steel suits hygiene-sensitive industries.

Consider wheel types for maneuverability and floor protection. Match wheel size to your load and terrain.

Look for ergonomic designs. Handles and features that improve comfort and safety help your team work better.

Make sure your trolley has brakes, stability features, and proper weight distribution. These features prevent accidents.

Pick trolleys based on your application. High-capacity carts work well in warehouses. Stainless steel trolleys fit the food and pharma sectors.

Powerful Machinery also offers customization options to meet your unique needs. You can request brand customization, such as OEM services, color, and logo adjustments. Material customization includes options for T80/T100 chains, copper, stainless steel, and aluminum alloys.

You can add features like 360° operation, load limiting, rust-proofing, and electronic scales. Chains can be polished, electro-galvanized, or blackened for extra durability. Packaging can be tailored to your requirements, including color boxes and wooden boxes.

Customization Type | Details |

|---|---|

Brand Customization | Offers OEM services, color, and logo adjustments. |

Material Customization | Options for T80/T100 chains, copper, stainless steel, and aluminum alloys. |

Functionality Customization | Features such as 360° operation, load limiting, rust-proofing, and electronic scale. |

Chain Customization | Chains can be polished, electro-galvanized, or blackened for durability. |

Packaging Customization | Custom packaging based on customer needs, including color boxes and wooden boxes. |

Powerful Machinery’s expert team can help you select and customize the right trolley for your operation. You get certified products, reliable support, and solutions tailored to your business.

Installation and Maintenance

Setup Steps

You need to install your geared trolley correctly to ensure safe operation. Start by checking all parts for damage before assembly. Make sure you select the right trolley size for your beam and confirm that the supporting structure can handle the load.

Adjust the trolley so it fits the beam width and sits centered. Tighten all nuts and bolts according to the manufacturer’s instructions. Always reattach runway end stops if you remove them during installation. If your trolley has an anti-tilt device, check that it moves freely and is set correctly.

Here is a table of common installation errors and checks you should perform:

Common Installation Errors | Additional Checks |

|---|---|

Worn wheel treads, damaged flanges, and bearings | Correct trolley size for the runway beam |

Loose wheels or axle pins | Proper adjustment—centered and correct side clearance |

Bent or distorted side plates or load bar | Anti-tilt device—correct setting and freedom of movement |

Wear on load-bearing parts | Correct hoist—properly fitted and suitable |

Cracked or poor welds | |

Incorrect or substituted parts | |

Damaged or corroded hand chain | |

Illegible markings (SWL, ID, etc.) | |

Pre-installation check for storage damage | |

Structural adequacy of the supporting structure | |

Correct selection for type and capacity | |

Beam compatibility | |

Width adjustment for adjustable trolleys | |

Reassembly check after fitting | |

Runway end stops are securely reattached | |

Anti-tilt device not obstructed | |

Tightening as per specifications | |

Electrical safety for powered hoists |

Tip: Always follow the manufacturer’s manual for installation. Never use damaged or mismatched parts.

Maintenance Best Practices

You can extend the life of your geared trolley by following a regular maintenance routine. Lubricate all moving parts at the intervals recommended by the manufacturer. Use the right lubricant for your load and working conditions. Apply lubricant carefully to avoid overheating.

Monitor the lubrication system and train your team on proper techniques. Add lubrication checks to your routine maintenance schedule.

Lubricate gears and wheels regularly.

Choose the correct lubricant for your application.

Monitor for signs of wear or inadequate lubrication.

Train staff on safe lubrication practices.

Create a preventive maintenance plan that includes lubrication.

Use technology to track maintenance schedules.

You should also inspect your trolley often. OSHA recommends inspections every 1 to 12 months. The Crane Manufacturers Association of America (CMAA) suggests a periodic load test every 3 to 4 years.

Source | Inspection Frequency |

|---|---|

OSHA | 1 to 12-month intervals |

CMAA | Every 3 to 4 years (load test) |

Regular inspections help you catch problems early and keep your equipment safe.

Powerful Machinery Support

You get reliable after-sales support when you choose Powerful Machinery. Their team responds quickly to questions and helps you solve problems fast. The logistics team ensures your orders arrive on time and without hassle. Many customers report high satisfaction with Powerful Machinery’s service.

You can count on their experts for help with installation, maintenance, and troubleshooting. This level of support helps you keep your operations running smoothly and safely.

If you need help, Powerful Machinery’s support team stands ready to assist you at every step.

Conclusion

You now understand why choosing the right geared trolley is essential for safety and efficiency. Informed industrial trolley selection helps you avoid risks and improve productivity. Powerful Machinery stands behind every product with strict quality standards and global certifications.

For expert advice and certified lifting solutions, reach out to Powerful Machinery. You get reliable support and products you can trust.

Make your next project safer.

Choose Powerful Machinery for your lifting needs.

FAQ

What is the main difference between a geared trolley and a push trolley?

You move a geared trolley using a hand chain and gears. This gives you more control and lets you handle heavier loads. You move a push trolley by pushing it along the beam with your hands.

How do you know which trolley size to choose?

You should check the weight of your heaviest load. Always pick a trolley with a higher capacity than your maximum load. Measure your beam’s width and height to make sure the trolley fits.

Can you use a geared trolley on curved beams?

Most geared trolleys work best on straight beams. Some models can handle gentle curves, but you should always check the manufacturer’s guidelines before using them on curved tracks.

How often should you inspect your geared trolley?

You should inspect your geared trolley at least once every month. Look for signs of wear, loose parts, or damage. Regular checks help you keep your equipment safe and working well.