A magnetic lifter uses powerful magnets to help you lift and move heavy metal items like steel plates or blocks. You rely on these lifting devices in factories, warehouses, and construction sites to handle large loads safely and efficiently.

When you select the right magnetic lifter, you protect your team and equipment from accidents such as overloading, poor positioning, or missed inspections. Some of the most common safety issues include:

Ignoring the load capacity of the lifting magnet may cause equipment failure.

Placing the magnetic lifting device incorrectly can lead to unstable loads.

Skipping regular inspections or maintenance increases the risk of malfunctions.

Letting untrained operators handle the device can result in mistakes.

Using the magnet lifter in unsuitable environments may affect performance.

Powerful Machinery has built a reputation for providing reliable, certified lifting solutions trusted by industries worldwide.

Key Takeaways

Magnetic lifters use strong magnets to lift heavy metal items safely, improving efficiency and reducing labor needs.

Choose the right magnetic lifter by considering the material type, lifting capacity, and work environment to ensure safe operation.

Regular inspections and maintenance of magnetic lifters are crucial to prevent accidents and extend equipment lifespan.

Operator training is essential for safe use; only trained personnel should operate magnetic lifters to minimize risks.

Investing in certified magnetic lifters enhances safety, boosts productivity, and leads to long-term cost savings.

Magnet Lifter Overview

What is a Magnetic Lifter?

You use a magnetic lifter to move heavy metal objects, especially those made of steel or iron. This device relies on strong magnets to grip and lift ferrous materials without the need for hooks, chains, or slings.

You activate the magnetic lifter with a lever or switch, which creates a powerful magnetic field that securely holds the load. Magnetic lifters come in different designs, but all share the same purpose: making your lifting tasks safer and more efficient.

You often find magnetic lifters in factories, warehouses, and construction sites where you need to handle large steel plates, blocks, or molds.

The main components of a magnetic lifter include a magnetic core, a safety lever, and a sturdy lifting hook. These features set magnetic lifters apart from traditional lifting equipment. The table below highlights the differences:

Feature | Magnetic Lifters | Traditional Lifting Equipment |

|---|---|---|

Efficiency | High efficiency with minimal setup time | Requires setup time with slings/chains |

Safety | Encapsulates materials, prevents slipping | Can be unsafe if not maintained |

Versatility | Limited to ferrous materials | Can handle a wider range of materials |

Maintenance | Low maintenance, fewer mechanical components | Requires regular checks and maintenance |

Cost-Effectiveness | Lower long-term costs, no consumables needed | Higher ongoing costs due to maintenance and parts |

Environmental Impact | Eco-friendly, no emissions | Polluting requires fuel for operation |

Key Benefits

When you choose a magnetic lifter, you gain several important advantages. Magnetic lifters boost your efficiency by reducing the time and effort needed for material handling.

You can complete tasks in minutes that used to take an hour or more. Magnetic lifters also improve safety by providing a firm grip on heavy loads, which lowers the risk of slipping or dropping materials.

Tip: You can often operate a magnetic lifter by yourself, which means you need fewer workers for lifting jobs.

Here are some key benefits you experience with magnetic lifters:

Secure and efficient lifting of steel and iron materials.

Enhanced safety, as the magnetic lifter maintains its grip even during power interruptions.

Streamlined workflow, allowing you to load and unload materials quickly.

Reduced labor requirements, since one operator can handle tasks that used to need several people.

You rely on a magnet lifter to make your lifting operations faster, safer, and more cost-effective. Magnetic lifters help you protect your team and equipment while improving productivity in your workplace.

Types of Magnetic Lifters

You will find three main types of magnetic lifters in industrial settings. Each type works differently and offers unique advantages for your lifting needs. The table below helps you compare the types of magnetic lifters:

Type of Magnetic Lifter | Functionality | Key Features |

|---|---|---|

Electromagnet Lifter | Uses electric current to generate a magnetic field for lifting ferrous materials. | Variable lifting capacity |

Permanent Magnetic Lifter | Has a fixed magnetic field, does not require power to operate. | No power supply needed |

Permanent Electromagnet Lifter | Uses an electric pulse for activation, maintains magnetic force without continuous power. | Power efficient |

Permanent Magnetic Lifter

You use a permanent magnetic lifter when you want a reliable tool that does not need electricity. This type of lifter uses strong magnets to create a constant magnetic field. You can lift steel plates, blocks, and molds safely. Permanent magnetic lifters do not lose their strength during power outages.

You save energy because these lifters do not require a power supply. The operational lifespan of permanent magnetic lifters depends on how you use them. If you avoid overloading and follow proper maintenance, you can expect many years of service.

Powerful Machinery’s permanent magnet lifter stands out in this category. It uses high-performance magnets and offers a pull-out force up to 3.5 times its rated capacity, making your lifting tasks safer and more efficient.

Electromagnet Lifter

You choose an electromagnet lifter when you need variable lifting power. This type uses electric current to create a magnetic field. You can adjust the lifting force by changing the current.

Electromagnet lifters work well for heavy-duty applications, but they need a continuous power supply. If the power fails, the magnet lifter may lose its grip, which can be a safety risk.

Electromagnetic lifters consume more energy during continuous operation compared to permanent magnetic lifters. You must monitor the power source to ensure safe lifting.

Permanent Electromagnet Lifter

You get the best of both worlds with a permanent electromagnet lifter. This type uses a short electric pulse to activate or deactivate the magnetic field. Once activated, it holds the load without needing continuous power. You benefit from enhanced safety because the grip remains secure even if the power goes out.

Permanent electromagnet lifters reduce the risk of accidents and material slippage. You also avoid overheating and electrical hazards since the system does not draw power all the time. This type of magnet lifter is ideal for operations where safety and reliability matter most.

How Do Lifting Magnets Work?

Understanding how different lifting magnets operate helps you choose the right tool for your job. Each type uses a unique method to create a strong magnetic field that grips and lifts heavy metal objects. The table below gives you a quick overview of the working principles:

Type of Lifting Magnet | Working Principle |

|---|---|

Permanent Lifting Magnets | Utilizes two magnets positioned to create magnetic flux, lifting metallic objects when aligned correctly. |

Electro Lifting Magnets | Generates lifting power through electric current flowing around coils, creating a magnetic field. |

Electro-permanent Magnets | Combines two sets of magnets to produce attraction, with current direction changes affecting the magnetic force. |

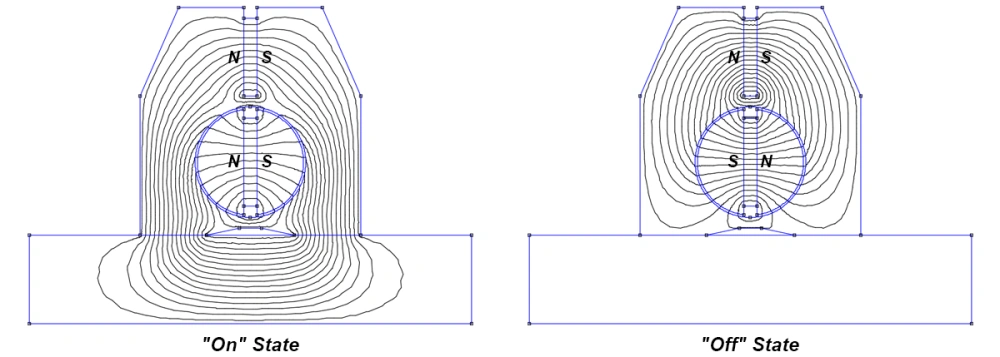

Permanent Magnetic Lifter Principle

You use a permanent magnetic lifter when you want a constant and reliable magnetic force. This device contains strong permanent magnets, often made from rare-earth materials. When you move the lever, you align the magnets inside, which creates a powerful magnetic field.

This field passes through the base and attracts ferrous materials like steel plates or blocks. The magnetic force remains active until you disengage the lever. You do not need electricity, so the lifter works even during power outages. The table below highlights the differences between permanent and electromagnetic lifters:

Feature | Permanent Magnetic Lifter | Electromagnetic Lifter |

|---|---|---|

Magnetic Field Generation | Uses a permanent magnet that is always active | Relies on electric current to generate a field |

Control Mechanism | Manual lever or mechanical means to disengage | The magnetic field disappears when the power is off |

Strength of Magnetic Field | Constant and does not change | Can be turned on/off, allowing for variable strength |

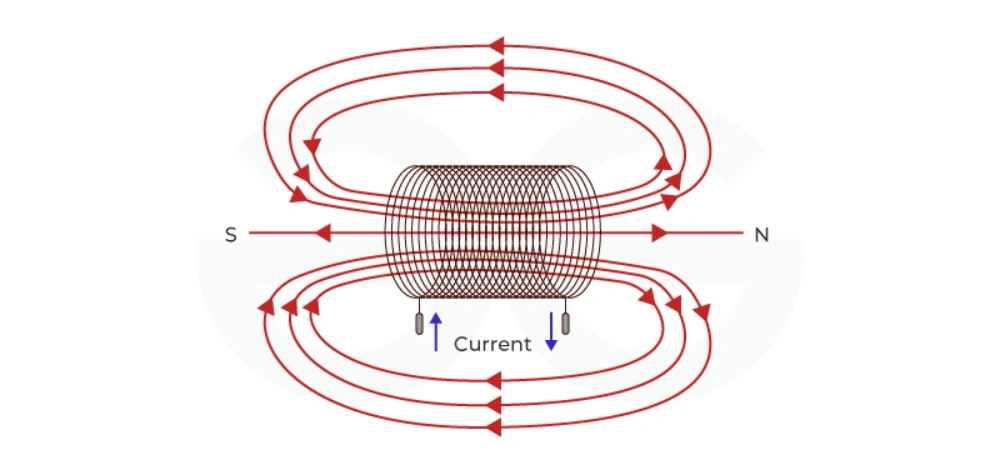

Electromagnet Lifter Principle

An electromagnet lifter uses electric current to create a magnetic field. You activate the device by switching on the power, which sends current through coils of wire. This current generates a magnetic field that attracts and holds metal objects. You can adjust the strength of the field by changing the amount of current.

When you turn off the power, the magnetic field disappears, and the load releases. For safe operation, you must receive proper training. Training teaches you how to activate and deactivate the lifter, understand weight limits, and use correct attachment methods.

Many electromagnet lifters include safety features such as fail-safe brakes and capacitive sensors to prevent accidental drops or releases.

Note: Regular maintenance and system monitoring help you keep electromagnet lifters safe and reliable.

Permanent Electromagnet Principle

A permanent electromagnet lifter combines the benefits of both permanent magnets and electromagnets. You activate the magnetic field with a short electric pulse. After activation, the device holds the load securely without needing continuous power.

You can deactivate the magnet with another pulse, making it easy to release the load. This design improves safety because the magnetic force stays active even if the power fails. Dual activation systems and magnetic interlocks help prevent accidental releases.

Continuous monitoring ensures the system works as expected, giving you peace of mind during lifting operations.

Industrial Applications

Use Cases by Type

You see magnetic lifters in many industries that need to move heavy objects safely and quickly. These devices help you handle steel plates, beams, and other ferrous materials with less effort. The table below shows how different industries use magnetic lifters for specific tasks:

Industry | Common Use Cases |

|---|---|

Steel Manufacturing | Moving large steel plates or beams, reducing injuries. |

Automotive | Handling engine blocks and chassis parts during assembly. |

Shipbuilding | Lifting heavy metal panels in ship construction. |

Recycling and Scrap Handling | Collecting and transporting scrap metal efficiently. |

Metal Fabrication | Lifting and moving heavy steel plates and beams. |

Construction | Moving heavy materials on site. |

Engineering Machinery | Lifting and transporting steel plates and molds. |

You rely on magnetic lifters to make lifting tasks safer and faster. In steel manufacturing, you move large plates with less risk. In automotive plants, you lift engine blocks and chassis parts during assembly.

Shipbuilding requires you to handle heavy metal panels, while recycling centers use magnetic lifters to collect and transport scrap metal. Construction sites benefit from these lifters when moving steel beams and other materials.

Powerful Machinery designs magnetic lifters that fit these tough jobs. You get reliable performance whether you work in a factory, shipyard, or warehouse. The permanent magnet lifter from Powerful Machinery gives you a strong grip and easy operation, making it ideal for lifting ferrous materials in demanding environments.

Custom Solutions

You often face unique challenges in your workplace. Custom magnetic lifter solutions help you solve these problems. You can lift steel plates, sheets, bars, and other metal components with less manual handling.

In construction, you use magnetic lifters to assemble steel structures by lifting and positioning beams and rods. Shipbuilding becomes more efficient when you manage metal inventory and handle heavy objects safely.

Tip: Custom magnetic lifters can reduce lifting time by up to 40%. You save energy and lower labor costs because one operator can control the lifting process.

Powerful Machinery offers custom-engineered magnetic lifters for your specific needs. You work with their team to design lifters that match your project requirements. These solutions help you improve safety, boost productivity, and cut costs in your operations.

Selection Criteria

Choosing the right magnetic lifter for your workplace means you need to match the device to your specific requirements. You must consider the application, lifting capacity, work environment, safety and regulatory compliance, and the reputation of your supplier.

Follow this step-by-step guide to make sure you select the best magnet lifter for your needs.

Application and Material

Start by identifying your application requirements. You need to know what type of material you plan to lift. Magnetic lifters work best with ferrous metals like steel and iron. Thicker steel plates allow for better magnetic performance than thin sheets or irregular shapes.

You should check if the surface is clean and smooth, since air gaps from rust, paint, or dirt can reduce the holding strength by half. Flat surfaces provide a better grip and maximize the lifting capacity.

Tip: Always match the magnetic lifter to the material type and thickness for safe and efficient lifting.

Here is a table to help you understand the most important factors for selecting a magnetic lifter based on your application:

Factor | Description |

|---|---|

Lifting Capacity | Every lifting magnet has a rated load maximum value indicating the highest weight it can handle safely. |

Load Considerations | The type and thickness of ferrous material affect the lifting strength and performance. |

Air Gaps and Surface Conditions | Air gaps, rust, or paint can reduce lifting force; clean, smooth surfaces maximize magnetic contact. |

Surface Flatness | Flat surfaces provide better grip, enhancing the lifting capability. |

When you choose a permanent magnetic lifter, you get reliable performance for lifting steel plates, blocks, and molds. Make sure you review your application requirements before making a decision.

Lifting Capacity

You must know the lifting capacity of the magnetic lifter before you use it. The rated load maximum value tells you the highest weight the lifter can handle safely. Industry standards recommend a safety factor of at least 3:1 for general lifting operations.

For more demanding applications, you may need a higher safety factor. Always test new, altered, or repaired magnet lifters with a qualified individual to ensure the rated load maximum value matches the breakaway force.

Note: Never exceed the lifting capacity listed by the manufacturer. Overloading can cause equipment failure and accidents.

You should also consider the load size and shape. Larger materials require stronger magnets, which may increase costs. Permanent magnetic lifters from Powerful Machinery offer a pull-out force up to 3.5 times their rated load maximum value, giving you extra safety and reliability.

Work Environment

Your work environment affects the performance and longevity of your magnetic lifter. Environmental conditions such as temperature, humidity, and chemical exposure can impact the device. Some lifters are designed for indoor use, while others can withstand outdoor conditions.

You need to check the operating temperature range. Some models work in extreme temperatures from -40°C to 50°C. High temperatures beyond the rated range can cause performance loss or demagnetization.

If you work in a hot environment, choose a magnetic lifter rated for high temperatures.

If you operate outdoors, select a lifter with corrosion-resistant materials.

Always minimize air gaps between the magnet lifter and the load to maximize holding power.

Surface finishes like paint or dust can also affect magnetic contact. Clean the surfaces before lifting to meet your requirements for safety and efficiency.

Safety and Compliance

Safety and regulatory compliance must be your top priority. You need to choose a magnetic lifter that meets industry standards and certifications. Look for products that comply with OSHA and ANSI standards. These certifications require safety features, operator training, and regular inspections.

Certification/Standard | Description |

|---|---|

OSHA Standards | Mandate safer lifting practices and regular inspections. |

ANSI Standards | Require safety features and operator training. |

Powerful Machinery’s permanent magnetic lifter meets major international safety and regulatory compliance requirements. You can trust their products for safe operation in demanding environments. Always verify that your magnet lifter has the necessary certifications before use.

Cost and Supplier

You need to consider both the initial cost and the total cost of ownership when selecting a magnetic lifter. Acquisition costs include the price of the lifter. Operational costs cover maintenance, repairs, and training.

Machine reliability affects uptime and revenue generation. Versatility increases utilization and potential revenue. Resale value is also important if you plan to upgrade equipment in the future.

Larger materials require stronger magnets, which can raise costs.

Lifters designed for high-temperature applications may cost more due to specialized components.

Longer magnetic hold times need more powerful magnets, increasing the price.

Choose a supplier with a strong reputation for quality, safety, and regulatory compliance. Powerful Machinery offers certified products, custom solutions, and reliable support. Their permanent magnetic lifter provides excellent value, durability, and safety for your lifting needs.

Tip: Investing in a high-quality magnetic lifter from a trusted supplier helps you meet your requirements for safety, efficiency, and long-term performance.

By following these steps, you can select the right magnet lifter for your application, lifting capacity, work environment, safety and regulatory compliance, and budget. Always review your requirements and consult with experts to ensure you make the best choice for your workplace.

Safety Guidelines

Operator Training

You must complete comprehensive training before operating a magnetic lifter. Training programs should follow ASME compliance guidelines, especially Section 20-3.4, which covers operator qualifications and conduct. You need to learn how to inspect the equipment before use and understand all controls and functions.

Training also teaches you about the machine’s capacity and limitations. You should recognize hazards and know how to shut down and store the lifter safely.

Complete training on pre-operational inspection procedures.

Understand all equipment controls and functions.

Know the rated capacity and limitations of your magnetic lifter.

Learn to identify hazards in your work area.

Practice proper shutdown and storage methods.

Tip: Only trained and authorized personnel should operate magnetic lifters.

Safe Operation

You must always follow safe operating procedures to prevent accidents. Inspect the magnetic lifter for damage before each use. Make sure the magnet has full contact with the load.

Never exceed the safe working load. Keep unauthorized people away from the lifting area and display warning signs. Always transport loads at the lowest possible height.

Key safety practices include:

Prepare and maintain safe operating procedures for each lifting task.

Use the correct equipment for the load type.

Follow the manufacturer’s instructions closely.

Check the load’s center of gravity, especially when using multiple magnets.

Train all employees on safe use and risks.

Here is a table of essential safety guidelines:

Safety Guidelines for Magnetic Lifters |

|---|

Never allow unauthorized personnel to operate the lifting magnets. |

Inspect the lifting magnet before every use. |

Always use a 3:1 safety factor for lifting. |

Stay clear of the load at all times. |

Warn all personnel before lifting. |

Avoid vibration or impact during transport. |

Never move loads over or near people. |

Prohibit standing or passing under the magnet. |

Pay close attention until the load is landed. |

Do not operate above 80℃. |

Ensure load surfaces are clean and level. |

Use a spreader bar for large plates. |

Move and set down loads gently. |

Environmental Limits

You must observe environmental limits to keep your magnetic lifter safe and effective. The safe operating temperature for most lifting magnets is up to 70ºC (150ºF). Higher temperatures can reduce magnetic strength.

Always check the manufacturer’s guidelines for temperature and humidity limits. Avoid using the lifter in extreme conditions that could affect performance.

Do not operate the lifter above 70ºC (150ºF).

Keep the work area dry and clean.

Avoid sudden temperature changes that may affect the magnet.

Note: Following these guidelines helps you maintain safety and extend the life of your magnetic lifter.

Lifting Magnet Inspection & Maintenance

Lifting Magnet Inspection Steps

You need to inspect your lifting magnet regularly to keep it working safely and efficiently. Start with a visual check before every lift. Look for signs of damage, rust, or wear.

During operation, watch for any unusual noises or movement. You should also follow a schedule for more detailed inspections. Powerful Machinery recommends the following intervals:

Inspection Type | Interval Description |

|---|---|

Every Lift Inspection | Visual examination by the operator before and during each lift. |

Frequent Inspection | Monthly for normal service; weekly to monthly for heavy service; daily to weekly for severe service; as recommended for special service. |

Periodic Inspection | Yearly for normal service; quarterly for heavy service; monthly for severe service; as recommended for special service. |

Regular inspections help you spot problems early. You can plan repairs before they interrupt your work. Inspections also show when you need extra training for operators.

Maintenance Tips

You can keep your lifting magnet in top condition by following simple maintenance steps. Clean the magnet with a mild detergent and water. Dry it completely to prevent rust.

Apply a protective coating, such as nickel or zinc, to shield the magnet from moisture and corrosion. Store your magnets in a dry place. Avoid letting them touch each other, which can cause damage.

Clean the magnet regularly with mild detergent and water.

Dry the magnet thoroughly after cleaning.

Apply a protective coating to prevent corrosion.

Store magnets in a dry environment, separated from each other.

Routine maintenance brings many benefits. You prevent wear and tear, extend the life of your equipment, and reduce the risk of accidents. The table below shows how regular care improves performance:

Maintenance Task | Benefit |

|---|---|

Regular inspections | Identifies potential issues early, allowing for timely repairs. |

Lubrication and cleaning | Prevents wear and tear, extending the equipment’s lifespan. |

Repair and replacement of parts | Prevents further damage and potential accidents. |

Enhanced safety | Reduces the risk of accidents and injuries in the workplace. |

Increased equipment lifespan | Ensures that lifting equipment lasts longer and performs optimally. |

Improved performance and efficiency | Leads to increased productivity through more efficient operation. |

Tip: Following Powerful Machinery’s recommended inspection and maintenance schedule helps you get the most out of your lifting magnet and keeps your workplace safe.

Conclusion

You improve workplace safety and efficiency when you understand the different types of magnetic lifters and follow proper selection criteria. Choosing certified products like those from Powerful Machinery ensures reliable performance and compliance with safety standards.

Regular maintenance and operator training help extend equipment lifespan and reduce downtime.

Select a magnetic lifter with the right load capacity and safety features.

Maintain a preventive schedule to avoid unexpected breakdowns.

Train operators to handle magnetic lifters safely.

Benefit | Description |

|---|---|

Enhanced Safety | Reduces accident risks and meets regulations. |

Increased Productivity | Quick operation and minimal downtime. |

Long-Term Savings | Lower operating costs and extended equipment life. |

Remember, investing in a quality magnet lifter and following safety guidelines protects your team and boosts productivity.

FAQ

What materials can you lift with a magnetic lifter?

You can lift ferrous metals like steel and iron. Magnetic lifters do not work on non-ferrous materials such as aluminum, copper, or wood.

How do you know which lifting capacity to choose?

Check the weight and thickness of your load. Always select a magnetic lifter with a rated capacity higher than your heaviest item. Never exceed the manufacturer’s limit.

Do you need electricity to use a permanent magnetic lifter?

No, you do not need electricity. Permanent magnetic lifters use strong magnets to hold loads. You activate and release the magnet with a simple lever.

How often should you inspect your magnetic lifter?

You should inspect your magnetic lifter before every use. Perform more detailed checks monthly or as recommended by the manufacturer. Regular inspections help you spot problems early.

Can one person operate a magnetic lifter safely?

Yes, one trained person can operate a magnetic lifter. Always follow safety guidelines and use the correct procedures to ensure safe lifting.