A snap hook is a spring-loaded metal connector that lets you quickly attach or release ropes, chains, or straps. You use snap hooks to secure gear, organize tools, or fasten equipment in your daily activities. You might spot them on dog leashes, marine ropes, climbing gear, or even construction sites.

If you wonder what is a snap hook used for, you will find it in outdoor adventures, pet gear, boating, military equipment, and industrial settings because it offers fast, reliable connections.

Key Takeaways

A snap hook is a spring-loaded metal connector that allows for quick attachment and release of ropes, chains, or straps.

Choose the right material for your snap hook: stainless steel for marine use, aluminum for climbing, and plastic for general tasks.

Always check the load rating and safety features of a snap hook to ensure it meets your specific needs and prevents accidents.

Inspect snap hooks regularly for damage or corrosion to maintain safety and reliability in their use.

Snap hooks are versatile and can be used in everyday tasks, industrial settings, and outdoor activities, making them essential tools.

What is a Snap Hook?

Definition

You may ask, what is a snap hook? A snap hook is a metal connector with a spring-loaded gate that opens and closes automatically. You use it to attach ropes, cables, or straps quickly and securely.

According to engineering and safety standards, It is a device designed with a self-closing and self-locking gate. This gate must withstand specific loads, such as 5,000 pounds along the spine, 220 pounds at the nose, and 350 pounds on the side.

You find snap hooks in many industries, including marine, climbing, and rigging. The main purpose is to provide a fast and reliable way to connect or disconnect equipment.

Tip: When you choose a snap hook, always check if it meets safety standards for your intended use. This ensures you get the strength and reliability you need.

Snap hooks come in different shapes and sizes. Manufacturers use materials like stainless steel, aluminum, and plastic. Stainless steel works best for marine environments because it resists corrosion.

Aluminum is lightweight, making it ideal for climbing gear. Plastic snap hooks offer flexibility and cost-effectiveness for general use.

Material | Application Context | Key Properties |

|---|---|---|

Stainless Steel | Marine contexts | Corrosion resistance |

Climbing gear, outdoor gear | Lightweight | |

Plastic | General use | Flexibility, cost-effective |

You may wonder, what is a snap hook’s impact on the environment? Many factories now use eco-friendly practices, renewable energy, and responsible sourcing. Choosing suppliers who prioritize sustainability helps reduce your carbon footprint and appeals to eco-conscious users.

How It Works?

You might still wonder, what is a snap hook’s working principle? The answer lies in its spring-loaded gate. When you push the gate, it opens, allowing you to insert a rope, chain, or strap.

Once you release the gate, it snaps shut, locking the item in place. This mechanism uses the elasticity of the material for temporary deformation during assembly. Snap fits allow you to join components securely with a simple push.

Snap hooks use a spring mechanism for quick attachment and release.

The gate closes automatically, keeping your gear secure.

You can operate most snap hooks with one hand, making them convenient in fast-paced environments.

Modern snap hooks feature several design principles to ensure safety and durability:

Design Principle | Description |

|---|---|

Stress Concentration | Gradual transitions prevent material fatigue or failure. |

Deflection Limit | Deflection stays within the material’s elastic limit to avoid breakage. |

Engagement and Disengagement Forces | Geometry optimizes ease of assembly and secure fit. |

Tolerance and Fit | Manufacturing tolerances ensure consistent fit across all parts. |

You see innovations in snap hook design, such as titanium and high-strength alloys for better durability and lighter weight. Some snap hooks use magnetic closures for easier access, especially if you have limited dexterity.

Ergonomic designs, including swivel eyes and anti-snag features, improve usability and safety. Manufacturers also use recycled materials and eco-friendly production methods to support sustainability.

Material durability improves performance in demanding environments.

Magnetic closures enhance accessibility and safety.

Ergonomic features make snap hooks easier to use in high-stakes situations.

Sustainable production methods appeal to eco-conscious consumers.

If you ask, what is a snap hook’s main function? It provides a secure, fast, and reliable connection for your gear, whether you use it for outdoor activities, industrial work, or everyday tasks.

Types of Snap Hooks

You will find several types of snap hooks designed for different tasks and environments. Powerful Machinery offers a range of high-quality snap hooks, including the Stainless Steel Swivel Eye Snap Hook, Stainless Steel Marine Snap Hooks, and Din5299 Snap Hooks. Each type has unique features that make it suitable for specific applications.

Swivel Eye Snap Hook

A swivel eye snap hook has a rotating base that lets the hook turn 360 degrees. This design prevents ropes or chains from twisting when you move or adjust your gear. You often use this type in manufacturing, rigging, or assembly lines where flexibility matters.

Feature | Description | Common Use Cases |

|---|---|---|

Swivel Mechanism | 360-degree rotation for flexibility | Manufacturing, rigging, assembly |

You can choose between a positioning swivel hook, which aligns during connection, and a true swivel hook with a bearing that rotates freely under load. Powerful Machinery’s stainless steel swivel eye snap hooks use high-grade materials for corrosion resistance and long-lasting performance.

Marine Snap Hooks

Marine snap hooks are built to withstand harsh, wet environments. You will see them made from stainless steel or plated brass, which resist rust and corrosion. These hooks secure mooring lines, boat hooks, and outdoor equipment.

Manufacturers often meet international standards like ISO and ASTM.

Products go through strict testing for strength and durability.

Powerful Machinery’s marine snap hooks use 316 stainless steel for extra protection against saltwater. You can order standard or custom sizes to fit your needs.

Din5299 Snap Hooks

Din5299 snap hooks follow a German industrial standard for size and strength. You will find them in heavy industry, mining, water treatment, and retail. These hooks come in many sizes and offer strong, reliable connections.

Feature | Description |

|---|---|

Durable Construction | High-quality stainless steel with polished finish for rust resistance |

Wide Range of Sizes | From 40mm to 180mm |

Compliance with Standards | Meets ISO 9001 certification |

Multi-Industry Use | Heavy industry, mining, water treatment, retail |

You can select from different locking styles, such as PIN lock or Hex nut lock, for added security. Powerful Machinery ensures each Din5299 snap hook meets strict quality standards.

Note: The types of snap hooks you choose depend on your application and environment. Understanding the common uses of snap hooks helps you select the right product for your needs.

Common Uses of Snap Hooks

Everyday Uses

You use snap hooks in many daily situations. You might attach your keys to a belt loop or secure a water bottle to your backpack. Pet owners often rely on snap hooks to connect leashes to collars.

You can also organize tools in your garage or hang decorations with ease. Snap hooks make it simple to connect and disconnect items quickly, so you save time and effort.

Attach gear to bags or belts

Secure pet leashes and collars

Hang plants or decorations

Organize tools in your workspace

Tip: Choose stainless steel snap hooks for outdoor use. They resist rust and last longer in wet conditions.

Industrial and Marine

You find snap hooks in many professional settings. Workers in construction use them to secure safety harnesses and tools. In marine environments, you see snap hooks connecting ropes, mooring lines, and boat equipment.

These hooks help you manage heavy loads and keep equipment safe. Powerful Machinery’s snap hooks, made from stainless steel, offer durability and corrosion resistance for tough jobs.

Industry | Common Uses |

|---|---|

Construction | Securing harnesses, lifting gear |

Marine | Attaching mooring lines, boat hooks |

Transportation | Fastening cargo, securing tarps |

Outdoor Events | Setting up tents, banners, lighting |

You benefit from snap hooks because they work well in a variety of applications, from lifting heavy loads to managing ropes on a boat.

Benefits

Snap hooks offer several advantages over other connectors. You can assemble or disassemble them quickly without special tools. You do not need extra hardware like screws or nuts.

When you use snap hooks correctly, they last for years and keep your gear secure. Their design often hides the connection, so your equipment looks neat.

Benefit | Description |

|---|---|

Easy Assembly/Disassembly | Snap fittings can be quickly assembled and disassembled without special tools. |

No Extra Hardware | They do not require additional components like screws or nuts for joining parts. |

Reliable and Long Service Life | Properly used snap fits can last for years, contributing to product longevity. |

Aesthetics | Snap fits are typically hidden, enhancing the visual appeal of products compared to visible fasteners. |

Note: Always check the load rating before using a snap hook for heavy-duty tasks. This helps you avoid accidents and keeps your equipment safe.

How to Use Snap Hook?

Usage Steps

You can use a snap hook easily if you follow a few simple steps. Start by checking the snap hook for any signs of damage or corrosion. Make sure the surface feels smooth and the spring gate moves freely. Select a snap hook with a corrosion-resistant finish and a strong locking mechanism for your task.

Follow these steps to attach and release a snap hook safely:

Inspect the snap hook for cracks, rust, or bent parts before each use.

Hold the snap hook and press the gate to open it.

Insert the rope, chain, or strap into the hook’s opening.

Release the gate so it snaps shut and locks the item in place.

Tug gently on the attached item to confirm a secure connection.

To release, press the gate again and remove the item.

Tip: Always use snap hooks that match the size and load requirements of your application. Avoid connecting snap hooks directly to webbing, rope, or cable unless the hook is designed for that purpose.

Safety Tips

You must use snap hooks correctly to prevent accidents. Improper use can lead to serious safety risks. Here are some important safety tips:

Never connect a snap hook to another snap hook or to a D-ring that already has another connector attached.

Use snap hooks with a minimum tensile strength of 5,000 lbs for heavy-duty tasks.

Choose locking snap hooks that prevent accidental disengagement.

Avoid using snap hooks in unintended configurations.

Make sure the anchorage point is strong enough to support the load.

Regularly inspect your snap hooks and replace them if you see any damage.

Ensure all users receive proper training on snap hook use.

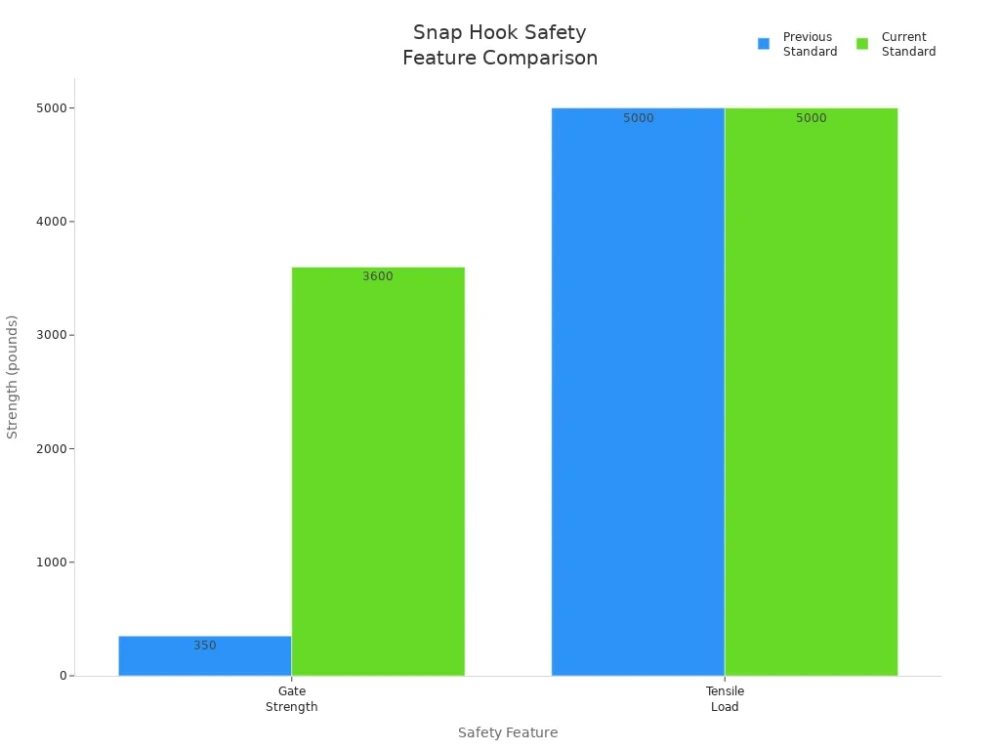

Powerful Machinery’s snap hooks meet or exceed current ANSI standards for gate strength and tensile load. The table below shows how these features compare to industry requirements:

Feature | Previous Standard | Current Standard |

|---|---|---|

Gate Strength (pounds) | 350/220 | 3,600 (all directions) |

Tensile Load (pounds) | 5,000 | 5,000 |

Self-closing & Locking Gate | Required | Required |

Education on Compatibility | Lacking | Emphasized |

Note: Powerful Machinery’s snap hooks use high-quality materials and advanced locking mechanisms to keep your gear secure in demanding environments.

Where to Buy Snap Hooks?

Buying Tips

When you look for snap hooks, you want to make sure you get the right product for your needs. You should consider several important factors:

Material: Choose plastic for light tasks or metal for heavy-duty jobs. Stainless steel works best for marine or outdoor use because it resists rust.

Load Capacity: Always check the load rating. Pick a snap hook that can handle the weight you plan to secure.

Size and Shape: Select a size and shape that fits your rope, chain, or equipment. The right fit improves safety and ease of use.

Safety Features: Look for snap hooks with locking gates or safety latches if you work in high-risk environments.

Tip: Choosing the right snap hook helps prevent accidents and keeps your gear secure.

You should also check for certifications and quality marks. These show that the snap hook meets safety and reliability standards. Here are some common certifications:

Certification Name | Issuing Authority | Benefits | Cost Range (USD) | Time to Obtain |

|---|---|---|---|---|

ISO 9001 | International Organization for Standardization | Quality Management Assurance | $5,000 – $15,000 | 3 – 6 months |

CE Marking | European Conformity | Meets EU Safety Standards | $2,000 – $10,000 | 1 – 3 months |

UL Certification | Underwriters Laboratories | Product Safety and Reliability | $3,000 – $12,000 | 3 – 6 months |

Snap hooks come in many price ranges. For example, a 1.75″ long snap hook for 3/16″ rod (3000 pieces) costs about $124.92, while a 4″ long snap hook for 3/8″ rod (3000 pieces) costs about $167.48.

You can buy certified snap hooks from trusted suppliers like Fasnap, which has provided quality products for over 40 years.

Powerful Machinery

You can trust Powerful Machinery when you need reliable snap hooks for any application. The company offers a wide range of products, including Din5299 Snap Hooks and Stainless Steel Marine Snap Hooks. Each product stands out for its material quality, finish, and design.

Feature | Din5299 Snap Hooks | Stainless Steel Marine Snap Hooks |

|---|---|---|

Material | Carbon or stainless steel | 304 or 316 stainless steel |

Finish | Polished, galvanized, or stainless | Highly polished |

Shape | Curved body | Oval design |

Applications | Construction, marine, mining | Marine, mooring buoys, boat hooks |

Customization | Multiple diameters, load ratings | Standard and custom sizes |

Advantages | Corrosion protection, load control | High corrosion resistance, durability |

Customers rate Powerful Machinery highly, with an average rating of 4.4 out of 5 and a reorder rate of 40%. You can find more details and browse the full product range on our official website.

Conclusion

A snap hook gives you a fast, secure way to connect gear in daily life or tough industrial jobs. You should always check the material, load rating, and locking features before choosing one. The table below highlights key components to look for:

Component | Description |

|---|---|

High-strength metal body | Durable steel or aluminum construction |

Spring-loaded gate | Closes automatically for secure attachment |

Load-bearing frame | Supports the weight of your gear |

High-quality snap hooks, like those from Powerful Machinery, improve safety and reliability. You can trust them for strength, durability, and corrosion resistance in any environment.

FAQ

What is the main difference between snap hooks and carabiners?

You use snap hooks for quick connections in everyday tasks. Carabiners often serve climbing or safety roles. Snap hooks usually have a simple spring gate. Carabiners may include locking mechanisms for extra security.

What materials are best for snap hooks in marine environments?

You should choose stainless steel snap hooks for marine use. Stainless steel resists corrosion from saltwater. This material keeps your snap hooks strong and reliable on boats or docks.

What should you check before using snap hooks for heavy loads?

You must inspect snap hooks for cracks, rust, or bent parts. Always check the load rating. Make sure your snap hook matches the weight of your gear. This step helps prevent accidents.

What are the most common uses for snap hooks in daily life?

You often use snap hooks to attach keys, secure pet leashes, or organize tools. Many people use snap hooks for hanging items or connecting gear to backpacks. Snap hooks make these tasks fast and easy.

What makes Powerful Machinery snap hooks a good choice?

You get snap hooks made from high-quality materials. Powerful Machinery snap hooks meet strict safety standards. You can use these snap hooks in tough environments. Many customers trust these snap hooks for durability and performance.