You use a toe jack when you need to lift, lower, or move heavy equipment in tight spaces. This tool has a long, toe-shaped arm that slides under the load, giving you the power to raise machinery, construction materials, or vehicles with a simple handle.

Powerful Machinery gives you trusted solutions for these demanding tasks. In recent years, industries worldwide have seen more toe jacks in action:

The market is growing by 13.3% each year.

Construction and manufacturing need reliable lifting tools.

Toe jacks help you work safely in automotive, industrial, and building environments.

Key Takeaways

Toe jacks are essential for lifting heavy equipment in tight spaces. They allow you to raise, lower, or move loads that other jacks cannot reach.

Always check the toe jack’s load capacity and ensure it fits securely under the load before lifting. This practice prevents accidents and equipment damage.

Regular maintenance is crucial for extending the life of your toe jack. Inspect for wear, clean after use, and lubricate moving parts to keep it in top condition.

Use personal protective equipment (PPE) like steel-toe boots and gloves when operating a toe jack. This gear protects you from potential injuries.

Hydraulic toe jacks offer smooth lifting and precise control. They are ideal for industrial applications, including construction, manufacturing, and logistics.

Toe Jack Overview

What is a Toe Jack?

You use a toe jack when you need to lift heavy machinery or equipment that sits close to the ground. This tool features a horizontal lifting arm, called the “toe,” which slides under loads with very little clearance.

Toe jacks play a key role in industrial lifting because they let you raise, lower, or move objects that other jacks cannot reach.

Powerful Machinery stands out as a trusted manufacturer of toe jacks and other lifting solutions. With over 20 years of experience, the company supplies certified products to industries like construction, marine, and transportation. You can rely on their toe jacks for strength, safety, and long-lasting performance.

Toe jacks serve several important roles in industrial settings. The table below shows how you might use them:

Role of Toe Jacks | Description |

|---|---|

Lifting Heavy Machinery | You can lift heavy machinery or objects, even when there is only a small gap from the ground. |

Fine Adjustments | You can make precise height adjustments, which helps when installing machines. |

Facilitating Movement | You can move or reposition equipment, change factory layouts, or adjust direction and height. |

Toe jacks come in different types and load capacities. Standard models can lift between 2,000 and 5,000 pounds. Heavy-duty toe jacks can handle up to 10,000 pounds. This range meets the needs of most industrial lifting tasks.

Jack Type | Load Capacity Range |

|---|---|

Standard Toe Jack | 2,000 to 5,000 pounds |

Heavy-Duty Toe Jack | Up to 10,000 pounds |

Key Components

A toe jack works because of several key parts. Each component helps you lift and move heavy loads safely and efficiently. The table below explains how each part contributes to the jack’s lifting power:

Component | Contribution to Lifting Capability |

|---|---|

Hydraulic Mechanism | Gives you the force needed to lift heavy loads with minimal effort. |

Toe | Lets you access and lift objects in low-clearance areas. |

Slide Shoe Design | Improves stability and lowers the risk of tipping during use. |

Base | Provides overall support and keeps the jack steady while lifting. |

You will notice that toe and head lifting points are essential for stability and precision. The hydraulic mechanism ensures smooth and reliable lifting, which keeps your work safe and productive.

Durable materials, such as carbon steel bases and chrome-plated plungers, help the jack last longer and perform well under stress.

Tip: Always check the toe jack’s lifting points and hydraulic system before use. This practice helps you avoid accidents and keeps your equipment in top condition.

Hydraulic toe jacks from Powerful Machinery include features like integrated hydraulic systems for smooth lifting, precision lowering valves for controlled descent, and pressure control valves to extend service life. These features make the jack reliable for repeated use in tough environments.

When you choose a toe jack from Powerful Machinery, you get a tool built for demanding jobs. The combination of strong materials, advanced hydraulic systems, and thoughtful design ensures you can lift, adjust, and move heavy equipment with confidence.

Toe Jack Features

Construction and Materials

When you choose a toe jack from Powerful Machinery, you get a tool built with strength and durability in mind. The base uses carbon steel, which stands up to tough jobs and resists wear. The plunger has a chrome-plated finish, so it fights off rust and corrosion. This means your jack lasts longer, even in harsh environments.

You can see the advantages of different materials in the table below:

Material | Advantages |

|---|---|

Forged steel | Ensures performance and operator safety |

Heavy-duty steel | Increases durability and strength for heavy use |

Q235 steel | Strong and durable, suitable for long-term use |

High-strength steel | Superior durability and wear resistance |

The compact design lets you fit the toe jack into tight spaces. Automated welding adds to the strength, making sure the jack can handle demanding tasks.

Hydraulic Mechanism

Hydraulic toe jacks use a powerful hydraulic system to lift heavy loads with ease. You operate the jack by pumping the handle, which builds up pressure and raises the load smoothly. This system gives you precise control and helps you avoid side loading, which can damage equipment.

Feature | Description |

|---|---|

Hydraulic System | Precision-oriented to avoid cylinder side load |

Lifting Positions | Capable of lifting both at toe and head |

Material | Durable steel construction |

Hydraulic systems provide smooth lifting action and keep performance steady, even under pressure. This makes hydraulic toe jacks a top choice for industrial work.

Safety and Control

You need safety and control when lifting heavy machinery. Powerful Machinery’s toe jack includes features that help you work safely:

Dual strain control for added stability

Overload protection valve to prevent damage

Quick adjustment of the starting toe height

Precise lowering control for delicate operations

Stable support in any position with adaptable swivel feet

You can operate the jack manually or connect it to a hydraulic pump for remote control. The adjustable lifting tooth lets you handle different loads and surfaces.

Compared to mechanical jacks, toe jacks fit into narrow gaps and work well in confined spaces. You get more versatility for tasks like machinery rigging and equipment maintenance.

Note: Always check the jack’s load capacity and use the safety features to protect yourself and your equipment.

Toe Jack Operation and Safety

How to Use a Toe Jack?

You can operate a toe jack by following a clear set of steps. First, place the jack on a stable, flat surface. Make sure the toe fits securely under the load. Pump the handle to raise the load slowly.

Watch the movement and keep the load centered on the jack. If you need to lower the load, release the hydraulic pressure gently. Always move the jack in small increments to maintain control.

Tip: Use wedges or blocks to support the load during lifting. This practice adds stability and reduces the risk of accidents.

Safety Guidelines

You must follow strict safety protocols when using lifting equipment. These steps help you protect yourself and your workplace:

Check the jack’s rated capacity before lifting. Never exceed this limit.

Position the toe correctly under the load.

Place the jack on a stable surface.

Keep the load centered to prevent tipping.

Support opposite corners with blocks or wedges.

Synchronize movements if you use more than one jack.

Wear impact-resistant goggles, steel-toe boots, and gloves.

Always use personal protective equipment (PPE).

Safety Step | Why It Matters |

|---|---|

Load capacity check | Prevents overload and jack failure |

Stable surface placement | Reduces risk of tipping |

PPE usage | Protects eyes, hands, and feet |

Maintenance Tips

You can extend the life of your toe jack with regular care. Follow these steps to keep your equipment in top condition:

Inspect the jack for wear, rust, and damage after each use.

Clean the jack to remove dirt and debris.

Use the recommended hydraulic fluid and check levels often.

Lubricate moving parts to reduce friction.

Train users on proper handling and storage.

Check seals for leaks and replace them if needed.

Tighten bolts and fittings to maintain stability.

Note: Regular maintenance prevents common problems like oil leaks, reduced lifting power, and restricted movement.

What is a Toe Jack Used For?

Industrial Applications

You will find toe jacks in many industries because they help you handle large and heavy items with ease. In manufacturing, you use them to install or remove assembly line machines, conveyors, and robotic arms. The energy sector relies on them for lifting power transformers, switchgear, and turbines.

Construction workers use them to position prefabricated structural components or heavy molds. In mining and metallurgy, you can transport crushers, mills, and smelting devices. Logistics and warehousing teams use them to adjust or shift large storage racks and packing systems.

Manufacturing: Install or remove assembly line machines, conveyors, and robotic arms.

Energy Sector: Lift power transformers, switchgear, and turbines.

Construction: Position prefabricated structural components or heavy molds.

Mining and Metallurgy: Transport crushers, mills, and smelting devices.

Logistics and Warehousing: Adjust or shift large storage racks and packing systems.

Powerful Machinery’s products stand out in these environments. You can rely on their hydraulic toe jacks for lifting precision machines and leveling equipment. The 5/10-ton models work well for medium lifting jobs and make it easy to level heavy machines like lathes.

The 2.5/10-ton models are lightweight and easy to carry, so you can use them for everyday tasks in workshops or warehouses. Standard hydraulic models offer high lifting capacity for machinery laying and movement, while heavy-duty models handle the toughest jobs in construction and manufacturing.

Moving Heavy Machinery

You often need to move and position heavy machinery in industrial environments. Toe jacks help you do this with accuracy and safety.

You can use them for machinery moving and installation, press and die lifting, transformer and switchgear positioning, construction equipment adjustment, HVAC unit and boiler setup, and heavy tool setup in industrial plants.

Application Area | Description |

|---|---|

Machinery moving and installation | Use toe jacks for precision lifting under heavy equipment. |

Press and die lifting | Lift heavy dies and presses in manufacturing settings. |

Transformer and switchgear positioning | Position heavy electrical equipment in utilities. |

Construction equipment adjustment | Level and adjust heavy construction machinery. |

HVAC unit and boiler setup | Set up heavy HVAC units and boilers in mechanical services. |

Heavy tool setup in industrial plants | Set up and position heavy tools in industrial environments. |

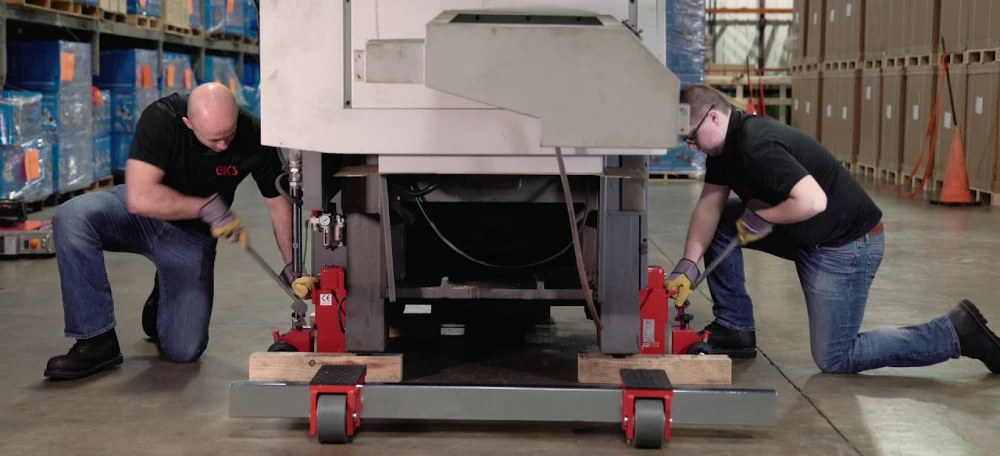

You do not use toe jacks alone when moving loads. You often pair them with roller skids or moving skates. First, you lift the equipment with the jack. Then, you position the skids underneath. This method lets you move the load safely and reduces physical strain.

Powerful Machinery’s toe jacks work well with other rigging hardware, giving you a complete solution for moving and positioning heavy equipment.

Tip: Always check the weight capacity and lift height before you start. Choose a jack made from strong materials like steel for better durability and efficiency.

Working in Confined Spaces

You sometimes face the challenge of lifting heavy items in tight or awkward spaces. Hydraulic toe jacks are the best choice for these situations. Their tall and narrow design fits into small areas where traditional lifting equipment cannot go.

You can use them independently or connect them to a pump to lift loads from a distance. Some models can lift to 10 tons, making them versatile for many heavy lifting tasks.

Feature | Description |

|---|---|

Design | Tall and narrow, ideal for small spaces where traditional jacks cannot fit. |

Operation | Use independently or with a pump to lift loads from a distance. |

Capacity | Lift loads to 10 tons (20,000 lbs). |

You will find that hydraulic toe jacks are preferred for lifting heavy items in confined spaces. They can handle objects weighing between 5 and 25 tonnes.

This makes them useful for many tasks, from lifting machinery in a crowded workshop to adjusting equipment in a packed warehouse. Experts recommend these jacks for their ability to operate where other tools cannot reach.

Note: Always use the right jack for the space and weight of your load. This practice keeps your work safe and efficient.

Conclusion

You can trust the toe jacks from Powerful Machinery for safe, reliable lifting in any industrial setting. Their seamless welded steel bodies and strong hydraulic systems give you smooth, controlled lifts every time.

Feature | Benefit |

|---|---|

Lifting Capacity | Up to 10 tons for heavy machinery |

Compact Design | Easy storage and transport |

Safety Features | Stable and secure during operation |

When choosing a toe jack, consider these factors:

Lifting capacity for your heaviest loads

Low-profile toe for tight spaces

Ergonomic handles for easy use

Overload protection for safety

Always inspect your jack before use and check for ANSI/ASME B30.1 or ISO 9001 certification. Regular maintenance keeps your equipment safe and ready for every job.

FAQ

What is the main difference between a toe jack and a bottle jack?

You use a toe jack for lifting heavy loads with low ground clearance. A bottle jack works best for vehicles or objects with higher clearance. Toe jacks have a horizontal lifting arm, while bottle jacks lift vertically.

How do you choose the right toe jack size?

Check the weight of your load. Select a toe jack with a capacity higher than your heaviest item. Measure the clearance under your equipment. Pick a jack with a low-profile toe that fits easily.

Can you use a toe jack on uneven surfaces?

You should always use a toe jack on a flat, stable surface. Uneven ground can cause the jack to slip or tip. For safety, place a steel plate or wooden block under the base if needed.

How often should you maintain your toe jack?

Inspect your toe jack before each use. Clean and lubricate moving parts every month. Check hydraulic fluid levels and look for leaks. Replace worn seals or damaged parts right away.

What safety gear should you wear when using a toe jack?

Wear steel-toe boots, gloves, and safety goggles. These protect your feet, hands, and eyes from injury. Always follow your workplace safety rules.