You rely on a toe jack when you need to lift or move heavy machinery from positions with very low clearance. This robust tool uses a fork-like toe or head to raise loads safely, even in tight spaces where other jacks cannot fit.

Powerful Machinery designs these hydraulic jacks for precise control and durability, making them essential for industrial tasks that demand strength and reliability.

Key Takeaways

Toe jacks are essential for lifting heavy machinery in tight spaces with low clearance, making them ideal for industrial tasks.

Choose a toe jack with the right lifting capacity and a low-profile design to ensure safe and efficient operation under heavy loads.

Regular maintenance, including checking hydraulic fluid and inspecting for leaks, extends the life of your toe jack and ensures safety.

Always prioritize safety by using appropriate gear, securing loads, and never exceeding the jack’s weight limit during operation.

Powerful Machinery offers a range of toe jacks tailored for various lifting needs, providing expert support for your selection process.

Toe Jack Design and Features

What Is a Toe Jack?

You use a toe jack when you need to lift heavy equipment in spaces with very little clearance. This tool features a horizontal lifting arm, called the toe, which slides under machinery or loads that sit close to the ground.

Unlike bottle jacks, which have a vertical lifting mechanism, toe jacks offer a compact and low-profile design. This makes them ideal for industrial environments where space is limited and precision is critical.

Tip: Toe jacks excel in situations where traditional jacks cannot fit due to height restrictions.

Here’s a quick comparison of toe jack and bottle jack design elements:

Component | Toe Jack | Bottle Jack |

|---|---|---|

Design and Size | Compact design, fits into tight spaces | Bulkier design, cylindrical shape |

Lifting Capacity | Ranges from 2 tons to 50 tons | Typically up to 20 tons |

Range of Motion | Limited vertical range, more horizontal movement | Higher vertical range, ideal for greater heights |

Key Features and Construction

You benefit from toe jacks because they combine robust construction with advanced safety features. Powerful Machinery builds its hydraulic toe jacks using high-quality carbon steel bases and automated welding. This ensures durability and resistance to wear.

The chrome-plated plunger resists corrosion, extending the service life even in harsh industrial settings.

Toe jacks feature a low-profile design, allowing you to position the jack under loads with minimal ground clearance. Dual strain control adds another layer of safety, giving you precise control during lifting operations.

Feature | Description |

|---|---|

Durable Construction | Made from high-quality materials, ensuring longevity and resistance to wear and tear. |

Wear and Corrosion Resistance | The hydraulic cylinder’s inner wall and main shaft are designed to be wear-resistant and corrosion-resistant, extending the service life of the jack. |

Hydraulic toe jacks offer several advantages:

You can operate them effectively under low ground clearance, making them versatile for different heavy loads.

The hydraulic system allows for controlled lifting and lowering, reducing the risk of sudden movements.

You can use toe jacks at different angles, increasing adaptability in various lifting scenarios.

Powerful Machinery Toe Jack Models

Powerful Machinery offers a range of toe jack models to suit your lifting needs. Each model provides specific capacities and dimensions, so you can select the right jack for your application.

For example, the SHL-05S model has a top capacity of 5 tons and a low toe-lift capacity of 2.5 tons. The SHL-50S model supports up to 50 tons, with a low toe-lift capacity of 25 tons.

Here are typical specifications for a toe jack:

Feature | Specification |

|---|---|

Load Capacity | 11,000 lbs (5 t) |

Toe Minimum Height | 1.2 in (30 mm) |

Lifting Height | 5.5 in (140 mm) |

Lifting Toe Positions | 3 |

Working Pressure | 7,542 psi (520 bar) |

Weight | 66 lbs (30 kg) |

You can rely on Powerful Machinery toe jacks for consistent performance and safety. These jacks meet rigorous industry standards, including ASTM F2412 and ASTM F2413, ensuring compliance with impact, compression, and puncture resistance requirements.

The average lifespan of hydraulic toe jacks ranges from 5 to 10 years under regular industrial use. Factors such as regular maintenance, proper load handling, and lubrication can extend service life significantly.

Jack Type | Average Lifespan | Key Factors Influencing Longevity |

|---|---|---|

Hydraulic Jacks | 5–10 years | Durable under heavy loads, but seals and fluid systems degrade over time. Regular maintenance can extend service life significantly. |

When you choose Powerful Machinery, you invest in reliable lifting solutions that deliver strength, safety, and longevity for your most demanding projects.

Advantages and Safety

Benefits of Using a Toe Jack

You gain several advantages when you choose a toe jack for heavy lifting tasks. This tool offers quick and efficient lifting, saving you time on the job. You find it more economical than hiring cranes or other heavy equipment.

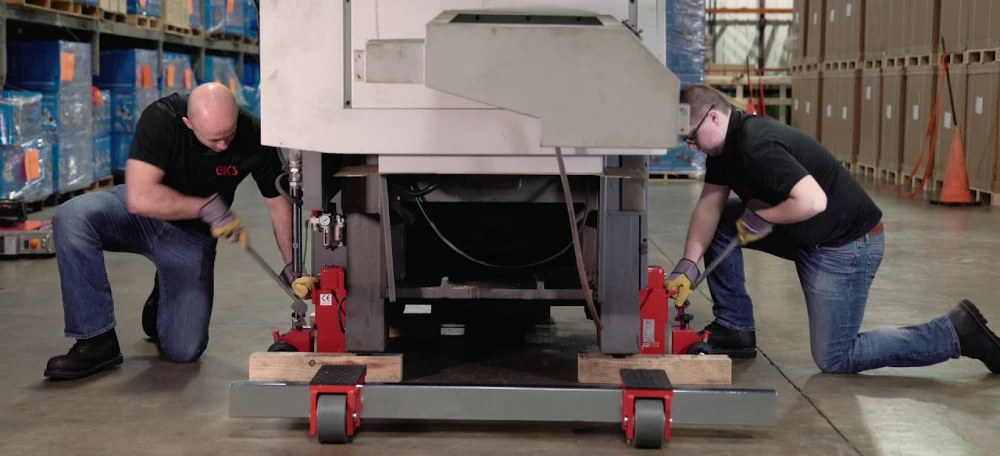

The versatility of a toe jack allows you to pair it with load-moving skates, making it easier to relocate heavy machinery after lifting. You can select from a wide range of lifting capacities, so you always have the right tool for your specific needs.

Advantage | Description |

|---|---|

Efficiency | You lift heavy loads quickly and with minimal effort. |

Cost-effectiveness | You avoid the high costs of alternative lifting methods. |

Versatility | You use toe jacks with skates to move machinery after lifting. |

Lifting capacity | You choose from models that suit various industrial tasks. |

Toe jacks feature a low-profile base, which lets you work in tight or confined spaces. You benefit from mechanical advantage, so you lift heavy loads with less physical strain. These jacks excel in industrial settings, cement work, and construction projects.

Tip: Powerful Machinery toe jacks include a safety overall valve to prevent overloads, protecting both you and your equipment from accidents.

Safety Tips and Best Practices

You must prioritize safety when operating a toe jack. Prepare your work area by removing clutter and ensuring stability. Always use the correct jack for your task and follow the operational guidelines. Wear appropriate safety gear, such as hard hats, gloves, and safety glasses.

Balance and secure your loads before lifting. Support lifted loads with jack stands and never stand under a suspended load.

Prepare your work area to avoid clutter and instability.

Use the correct type of jack and follow its operational guidelines.

Always wear appropriate safety gear, including hard hats, gloves, and safety glasses.

Ensure loads are balanced and secured before lifting.

Use jack stands to support lifted loads.

Never stand under a suspended load.

Perform regular maintenance checks and lubrication on jacks.

You should inspect your surroundings for obstacles and ensure enough clearance before lifting. Position the jack on a level surface and align it with the load’s center of gravity. Secure loads with straps or chains to prevent shifting. Lift slowly and steadily to maintain balance, and never exceed the jack’s maximum weight limit.

Maintenance Practices

You extend the life and reliability of your toe jack by following proper maintenance routines:

Check the hydraulic oil level daily and keep it at least two-thirds full.

Replace the oil twice a year or immediately if it appears cloudy or milky.

Inspect hydraulic hoses and couplers for cracks, leaks, or wear.

Test the load-holding capabilities before each lift.

Lubricate guides and the lifting piston regularly.

Clean the air vent screw with compressed air.

Remove screws from the housing to change oil and dispose of used oil according to regulations.

Note: Regular maintenance ensures your toe jack operates safely and efficiently, reducing the risk of breakdowns or accidents.

Powerful Machinery Toe Jack Value

You receive exceptional value when you invest in Powerful Machinery toe jacks. These jacks feature a stable base and precision control mechanisms, which minimize the risk of accidents during lifting operations. The safety overall valve prevents overload, protecting both you and the jack.

You benefit from ultra-low clearance operation, exceptional load capacity, and precision hydraulic controls. The wide base provides stability, and the compact design with wheels makes transportation easy.

Feature | Powerful Machinery Toe Jack | Industry Standards |

|---|---|---|

Ultra-low clearance operation | Yes | Varies |

Exceptional load capacity | 3 to 100 tons | Typically lower |

Precision hydraulic controls | Yes | Often basic |

Stability | Wide base | Varies |

Portability | Compact design with wheels | Often bulkier |

Efficiency | 360° rotatable handles | Limited rotation options |

You overcome common challenges in confined spaces, such as limited access and poor ventilation, by using a toe jack with a compact and stable design. Powerful Machinery toe jacks meet and exceed industry standards, giving you confidence in every lift.

What is a Toe Jack Used For?

Industrial and Precision Uses

You rely on a toe jack for tasks that demand accuracy and control in industrial settings. In manufacturing, you lift and position assembly line machines, conveyors, and robotic arms. The energy sector uses toe jacks to raise power transformers and turbines.

Construction teams move prefabricated components and heavy molds with ease. Mining operations depend on toe jacks to transport crushers and mills. Logistics and warehousing professionals adjust large storage racks and packing systems efficiently.

Machinery installation and maintenance

Precision alignment in automotive manufacturing

Infrastructure repair, such as bridge section stabilization

Toe jacks minimize vibration during lifts, which helps you protect sensitive equipment like CNC machines and semiconductor tools. You make fine height adjustments, ensuring precise placement and reducing downtime.

Machinery Rigging and Heavy Lifting

You use toe jacks at the start of machine moves, especially when you need to position equipment under tight clearances. The compact design allows you to slide the jack under loads easily. Toe jacks provide dual lifting capabilities, so you handle both low-clearance and high-clearance objects.

You find them essential for rigging, repairs, and installations.

Feature | Capacity |

|---|---|

Toe capacity | 5 tons |

Head capacity | 10 tons |

Typical range | 5 to over 100 tons |

You trust toe jacks for lifting and handling heavy loads in confined spaces, where traditional equipment cannot operate safely.

Use Cases in Construction and Warehousing

You encounter toe jacks in construction when positioning beams, molds, or prefabricated panels. Warehousing teams use them to shift large racks or heavy packing systems. The ability to lift, align, and move bulky items with precision makes toe jacks indispensable in these environments.

Tip: Always check the load capacity and ensure stable placement before lifting. This practice keeps your operation safe and efficient.

Toe jacks help you streamline workflows, reduce manual labor, and maintain safety standards across diverse industries.

Toe Jack vs Bottle Jack

Design and Use Differences

You often face the choice between a toe jack and a bottle jack when lifting heavy loads. Each tool serves a unique purpose. A toe jack features a low-profile toe that slides under equipment with minimal ground clearance. You use it for machinery that sits close to the floor.

The hydraulic mechanism gives you precise control, even in tight spaces.

A bottle jack stands upright with a vertical lifting piston. You use it for vehicles or objects with enough clearance for the jack to fit underneath. Bottle jacks offer a higher vertical lift, but they require more space to operate.

Feature | Toe Jack | Bottle Jack |

|---|---|---|

Lifting Position | Horizontal toe or top head | Vertical piston |

Clearance Needed | Ultra-low, fits under 1.2 in (30 mm) | Requires higher clearance |

Typical Use | Machinery, industrial equipment | Vehicles, general lifting |

Portability | Compact, easy to maneuver | Often heavier, less compact |

Precision | High, ideal for fine adjustments | Moderate, best for straight lifts |

Tip: Use a toe jack when you need to lift heavy equipment in confined spaces. Choose a bottle jack for straightforward vertical lifts where space is not an issue.

When to Choose Each Jack?

You should select a toe jack if you work in environments with low clearance or need to position heavy machinery with precision. Toe jacks excel in factories, warehouses, and construction sites where equipment sits close to the ground.

You benefit from their compact design and dual lifting points, which allow for both toe and head lifts.

Choose a bottle jack when you need to lift vehicles, trailers, or objects with enough space underneath. Bottle jacks provide greater vertical lift and work well for automotive repairs or general maintenance.

Consider these factors when making your choice:

Clearance: Use a toe jack for low-clearance jobs. Use a bottle jack for higher-clearance tasks.

Load Type: Select a toe jack for heavy, awkward machinery. Select a bottle jack for vehicles or simple lifts.

Precision: Rely on a toe jack for fine adjustments. Rely on a bottle jack for quick, vertical lifts.

Note: Powerful Machinery offers a range of hydraulic toe jacks designed for industrial precision and safety. You can explore their models to find the best fit for your lifting needs.

Choosing a Toe Jack

Selection Factors and Specifications

You want to choose the right lifting jack for your operation. Start by considering the lifting capacity you need. Always match the jack’s rated capacity to the heaviest load you plan to lift. Measure the clearance under your equipment. Select a jack with a toe height that fits easily beneath your machinery.

Build quality matters. Look for a jack with a carbon steel base and corrosion-resistant features. These details ensure long service life and safe operation.

Think about the environment where you will use the jack. If you work in tight or confined spaces, a compact design will help you maneuver the jack more easily. Dual strain control and a stable base add extra safety during high-capacity lifting tasks.

You should also review the total cost of ownership, not just the purchase price. Maintenance, compliance with safety standards, and staff training all affect your long-term investment.

Cost Factor | Description |

|---|---|

Unit Price | The initial cost of purchasing a toe jack. |

Minimum Order Quantities (MOQ) | Bulk orders can lead to reduced per-unit costs, typically by 15-30%. |

Total Ownership Costs | Includes maintenance and other long-term expenses associated with the jack. |

Compliance with Safety Standards | Costs related to ensuring the toe jack meets necessary safety regulations. |

Specialized Training | Potential costs for training staff to use and maintain the equipment. |

Tip: Advanced toe jacks may have higher initial costs, especially for small and medium businesses. Regulatory compliance can also add complexity, depending on your location.

Powerful Machinery Support and Consultation

You can rely on Powerful Machinery for expert guidance when selecting a toe jack. The team offers personalized consultations to help you match the right model to your specific needs.

You receive support from the initial inquiry to after-sales service. Powerful Machinery provides detailed product specifications, safety certifications, and maintenance advice. If you need a custom solution, the company can engineer a jack to fit your unique requirements.

You benefit from a wide product range, including models for both standard and high-capacity lifting. The support team helps you understand technical details and cost factors, so you can make an informed decision.

Visit the Powerful Machinery website to explore available models or request a consultation. With the right lifting jack and expert support, you ensure safe, efficient, and reliable lifting for every project.

Conclusion

You depend on toe jacks for safe, precise lifting in demanding environments. Their low profile lets you slide under equipment with minimal clearance. Hydraulic controls give you smooth, accurate movement. Wide bases and overload protection keep your operation stable.

Powerful Machinery Toe Jacks deliver reliable performance for every project.

Key Benefit | Why It Matters |

|---|---|

Low Profile Lifting | Fits under tight spaces |

Precision Load Control | Ensures safe, smooth operation |

Stability and Safety | Reduces risk during heavy lifting |

Always follow safety guidelines and consult experts to choose the right jack for your needs.

FAQ

What is the main advantage of using a toe jack?

You can lift heavy equipment in spaces with very low clearance. The toe jack’s low-profile design lets you position it under machinery where other jacks cannot fit.

How do you maintain a hydraulic toe jack?

You should clean the jack regularly, check hydraulic fluid levels, and inspect for leaks. Lubricate moving parts and store the jack in a dry place to prevent rust.

Can you use a toe jack for lifting vehicles?

You can use a toe jack for vehicles if the toe fits under the frame and the weight does not exceed the jack’s rated capacity. Always check clearance and load limits first.

What safety precautions should you follow when using a toe jack?

Always place the jack on a stable surface. Wear safety gear. Never exceed the rated capacity. Support the load with jack stands and never work under a suspended load.

How do you choose the right toe jack for your needs?

You should match the jack’s capacity to your heaviest load. Measure the clearance under your equipment. Choose a model with a durable base and safety features for your environment.