From the towering cranes that shape our city skylines to the mine hoists operating deep within the earth, steel wire rope is the unsung hero performing immense work under constant stress. But the greatest threat to a rope’s integrity often isn’t a single, catastrophic overload. It’s a more gradual, invisible force: metal fatigue. This silent process of weakening from repeated bending and loading is a primary cause of unexpected rope failure. A rope’s ability to withstand this grueling cycle is called fatigue resistance.

What is Metal Fatigue in Wire Rope?

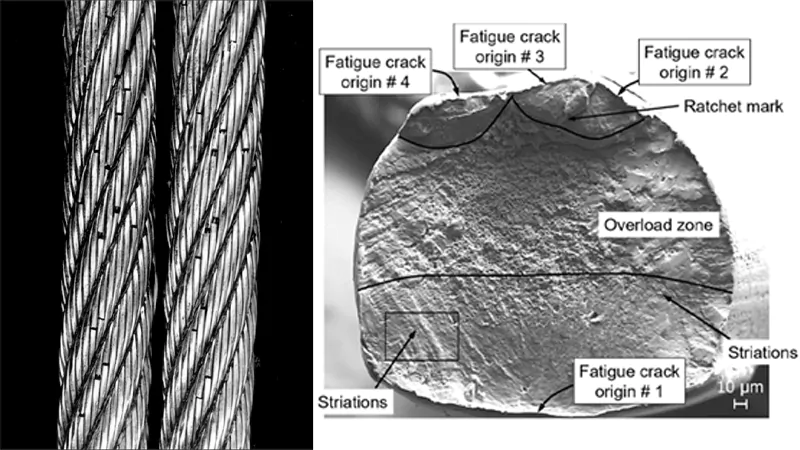

Unlike a failure from a single overload event, metal fatigue is a more insidious process. It doesn’t happen all at once. Instead, it’s the progressive structural damage that occurs when a material is subjected to repeated, or cyclic, loading. Even if the stress applied in each cycle is well below the material’s ultimate tensile strength, tiny, microscopic cracks can begin to form, usually at a point of stress concentration. With every subsequent cycle of bending and loading, these cracks slowly grow and propagate through the steel’s crystalline structure until the remaining cross-section of the wire can no longer support the load, leading to a sudden and often unexpected fracture.

A simple way to visualize this is to bend a paperclip back and forth in the same spot. It doesn’t break on the first bend, but each repetition adds to the internal damage until it suddenly snaps. This is fatigue in action.

For a steel wire rope, this cyclic stress primarily manifests in three ways:

- Bending Fatigue: The most common and significant type, caused every time the rope bends as it passes over a sheave or around a drum.

- Tensile Fatigue: The stress variation from the rope repeatedly lifting and lowering a load.

- Vibratory Fatigue: Caused by high-frequency, low-amplitude vibrations, which can be a factor in stationary ropes or long spans.

Why Fatigue Resistance is a Critical Property

While specifications like minimum breaking strength are important, fatigue resistance is arguably the most critical performance indicator for ropes in dynamic, high-cycle applications. Understanding its importance is key to enhancing safety, maximizing uptime, and achieving long-term value. The benefits are threefold:

1. Foundational for Safety: Fatigue failure is particularly dangerous because it can occur suddenly and without obvious prior warning signs, often under normal working loads. A rope with high fatigue resistance provides a crucial safety margin, mitigating the risk of catastrophic failure that could endanger personnel, damage expensive equipment, and halt operations. It is a direct investment in a safer work environment.

2. Extended Service Life and Reliability: A wire rope is a consumable component, but its lifespan can vary dramatically. High fatigue resistance directly translates to a longer, more predictable service life. This means fewer replacements, more reliable performance, and greater confidence in your equipment’s ability to perform day in and day out.

3. Lower Total Cost of Ownership (TCO): The true cost of a wire rope goes beyond its initial purchase price. A rope with poor fatigue resistance may be cheaper upfront but will lead to more frequent replacements, increased labor costs for installation, and costly operational downtime. By choosing a rope engineered for high fatigue resistance, you lower the TCO by maximizing the working life of your components and keeping your operations running smoothly and profitably.

Key Factors That Influence Wire Rope Fatigue Resistance

A wire rope’s resistance to fatigue is not a single property but the result of a complex interplay between its design, its operating environment, and its quality of manufacture. Understanding these key factors is essential for selecting the right product and maximizing its service life.

A. Rope Construction and Design

The internal architecture of a wire rope is the primary determinant of its inherent fatigue resistance.

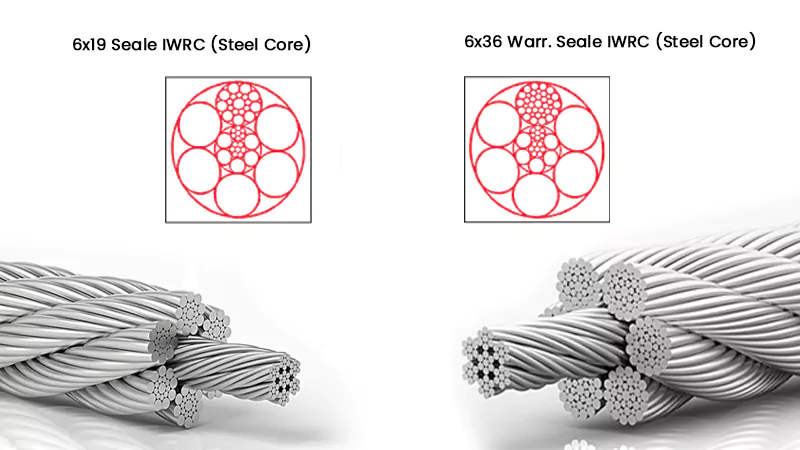

- Wire Count and Flexibility: Ropes with a higher number of smaller individual wires per strand (e.g., a 6×36 classification) are more flexible than those with fewer, larger wires (e.g., a 6×19 classification). This increased flexibility allows the rope to bend more easily over sheaves, reducing internal stresses and significantly improving fatigue life.

- Lay Type (Lang vs. Regular): In a Lang Lay rope, the wires in the strands are twisted in the same direction as the strands around the core. This creates a larger surface area for each wire to contact the sheave, distributing wear and bending stresses more evenly and resulting in superior fatigue resistance compared to Regular Lay ropes.

- Core Type (IWRC vs. Fiber Core): An Independent Wire Rope Core (IWRC) provides a solid steel foundation that supports the outer strands, helping the rope maintain its shape under heavy loads. This firm support prevents internal cross-wiring and crushing, which are major contributors to premature fatigue failure, especially in demanding applications.

B. Equipment and Operational Factors

How a rope is used has as much impact on its fatigue life as its construction.

- The Critical D/d Ratio: This is the single most important operational factor. It is the ratio of the diameter of the sheave or drum (D) to the nominal diameter of the wire rope (d). A small D/d ratio forces the rope into a sharp bend, drastically increasing internal stresses and accelerating fatigue. A larger D/d ratio creates a gentler bend and exponentially increases fatigue life. Following recommended D/d ratios for your application is crucial.

- Reverse Bends: Forcing a rope to bend in one direction and then back in the opposite direction (an ‘S’ path) is exceptionally damaging. A single reverse bend can inflict more fatigue damage than several simple bends.

- Load Conditions: While fatigue is caused by cyclic loading, factors like shock loading, overloading, and excessive vibration place additional stress on the rope, speeding up the fatigue process.

C. Manufacturing Quality and Maintenance

- Material and Manufacturing: The fatigue life of a rope begins with high-quality, high-carbon steel wire that is manufactured to precise specifications. Proper tension control during the stranding and closing processes ensures that all wires and strands work together harmoniously.

- Lubrication: Proper lubrication is the lifeblood of a wire rope. It reduces the internal friction generated as wires and strands move against each other during bending. This not only fights fatigue but also prevents corrosion, another factor that can accelerate crack formation.

How to Select a Wire Rope with High Fatigue Resistance

With an understanding of the key factors, you can make a more informed decision when selecting a wire rope. The right choice is a balance between the rope’s design and your application’s specific demands. Follow this simple three-step approach:

- Analyze Your Operating Conditions: Before looking at any catalog, evaluate your equipment. What is the D/d ratio of your sheaves and drums? Does the rope path involve reverse bends? What are the typical and maximum loads? Answering these questions will define the performance you need.

- Review the Rope Specifications: Based on your analysis, you can now intelligently read a spec sheet. For applications demanding high fatigue life, prioritize ropes with more wires (like 6×36 classification), consider Lang Lay construction for better wear distribution, and almost always choose an Independent Wire Rope Core (IWRC) for superior strength and crush resistance.

- Consult the Experts (The Most Crucial Step): Every application has unique challenges. To ensure maximum safety, service life, and return on investment, relying on expert advice is paramount. A technical specification sheet can’t always account for the nuances of your specific operational environment.

That’s where we come in. The engineering team at Qingdao Powerful Machinery specializes in analyzing application requirements to recommend the optimal wire rope solution. Don’t guess when it comes to safety and performance.

Contact our technical experts today for a free consultation to find the perfect high-fatigue-resistance rope for your needs.

Conclusion

Fatigue resistance is more than just a technical term; it’s the core measure of a wire rope’s endurance, safety, and long-term value. While factors like rope construction, D/d ratios, and proper lubrication are critical, the most important decision is choosing the right rope for the job from the start.

By prioritizing high-fatigue-resistance ropes, you are not just buying a component; you are investing in operational reliability, a safer workplace, and a healthier bottom line.