Look at any major feat of modern engineering—a skyscraper touching the clouds, a massive ship being moored, or a deep-sea drilling rig exploring the ocean floor—and you will find an unsung hero at its core. While often perceived as a simple cable, a steel wire rope is more accurately defined as a complex machine. It is a precisely engineered assembly of individual steel wires twisted into strands, which in turn are laid helically around a central core. Each component is designed to move and interact, working in unison to support immense loads and transmit incredible force across vast distances.

We will go beyond a basic definition to delve into the materials that provide its strength, the construction and lay that dictate its performance characteristics, and the protective finishes that ensure its longevity. Our goal is to equip you with the essential knowledge to specify the right rope for your project, ensuring maximum safety, efficiency, and service life.

What is Wire Rope Made Of? The Core Components

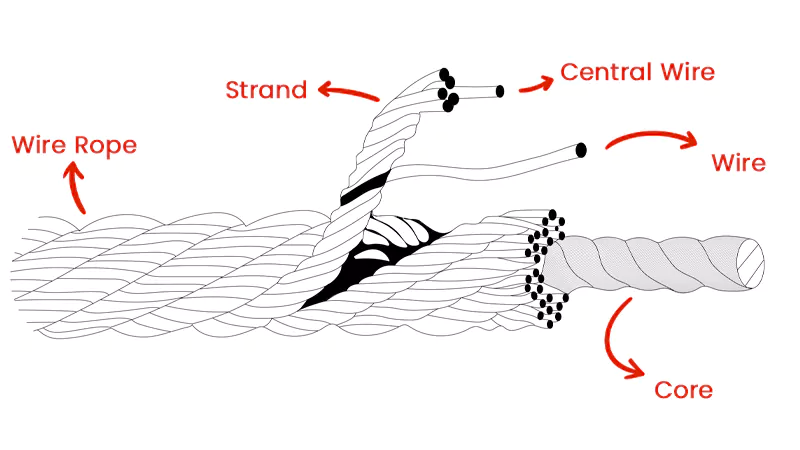

To truly understand a wire rope‘s capabilities, one must first understand its anatomy. Every wire rope, regardless of its size or ultimate application, is constructed from three fundamental components. The specific material, size, and arrangement of these components are precisely engineered to produce a rope with specific characteristics like strength, flexibility, and resistance to abrasion and fatigue.

The Wire: The Basic Building Block

The wire is the most basic element of a rope. These wires are typically manufactured from high-carbon steel, selected for its high tensile strength and durability. The steel rods are cold-drawn through a series of dies that reduce their diameter and increase their strength. The final tensile strength of the wire is designated by grades. While there are many grades, common ones in the lifting industry include Extra Improved Plow Steel (EIPS) and Extra Extra Improved Plow Steel (EEIPS), with EEIPS being approximately 10% stronger than EIPS.

The Strand: The First Level of Assembly

Individual wires are helically twisted together into a single group to form a strand. This arrangement allows the stresses of bending and tension to be distributed among the wires, giving the rope its ability to move and flex. Strands can be produced in various configurations with different numbers of wires and geometric patterns (e.g., Seale, Warrington, Filler), each offering a different balance between properties like abrasion resistance and fatigue resistance. A strand with fewer, larger wires will be more abrasion-resistant, while a strand with more, smaller wires will be more flexible and fatigue-resistant.

The Core: The Heart of the Rope

The core is the central member around which the main strands are laid. It provides proper support and positioning for the strands, especially when the rope is under load. The core type is one of the most critical factors in a rope’s design. There are three primary types:

- Fiber Core (FC): This core is made of natural (sisal) or synthetic (polypropylene) fibers. It offers the highest flexibility and acts as a reservoir for lubrication. However, it provides the least amount of support and is susceptible to crushing on drums.

- Independent Wire Strand Core (IWS): This core is a single steel strand, typically of the same construction as the main strands. It offers better support and higher strength than an FC core.

- Independent Wire Rope Core (IWRC): This is the strongest and most durable core type. It is a fully-formed wire rope in itself, offering the best support against crushing, the highest strength, and superior heat resistance.

Choosing the right core is critical for a rope’s performance and service life, especially under high loads or on multi-layer drums. To determine which core type—FC, IWS, or IWRC—is optimal for your specific equipment and operating conditions, contact our technical experts for a consultation.

What is Wire Rope Lay? The Art and Science of Construction

If the wires, strands, and core are the components of a wire rope, then the “lay” is the precise architectural blueprint that dictates how they are assembled. The term “lay” refers to the direction in which the wires are twisted to form a strand, and the direction the strands are twisted around the core. This geometric arrangement may seem like a minor detail, but it fundamentally defines the rope’s handling characteristics, stability, and resistance to wear and fatigue. Understanding lay is essential for specifying a rope that will perform optimally and safely in its intended application.

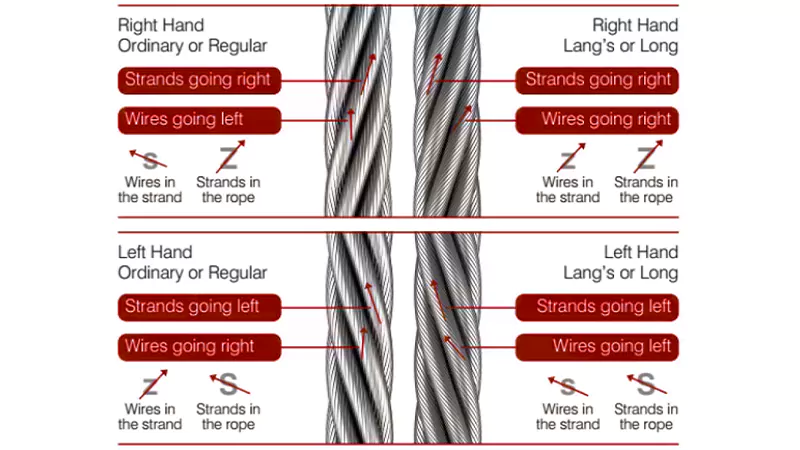

Direction of Lay: Right vs. Left

This is the most basic classification of lay and simply refers to the direction in which the strands are laid around the core. When looking down a rope, if the strands appear to spiral away from you to the right (like a standard screw thread), it is a Right Hand Lay (RHL). If they spiral to the left, it is a Left Hand Lay (LHL). Right Hand Lay is the most common and is considered the standard for most applications unless otherwise specified.

Type of Lay: Regular Lay vs. Lang Lay

This is the most critical distinction in lay type, describing the relationship between the wire lay direction and the strand lay direction.

- Regular Lay (or Ordinary Lay): The wires in the strands are laid in the opposite direction to the direction of the strands around the core. This creates an appearance where the outer wires are roughly parallel to the rope’s axis.

- Advantages: Regular Lay ropes are highly stable, have good crush resistance, are less prone to kinking, and are easier to handle. Their stability makes them the default choice for a wide variety of applications.

- Disadvantages: The shorter exposed length of the outer wires means they can wear more quickly, and their fatigue resistance is generally lower than a Lang Lay rope.

- Lang Lay: The wires in the strands are laid in the same direction as the strands around the core. This creates a smoother appearance where the outer wires appear to run diagonally across the rope.

- Advantages: Lang Lay ropes offer superior wear resistance because the outer wires have a longer exposed surface area. They are also more flexible and have a significantly better fatigue life, making them excellent for applications with a lot of bending over sheaves.

- Disadvantages: They have a strong tendency to untwist and are highly susceptible to kinking and damage from improper handling. They must only be used in applications where both ends of the rope are fixed and prevented from rotating.

The choice between Regular and Lang Lay directly impacts a rope’s handling characteristics, wear patterns, and lifespan. For expert guidance on selecting the correct lay for your specific crane, hoist, or winch, consult with a PowerFul Machinery specialist to prevent premature wear and enhance safety.

Understanding Rope Construction (e.g., 6×19, 6×36)

Finally, the lay and components come together in a specific “construction,” denoted by numbers. For example, in “6×19,” the first number (6) is the number of strands, and the second number (19) represents a class or nominal count of wires per strand. Different constructions create different performance trade-offs:

6×36 Class: This construction uses a greater number of finer wires. It provides excellent flexibility and superior fatigue resistance, but is more susceptible to abrasion.

6×19 Class: This construction uses fewer, larger wires. It provides excellent abrasion resistance and good strength, but it is less flexible.

What is Galvanized Wire Rope? Protection Against the Elements

Even the strongest steel is vulnerable to an insidious enemy: corrosion. Rust is not merely a cosmetic issue; it degrades the metallic cross-section of the wires, reduces a rope’s strength, accelerates fatigue, and can lead to unexpected and dangerous failures. For any wire rope that will be exposed to moisture, humidity, rain, or a marine environment, a protective barrier is not optional—it is essential for safety and a reasonable service life. Galvanization is the industry’s most trusted and widely used method for providing this protection.

The Galvanizing Process

Galvanizing is the process of applying a protective zinc coating to the steel wires to prevent rusting. Zinc is used because it acts as a “sacrificial anode”—if the coating is scratched, the zinc will corrode first, continuing to protect the underlying steel. The most effective method, and our standard for durable protection, is Hot-Dip Galvanizing. In this process, the individual wires are passed through a bath of molten zinc, which forms a thick, durable, and metallurgically bonded coating.

Finishes and Alternatives

While galvanization is the standard for corrosion protection, other options exist for specific applications:

- Bright (or Un-galvanized): This is a bare steel rope with no protective coating, typically lubricated to offer minimal protection. It is only suitable for dry, indoor, low-corrosion environments.

- Stainless Steel: For the highest level of corrosion resistance, stainless steel wire rope is the premium choice. It is ideal for marine, wastewater, chemical, and food processing applications where the rope is constantly exposed to highly corrosive agents.

The operational environment dictates the best protection. Choosing between a bright, galvanized, or stainless steel finish is a critical cost-versus-lifespan decision. Allow our team to help you specify the most cost-effective solution to maximize the service life of your rope and ensure long-term safety.

What is Wire Rope Used For? A World of Critical Applications

As one of the most fundamental components in modern engineering, steel wire rope is the indispensable muscle behind countless operations that shape our world. Its unique combination of strength, flexibility, and durability makes it the optimal solution for transmitting immense force over distances, lifting heavy loads to great heights, and providing steadfast structural support. Its applications are vast and varied, touching nearly every foundational sector of the global economy. Below are some of its most critical uses, categorized by function.

Lifting & Hoisting

This is the most common application, where the rope is used to lift and lower heavy objects. The rope must have a balance of strength, flexibility, and fatigue resistance to handle the dynamic loads and repeated bending over sheaves.

- Examples: Main and auxiliary hoist lines on tower cranes, mobile cranes, and overhead factory cranes; elevator hoist ropes; and hoist lines for industrial electric hoists.

Mooring & Towing

In marine environments, wire rope is used to secure and move massive vessels. These ropes must have high strength and excellent resistance to corrosion and abrasion.

- Examples: Mooring lines to secure supertankers and container ships to docks; main tow lines for ocean-going tugboats; and anchor lines for offshore platforms and vessels.

Rigging & Support

In these static or semi-static applications, the rope is used to support, suspend, or secure structures. Strength and low stretch are often the most critical properties.

- Examples: Fabricating slings for versatile lifting; serving as structural guy wires for communication towers, flare stacks, and antennas; and as suspension cables for bridges.

Specialized Industries

Beyond general use, highly specialized wire ropes are engineered for some of the world’s most demanding industries, each with its own unique challenges.

- Examples: Hoist ropes in deep-shaft mining; high-strength drilling lines in the oil and gas industry; and durable skidding and skyline ropes in forestry and logging operations.

Conclusion

As this guide has illustrated, a steel wire rope is far more than a simple commodity; it is a complex and highly engineered machine. From the grade of steel used in its wires to the specific lay of its strands and the type of core at its heart, every detail is critical to its performance. Understanding these components is the first step, but applying that knowledge to select the optimal rope from hundreds of potential configurations is a crucial engineering decision. An incorrect choice can lead to inefficient operations, premature wear, and—most critically—a compromise in safety.

Don’t leave the safety and efficiency of your operation to chance. For expert guidance on specifying the perfect steel wire rope for your application—from material grade to final termination—contact the engineering team at PowerFul Machinery today for a comprehensive consultation.