Wire rope splicing joins two wire ropes or creates a loop at the end of a rope using specialized techniques. You need strong, secure connections for lifting and rigging tasks. Proper splicing helps prevent accidents and equipment failure. Powerful Machinery’s certified Steel Wire Rope gives you confidence in every splice.

Safety and reliability start with the right tools and methods. You will learn practical steps and smart safety tips for successful splicing.

Key Takeaways

Wire rope splicing creates strong connections for lifting tasks. Proper splicing prevents accidents and equipment failures.

Use the right tools, like marlin spikes and fids, to ensure a secure splice. Always check local regulations before starting.

Regular inspections of spliced wire ropes are crucial. Inspect before each use in harsh conditions and at least once a year for lighter use.

Choose certified wire rope for splicing. Certified products meet safety standards and enhance reliability during lifting operations.

Follow safety practices when splicing. Wear protective gear, keep your workspace clean, and inspect your splices for damage.

Wire Rope Splicing Basics

What Is Wire Rope Splicing

Wire rope splicing creates a strong connection between two wire ropes or forms a secure loop at the end of a rope. You use this technique to make wire ropes longer or to prepare them for lifting tasks. Splicing involves weaving or joining the strands of wire rope in a way that keeps the rope’s strength and flexibility.

You need to follow specific steps and use the right tools to make sure the splice holds up under heavy loads.

Wire rope splicing is not just a simple knot. You must use methods that match the demands of your job. For example, marlin spikes help you separate strands and tuck them properly. Some types of splices are only allowed for non-load-bearing lines, so you need to know which method fits your application.

Tip: Always check local regulations before you start splicing. Some rules restrict the use of certain splices for safety reasons.

Why Splicing Matters in Lifting and Rigging?

You rely on wire rope splicing to keep lifting and rigging operations safe and efficient. A well-made splice prevents accidents and equipment failures. You see wire rope splicing in many industries where safety is critical.

Mining: You use wire ropes for mineshaft elevators and lifting minerals in tough environments.

Transportation: Wire ropes help build automobile parts and operate cranes. Their durability and resistance to corrosion make them ideal for these jobs.

Manufacturing: Wire rope slings lift heavy loads on construction sites and shipyards.

You must follow strict safety standards when you splice wire ropes. Monthly inspections are required by OSHA. Each inspection needs an identifier, date, and the inspector’s name.

You also need to use approved tools and methods. For example, marlin spikes are required for splicing, and some splices are not allowed except for non-load-bearing lines.

Regulation | Description |

|---|---|

OSHA | Requires adherence to safety standards in wire rope operations. |

ASME | Sets standards for equipment and practices in lifting operations. |

ISO | Provides international standards for quality and safety. |

State Regulations | Specific local laws govern splicing practices. |

Marlin spikes must be used for splicing, and specific types of splices are prohibited except for non-load-bearing lines. (Wash. Admin. Code § 296-54-55720)

Powerful Machinery Steel Wire Rope Features

You need wire rope that stands up to tough jobs and meets safety standards. Powerful Machinery’s Steel Wire Rope gives you high tensile strength and durability. The non-rotating design keeps the rope stable and prevents twisting or kinking during lifting.

You can use this wire rope in harsh environments because it resists abrasion and corrosion.

Powerful Machinery offers several configurations, such as 35W×7, 18×19, and 8×55SWS. You choose the right type for your project, whether you need extra flexibility or maximum strength. Each wire rope meets international safety standards like ISO and OSHA.

You get peace of mind knowing your splicing work uses certified, reliable products.

Note: Powerful Machinery’s Steel Wire Rope is trusted by professionals in construction, marine, transportation, and cargo handling. You can find more details on their official website.

Common Splicing Techniques

Hand Tucked Splice Method

You use the hand-tucked splice when you need a strong and flexible connection. This method involves weaving the wire rope strands back into the rope body. You perform a full tuck by separating the strands and tucking each one under the others in a specific pattern.

You repeat the full tuck several times to secure the splice. The hand-tucked splice works well for custom rigging jobs and repairs. You often see this technique in industries that require precise control over the rope’s strength and flexibility.

Powerful Machinery’s Steel Wire Rope supports the hand-tucked splice method. The rope’s multi-layer construction allows you to separate and tuck strands easily. You achieve a secure full tuck because the rope resists abrasion and holds its shape during splicing.

Eye Splice and Wire Rope Sling Creation

You create an eye splice when you need a loop at the end of a wire rope. This loop helps you attach hooks, shackles, or other lifting hardware. You use a full tuck to weave the strands back into the rope, forming a strong and reliable eye. You often use eye splices to make wire rope slings for lifting heavy loads.

Industry standards require you to use the correct number of clips for each splice type. The table below shows the requirements:

Type of Splice | Number of Clips Required |

|---|---|

Turnback Eye Splice | Must use the number of clips specified by the manufacturer or as per Table 15-2. |

Lap Splice | Must use double the number of clips specified for a turnback eye termination or Table 15-2. |

Powerful Machinery’s Steel Wire Rope gives you the strength and stability needed for eye splices. You can trust the rope to maintain its shape and resist twisting, which is important for safe lifting operations.

Mechanical Splicing Options

You choose a mechanical splice when you want quick installation and reliable performance. Mechanical splicing techniques use metal sleeves or fittings to join wire ropes. You compress the sleeve with a special tool, creating a strong bond.

Recent advancements include fused splicing and insertion rigging, which improve strength and durability. Grommet slings offer a jointless option with a smooth surface.

Mechanical splicing is more widely used in the United States, suggesting a preference for quicker installation methods.

Hand-spliced slings may require more labor due to their traditional nature and lower capacity, indicating potentially higher labor costs.

Mechanical splices, when done properly, can be efficient and reliable, which may reduce installation time.

Powerful Machinery’s Steel Wire Rope works well with mechanical splice methods. The rope’s high tensile strength and non-rotating design ensure a secure connection. You save time and reduce labor costs by choosing mechanical splicing techniques for large projects.

Tip: Always inspect your splices before use. You improve safety and extend the life of your wire rope by following best practices.

Wire Rope Splicing Steps

Tools and Preparation

Before you start wire rope splicing, you need the right splicing tools and a safe workspace. Using the correct equipment helps you create strong, reliable connections. Each tool serves a specific purpose and affects the quality of your splice. Here is a table that shows the most common tools and their uses:

Tool | Purpose |

|---|---|

Fids | Used for splicing single and double braid ropes; different diameters for various rope types. |

Toss Splicing Wand | Makes it easier to splice braided rope; essential for arborists. |

Marlin Spike | Helps you unlay rope, untie knots, and join ropes; allows precise pulling of fibers. |

Splicing Kit | Includes a complete set of tools and a splicing manual for accurate rope splicing. |

You may also need a wooden mallet, pliers, wire cutters, a metal spike or screwdriver, and cable clips. Always check that your tools match the size and type of wire rope you plan to splice. Clean your workspace and wear gloves and safety glasses to protect yourself.

Step-by-Step Splicing Guide

You can follow these splicing steps to create a strong and safe connection. This guide covers a basic eye splice, which is one of the most common methods in wire rope splicing.

Mark the point where you want to start the splice. Use tape or chalk for a clear guide.

Unlay the strands by separating them at the marked point. Unlay about 6 to 8 strand lengths.

Insert the sling socket or sleeve, making sure the strands are evenly spread.

Tuck each strand under and over the adjacent strands of the main rope using a fid or marlin spike.

Repeat the tucking process 3 to 4 times. Use a wooden mallet to compact the tucks and keep the splice tight.

Trim the ends of the strands so they are flush with the main rope.

If you use a sleeve, compress it with a hydraulic press for extra security.

Inspect the finished splice for any signs of damage, unevenness, or loose strands.

You can also use these steps for other types of splicing, such as back or end splices, which help prevent fraying. Always follow the manufacturer’s instructions for your specific wire rope.

Tip: Powerful Machinery’s certified steel wire rope makes each splice more secure. The non-rotating design keeps the rope stable and helps you achieve a professional result.

Safety Tips for Splicing

Safety should always come first when you work with wire rope. You protect yourself and your team by following these best practices:

Wear protective gloves and safety glasses at all times.

Keep your workspace clean and free of clutter.

Use only certified wire rope and approved splicing tools.

Inspect the rope for fraying, broken wires, or corrosion before you begin.

Follow all relevant safety regulations and standards, such as OSHA and ISO.

Clean the wire rope before and after splicing to prevent internal wire breakage.

Lubricate the rope regularly to protect against corrosion and reduce friction.

Check your finished splice for loose strands or uneven tucks.

Note: Regular inspections and proper maintenance extend the life of your spliced wire rope. Powerful Machinery’s steel wire rope meets international safety standards, giving you peace of mind during every lift.

By preparing carefully, following each step, and using certified products, you ensure your wire rope splicing is safe and reliable.

Repair and Maintenance of Spliced Wire Rope

Inspecting and Repairing Splices

You need to inspect spliced wire ropes regularly to keep your equipment safe and reliable. Inspection intervals depend on how often you use the rope, the environment, and the type of lifts you perform.

Light use or clean environments: Inspect at least once a year.

Heavy or frequent use: Inspect every quarter or month.

Extreme conditions: Inspect before each use.

Look for these common signs of wear or damage:

Six or more broken wires in one lay

Three or more broken wires in one strand across one lay length

Rope diameter reduced by up to one-third

Distorted or misshapen rope

Heat damage or discoloration

Excessive stretching

Kinks, knots, or improper splices

If you find damage, follow these repair steps:

Locate the break or damaged area.

Retwist any loose ends and tighten the wire.

Create a new loop if needed and secure it with U-bolt studs.

Test the repaired area before returning the rope to service.

Maintaining Wire Rope Sling Integrity

You maintain wire rope sling integrity by following a routine maintenance plan. Always store your ropes in dry, cool areas away from chemicals and high temperatures. Corrosion and extreme heat can weaken the rope and cause stress corrosion cracking.

Clean your wire rope sling after each use to remove dirt and contaminants.

Inspect for internal and external wear, especially after heavy lifts or exposure to harsh environments.

Replace any sling that shows advanced corrosion, significant diameter loss, or structural distortion.

Powerful Machinery’s Steel Wire Rope resists abrasion and corrosion, making it easier for you to maintain sling integrity even in tough conditions.

Lubrication and Replacement Guidelines

Lubrication plays a key role in extending the life of your spliced wire rope. Regular lubrication reduces friction, prevents corrosion, and minimizes wear. Well-lubricated ropes can last up to three times longer than those without proper care. Using penetrating lubricants can double the life cycle of your wire rope sling.

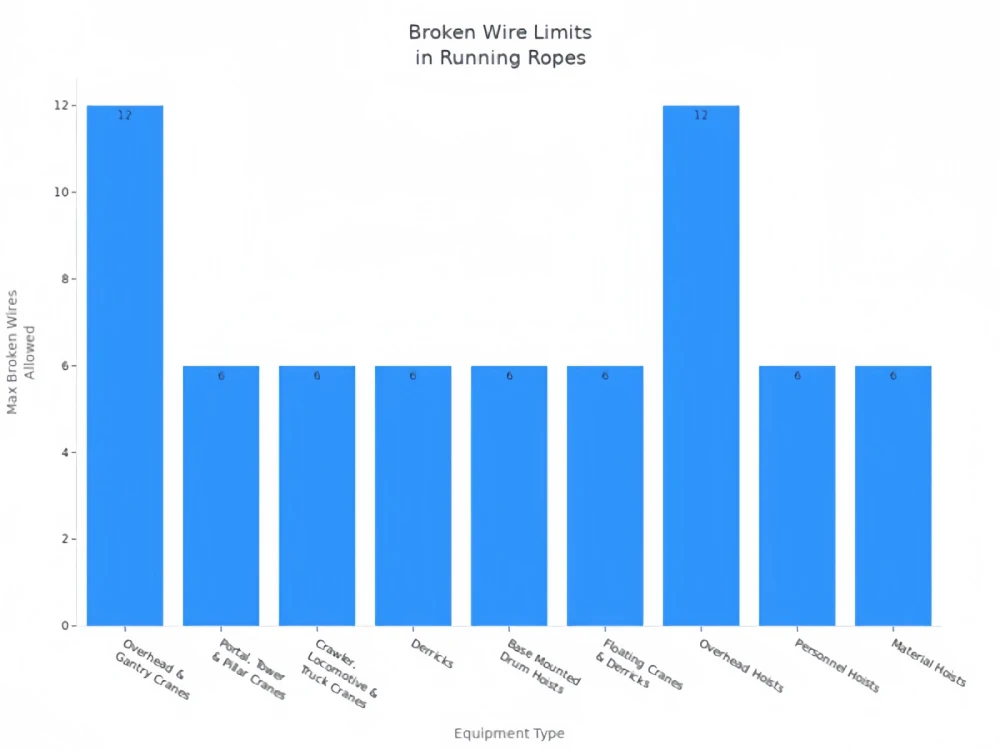

Neglecting maintenance can shorten rope life by 40%. Regular care helps you avoid costly replacements and downtime. Replacement guidelines depend on the type of equipment and the number of broken wires.

Here is a table with industry standards:

Equipment Type | Max Broken Wires (Running) | Max Broken Wires (Standing) |

|---|---|---|

Overhead & Gantry Cranes | 12 | Not Specified |

Portal, Tower & Pillar Cranes | 6 | 3 |

Crawler, Locomotive & Truck | 6 | 3 |

Derricks | 6 | 3 |

Base-Mounted Drum Hoists | 6 | 3 |

Floating Cranes & Derricks | 6 | 3 |

Overhead Hoists | 12 | Not Specified |

Personnel Hoists | 6 | 2 |

Material Hoists | 6 | Not Specified |

You protect your investment and ensure safety by following these guidelines. Powerful Machinery’s Steel Wire Rope offers durability and easy maintenance, helping you get the most out of every wire rope sling.

Conclusion

You improve safety and performance when you use proper wire rope splicing. The table below shows that eye splices reach 100% efficiency, making them the best choice for lifting tasks.

Splice Type | Efficiency Comparison | Notes |

|---|---|---|

Eye Splice | 100% | Most efficient in practical use |

Short Splice | Close to Eye Splice | Similar efficiency if done well |

Long Splice | Less than Short | Smaller diameter increase |

Long Blind Splice | Sacrifices strength | Maintains diameter, reduces strength |

Certified wire rope, like Powerful Machinery’s Steel Wire Rope, gives you high strength and durability. Regular inspection and maintenance help you extend rope life. For expert advice, you can consult professionals who offer custom solutions and trained support for your splicing needs.

FAQ

What is the main advantage of using non-rotating steel wire rope for splicing?

You get better safety and stability. Non-rotating wire rope resists twisting and kinking during lifts. This feature helps you maintain control and reduces the risk of accidents in demanding environments.

How often should you inspect spliced wire rope?

You should inspect spliced wire rope before each use in harsh conditions. For lighter use, check at least once a year. Regular inspections help you spot damage early and keep your equipment safe.

Can you use any wire rope for splicing?

You need certified wire rope for splicing. Certified products, like Powerful Machinery’s Steel Wire Rope, meet safety standards and perform reliably. Using uncertified rope increases the risk of failure and accidents.

What tools do you need for wire rope splicing?

You need fids, marlin spikes, wire cutters, and a splicing kit. These tools help you separate strands, tuck wires, and secure the splice. Always match your tools to the rope size and type.

How do you know when to replace a spliced wire rope?

You should replace the rope if you see broken wires, reduced diameter, kinks, or corrosion. Follow industry guidelines for maximum broken wires. Replacing damaged rope keeps your lifting operations safe.