You need to certify lifting chains at least once every 12 months, following OSHA, ASME, and global standards. Certification protects your team and business from costly accidents. Over 2.6 million nonfatal workplace injuries occurred in 2023, with each incident averaging $43,000 in costs.

Poor rigging caused 27% of load drops. To answer the question of how often lifting chains need to be certified, it’s essential to adhere to these guidelines to ensure safety and compliance. Powerful Machinery provides certified lifting chains that help you meet these strict requirements and improve safety.

Workplace Injuries | Cost of Injuries | Load Drops |

|---|---|---|

2.6 million+ | $43,000 avg. | 27% due to poor rigging |

Key Takeaways

Certify lifting chains at least once every 12 months to comply with OSHA and ASME standards. This protects your team and reduces the risk of accidents.

Perform regular inspections based on usage: inspect chains before each shift for frequent use, and conduct thorough inspections at least annually for normal service.

Keep detailed records of all inspections and certifications. This documentation helps prove compliance and enhances workplace safety.

Choose certified products like Powerful Machinery’s G80 Lifting Chain. These chains meet strict safety standards and provide peace of mind during lifting operations.

Stay proactive by scheduling inspections and using certified equipment. This approach helps maintain a safe and compliant workplace.

How Often Do Lifting Chains Need to Be Certified?

Annual Certification Requirements

You must understand how often lifting chains need to be certified to maintain a safe and compliant workplace. OSHA and ASME standards require you to certify lifting chains at least once every 12 months. This annual interval applies to most industries and ensures that your equipment remains in top condition.

Powerful Machinery’s G80 Lifting Chain meets these strict standards. Each chain comes with a certificate of conformity and passes rigorous testing, so you can trust its reliability for overhead lifting.

Annual certification is not just a legal requirement. It is a vital step to protect your team and assets from unexpected failures.

The frequency of certification can change based on how you use your lifting chains. You need to consider the service type and environment. The following table shows how often lifting chains need to be certified under different conditions:

Service Type | Definition | Inspection Timing |

|---|---|---|

Normal | Less than 65% of the rated load and used 15% of the time or less | Annual |

Heavy | Greater than 65% of rated load and/or used more than 15% of the time | Every 6 months |

Severe | Non-standard conditions: High or low temperatures, outdoor and/or salt water exposure, caustic environment, etc. | Quarterly |

If you work in general industry or construction, you do not need formal certification for cranes or material handling devices. You must keep inspection records and ensure a competent person performs the checks.

In maritime sectors, certification may be required for cranes used in longshoring or aboard vessels. You must use specific forms to comply with OSHA regulations.

Periodic and Frequent Inspections

Knowing how often lifting chains need to be certified is only part of the process. You must also perform regular inspections to catch wear and damage before they become hazards.

OSHA and ASME recommend periodic inspections every 12 months for normal service. For severe conditions, you should inspect quarterly or even monthly.

You need to understand the types of inspections:

Inspection Type | Frequency |

|---|---|

Periodic Inspection | Minimum every 12 months; more frequent (monthly to quarterly) for severe service conditions. |

Frequent Inspection | Recommended before any change in shift or lifting application; before each use for severe service. |

Initial Inspection | Conducted upon receiving new rigging products to ensure proper ratings and conditions. |

If your lifting chains see frequent use, inspect them before each shift. For special or infrequent use, inspect before every lift and document your findings. The table below summarizes these requirements:

Service Condition | Inspection Requirement |

|---|---|

Frequent Use | Inspect rigging equipment before each shift. |

Periodic Inspection | Conduct thorough inspections at least once every 12 months, based on severity and use. |

Special/Infrequent Use | Inspect before each use and document the inspection. |

Powerful Machinery’s G80 Lifting Chain supports your compliance efforts. Each chain is designed for easy inspection and comes with clear documentation. You can rely on its strength and certification to meet OSHA, ASME, and international standards.

Tip: Always keep detailed inspection records. This practice helps you prove compliance and improves workplace safety.

You must stay proactive. By understanding how often do lifting chains need to be certified and following inspection schedules, you reduce risks and ensure your lifting operations run smoothly.

Standards and Regulations (LOLER, OSHA, ASME)

LOLER and International Standards

You must understand how LOLER and other international standards shape the way you handle lifting chain certification. The Lifting Operations and Lifting Equipment Regulations (LOLER) set strict requirements for all lifting equipment in the UK and Europe.

Loler testing ensures that you perform a thorough examination of your chains at set intervals. You need to follow these intervals to stay compliant:

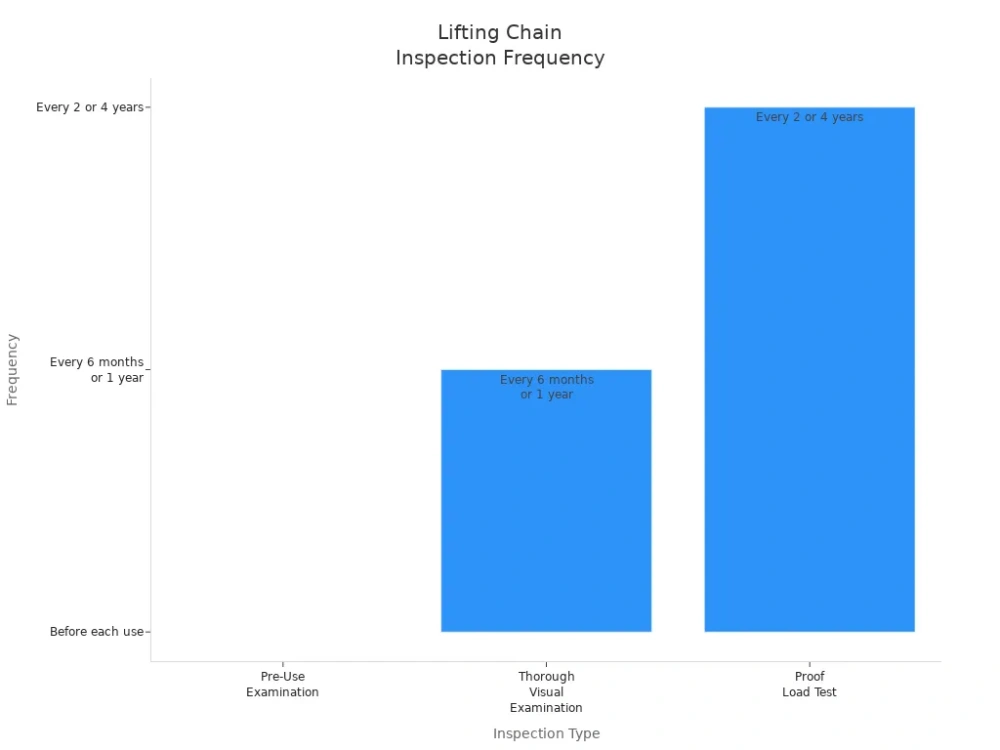

Inspection Type | Frequency | Responsible Party |

|---|---|---|

Pre-Use Examination | Before each use | User |

Thorough Visual Examination | Every 6 months or 1 year | A competent person from the Certifying Society |

Proof Load Test | Every 2 or 4 years | A competent person from the Certifying Society |

Loler requires you to conduct a pre-use examination before every lift. You must also schedule a thorough examination at least every 6 to 12 months, depending on your application. Loler testing also mandates a proof load test every few years. These regulations help you prevent failures and keep your workplace safe.

The EN 818 standard supports loler by defining technical requirements for chain slings. You must follow these lifting equipment regulations to avoid penalties and ensure safety.

OSHA and ASME Guidelines

In the United States, OSHA and ASME set the foundation for lifting chain regulations. OSHA enforces workplace safety, while ASME develops technical standards for design, inspection, and training. You must follow these guidelines to meet legal and safety requirements:

Organization | Role | Key Functions |

|---|---|---|

OSHA | Enforcer | Inspects workplaces, issues citations, and can shut down operations for violations. |

ASME | Developer | Creates standards for equipment design, inspection, and training. |

ANSI | Facilitator | Accredits organizations and approves standards to promote safety. |

You must perform a proof test before using new or repaired gear. ASME requires you to test most slings at 125% of their working load limit. You need to inspect slings regularly and keep records. Tag each sling with its load capacity and manufacturer.

Remove any sling that fails inspection. OSHA and ASME also require you to train your team and document every examination. These regulations ensure you catch problems early and keep your lifting operations safe.

Requirement | Description |

|---|---|

Frequency of Inspection | At least one periodic inspection every 12 months, with more frequent inspections based on duty class. |

Compliance | Enforce and comply with all OSHA and ASME standards. |

Training | Ensure proper personnel training. |

Documentation | Maintain records of inspections. |

Powerful Machinery Product Compliance

You can trust Powerful Machinery to meet all major lifting equipment regulations. The G80 Lifting Chain undergoes strict loler testing and examination at every stage. Powerful Machinery selects only high-quality steel from trusted suppliers. The manufacturing process uses advanced heat treatment to boost strength.

Every chain passes rigorous load and non-destructive testing. You receive a certificate of conformity with each product, proving compliance with Loler, OSHA, ASME, NACM, and ASTM standards. Powerful Machinery’s commitment to quality and safety helps you pass every examination and inspection.

You can rely on these chains for demanding rigging inspections and lifting operations worldwide.

Tip: Always keep your inspection and examination records up to date. This habit helps you stay compliant with all lifting equipment regulations and pass any loler or OSHA audit.

Certification vs Inspection

What does Certification mean?

Certification confirms that your lifting chains meet all safety and performance standards. You receive a certificate after a thorough examination and a proof load test. This document shows that your equipment passed all required inspections and meets OSHA, ASME, and international regulations.

Certification is not just a formality. It proves your chains are safe for use and ready for demanding lifting operations. You must keep this certificate available for review during audits or workplace inspections.

Powerful Machinery provides a certificate of conformity with every G80 Lifting Chain, giving you confidence in your compliance.

Inspection Types

You need to understand the difference between certification and inspection. Certification is a formal process, while inspection is an ongoing activity. You must perform several types of inspections to maintain safety:

Pre-use inspection: Check your chain slings before every lift. Look for wear, deformation, or damage.

Frequent inspection: Inspect your equipment before each shift or change in application.

Periodic inspection: Schedule a thorough examination at least once a year. Increase the frequency for severe service conditions.

Thorough examination: Conducted by a competent person, this inspection reviews every aspect of your lifting chain. You must document the results and keep records for compliance.

Tip: Always perform a thorough examination before using new or repaired chains. This step ensures your equipment meets all safety standards.

Documentation and Recordkeeping

Proper documentation is essential for compliance and safety. You must keep detailed records of every inspection and thorough examination. These records help you prepare for regulatory audits and support operational safety.

Powerful Machinery assists you by providing clear documentation and certificates for every product.

Documentation Requirement | Source |

|---|---|

Periodic inspections must be documented and records retained as per ASME B30.9 | Mazzella Companies |

Employers must maintain a record of the most recent thorough inspection | Mazzella Companies |

A record of each inspected sling is required per OSHA 1910.184 | Mazzella Companies |

Employers must retain a certificate of the proof test | eCFR |

The certificate must be available for examination | eCFR |

You should store all inspection certificates and reports in a secure, organized system. Digital tools can help you track inspection dates and results. Monthly inspections are required for below-the-hook lifting devices, even if not used.

Chain slings must be inspected by a trained user before use and by a competent person at least annually. Written records of the most recent inspection are required for valid Chain Sling Certifications under ASME B30.9, WSTDA, and RS-1.

Note: Keeping your inspection and thorough examination records up to date helps you stay compliant and ensures workplace safety.

Ensuring Compliance and Safety

Training and Responsibilities

You play a critical role in maintaining compliance and safety when using lifting equipment. Effective training programs help you understand safety protocols, equipment inspection, and proper usage. The best training includes:

Comprehensive curriculum covering safety, equipment inspection, and inspection procedures.

Qualified instructors who share real-world experience.

Hands-on training with up-to-date lifting equipment.

Regular refresher courses and assessments to keep your skills current.

Customization to fit your workplace needs.

Knowledge evaluation and certification to confirm understanding.

Employers must inspect and document lifting slings at least every 12 months. You need to keep records of the most recent thorough equipment inspection. Lifting equipment inspectors perform essential checks to ensure all lifting equipment remains operational and compliant with regulations.

Tip: Regular training and clear responsibilities help prevent accidents and ensure everyone knows how to perform equipment inspection and checks correctly.

Common Mistakes to Avoid

Mistakes during equipment inspection and certification can lead to serious safety risks. You should watch for these common errors:

Mistake Description | Details |

|---|---|

Direct Heat Damage | Chains exposed to high heat may lose capacity; always check manufacturer charts. |

Wear from Sharp Edges | Chains without wear pads can suffer nicks and gouges from rough edges. |

Broken Wires/Corrosion | Kinking or distortion in wire ropes means immediate removal from service. |

Damaged Rigging Hardware | Broken latches or improper pin sizes can cause failures. |

To avoid these issues:

Create detailed records of every equipment inspection, including dates and findings.

Use digital documentation for easy access and compliance.

Review your records regularly to plan maintenance.

Implement structured inspection plans and train your team to handle lifting equipment safely.

Note: Adequate training and regular equipment inspection reduce the risk of mishandling and accidents.

Benefits of Using Powerful Machinery G80 Lifting Chain

Choosing Powerful Machinery’s G80 Lifting Chain gives you a clear advantage in safety and reliability. This lifting equipment meets international standards such as ASME B30.9 and ISO 1834. Each chain undergoes rigorous testing and traceable heat treatments.

You can rely on its minimum tensile strength of 800 MPa and proven performance under dynamic loads, extreme temperatures, and corrosive environments.

Feature | G80 Lifting Chain | Uncertified Alternatives |

|---|---|---|

Manufacturing Standards | Meets global standards | No standardized manufacturing |

Testing | Rigorous, documented | Often lacks testing |

Traceable Heat Treatments | Yes | No |

Minimum Tensile Strength | 800 MPa | Varies, often lower |

Performance Under Conditions | Reliable in harsh environments | Uncertain performance |

You gain peace of mind knowing your lifting equipment passes every equipment inspection and meets all compliance requirements. Powerful Machinery supports your safety goals and helps you avoid costly downtime or accidents.

Conclusion

You protect your team and business when you follow annual certification requirements for lifting chains. Choosing certified products like Powerful Machinery’s G80 Lifting Chain ensures compliance with health and safety regulations and industry standards.

Regular inspections and proper documentation help you avoid preventable accidents, costly downtime, and legal penalties.

Ignoring certification can lead to:

Workplace accidents and injuries

Legal action and fines

Damage to your company’s reputation

Service Type | Recommended Interval |

|---|---|

Normal Service | Yearly |

Severe Service | Monthly to Quarterly |

Special Service | As recommended by a Qualified Person |

Stay proactive. Schedule inspections, keep records, and use certified equipment to maintain a safe, compliant workplace.

FAQ

How often should you perform a periodic inspection on lifting chains?

You should schedule a periodic inspection at least once every 12 months. This process helps you identify wear, corrosion, or damage before it leads to equipment failure.

What is the difference between periodic inspections and frequent inspections?

Periodic inspections involve a thorough review by a qualified person at set intervals. Frequent inspections occur before each shift or use, allowing you to catch immediate issues and maintain safety.

Who determines the inspection frequency for lifting chains?

A competent person assesses your workplace conditions and recommends the inspection frequency. You must follow their guidance to ensure compliance and protect your team.

Why is regular inspection important for lifting chains?

Regular inspection helps you detect problems early. You reduce the risk of accidents and extend the lifespan of your lifting chains by maintaining a consistent inspection schedule.

Can Powerful Machinery’s G80 Lifting Chain simplify compliance?

You receive clear documentation and certificates with every G80 Lifting Chain. This support makes it easier for you to meet periodic inspection requirements and pass audits.