Selecting the right wire rope clips for your project ensures safety, efficiency, and long-term performance. You need to match the clip to your application, load, and working environment.

Different types of wire rope clips serve specific purposes, from lifting and rigging to marine or heavy-duty construction. The table below shows where each type often works best:

Type of Wire Rope Clip | Common Applications |

|---|---|

U-Bolt Wire Rope Clips | Construction sites, Lifting and rigging, Marine applications |

Double Loop Wire Rope Clips | Cable stays for bridges, Tensioning in structural applications, Heavy lifting scenarios |

Plated Wire Rope Clips | Marine environments, Chemical plants, Outdoor rigging operations |

Screw Pin Wire Rope Clips | Temporary installations, Welding and fabrication, Rigging for events |

Specialized Wire Rope Clips | Aerospace applications, Heavy-duty construction, Mining operations |

Understanding the differences between types of wire rope clips helps you make confident and safe decisions. Powerful Machinery delivers proven solutions, including stainless steel wire rope clips, trusted by professionals worldwide.

Key Takeaways

Choose the right wire rope clip based on your project’s load, environment, and safety needs. This ensures safety and efficiency.

Always match the clip size to your wire rope diameter. An improper fit can lead to failure or slippage.

Select clips made from durable materials like forged steel or stainless steel for better strength and corrosion resistance.

Regularly inspect and maintain your wire rope clips to extend their lifespan and ensure safe operation.

Consult experts or instruction manuals when in doubt. This helps avoid common mistakes and enhances safety.

Key Factors for Choosing Wire Rope Clips

Load and Safety

You must always consider the load and safety requirements before selecting wire rope clips. The type of work, the diameter of the wire rope, and the material all play a role in your decision.

Different grades and sizes of clips offer varying load capacities. Manufacturers provide detailed specifications to help you choose the right product for your needs. For example, a U-bolt wire rope clip is common in lifting and rigging because it delivers reliable holding strength.

Tip: Always check for a proper instruction manual with your clips and consult an expert for critical applications.

Safety standards, such as OSHA section 1926.1414(f), require correct installation, especially in load-bearing situations. You should also look for products from trusted manufacturers known for quality rigging hardware.

Key factors to evaluate:

Tensile strength

Crushing strength

Flexibility

Resistance to fatigue, abrasion, and corrosion

Size and Compatibility

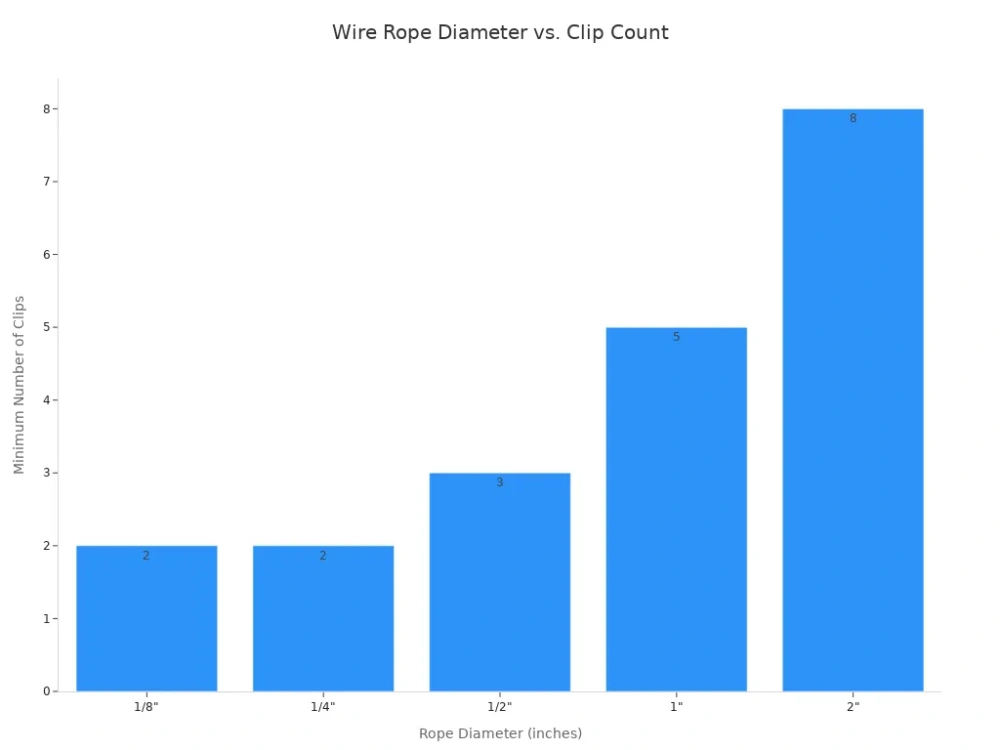

Matching the size of the wire rope clip to your wire rope is essential for safety and performance. An improper fit can lead to failure or slippage. Always select clips that correspond exactly to your rope’s diameter. The table below shows the minimum number of clips and turn-back length needed for different rope sizes:

ROPE DIAMETER | MINIMUM # OF CLIPS | MINIMUM TURN BACK FROM THIMBLE |

|---|---|---|

1/8″ | 2 | 3-1/4″ |

1/4″ | 2 | 4-3/4″ |

1/2″ | 3 | 11-1/2″ |

1″ | 5 | 26″ |

2″ | 8 | 71″ |

ASME B30.26 requires that the clip size be marked on the body of all wire rope clips. This ensures you can easily verify compatibility during installation.

Environment

The environment where you use wire rope clips affects their longevity and performance. Humidity, temperature changes, and industrial pollution can all impact the metal.

Moisture, especially in coastal or tropical areas, can cause electrolytic reactions and corrosion. Temperature swings may crack protective layers, while pollutants can speed up rusting.

Note: Regular maintenance and protective coatings help extend the life of your wire rope clips. Stainless steel types of wire rope clips work best in harsh or marine environments due to their superior corrosion resistance.

Types of Wire Rope Clips

Wire rope clips come in several designs, each serving a specific purpose in rigging and lifting operations. You need to understand the differences between these types of wire rope clips to select the right one for your project. The table below summarizes the main types and their features:

Type of Clip | Description |

|---|---|

U-Bolt Wire Rope Clips | U-shaped bolt with a saddle and two nuts. Distributes the load evenly and suits many applications. |

Wedge Socket Clips | High-strength design for lifting tasks. Often paired with other fittings for added safety. |

Swage Wire Rope Clips | Permanently attached using hydraulic tools. Ideal for low-profile connections. |

Single and Double Saddle Clips | Single saddle for basic support. Double saddle wire rope clips offer better load distribution. |

Safety Wire Rope Clips | Locking mechanism prevents accidental release. Used in high-risk environments. |

U-Bolt Clips

You will find u-bolt wire rope clips in many industrial settings. These clips use a U-shaped bolt, a saddle, and two nuts to secure the wire rope. U-bolt wire rope clips provide reliable holding strength and even load distribution.

You can use them for power lines, construction sites, and temporary or semi-permanent connections. The design makes installation straightforward and ensures a secure grip on the rope.

Double Saddle Clips

Double saddle wire rope clips feature two saddles that clamp the rope from both sides. This design improves load distribution and reduces the risk of wire rope damage. You should choose double-saddle wire rope clips for heavier loads or when you need extra stability.

These clips work well in structural tensioning, bridge cable stays, and heavy lifting scenarios. The dual-saddle construction offers enhanced safety and durability.

Forged vs. Malleable Clips

You must consider the material when selecting types of wire rope clips. Forged steel wire rope clips deliver superior strength and durability. The forging process creates a strong grain structure, making these clips reliable for critical applications.

Malleable cast iron clips do not match the strength of forged clips. Standards like ASME B30.5 prohibit malleable cast iron clips in critical uses. ASME B30.26 requires forged steel saddles for safety. Always select forged clips for demanding environments.

Standard | Recommendation |

|---|---|

ASME B30.5 | Prohibits malleable cast iron clips in critical applications. |

ASME B30.26 | Requires saddles to be forged steel. |

Stainless Steel Wire Rope Clips by Powerful Machinery

Powerful Machinery offers stainless steel wire rope clips designed for maximum corrosion resistance and durability. These clips excel in marine, outdoor, and industrial environments. Stainless steel wire rope clips resist rust better than galvanized or plain steel clips.

You can use them for lifting, rigging, and securing tasks where exposure to moisture or chemicals is common. The polished finish and robust construction ensure long-lasting performance.

Powerful Machinery provides simplex, duplex, and DIN741 designs, giving you options for different load requirements. You benefit from easy installation, secure grip, and reliable safety in every application.

Type of Clip | Corrosion Resistance Properties |

|---|---|

Stainless Steel Clips | Excellent corrosion resistance, suitable for marine or outdoor use. |

Galvanized Clips | Zinc coating protects against rust, but is less resistant than stainless steel. |

Plain Steel Clips | More prone to rust and corrosion without a protective coating. |

Tip: Choose stainless steel wire rope clips for harsh environments or when you need the highest level of corrosion resistance.

How to Select the Right Wire Rope Clips?

Step-by-Step Selection

Selecting the right wire rope clips for your project requires a systematic approach. You want to ensure safety, reliability, and compliance with industry standards. Follow these steps to make the best choice:

Choose a Trusted Manufacturer

Start by selecting wire rope clips from a reputable manufacturer. Brands like Powerful Machinery have a proven track record for quality and safety.Consult the Instruction Manual

Always review the instruction manual. It provides essential details about installation, load capacity, and maintenance.Seek Expert Assistance

If you have doubts, consult an expert. They can help you match the right clip to your specific application.Check Size and Fit

Make sure the clip size matches your wire rope diameter. An improper fit can compromise safety.Consider Environmental Conditions

Assess the environment where you will use the clips. Stainless steel options work best in corrosive or marine settings.Inspect and Maintain Regularly

Schedule regular inspections for wear, rust, or deformation. Replace any damaged clips immediately.Store Properly

Store your clips in a dry, cool place. Proper storage extends their lifespan and maintains performance.

Tip: Use the table below to compare material types and select the best option for your environment.

Material Type | Description |

|---|---|

Carbon Steel | Galvanized or hot-dipped for rust prevention; offers strength and hardness. |

Cast Iron | Malleable iron for general applications. |

Stainless Steel | Superior corrosion resistance; ideal for saltwater and harsh environments. |

Common Mistakes

Many users encounter issues during installation or selection. Understanding common mistakes when using wire rope clips helps you avoid costly errors and ensures safety.

Mistake | Consequence | Solution |

|---|---|---|

Installing wire rope clips backwards | Poor grip, slippage, or failure | Place the saddle on the live end and the U-bolt on the dead end. Use at least three clips. |

Using the wrong number of clips | Complete failure under load | Torque the clips to the specified tightness. |

You must always install a wire rope clip with the saddle on the live end of the rope. Remember the saying: “Never Saddle a Dead Horse.” Using too few clips or improper spacing can cause the rope to snap.

This mistake can lead to catastrophic accidents or equipment failure. Always follow the manufacturer’s guidelines for the number of clips and their placement.

⚠️ Using the wrong type or size of wire rope clip can result in a snapped wire rope. This risk can compromise the strength and integrity of your sling, leading to dangerous situations.

Application Tips

You can maximize the performance and safety of your wire rope clips by following these best practices:

Inspect your wire ropes before each use. Look for visible damage, wear, corrosion, or distortion.

Retire ropes that show signs of excessive wear to prevent unexpected failure.

Use at least two clips for light loads. For heavy-duty applications, use three or more.

Tighten nuts evenly during installation. Re-torque after the initial load is applied.

Space the clips evenly between the first and last clip for optimal grip.

Lubricate wire ropes regularly to reduce friction and protect against corrosion.

Store wire ropes and clips in a dry place, away from corrosive substances and extreme temperatures.

When you install a wire rope clip, wrap the rope around the thimble or form the eye, turning back the correct amount of rope as specified. Place the first clip at the dead end, one saddle length from the extremity.

Tighten the nuts with a torque wrench. Place the second clip as close to the eye loop or thimble as possible. If you need more than two clips, space them evenly between the first two. Always tighten the nuts to the recommended torque.

✅ Regular inspection and proper installation keep your rigging safe and extend the life of your equipment.

How to Install a Wire Rope Clip?

Installation Steps

Proper installation ensures maximum holding strength and safety for your wire rope clips. Powerful Machinery designs each clip for easy and secure assembly. Follow these steps for the best results:

Turn back the specified amount of rope from the thimble or loop. Place the first clip one base width from the dead end of the rope. Position the U-bolt over the dead end, with the live end resting in the saddle. Tighten the nuts evenly, alternating between them until you reach the recommended torque.

If you need two clips, apply the second clip as close to the loop or thimble as possible. Tighten the nuts evenly, alternating until you reach the recommended torque.

For three or more clips, space the additional clips equally between the first two. Take up any slack in the rope. Tighten the nuts on each U-bolt evenly, alternating between nuts until you reach the recommended torque.

Apply the first load to test the assembly. Use a load equal to or greater than what you expect in operation. Check and retighten the nuts to the recommended torque.

Tip: Always use a torque wrench to ensure each nut meets the required specification. This step prevents slippage and maintains safety.

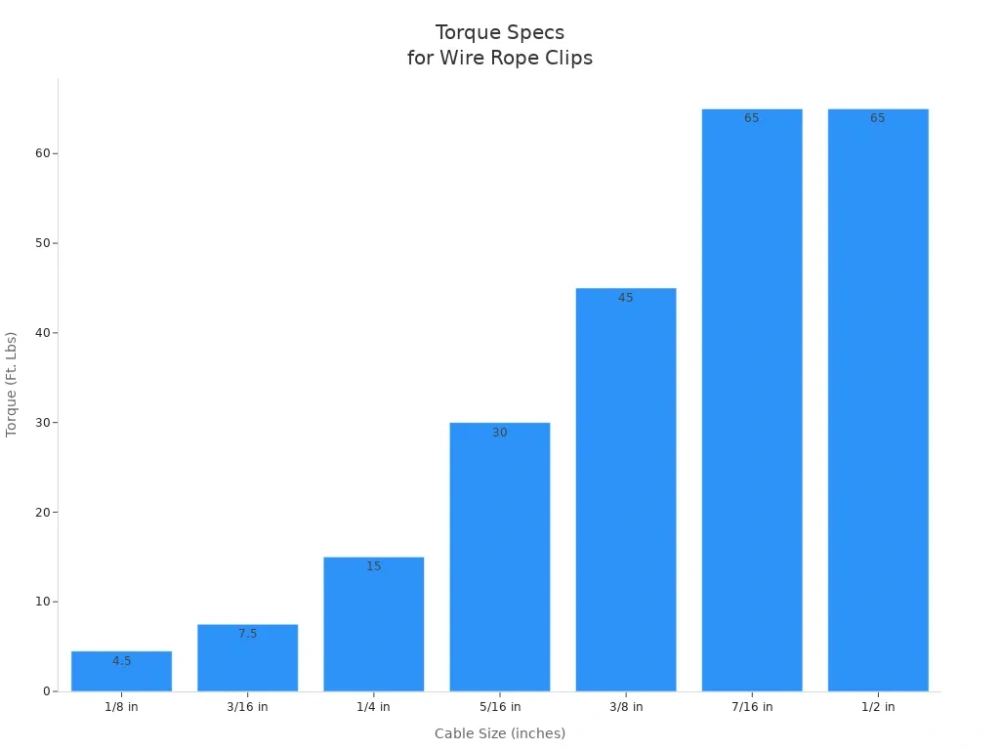

You can reference the table below for torque requirements based on cable size:

Cable Size (Inches) | Minimum Clips | Rope Turnback (Inches) | Torque (Ft. Lbs) |

|---|---|---|---|

1/8 | 2 | 3-3/4 | 4.5 |

3/16 | 2 | 3-3/4 | 7.5 |

1/4 | 2 | 4-3/4 | 15 |

5/16 | 2 | 5-1/4 | 30 |

3/8 | 2 | 6-1/2 | 45 |

7/16 | 2 | 7 | 65 |

1/2 | 3 | 11-1/2 | 65 |

Inspection and Maintenance

Regular inspection and maintenance extend the life and reliability of your wire rope clips. You should check for wear, corrosion, and proper torque on the nuts. Powerful Machinery recommends the following schedule:

Application Type | Inspection Frequency |

|---|---|

General Use | Every 3 to 6 months |

Heavy-Duty Applications | Every 1 to 3 months |

High-Risk Environments | Monthly or weekly |

Post-Installation | After initial installation and re-tightening after the first few uses |

Before/After Critical Ops | Inspect before and after critical tasks |

After Significant Events | Immediate inspection after heavy loads or harsh conditions |

Annual Inspection | At least once a year |

Note: Inspect wire rope clips after installation and retighten the nuts after the first few uses. Increase inspection frequency in heavy-duty or high-risk environments.

For maintenance, follow these best practices:

Store clips in ventilated areas to prevent moisture buildup.

Maintain at least 15cm ground clearance to avoid contamination.

Apply lubricants quarterly using spray, swabbing, or painting methods.

Check reels monthly for structural integrity.

Prevent ropes from crossing over themselves on reels.

You protect your equipment and ensure safe operation by following these guidelines. Regular care keeps your wire rope clips performing at their best.

Conclusion

Selecting the right wire rope clip starts with understanding your project’s load, environment, and safety requirements. You should always match the clip type and material to your application.

High-quality clips, such as those from Powerful Machinery, offer robust construction and corrosion resistance. Look for products that meet strict industry standards, including:

Compliance with recognized safety and quality certifications.

Adherence to standards from organizations like AISI, TIA, and EIA.

Use of forged steel or stainless steel for strength and durability.

Project managers often ask about material, installation methods, torque ratings, clip size, and quantity. For complex or high-risk projects, expert consultation provides valuable benefits:

Benefit | Description |

|---|---|

Safety & Compliance Assurance | Ensures adherence to regulations and identifies potential hazards. |

Equipment Longevity | Extends the lifespan of wire rope and rigging equipment. |

Expert Guidance | Offers insights on configurations, load calculations, and compliance with standards. |

You improve safety and reliability when you choose certified clips and seek expert advice for demanding applications.

FAQ

What is the correct way to install U-bolt wire rope clips?

You should place the saddle on the live end and the U-bolt on the dead end. Tighten the nuts evenly. Always follow the manufacturer’s installation instructions for safety and performance.

When should you choose double-saddle wire rope clips?

You should select double saddle wire rope clips when you need better load distribution or extra security. These clips work well for heavy-duty lifting or structural tensioning projects.

What are some common mistakes when using wire rope clips?

Many users install clips backwards or use too few clips. These mistakes can cause slippage or failure. Always follow guidelines to avoid these common mistakes when using wire rope clips.

Can you use wire rope clips for wire rope end termination?

Yes, you can use wire rope clips for wire rope end termination. Make sure you use the correct number and type of clips for your application.

How do you maintain dual-saddle wire rope clips after installation?

Inspect dual-saddle wire rope clips regularly for wear, corrosion, or loose nuts. Retighten after the first load. Schedule routine checks to ensure continued safety and reliability.