You ensure safe and effective lifting by understanding how to use an anchor shackle in your daily operations. An anchor shackle connects lifting equipment securely, making it essential for moving heavy loads. You often see these shackles in construction and marine work, but they also play a key role in other industries.

Industry | Application |

|---|---|

Automotive | Suitable for lifting and securing loads |

Manufacturing | Used in various lifting operations |

Warehousing | Essential for load handling |

Steel Mills | Commonly used for heavy lifting tasks |

You protect your team and equipment by following safety steps and selecting the right shackle for the job. PowerFul Machinery provides reliable, certified shackles trusted by professionals worldwide.

Key Takeaways

Always inspect shackles before use. Look for cracks, wear, or corrosion to ensure safety.

Select the right shackle based on load requirements. Check the working load limit to prevent accidents.

Load shackles along their centerline. Avoid side loading to maintain their strength and integrity.

Secure the shackle pin properly. Use threadlock or torque adjustments to prevent loosening during use.

Follow safety rules and conduct regular maintenance. This practice keeps shackles in top condition and ensures compliance.

Anchor Shackle Basics

What is an Anchor Shackle?

You use shackles as essential connectors in rigging and lifting operations. An anchor shackle, also called a bow shackle, features a rounded “O” shape. This design gives you ample internal clearance, making it easy to attach multiple slings or chains.

Anchor shackles handle loads from different directions without bending or distorting. You find them in construction, marine, and transportation industries for heavy lifting tasks. The table below highlights the standard features of anchor shackles recognized by international organizations:

Feature | Description |

|---|---|

Shape | Bow shackles have a large, rounded ‘O’ shape, suitable for multi-directional loads. |

Internal Clearance | Ample internal space for connecting multiple slings or chains. |

Loading Capability | Accommodates angular loading without bending or distorting. |

Material | Available in carbon steel, alloy steel, and stainless steel. |

Applications | Used in construction, marine, and transportation industries for heavy lifting. |

Anchor Shackle Types

You choose from several types of shackles based on your lifting needs. The two main types are bow (anchor) shackles and D (chain) shackles. Bow shackles have a larger, rounded shape that allows you to connect multiple slings and handle side loading.

D shackles, with their narrow, D-shaped design, are best for in-line tension and should not be side-loaded. The table below compares these two types:

Feature | Bow Shackles (Anchor) | D Shackles (Chain) |

|---|---|---|

Shape | Larger, rounded ‘O’ shape | Narrow, D-shaped design |

Load Handling | Handles loads from multiple directions | Rated only for in-line tension |

Side Loading | Suitable for side loading and multiple sling connections | Should not be side-loaded, can twist or bend |

Working Load Limit | Generally lower working load limit | Designed for higher load capacities |

You also select from different closure types. Screw pin anchor shackles are ideal when you need to assemble and disassemble connections frequently. Bolt-type anchor shackles offer higher strength and security for long-term or critical applications.

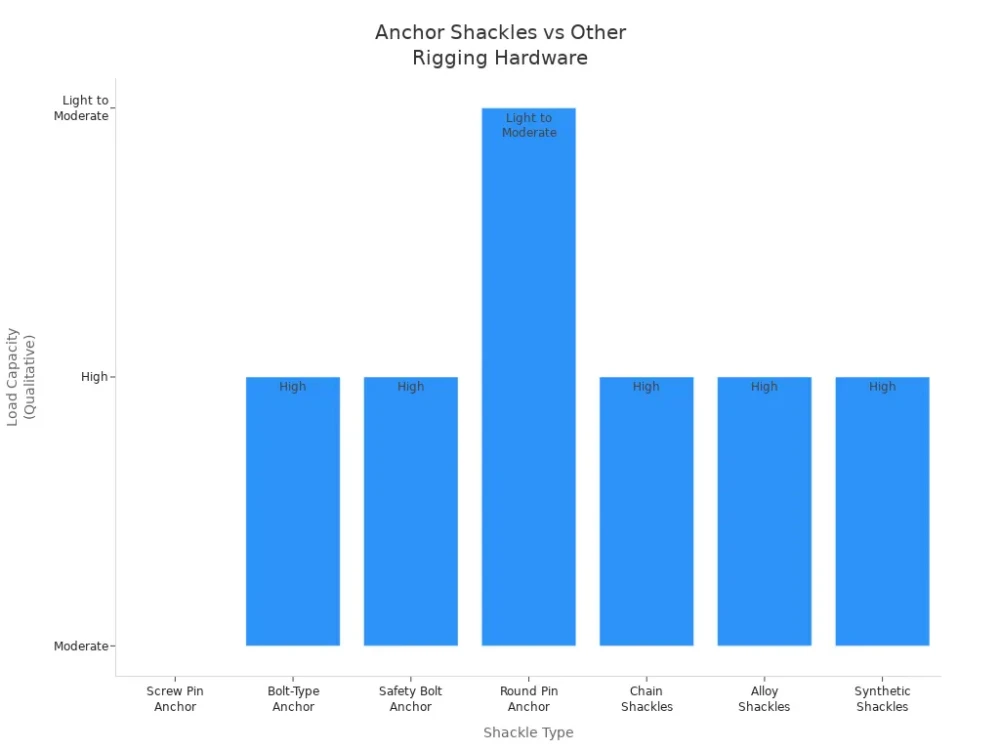

Safety bolt anchor shackles include locking mechanisms for added protection. The chart below shows how different shackle types compare in load capacity:

Powerful Machinery Shackles

You rely on Powerful Machinery shackles for certified quality and performance. Powerful Machinery manufactures shackles that comply with ASME B30.26 standards for rigging hardware.

Each shackle features clear identification markings on both the body and the pin, ensuring traceability and safety throughout its service life. You benefit from a wide selection, including European and U.S. types, Dee and Bow shapes, and both screw pin and bolt-type closures.

Powerful Machinery uses high-quality materials such as alloy steel and stainless steel, giving you excellent strength and corrosion resistance. You can trust these shackles for demanding lifting, marine, and industrial applications.

How to Use an Anchor Shackle?

Step-by-Step Instructions

You must know how to use an anchor shackle correctly to ensure safety and efficiency in every lifting operation. Follow these steps each time you use shackles:

Inspect the shackle before every use. Look for cracks, deformation, excessive wear, or corrosion. If you find any damage, remove the shackle from service immediately.

Select the right shackle for your load. Check the working load limit (WLL) and ensure it matches or exceeds your lifting requirements. Powerful Machinery shackles display clear markings for easy identification.

Open the shackle by unscrewing the pin or bolt. Make sure the threads are clean and undamaged.

Connect the shackle to your lifting equipment or load. Position the shackle so the load aligns with the centerline of the pin. Avoid side loading, which can reduce capacity and cause failure.

Close the shackle by tightening the pin or bolt securely. Do not use excessive force, as over-tightening can damage the threads.

Test the connection by gently applying tension. Confirm that the shackle holds the load securely and that the pin remains tight.

Tip: Keep detailed records of inspections and maintenance. This practice helps you stay compliant with safety standards and prepares you for unannounced inspections.

Proper Way to Use a Shackle

Understanding the proper way to use a shackle prevents accidents and extends the life of your equipment. You should always load shackles along their centerline. Never allow the load to pull at an angle, as this can reduce the working load limit. The table below shows how side loading affects capacity:

Side Load Angle | WLL Reduction |

|---|---|

6° to 45° | ~30% |

46° to 90° | ~50% |

>90° | Not recommended |

You should use bow-type shackles when connecting multiple slings. Add spacers to prevent the pin from rotating or unscrewing. When you connect several shackles, attach them to the body, not the pin, to distribute the load evenly. Avoid letting a single sling run along the pin while pulling sideways.

Note: Use a loose spacer on either end of the shackle pin to prevent eccentric loading. Never weld or close the jaws to reduce width, as this can weaken the shackle.

How to Secure an Anchor Shackle?

Securing the shackle pin is a critical step in how to use the anchor shackle safely. You have several options to keep the pin from loosening during use:

Adjust tension using a torque wrench, following the manufacturer’s specifications. Avoid over-tightening, which can cause premature failure.

Apply threadlock to the pin. This adhesive holds the pin in place but allows for future removal.

Use cable ties as a temporary solution. Make sure they are tight and trimmed to avoid fouling, but remember they may degrade over time.

Seize with Monel wire for a durable, corrosion-resistant solution. This method works well in marine environments.

Perform regular maintenance. Clean and lubricate the shackle to prevent rust and wear. Inspect the shackle for signs of loosening or damage before each use.

Pro Tip: Document your tension adjustments and maintenance activities. This habit ensures accountability and helps you track the condition of your shackles.

You must always inspect the shackle before and after each use. Powerful Machinery shackles are engineered for reliability, but your attention to detail ensures maximum safety. When you know how to use an anchor shackle properly, you protect your team and equipment from unnecessary risks.

Shackle Selection and Inspection

How to Read Anchor Shackles?

You must read the markings on shackles before every lift. These markings give you critical information about the product’s size, working load limit, and manufacturer. Always check for certifications and compliance with safety standards. The table below shows the most important markings you will find on quality shackles:

Marking Type | What It Means | Why It Matters |

|---|---|---|

Diameter of body or pin | Ensures correct fit for your rigging | |

WLL | Maximum safe load | Prevents overloading |

Manufacturer Info | Brand, logo, or batch number | Tracks quality and certification |

Angle Indicators | Forged marks for hitch angles | Helps reduce risk in side loading |

You should always verify that the working load limit matches your lifting needs. Powerful Machinery shackles display clear markings and meet international standards such as ASME B30.26 and EN 13889. These certifications guarantee that you use shackles built for safety and reliability.

How to Count Anchor Shackles?

You need to count shackles accurately for every rigging setup. Start by listing all connection points in your lifting plan. Include every shackle used for slings, hooks, and anchor points.

Double-check your count before starting the lift. If you use multiple slings or complex rigging, count each shackle at every connection. This practice helps you avoid missing components and ensures safe load distribution.

Nearly half of hoisting accidents start with a failed shackle. Always perform a thorough shackle inspection before use.

One worker shared, “I learned this lesson 12 years ago on an oil platform in the North Sea. We were swapping out a compressor using what looked like a perfectly good 8-ton bow shackle. The pin sheared at 5 tons. The falling load missed my boot by six inches. That shackle had passed visual inspection that morning.”

Choosing the Right Shackle

You must select shackles that fit your application and environment. Follow these steps:

Identify your working load limit. Choose shackles rated above your heaviest load.

Select the correct type, such as anchor or chain shackles, for your task.

Pick the right pin style—screw pin, bolt type, or round pin.

Consider environmental factors like corrosion or extreme temperatures.

Ensure the shackle fits snugly in your rigging system.

Powerful Machinery shackles comply with global standards. The table below highlights key certifications:

Standard | Region | Key Requirements |

|---|---|---|

ASME B30.26 | North America | Manufacturer’s name, working load limit, 5:1 safety factor, proof testing, inspection criteria |

EN 13889 | Europe | CE marking, traceability, 6:1 safety factor, certificate of conformity |

You protect your team and equipment by choosing certified shackles and following a strict shackle inspection routine.

Rules on How to Use Shackles

Safety Precautions

You must follow strict safety rules when working with shackles. These rules on how to use shackles help you prevent accidents and protect your team. Always know the break strength and working load limit of each shackle. Never exceed these limits.

Before every lift, conduct a visual inspection. Look for cracks, deformation, or metal loss. Regular maintenance keeps shackles in top condition. Store them in a dry, well-ventilated area, away from corrosive chemicals. The table below summarizes key safety rules:

Safety Rule | Description |

|---|---|

Break Strength and Working Load Limit | Always know the break strength and working load limit of shackles and never exceed these limits. |

Visual Inspection | Conduct a visual inspection before use to check for wear, deformation, cracks, or metal loss. |

Regular Maintenance | Perform periodic inspections and maintenance, keeping shackles away from sharp edges and avoiding excessive wear. |

Proper Storage | Store shackles in a dry, well-ventilated area, keeping them clean and away from corrosive chemicals. |

You should always use the correct type of shackle for your application. International regulations require different inspection routines for the marine and construction industries.

For example, the International Maritime Organization focuses on strength and durability in harsh marine environments. Local building codes in construction require load testing and certification for structural safety. Powerful Machinery shackles meet or exceed these standards, giving you confidence in every lift.

Common Mistakes to Avoid

You can avoid many accidents by knowing the most common mistakes. Here are the top errors and how to prevent them:

Failing to check the capacity of a shackle or the weight of the load.

Not inspecting the gear or knowing what to inspect for.

Using improperly fabricated below-the-hook devices or modified equipment.

Not using the correct sling, device, or hitch for the application.

Not using sling protection.

Not understanding the structural integrity of the load.

Failure to maintain load control.

Failure to consult rigging charts.

You should always follow best practices and consult rigging charts before every lift. This approach supports the importance of safety in crane lifting.

Powerful Machinery shackles undergo rigorous product testing and hold certifications from leading regulatory bodies. These steps ensure you have reliable equipment for every job.

Conclusion

You improve safety and efficiency by following essential steps when using anchor shackles. The table below highlights the recommended rules for safe operation:

Rule | Description |

|---|---|

1 | Use trained and qualified personnel to ensure safety and proper handling of equipment. |

2 | Inspect equipment and the environment before any lift to prevent failures. |

3 | Check load balance and stability to avoid risks during lifting. |

4 | Maintain clear communication among team members to ensure coordinated lifts. |

Selecting certified anchor shackles is vital. Certified products undergo rigorous testing for load-bearing capacity and durability. This process helps prevent accidents and protects both your team and equipment.

You face serious risks when using uncertified shackles:

Unexpected failure can damage vessels and injure crew.

Legal penalties and financial loss may result from non-compliance.

Anchor shackles support versatile load handling and secure connections. You reduce workplace accidents and gain peace of mind by choosing Powerful Machinery shackles for every lift.

FAQ

What is the difference between a bow shackle and a D shackle?

You use a bow shackle for multi-directional loads and connecting multiple slings. A D shackle works best for straight-line pulls. Bow shackles offer more versatility, while D shackles provide higher strength for in-line applications.

How do you know if a shackle is safe to use?

You check for clear markings, such as working load limit and manufacturer. Inspect the shackle for cracks, deformation, or corrosion. If you find any damage, remove the shackle from service immediately.

Can you use anchor shackles in marine environments?

Yes, you can use anchor shackles in marine environments. Powerful Machinery shackles use corrosion-resistant materials and coatings. These features help prevent rust and ensure long-term performance in harsh conditions.

How often should you inspect your shackles?

You should inspect shackles before every use. Schedule regular maintenance checks based on usage frequency and environmental conditions. Frequent inspections help you catch wear or damage early.