Selecting the right crane hook block manufacturers in 2025 provides a significant advantage in both safety and operational efficiency. Top crane hook block manufacturers distinguish themselves through innovation, proven reliability, and a robust global footprint.

Dependable crane hook block manufacturers supply the essential equipment you need for secure lifting, precise load management, and seamless operation in cranes and other lifting systems. These blocks are crucial for material handling and lifting tasks across construction, manufacturing, and logistics industries.

The market for crane hook blocks is expanding rapidly, with a projected annual growth rate of 13.6%, fueled by the increasing demand for advanced lifting solutions.

Industry professionals advise choosing crane hook block manufacturers with extensive experience, proper certifications, and state-of-the-art manufacturing technology.

By partnering with reputable crane hook block manufacturers, you ensure that every lifting operation upholds the highest standards of safety and performance.

Key Takeaways

Choosing reputable crane hook block manufacturers enhances safety and operational efficiency in lifting tasks.

Look for manufacturers with rigorous testing and certifications to ensure reliable and safe lifting equipment.

Select companies that offer advanced technology and customization options to meet specific lifting needs.

Prioritize manufacturers with a strong global presence for reliable support and timely delivery of equipment.

Stay informed about industry trends and innovations to keep your lifting solutions up to date and efficient.

1. PowerFul Machinery

Strengths

When you choose PowerFul Machinery, you gain access to a wide range of lifting solutions designed for demanding environments. The company offers high-tensile Grade 80 and G100 chains, hooks, and custom blocks that meet strict safety standards.

You benefit from certified lifting equipment products that support construction, marine, transportation, and cargo handling projects. PowerFul Machinery tests every product to exceed international requirements, so you can trust the reliability and performance of your crane hook block during every lift.

Tip: Selecting a manufacturer with rigorous testing and certification helps you avoid equipment failures and ensures safe lifting operations.

Innovation

Powerful Machinery stands out for its advanced manufacturing technology. You see the results in their automated welding systems, precision forging presses, and use of robotics and AI. These innovations boost productivity and improve product quality.

You can request custom lifting solutions, and their engineers will work with you to design equipment that fits your project needs. The company’s mobile, containerized manufacturing capabilities allow rapid development and deployment, especially in regions like the Indo-Pacific.

This agility means you receive tailored lifting equipment products faster, keeping your operations efficient.

Automated production lines reduce lead times.

Robotics and AI streamline processes for consistent quality.

Customization options let you solve unique lifting challenges.

Global Reach

You benefit from PowerFul Machinery’s strong global logistics network. The company ships crane hook block orders worldwide, managing secure packaging and customs clearance. Their logistics team ensures on-time delivery, so your lifting projects stay on schedule.

Decades of export experience mean you receive reliable service, no matter where your site is located. PowerFul Machinery’s commitment to innovation and agility in logistics supports partners across the globe.

Reliable shipping keeps your lifting equipment products moving.

Global support helps you manage projects in any region.

Advanced logistics minimizes downtime and maximizes efficiency.

2. Henan Zhongzao Industry Co., Ltd

High-Strength Materials

You want your lifting operations to be safe and efficient. Henan Zhongzao Industry Co., Ltd uses advanced materials to make sure every crane hook block meets strict standards. The company selects materials that offer both strength and durability. Here is a quick look at the main materials used:

Material Type | Properties |

|---|---|

Alloy Steel | High strength, wear-resistant |

Special Steel | Good welding performance, durability |

These materials help you handle heavy lifting tasks with confidence. You can trust that each block will stand up to tough conditions and repeated use.

Precision Sheaves

You need smooth and reliable movement when you lift heavy loads. Henan Zhongzao Industry Co., Ltd designs its sheaves with high precision. This attention to detail reduces friction and wear during lifting. You get better control over your loads, which helps prevent accidents and equipment damage.

The company uses advanced machining tools to create sheaves that fit perfectly with the rest of the crane hook block. This means you can expect consistent performance every time you use their lifting equipment products.

Note: Precision sheaves can extend the life of your lifting gear and improve safety on the job site.

Market Presence

You want a manufacturer with a strong reputation and wide reach. Henan Zhongzao Industry Co., Ltd supplies crane hook block solutions to customers around the world. The company serves industries such as construction, shipping, and manufacturing.

You benefit from their experience and commitment to quality. Many companies choose Henan Zhongzao for their lifting needs because of its reliable products and excellent customer support. When you select their blocks, you join a global network of professionals who value safety and performance in lifting.

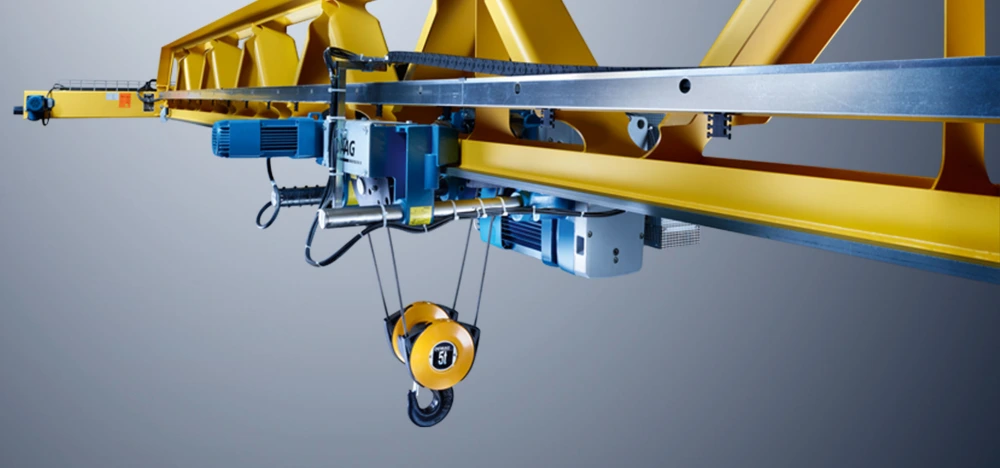

3. Konecranes

Safety Features

You want your lifting operations to be as safe as possible. Konecranes designs every crane hook block with safety as the top priority. The company follows strict safety certifications and standards. You can trust their products because they meet important requirements, such as:

OSHA standards for crane safety and load handling

Safe load handling procedures

Rated load limits for each crane hook block

Clear operator responsibilities

These standards help you avoid accidents and keep your team safe during every lifting task. Konecranes also provides detailed instructions and support, so you always know how to use their equipment correctly.

Performance

You need equipment that performs well under pressure. Konecranes uses advanced engineering to make sure each crane hook block delivers reliable results. Their products handle heavy lifting jobs in construction, shipping, and manufacturing.

You get smooth operation and precise control, which helps you move loads safely and efficiently. Konecranes invests in research and development to improve lifting technology. This means you benefit from the latest innovations in lifting equipment. You can count on their products to last through repeated use and tough conditions.

Tip: Using high-performance lifting equipment reduces downtime and increases productivity on your job site.

Global Network

You want support wherever your lifting projects take you. Konecranes has a strong global network that gives you access to expert service and fast delivery. The company’s global reach helps you solve problems quickly and keep your lifting operations running smoothly.

Evidence Type | Description |

|---|---|

Strong R & D Capability | Konecranes invests significantly in R&D to enhance product performance and quality, keeping it competitive. |

Global Service Network | The extensive service network ensures customers receive prompt and professional support, crucial for crane operation. |

Safety – First Approach | Konecranes prioritizes safety, ensuring its products meet high safety standards, which builds customer trust. |

You can rely on Konecranes for consistent quality and support, no matter where you work. Their commitment to safety, performance, and global service makes them a leader in the lifting industry.

4. Hangzhou Jindiao Hoisting Machinery

Domestic Leadership

You want a manufacturer that leads the way in the domestic market. Hangzhou Jindiao Hoisting Machinery stands out as one of the top companies in the lifting block industry in China. Many professionals recognize this brand for its strong presence and influence.

When you choose Hangzhou Jindiao, you join a group of lifting experts who trust their products for safe and efficient lifting operations. The company’s leadership means you benefit from proven solutions and reliable service.

Tip: Working with a domestic leader helps you access the latest lifting technology and support for your crane hook block needs.

Product Range

You need options for every lifting challenge. Hangzhou Jindiao Hoisting Machinery offers a wide selection of crane hook block products and accessories. You can find equipment for overhead cranes, gantry cranes, and jib cranes.

The company provides single and double crane hooks, as well as a variety of lifting accessories. This range allows you to match the right product to your lifting project.

Here is a quick overview of their product offerings:

Type | Max Capacity | Material | Application |

|---|---|---|---|

Single Crane Hook | Up to 60 Ton | Alloy | Overhead crane, gantry crane |

Double Crane Hook | Up to 40 Ton | Alloy | Jib crane |

Crane Accessories | N/A | N/A | Hooks, blocks, sheaves, beams |

Wire Rope Diameter | 6.2-38 mm | N/A | N/A |

You can select the right lifting equipment for your job, whether you need to move heavy loads or handle precise lifting tasks.

Industry Reputation

You want to work with a company that others respect. Hangzhou Jindiao Hoisting Machinery has built a strong reputation in the lifting industry. Many customers choose their crane hook block products because they deliver consistent quality and safety.

The company’s commitment to lifting innovation and customer service sets it apart from competitors. You can rely on Hangzhou Jindiao for expert advice and dependable lifting solutions.

Trusted by lifting professionals across China

Known for reliable crane hook block products

Offers support for complex lifting projects

When you select Hangzhou Jindiao Hoisting Machinery, you invest in lifting equipment that helps you achieve safe and successful lifting operations.

5. Demag

Load Control

You want precise control when you manage heavy lifting tasks. Demag gives you advanced load control features in every crane hook block. These features help you handle loads safely and efficiently.

You can rely on smart technologies that monitor and adjust lifting operations in real time. Demag includes overload cut-off, electric load management, and predictive maintenance. These systems protect your equipment and your team.

Here is a quick overview of Demag’s load control technologies:

Feature | Description |

|---|---|

Hoist Motor Options | P-motor, W-motor with ProHub, S-motor with ProHub |

Protection Class | IP 55, optional IP 66 for motors |

Temperature Monitoring | Bi-metal temperature monitoring for all motors |

Electric Equipment | Universal control cabinet, DMU with modem for monitoring |

Advanced Control | CanBus control, smart load management features |

Safety Features | Overload cut-off, Electric Load Management, predictive maintenance |

Smart Features | Load-sway reduction, slack rope protection, area-dependent load reduction |

Remote Monitoring | StatusControl 2.0, Demag Equipment App for real-time data |

Tip: Smart load control reduces the risk of accidents and keeps your lifting operations running smoothly.

Reliability

You need equipment you can trust for every lifting job. Demag builds each crane hook block with high-quality materials and strict manufacturing standards. You get consistent performance, even in tough environments. Demag’s temperature monitoring and protection systems help prevent overheating and equipment failure.

You can use their remote monitoring tools to check the status of your lifting equipment at any time. This reliability means you spend less time on repairs and more time on safe lifting.

Consistent performance in demanding conditions

Real-time monitoring for quick problem detection

Long service life for all lifting components

Capacity

You want a crane hook block that can handle your biggest lifting challenges. Demag offers some of the highest lifting capacities in the industry. Their equipment supports projects that require moving extremely heavy loads. You can choose from a range of capacities and speeds to match your lifting needs.

Feature | Specification |

|---|---|

Max Capacity | 1250 t |

Max Load Moment | 21,120 tm |

Boom Lengths | 9m–154m (main), up to 108m (fly) |

Hoist Speeds | Up to 120 m/min (main hoist) |

Slewing Speed | 0–0.6 RPM |

Travel Speeds | 0.4 km/h (1st gear), 0.8 km/h (2nd gear) |

You can rely on Demag for lifting solutions that meet the demands of large-scale construction, shipping, and industrial projects. Their crane hook block designs help you complete lifting tasks safely and efficiently, no matter the size of the load.

6. Liebherr

Durability

You want your lifting equipment to last through years of tough jobs. Liebherr builds every crane hook block with durability in mind. The company uses high-quality materials and advanced engineering to make sure each product stands up to heavy use.

You can trust these blocks to handle repeated lifting cycles without losing strength or performance. When you work in construction, shipping, or manufacturing, you need equipment that keeps going. Liebherr’s focus on durability means you spend less time on repairs and more time on safe, efficient lifting.

Note: Durable crane hook blocks help you avoid unexpected downtime and keep your projects on schedule.

Heavy-Duty Design

You need a crane hook block that can handle the most demanding lifting tasks. Liebherr’s heavy-duty designs give you advanced features that improve safety and precision.

The company includes technology that helps you control loads, reduce sway, and position items with millimeter accuracy. Take a look at some of the key features you get with Liebherr’s heavy-duty lifting solutions:

Feature | Description |

|---|---|

Sway Control | Corrects sway from wind or movement, making lifting safer and more efficient. |

Vertical Line Finder | Keeps the hook above the load’s center, reducing the risk of swinging during lifting. |

Guided Hook | Lets you move the hook by hand, which lowers communication errors and boosts safety. |

Positioning Pilot | Offers semi-automated movements for better workflow and safer lifting. |

Micromove | Gives you precise, millimeter-level control for complex lifting operations. |

Load-Plus | Increases lifting capacity by up to 20%, so you can move heavier loads safely. |

These features help you manage every lifting challenge with confidence. You get more control, better safety, and higher productivity.

Lifting Equipment Manufacturers

You want to work with a leader in the lifting industry. Liebherr ranks as the 5th largest construction machinery manufacturer in the world, according to Statista. Many professionals choose Liebherr because the company delivers reliable lifting solutions for projects of all sizes.

You benefit from their global experience and strong reputation. When you select Liebherr, you join a network of experts who trust their crane hook block and lifting equipment for critical jobs.

Liebherr is ranked as the 5th largest construction machinery manufacturer globally based on sales.

This ranking is supported by data from Statista.

You can count on Liebherr to support your lifting needs, whether you work in construction, logistics, or heavy industry. Their commitment to quality and innovation makes them a top choice for lifting equipment worldwide.

7. Caldwell Group

Accessories

When you look for crane hook block manufacturers that offer a complete range of lifting solutions, Caldwell Group stands out. You can choose from a wide selection of accessories that help you handle different lifting tasks safely and efficiently. These accessories work with many types of crane hook block systems and make your lifting operations more flexible.

Lifting beams

Spreader beams

Vacuum attachments

Remote releasing hooks

Forklift attachments

Lifters

RUD Lifting Eyes

RUD Chain slings

Each accessory helps you solve unique lifting challenges. For example, lifting beams and spreader beams let you balance loads, while vacuum attachments help you lift smooth or delicate materials. You can use remote releasing hooks to improve safety during lifting by letting you release loads from a distance.

Crane Hook Block Manufacturers

You want crane hook block manufacturers that lead the industry in innovation and reliability. Caldwell Group has built a strong reputation among crane hook block manufacturers for its focus on quality and advanced technology.

You benefit from their SmartSpec Configurator, an online tool that lets you customize lifting solutions quickly. This tool gives you detailed drawings and pricing in minutes, so you can plan your lifting projects without delay.

Feature | Description |

|---|---|

SmartSpec Configurator | An online tool that allows you to customize lifting solutions for your needs. |

Fast Turnaround | Get drawings and pricing in minutes, which speeds up your project planning. |

Custom Lifting Solutions | Caldwell develops products like the Telescoping Forklift Beam for special lifting applications. |

You can trust Caldwell Group to deliver crane hook block products that meet your lifting requirements and help you stay ahead in the industry.

Custom Solutions

You often face lifting situations that need more than standard equipment. Caldwell Group works with you to design custom lifting solutions that fit your exact needs. You can use the SmartSpec online product configurator to select and order custom lifting devices.

Caldwell Group developed the Telescoping Forklift Beam to help you lift long loads and make your forklift more versatile. This focus on custom solutions makes Caldwell Group a top choice among crane hook block manufacturers.

Tip: Custom lifting solutions help you improve safety and efficiency on every lifting project.

You get support from a team that understands the demands of lifting in different industries. Caldwell Group helps you find the right crane hook block for your job, whether you work in construction, manufacturing, or logistics. You can rely on their experience to keep your lifting operations safe and productive.

8. Airpes

Precision Engineering

You want lifting equipment that delivers accuracy and safety every time. Airpes focuses on precision engineering in every crane hook block they produces. Their design team uses advanced technology to create products that meet strict quality standards.

You can trust each hook block to perform with exactness, even when you handle heavy or delicate loads. Airpes tests every product to ensure it meets your expectations for reliability and performance. This attention to detail helps you avoid mistakes and keeps your lifting operations running smoothly.

Tip: Precision engineering reduces the risk of accidents and helps you complete projects on time.

Adaptability

You often face different lifting environments, from indoor factories to outdoor construction sites. Airpes designs crane hook blocks that adapt to your needs.

You can choose custom-engineered solutions that match your exact specifications, including wire rope configurations. Their products work well in rough terrain and outdoor conditions, so you stay productive in any setting. Airpes ensures each hook block performs at its best, no matter the challenge.

Feature | Description |

|---|---|

Custom-Engineered Hook Blocks | Tailored to exact specifications, including wire rope configurations. |

Adaptability | Designed for outdoor use or rough terrain environments. |

Performance | Ensures optimal performance in various lifting conditions. |

You gain flexibility and confidence when you use equipment built for your unique lifting tasks.

International Reach

You need a partner with a strong global presence. Airpes operates subsidiaries in Europe, the USA, and China. The company continues to expand in America, Australia, and Asia. You benefit from their experience as a recognized lifting equipment supplier across Europe. Airpes provides handling solutions to cranes and industries worldwide, including beams, hooks, and magnets.

Subsidiaries in Europe, the USA, and China

Expanding in America, Australia, and Asia

Recognized supplier across Europe

Handling solutions for cranes and industries globally

Supplies beams, hooks, and magnets worldwide

You can rely on Airpes for support and solutions wherever your projects take you. Their international network ensures you receive the right equipment and service, no matter your location.

Conclusion

You see why these eight lifting equipment manufacturers lead the industry in 2025. They focus on customer needs, use advanced technology, and offer a wide range of lifting solutions for cranes. Their products stand up to tough jobs and help you work safely. Here are the main reasons they stand out:

Customer-centric service and support

Industry-leading technology for cranes and lifting, and material handling

Comprehensive product range for lifting solutions

Heavy-duty construction for harsh environments

Advanced safety features for lifting equipment manufacturers

Global presence to support your projects

Recent innovations include smart cranes, IoT integration, and modular designs. These advancements help you manage lifting and material handling tasks with greater efficiency.

When you choose reliable lifting equipment manufacturers, you protect your team and improve productivity. Always check for strong safety systems, regular inspections, and the latest technology. Stay informed about trends in cranes and lifting, and material handling to keep your lifting solutions up to date.

FAQ

What is a crane hook block?

A crane hook block is a device you use to lift and move heavy loads. It connects to the crane’s wire rope and holds the hook. You rely on it for safe and efficient lifting in construction, shipping, and manufacturing.

How do you choose the right crane hook block manufacturer?

You look for manufacturers with strong safety records, certifications, and advanced technology. You check their experience, product range, and customer support. Reliable manufacturers help you avoid accidents and keep your lifting operations running smoothly.

Why does material quality matter for crane hook blocks?

High-quality materials give you strength and durability. You need blocks made from alloy or special steel to handle heavy loads and resist wear. Good materials help you prevent equipment failure and ensure safe lifting every time.

What certifications should you check before buying?

You should check for ISO, CE, and other international safety certifications. These show that the manufacturer meets strict standards. Certified products help you trust the equipment and protect your team during lifting tasks.

Can you get custom crane hook blocks for special projects?

Yes, many manufacturers offer custom solutions. You work with their engineers to design blocks that fit your project needs. Custom crane hook blocks help you solve unique lifting challenges and improve safety on the job site.