You use an electric hoist when you need a powerful lifting device for heavy loads in industrial settings. This equipment combines automation and advanced safety mechanisms to deliver efficient lifting and reliable heavy-load handling. Electric hoists come in two main types: chain and wire rope.

These machines help reduce risks in your workspace by providing real-time monitoring and automated limit switches. You can trust electric hoists to support OSHA hoist safety standards and keep your operations safe.

Type of Incident | Description |

|---|---|

Improper lifting methods | It can lead to decoupling and swinging of loads, causing injuries. |

Equipment failures | Includes failures of hooks, wire ropes, and control systems, which can result in dropped loads. |

Environmental hazards | Risks from cluttered workspaces, poor visibility, and natural disasters affect equipment stability. |

Electric hoist features | Real-time monitoring, automated limit switches, and regular maintenance help reduce these risks. |

Key Takeaways

Electric hoists are essential for lifting heavy loads safely in industrial settings. They reduce the risk of injury and improve efficiency.

Always check the specifications of an electric hoist to ensure it meets your load size and safety standards before use.

Safety features like limit switches and overload protection are crucial. They help prevent accidents and protect both the operator and equipment.

Regular maintenance and inspections are necessary to keep electric hoists in good working condition. This ensures safety and reliability.

Choosing the right type of electric hoist, such as chain or wire rope, depends on your specific lifting needs and work environment.

What is an Electric Hoist?

You use electric hoists when you need to lift heavy loads vertically in industrial environments. An electric hoist is a powered device that uses a motor to raise and lower objects with precision and safety. You often see electric hoists in factories, warehouses, construction sites, and shipyards.

These machines help you move materials quickly and reduce the risk of injury from manual lifting.

Electric hoists stand out because they offer advanced safety features and high efficiency. You control them with a pendant or remote, which lets you operate them from a safe distance. Most electric hoists include limit switches, overload protection, and emergency stop functions.

These features help you avoid accidents and protect your equipment.

When you compare electric hoists to other hoisting equipment, you notice some important differences:

Feature | Electric Hoists | Other Hoisting Equipment |

|---|---|---|

Direction of Operation | Vertical lifting | Horizontal pulling (e.g., winches) |

Efficiency | High energy efficiency, optimized use | Lower efficiency, higher labor costs |

Safety Mechanisms | Advanced safety features | May lack advanced safety features |

Initial Cost | Higher initial investment | Lower initial costs |

Long-term Costs | Reduced operational costs | Increased labor costs over time |

You benefit from electric hoists because they save time and money in the long run. The initial investment may be higher, but you get lower operational costs and better safety. You also get more consistent performance, which helps you meet deadlines and maintain productivity.

When you look at an electric hoist specification, you see details like lifting capacity, speed, power supply, and safety features. You should always check the electric hoist specification before choosing a model for your job. This ensures the electric hoist matches your lifting needs and workplace requirements.

Tip: Always review the electric hoist specification to make sure the model fits your load size and safety standards.

Electric hoists give you a reliable, efficient, and safe way to handle heavy lifting in any industrial setting.

How Does an Electric Hoist Work?

Understanding how an electric hoist works helps you operate it safely and efficiently. You will see that the process involves several key components working together to lift and move heavy loads with precision.

Operating Principles

When you ask, “How does an electric hoist work?” you start with the electric motor. The motor converts electrical energy into mechanical energy. This process creates torque, which the gearbox transmits to the lifting mechanism.

The gearbox slows down the high-speed rotation of the motor, increasing torque and making it possible to lift heavy objects.

The electric motor is the main part that transforms electrical energy into a mechanical lifting force.

The gearbox concentrates this force and rotates the chain wheel or drum.

The lifting chain or wire rope wraps around the drum or passes over the chain wheel, raising or lowering the load.

The controller manages the speed, so you can lift or lower materials with precision.

You can see these principles in Powerful Machinery’s electric hoist product range. For example, the HHSY Electric Chain Hoist uses a compact motor and robust gearbox to deliver reliable lifting in tight spaces.

The CD1/MD1 Electric Wire Rope Hoist uses a high-torque conical motor and durable steel wire rope for smooth operation.

Here is a quick look at typical lifting capacities and power types:

Lifting Capacity | Typical Applications |

|---|---|

1-Ton | Light-duty tasks: lifting small components, toolboxes, or light machinery parts |

2-Ton | Warehouses and production lines for medium-duty applications |

3-Ton | Fabrication shops and assembly lines with medium to heavy loads |

4-Ton | Mid-sized manufacturing plants and machine shops |

5-Ton | Heavy equipment maintenance and construction sites |

Power Type | Voltage Options |

|---|---|

Single Phase | 120 or 230 VAC |

Three Phase | 208, 230, 460, or 575 V |

You choose the right model based on your load requirements and available power supply.

Control Systems

The control system is a vital part of every electric hoist. It lets you manage lifting operations safely and efficiently. You can use either a pendant control or a wireless remote control.

Feature | Pendant Control System | Wireless Remote Control System |

|---|---|---|

Operator Safety | Lower; the operator stands near the load | Higher, the operator stands at a safe spot |

Efficiency | Lower; movement is restricted | Higher, the operator can move freely |

With a pendant control, you must stay close to the load. This can limit your movement and increase risk. A wireless remote control allows you to operate the hoist from a distance.

You can choose the safest vantage point and make real-time adjustments without moving back and forth. This setup improves both safety and efficiency.

Modern electric hoists, like those from Powerful Machinery, include advanced control systems. These systems offer real-time monitoring, alerting you to issues such as overheating or overload. Limit switches and sensors prevent the hoist from moving beyond safe positions.

Overload protection ensures you never lift more than the rated capacity. Emergency stop buttons let you halt operations instantly if something goes wrong.

Safety Features

Safety is the top priority when you use an electric hoist. You need to follow strict safety protocols to protect yourself and your team. Powerful Machinery’s electric hoists meet or exceed industry standards for safety. They include a comprehensive package of automated systems that reduce operator burden.

Some of the most advanced safety features you will find include:

Feature | Description |

|---|---|

Smart Brake Technology | Uses DC for brake activation, reducing wear and providing maintenance-free operation |

Smart Limit Option | Let’s you program upper and lower limit positions with a soft stop for precise load placement |

Overload Protection | Prevents the hoist from lifting loads beyond its rated capacity |

Emergency Stop | Instantly halts all motion in critical situations |

Real-Time Monitoring | Provides immediate feedback on equipment status |

Note: Powerful Machinery’s electric hoists comply with national and international safety standards. You get peace of mind knowing your equipment is built and tested to recognized protocols.

Recent advancements in electric hoist design include wireless controls, energy-efficient motors, and AI-enabled safety features. These improvements help you minimize risks and improve productivity. The global electric hoist market continues to grow as industries demand safer and smarter lifting solutions.

When you understand the operating principles of electric hoists, the role of the control system, and the importance of safety features, you can make informed decisions for your workplace. Always choose equipment that meets the highest safety standards and supports your operational needs.

Types of Electric Hoist

You will find several types of electric hoists in industrial settings. Each type has unique features that make it suitable for different lifting tasks. Powerful Machinery offers a full range of equipment, including electric chain hoists, wire rope hoists, and specialized variants for unique environments.

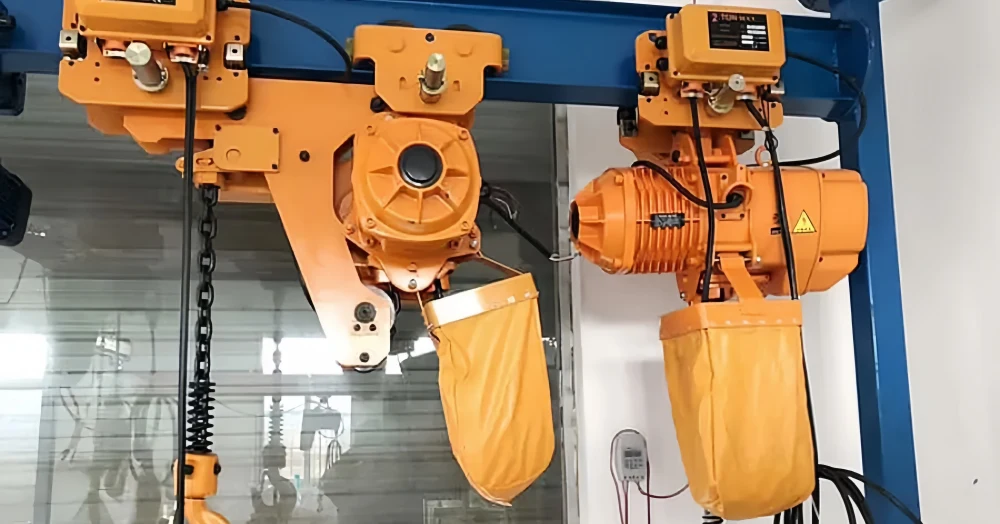

Electric Chain Hoist

You use an electric chain hoist when you need a compact and portable lifting solution. This equipment uses a chain and sprocket system to lift loads. Chain hoists are lighter and easier to install than other types. You can move them quickly between workstations.

They work best in warehouses, factories, and places where you need to lift loads to 30 tons. You get precise control, which helps when you need to position materials carefully. Powerful Machinery’s electric chain hoists feature robust G80 or G100 chains and advanced safety systems.

Electric Wire Rope Hoist

You choose wire rope hoists for heavy-duty lifting. This equipment uses a wire rope that wraps around a drum. Wire rope hoists handle higher capacities, often exceeding 10 tons. They lift loads faster and work well in construction, shipping, and large manufacturing plants.

These hoists are more durable and can withstand tough conditions. Powerful Machinery’s wire rope hoists offer advanced overload protection and reliable performance for demanding jobs.

Note: You should select the right hoist based on your load size, speed needs, and work environment.

Other Variants

You may also need specialized equipment for unique tasks. Some electric hoists come with explosion-proof features for hazardous areas. Others have dual-speed motors or remote controls for extra safety and convenience. Powerful Machinery provides custom solutions to fit your specific requirements.

Here is a quick comparison to help you choose the right equipment:

Feature | Electric Chain Hoists | Electric Wire Rope Hoists |

|---|---|---|

Construction | Compact, lightweight | Heavier, robust |

Lifting Mechanism | Chain and sprocket | Wire rope and drum |

Capacity Range | Up to 30 tons | 2 to 100 tons or more |

Lifting Speed | Slower, precise | Faster, flexible |

Best Use | Warehouses, factories | Construction, shipping |

Chain hoists are ideal for lighter loads and precise placement.

Wire rope hoists excel in heavy-duty, high-speed lifting.

You can find equipment for almost any industrial need from Powerful Machinery.

Key Components of Electric Hoists

Understanding the key components of an electric hoist helps you choose equipment that delivers both safety and long-term reliability. Each part plays a vital role in lifting heavy loads efficiently.

Motor and Gearbox

The motor powers the lifting process. It converts electrical energy into mechanical force. The gearbox then adjusts this force, increasing torque and controlling speed. You get smooth and precise lifting, even with heavy loads. Powerful Machinery uses high-quality motors and gearboxes designed for industrial use.

These parts meet strict standards for performance and durability, so you can trust your electric hoist to work under tough conditions.

Load Chain, Wire Rope, and Hook

The load chain or wire rope carries the weight. Hooks connect the load to the hoist. Powerful Machinery uses G80 and G100 grade chains, which meet international standards like ISO 3076 and DIN EN 818-2.

These certifications ensure the chains and hooks can handle high stress without breaking. You benefit from strong, reliable lifting every time you use an electric chain hoist.

Certification Standard | Description |

|---|---|

ISO 3076 | Performance requirements for welded lifting chains |

DIN EN 818-2 | European standard for grade 8 and 10 lifting chains |

NACM1996/2010/2016 | American safety standards for lifting chains |

DIN 5687/DIN 5688 | German standards for quality and load capacity |

Brakes and Limit Switches

Brakes hold the load securely when you stop lifting. Limit switches prevent the hoist from moving too far up or down. These safety mechanisms protect both you and your equipment. Powerful Machinery equips every electric hoist with advanced brakes and precise limit switches.

You get peace of mind knowing your load stays secure.

Control and Trolley Systems

The control system lets you operate the hoist safely. You can use a pendant or remote control for easy operation. The trolley system moves the hoist along a beam, giving you flexibility in positioning your load. Powerful Machinery designs these systems for smooth movement and reliable performance.

Component | Description |

|---|---|

Structural Specifications | Rated capacity, working load limit, duty cycle, and beam deflection for safe operation |

Safety Mechanisms | Limit switches and braking systems for load security |

Environmental Considerations | IP ratings protect against dust and moisture |

Maintenance Requirements | Proactive maintenance ensures longevity and safety |

Tip: Always check the certifications and maintenance guidelines for your electric chain hoist. This ensures maximum safety and durability.

Choosing the Right Electric Hoist

Selecting the best electric hoist for your operation requires careful planning. You need to match your equipment to your workload, environment, and safety requirements.

When you focus on choosing the right hoist, you improve efficiency and reduce risks in your workplace. Let’s break down the main considerations in electric hoist selection.

Capacity and Duty Cycle

You must start by understanding your load requirements. Always check the weight and height of the lifts you plan to make. If you underestimate, you risk overloading the hoist, which can cause equipment failure and safety hazards. Analyze how often you will use the hoist and how long each lift will take.

This helps you choose a duty cycle that matches your operational tempo.

Here’s a simple checklist to guide your selection:

Determine the maximum weight you need to lift.

Measure the height you need to raise the load.

Assess how many lifts you perform each day or week.

Choose a hoist with a duty classification that fits your workload.

Tip: Never select a hoist with just enough capacity. Always allow a safety margin to handle unexpected loads.

Powerful Machinery offers custom solutions with certified lifting capacities and duty cycles. You can trust their products to meet your specific needs.

Suspension and Trolley Options

The way you mount your hoist affects flexibility and installation. You have several suspension and trolley options, each with unique benefits. The table below compares the main methods:

Suspension Method | Function | Applications | Advantages |

|---|---|---|---|

Hook Suspension | Temporary attachment for quick setup | Frequent repositioning of environments | Easy to move; no permanent changes to your structure |

Lug Mount Suspension | Fixed installation by bolting to a structure | Static lifting in plants | Stable; reduces the risk of movement during operation |

Trolley Suspension | Allows horizontal movement along a beam | Assembly lines, storage areas | Streamlines workflow; works with manual or motorized trolleys |

When choosing the right hoist, think about how often you need to move it and whether you need horizontal travel. Powerful Machinery provides all these options, so you can select the best fit for your workspace.

Environment and Power

Environmental factors play a big role in hoist performance and lifespan. Dust, moisture, and extreme temperatures can damage your equipment. For example, damp or salty air can cause corrosion on metal parts. Excessive dust may clog moving parts and reduce efficiency.

Very hot or cold conditions can affect lubricants and materials, making the hoist less reliable.

Before making your selection, assess your workplace:

Check for dust, humidity, or chemicals in the air.

Consider temperature extremes.

Look for any special industry demands, such as explosion-proof features.

You also need to match the hoist to your available power supply. Make sure the voltage and phase (single or three-phase) are compatible with your facility. Powerful Machinery offers models designed for a wide range of environments and power sources.

Safety and Compliance

Safety and compliance are critical in every industrial setting. You must follow national and international standards to protect your team and equipment. The most important standards for electric hoists include OSHA, ASME B30.16, and ASME B30.21. These rules cover construction, inspection, use, and operator training.

Standard | Description |

|---|---|

ASME B30.16 | Covers underhung powered hoists, including construction, marking, inspection, and training. |

ASME B30.21 | Applies to lever hoists, including chain, wire rope, and strap hoists. |

You should always:

Perform an initial inspection before using a new or modified hoist.

Conduct frequent inspections weekly or monthly.

Schedule periodic inspections at least once a year.

Powerful Machinery’s electric hoists come with full certifications, so you can be confident they meet or exceed all safety and compliance requirements.

Maintenance and Inspection

Regular maintenance and inspection keep your hoist safe and reliable. You should set up a program that includes daily, frequent, and periodic checks. The table below shows recommended intervals:

Inspection Type | Frequency | Description |

|---|---|---|

Daily (Pre-Operational) | Before each shift | Operator checks for obvious defects and tests basic functions. |

Frequent | Monthly to quarterly | A trained person inspects and documents findings. |

Periodic | Annually | A qualified person performs an in-depth inspection, may disassemble parts for measurement. |

Keep records of all inspections and maintenance. This helps you track the condition of your hoist and proves compliance with safety standards.

Note: Powerful Machinery provides detailed maintenance guides and supports you with certified replacement parts. This ensures your equipment stays in top condition.

When you follow these considerations in electric hoist selection, you protect your investment and your team. Choosing the right hoist means looking at capacity, suspension, environment, safety, and maintenance.

Always work with a trusted supplier like Powerful Machinery to get certified, reliable solutions for your lifting needs.

Electric Hoist Applications & Pricing

Industrial Applications

You will find electric hoists in many industries that rely on electric chain hoists for daily operations. These machines play a key role in material handling applications where you need to move heavy materials safely and efficiently.

The most common industries include manufacturing, warehousing, and construction. Each industry has unique requirements for the applications of electric hoists.

Industrial Sector | Application Requirements |

|---|---|

Manufacturing | Load stability, safety features, and optimized suspension methods for lifting applications |

Warehousing | Efficient load handling and safety mechanisms to prevent operational hazards |

Construction | High load capacities and robust safety features for heavy lifting tasks |

You often use electric hoists for shifting engines, lifting transformers, moving dies, handling injection mold tools, hoisting turbines, and transporting steel coils. These applications of electric hoists help you streamline workflow and reduce manual labor.

In logistics, marine, and transportation industries, you depend on electric hoists to move heavy materials quickly and safely.

Pricing Factors

The price of an electric hoist depends on several factors. You should consider the type of hoist, load capacity, lift height, and duty cycle. Advanced features like variable speed, remote controls, and safety systems can increase the cost. The table below shows the main pricing factors:

Factor | Description |

|---|---|

Type of Electric Hoist | Different types (wire rope, chain, etc.) have varying costs. |

Load Capacity | Higher load capacities lead to increased prices. |

Lift Height | Longer lift heights typically result in higher costs. |

Duty Cycle | Hoists for continuous use are more expensive than those for intermittent use. |

Speed and Control | Advanced features and variable speeds increase the cost. |

Trolley System | Additional costs for horizontal movement systems. |

Quality | Higher quality hoists may have a higher initial cost but offer better reliability. |

Power Supply | Installation costs may rise if electrical systems need modification. |

Additional Features | Extra features like remote controls and safety systems can add to the overall cost. |

Environmental Requirements | Specialized hoists for specific conditions may incur higher costs due to engineering needs. |

A basic 1-ton manual chain hoist starts at around $100. A similar capacity electric hoist may cost $500 or more. Manual hoists work well for small workshops, but electric hoists offer better value for industries that rely on electric chain hoists for frequent lifting.

Efficiency and Value

You gain many benefits when you use electric hoists in your operations. These machines enhance efficiency by handling heavy materials quickly and precisely. Automation reduces manual lifting, which lowers the risk of injuries and keeps workers safe.

Reliable equipment also minimizes downtime and maintenance costs, leading to higher productivity.

Investing in energy-efficient hoists not only reduces operating costs through lower energy consumption but also enhances the lifespan of electrical infrastructure, thereby deferring costly upgrades. Additionally, these hoists contribute to a better working environment, which can improve employee morale and productivity.

The typical return on investment for high-cycle hoists can be as short as 12 to 24 months based on energy savings alone, with even faster returns when considering reduced maintenance and increased productivity.

Most industries that rely on electric chain hoists report improved efficiency and reduced labor costs. You can expect a strong return on investment, especially when you choose certified products from Powerful Machinery for your material handling applications.

Conclusion

You improve safety and efficiency when you understand how an electric hoist works and select the right type for your needs. Review the table below to see the most important factors for industrial users:

Key Factor | Description |

|---|---|

Load Capacity | Choose the right hoist for your maximum load. |

Lift Speed and Height | Match speed and height to your workflow. |

Duty Cycle | Prevent overheating by selecting the correct duty cycle. |

Suspension Type | Pick the best suspension for your workspace. |

Safety Features | Use limit switches and overload protection. |

Maintenance Practices | Inspect and maintain your hoist regularly. |

Environmental Considerations | Consider your environment for durability. |

You should follow these expert recommendations:

Train operators to report issues quickly.

Inspect your hoist daily and schedule regular checks.

Lubricate the load chain as recommended.

Keep records of all maintenance activities.

Choose certified products from Powerful Machinery and consult with experts for tailored solutions. Prioritize safety, compliance, and regular maintenance to maximize your equipment’s lifespan.

FAQ

What is the difference between an electric chain hoist and an electric wire rope hoist?

You use an electric chain hoist for lighter loads and precise placement. You choose an electric wire rope hoist for heavier loads and faster lifting. Chain hoists work well in tight spaces. Wire rope hoists handle demanding industrial tasks.

How often should you inspect your electric hoist?

You should inspect your electric hoist before each use. Perform a more detailed inspection every month. Schedule a full inspection by a qualified technician at least once a year. Regular checks help you prevent accidents and extend equipment life.

Can you use an electric hoist outdoors?

You can use many electric hoists outdoors. Always check the model’s specifications for weather resistance. Choose a hoist with a high IP rating for dust and moisture protection. Store your hoist properly when not in use to prevent damage.

What safety features should you look for in an electric hoist?

Look for overload protection, emergency stop buttons, limit switches, and reliable brakes. These features help you prevent accidents and protect your team. Certified hoists from Powerful Machinery include advanced safety systems for peace of mind.

How do you maintain your electric hoist for long-term use?

You should clean and lubricate moving parts regularly. Inspect the chain or wire rope for wear. Test the brakes and controls. Follow the manufacturer’s maintenance guide. Proper care helps you keep your hoist safe and reliable for years.