You need a safe and efficient electric hoist installation to protect your team and equipment in industrial environments. Systematic procedures reduce risks and boost operational performance. Features such as limit switches, braking systems, overload protection, and emergency stop functions keep your workplace secure:

Safety Feature | Description |

|---|---|

Limit Switches | Prevent collisions and maintain safe rope wraps. |

Braking System | Engage automatically during a power failure to prevent a load drop. |

Overload Protection | Stop lifting if the load exceeds capacity. |

Emergency Stop | Cut power instantly for a quick response in emergencies. |

Powerful Machinery delivers certified lifting solutions trusted across industries.

Key Takeaways

Prioritize safety by using essential features like limit switches and overload protection to prevent accidents during hoist operation.

Ensure proper training for all operators to enhance safety and compliance with industry regulations, reducing risks in the workplace.

Conduct regular maintenance and inspections to extend the lifespan of your electric hoist and minimize unexpected breakdowns.

Select the right hoist based on your specific operational needs, considering load capacity and environmental factors for optimal performance.

Document all installation and maintenance activities to maintain compliance and support ongoing safety in your industrial environment.

Why Electric Hoist Installation Matters?

Safety and Compliance

You protect your team and equipment when you follow the right steps for electric hoist installation. Industrial environments present many risks, so you must address each one before starting work.

The most common safety risks include overloading, using the wrong attachments, and poor training. You also need to keep the area clear and perform regular maintenance. The table below highlights key safety tips:

Safety Tip | Description |

|---|---|

Ensure Proper Load Weight Capacity | Exceeding the maximum load can lead to hoist malfunction or failure, causing accidents. |

Use the Right Lifting Attachments | Proper attachments are necessary to safely lift large or irregularly shaped objects. |

Train Your Operators and Supervisors | All operators and supervisors must receive appropriate training to ensure safe operation. |

Keep a Safe Operating Area | The area around the hoist should be clear, and communication among crew members is essential. |

Prioritize Preventive Maintenance | Regular maintenance is crucial for safe and effective hoist operation. |

You must also comply with strict industry regulations. Organizations such as OSHA, ASME, and HMI set standards for electric hoist installation. These standards help you maintain safety and avoid costly penalties. The table below summarizes important regulations:

Regulation/Standard | Description |

|---|---|

OSHA | Ensures safety and reliability in electric hoist installation. |

ASME | Provides guidelines to improve safety performance and compliance. |

HMI | Focuses on safety standards for hoist operation. |

ASME B30 | Guidelines to help employers and contractors maintain safety and compliance. |

You need to meet requirements such as safe access, proper suspension height, and reliable brakes. Each hoisting machine must handle 125% of its rated load and have both primary and secondary brakes.

Efficiency and Longevity

Proper electric hoist installation does more than keep your workplace safe. It also boosts efficiency and extends the life of your equipment. When you select the right fixation points and use the correct tools, you ensure stable operation under heavy loads. Testing the installation before use confirms that the hoist works as expected.

You benefit from expert installation in several ways:

Fewer unplanned repairs and less downtime.

Proper alignment and lubrication reduce mechanical stress.

Lower energy costs and maintenance expenses over time.

A logistics company saw a 20% drop in energy use and a 30% decrease in maintenance costs over five years after professional installation. You can expect similar results when you follow best practices. Reliable equipment means fewer interruptions and a safer, more productive workplace.

Choosing an Electric Hoist from Powerful Machinery

Capacity and Application

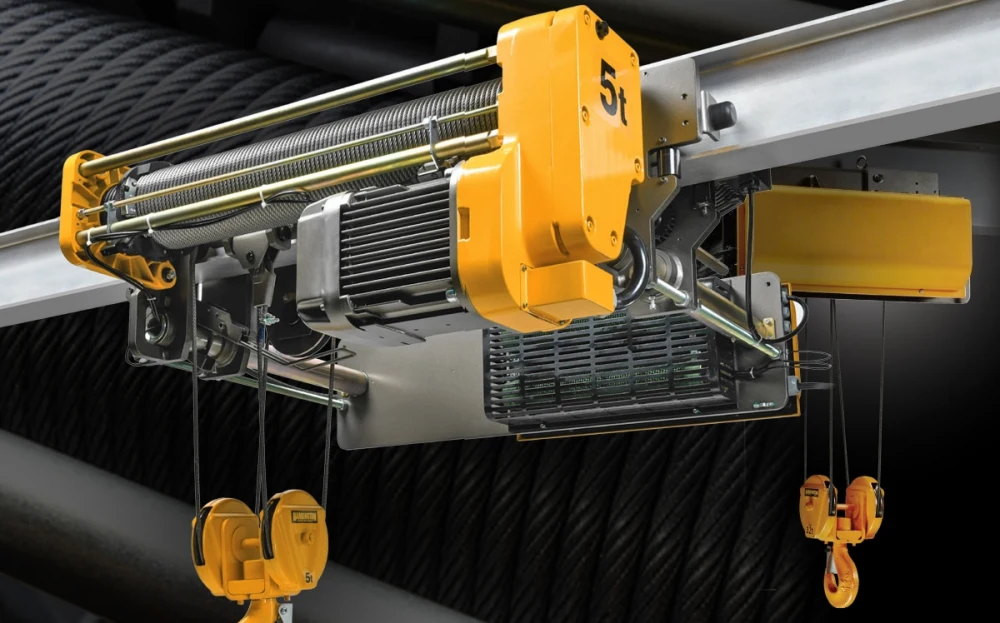

You must select an electric hoist that matches your operational needs. Powerful Machinery offers a range of models designed for different load capacities and usage scenarios.

Start by assessing the maximum weight you plan to lift. Always choose a hoist with a capacity that exceeds your heaviest load. Consider the safety factor, which should be 1.5 to 2 times your maximum load.

Review the type of hoist—wire rope or chain—based on your application. Decide if you need single-speed, dual-speed, or variable-speed lifting. The table below helps you match typical industrial applications with recommended hoist classes:

Application Description | Typical HMI Class | Typical FEM Group |

|---|---|---|

Standby or Repair Hoist (Infrequent Use) | H1 / H2 | 1Dm / 1Cm |

General Workshop, Light Assembly, Warehousing | H3 | 1Bm / 1am |

General Manufacturing, Heavy Assembly | H4 | 2m / 3m |

Steel Mills, Foundries, High-Volume Production | H5 | 4m / 5m |

Tip: Always verify the hoist’s rated capacity and safety features before finalizing your selection.

Environmental and Site Factors

You need to evaluate your work environment before choosing a hoist. Standard models work best indoors in clean, dry conditions. If you operate in outdoor or humid areas, select a hoist with a higher IP rating to protect against dust and water.

Extreme temperatures require components rated for those conditions. Powerful Machinery provides options for both single-phase and three-phase power sources, so match the hoist to your facility’s electrical system.

Standard hoists suit indoor, dry environments.

High IP-rated hoists resist dust and moisture.

Temperature-rated components ensure reliable performance in extreme climates.

Certifications and Standards

You must ensure your hoist meets international safety and quality standards. Powerful Machinery’s products comply with certifications such as CE, ISO 9001, UL, and CCC. These certifications guarantee that your equipment passes rigorous inspection and testing.

The table below lists key standards for electric hoist installation in industrial environments:

Certification/Standard | Description |

|---|---|

ASME B30.17 | Standard for Cranes and Monorail |

ASME B30.10 | Standard for Hooks |

ASME B30.26 | Standard for Lifting Elements (Rigging hardware) |

OSHA 1926.1400 | Standards for Cranes and Derricks in Construction |

CE, ISO 9001, UL, CCC | International safety and quality certifications |

Note: Certified hoists help you meet regulatory requirements and maintain a safe workplace.

Proper Installation Planning

Structural and Electrical Checks

You must begin every proper installation with a thorough site assessment. Inspect all components for cracks, deformations, or other signs of damage. Confirm that the structure supporting the hoist can handle the intended load. Check for dimensional accuracy and ensure the mounting points are secure.

Clean the installation area and remove any debris or obstacles. Plan clear transportation channels and working platforms to support a smooth installation process. Before you proceed, verify the electrical system meets the requirements for your hoist model.

Perform safety checks on wiring, grounding, and circuit protection. Install safety nets, guardrails, and warning systems to protect both personnel and equipment during the installation process.

Tools, Equipment, and PPE

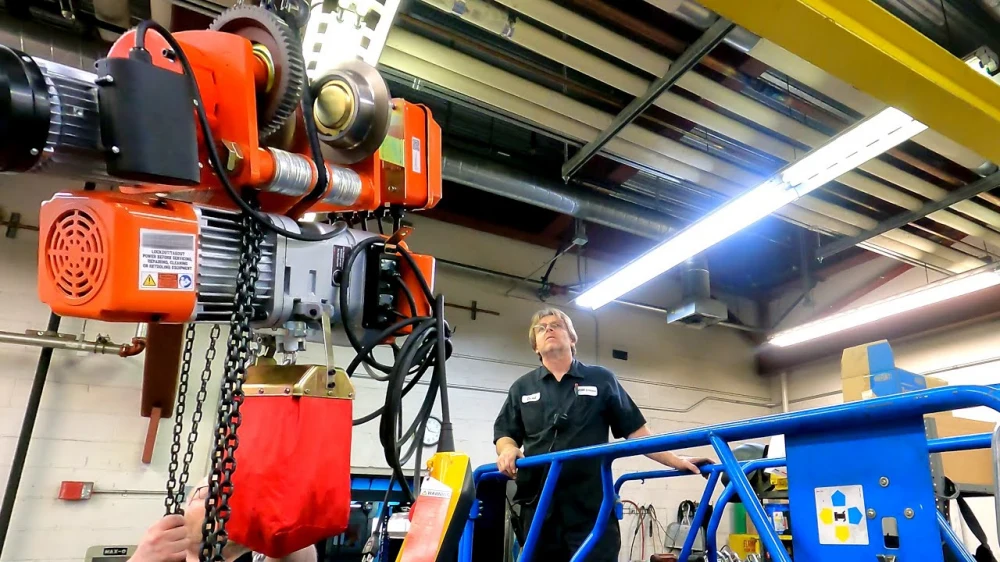

Proper installation requires the right tools and personal protective equipment. Gather all necessary tools, such as wrenches, screwdrivers, and electrical testing equipment. Use lifting equipment like a forklift or crane for heavy components. Always inspect your tools for reliability before use.

Wear safety helmets, gloves, eye protection, and steel-toed boots. These items help prevent injuries and ensure safety throughout the installation process. Specialized tools recommended by the manufacturer may also be required for certain hoist models.

Reviewing Manuals and Safety Protocols

Before you start, review the manufacturer’s operation manual for your specific hoist. Understand all safety precautions and follow the recommended procedures. Conduct pre-operational safety checks to prevent accidents and ensure safe handling of equipment and loads.

Comply with established safety standards, including OSHA and ASME guidelines. Document periodic inspections to maintain compliance and keep records up to date. Provide ongoing training for operators so they can recognize signs of wear and understand the limits of the equipment.

This approach ensures proper installation and long-term safety for your team.

Electric Hoist Installation Steps

A successful electric hoist installation starts with careful preparation and follows a clear step-by-step guide. You need to pay close attention to each phase, from unpacking to final adjustments, to ensure safety and efficiency.

Whether you are installing an electric chain hoist or a wire rope hoist from Powerful Machinery, these steps will help you achieve a reliable setup.

Unpacking and Inspection

Begin by unpacking your electric chain hoist or wire rope hoist in a clean, organized area. Inspect every component before starting the installation process. Use this checklist to guide your inspection:

Check the pendant cord. The strain relief cable should take the force, not the pendant cord itself. Replace or repair if you find any damage.

Test the up and down buttons. Make sure they operate correctly. If the hoist does not function as expected, tag it out for repair.

Inspect the braking system. Measure the braking distance and examine the motor brake according to the manufacturer’s specifications.

Examine the pendant. Look for damage to the cord and housing. Ensure the push buttons are interlocked and undamaged.

Prepare for operation. Confirm that the hoist operates without interference. Only trained operators should handle rigging procedures.

Tip: Document any issues you find during inspection. Address them before moving forward with installing an electric hoist.

Mounting Location Preparation

You must prepare the mounting location to guarantee a stable and safe foundation for your electric hoist installation. Follow these steps:

Assess the ground. Make sure the foundation is solid and level. Conduct a soil analysis if needed to confirm load-bearing capacity.

Clear debris. Remove obstacles that could interfere with the installation or future operation.

Establish safety zones. Mark off the area to keep unauthorized personnel away during the installation process.

Check for utilities. Identify the location of underground utilities to avoid accidental damage when drilling anchor points.

A well-prepared site reduces risks and ensures your electric chain hoist will operate safely and efficiently.

Fixed Hoist Installation

When installing an electric hoist in a fixed position, you need to follow a precise step-by-step guide. This approach ensures the hoist remains secure and functions as intended:

Prepare the beam or track. Inspect it for structural integrity and remove any debris.

Assemble the trolley if required. Follow the manufacturer’s instructions and adjust for the correct beam width.

Mount the hoist to the trolley or directly to the beam. Secure all fasteners and ensure the hoist is balanced.

Install the trolley on the beam or track. Position it carefully and check for proper alignment.

Connect electrical components. Wire the hoist to the power supply and ensure proper grounding.

Attach the chain box. Make sure it is securely fastened and aligned with the hoist.

Perform safety and operational checks. Test all controls, limit switches, and the braking system before lifting any load.

Powerful Machinery’s electric chain hoist models, such as the HHSY or DHS series, come with detailed manuals to guide you through each step. Always refer to the manufacturer’s recommendations for your specific model.

Trolley Hoist Installation

For trolley-mounted hoists, you need to follow a similar but slightly more detailed process. This method allows the hoist to move along a beam, increasing flexibility in your workspace. Use this step-by-step guide:

Inspect the beam or track. Confirm it is structurally sound and free of debris.

Assemble the trolley. Use the manufacturer’s instructions to ensure correct assembly.

Attach the hoist securely to the trolley. Double-check all connections.

Position the trolley on the beam or track. Align it for smooth movement.

Connect the hoist to the power supply. Ground the system according to safety standards.

Adjust the limit switches. Test the hoist’s controls to ensure safe operation.

Conduct a load test. Lift a test load to verify safety and efficiency.

Complete a final inspection. Document the installation and confirm all safety features function correctly.

You can use Powerful Machinery’s electric chain hoist or electric wire rope hoist models for trolley installations. These products offer robust performance and meet international safety standards.

Special Environments and Configurations

Some industrial environments require special considerations when installing an electric hoist. If you work in hazardous areas with flammable gases, dust, or vapors, you must use explosion-proof hoists.

Always check the zone or class rating, such as ATEX Zone 1 or NEC Class I, to select the right equipment. Make sure your hoist has the required certifications for the environment, like ATEX or IECEx.

Match the hoist’s load capacity and duty cycle to your workload. This step prevents equipment failure.

Use explosion-proof controls in hazardous zones. These controls may affect the design and cost of your installation.

Prioritize safety over budget. Never compromise on certified equipment for hazardous environments.

Note: Powerful Machinery offers electric chain hoist models with advanced safety features and certifications for demanding industrial settings.

A careful, methodical approach to electric hoist installation ensures long-term safety and performance. By following this step-by-step guide, you set the foundation for reliable lifting operations in any industrial environment.

Electrical Safety and Testing

Power Supply and Grounding

You must ensure a reliable power supply and proper grounding before operating your electric chain hoist. Always turn off the power before connecting the power cord. This step protects you from accidental electric shock. Properly ground the grounding wire to prevent electrical hazards.

Never rely on wheel-to-track contact for grounding. Instead, use a separate bonding conductor for the trolley frame and bridge frame. The table below outlines essential grounding requirements:

Requirement | Description |

|---|---|

Grounding Conductor | Provide a separate bonding conductor for the trolley and bridge frames. |

Safety Amendment | NEC Article 610.61 requires a reliable grounding path to prevent electrical shocks. |

Conductor Bar Systems | Connect bare uninsulated conductor bars to a grounding conductor if grounding is uncertain. |

Note: Proper grounding prevents electrical shock and overload. Always keep conductor bars away from hoist cables and ensure dirt or debris does not block electrical connections.

Voltage and Circuit Protection

You need to follow strict voltage and circuit protection standards during the installation process. These standards help maintain safety and protect your electric chain hoist from electrical faults. Key standards include:

ISO 4301-1 defines duty cycles and service conditions for fluctuating power environments.

IEC 60204-32 outlines electrical safety requirements, including emergency stop circuits and protection against overcurrent, undervoltage, and phase loss.

EN 14492-2 covers overload protection and emergency lowering devices for power loss situations.

ASME B30.16 guides safety devices and operational practices for unstable power conditions.

NFPA 70 (NEC) details wiring and grounding requirements to reduce electrical hazards.

Install circuit breakers and fuses that match your hoist’s specifications. Test emergency stop circuits and verify all wiring connections before use.

Initial Load and Safety Checks

After you complete the installation process, you must perform a series of initial load and safety checks to confirm proper operation of your electric chain hoist:

Verify that upper and lower limit switches are set correctly to prevent over-traveling.

Test the brake system to ensure it holds the load securely.

Perform a load test with a weight that does not exceed the hoist’s rated capacity.

Operate the hoist without a load to check for smooth movement.

Test all control functions, including lifting, lowering, and emergency stop.

Inspect the entire installation for any issues.

Record the installation and test results for future reference.

Tip: Always keep detailed records of your safety checks. These records help you maintain compliance and support ongoing maintenance for your electric chain hoist.

Commissioning and Documentation

Final Inspections

You must complete a thorough final inspection before you commission your electric chain hoist. This step ensures that every part of your installation process meets safety and operational standards. Start by checking the integrity of all grounding connections.

Inspect circuit breakers and fuses for any signs of wear or tripping. Evaluate connectors and terminals for corrosion or looseness. Test remote control units to confirm they communicate with the hoist. Perform a continuity test on all key electrical components.

Move on to the mechanical parts. Examine the hoist frame and housing for any damage. Inspect the lifting mechanism, gears, and bearings for wear. Check the rope or chain for fraying, kinks, or other damage.

Lubricate moving parts as specified by the manufacturer. Inspect the load block, limit switches, sheaves, and pulleys for proper operation and alignment. Verify that the hoist is plumb and level. Ensure all fasteners are tight and secure. Complete a load test to confirm the electric chain hoist operates smoothly under load.

Tip: Document any findings, including electrical or mechanical issues, and recommend repairs before placing the hoist into service.

Compliance Records

You need to maintain detailed records to demonstrate compliance after commissioning your electric chain hoist. Keep all manuals, drawings, and the installation log. Complete a commissioning record sheet with serial numbers and test dates.

Use standard forms or checklists to document all commissioning tests, including load, duration, and observations. Issue a formal commissioning report or certificate once all tests pass.

Maintain the following compliance records:

Inspection records for hoist components and operating mechanisms

Maintenance records for repairs, adjustments, and lubrication

Test certificates for static and dynamic load tests

Specialized licenses and certifications

Insurance verification and proof of OSHA-compliant safety training

Signed acknowledgment of site-specific safety procedures

Compliance Record Type | Description |

|---|---|

Inspection Records | Documented inspections of hoist components and safety systems |

Maintenance Records | Records of all repairs, adjustments, and lubrication performed |

Test Certificates | Written reports of static and dynamic testing results |

These records support future maintenance and help you meet regulatory requirements for your electric chain hoist.

Maintenance and Troubleshooting

Routine Maintenance Tasks

You must perform regular maintenance to keep your electric chain hoist operating safely and efficiently. Routine tasks help you prevent unexpected breakdowns and extend the lifespan of your equipment. Follow these steps:

Schedule inspections by professional technicians before each use and at regular intervals.

Lubricate and inspect the load chain for signs of wear.

Test the electrical system and check all connections.

Examine hooks and latches for deformation or malfunction.

Verify the operation of the limit switches and inspect the braking system.

Keep detailed records of all maintenance activities.

Train operators on proper hoist operation and safety protocols.

Maintain a clear area under the load and follow workplace safety standards.

Regular maintenance reduces risks and ensures compliance with industry regulations.

Inspection and Lubrication

You need to inspect and lubricate your electric chain hoist according to Powerful Machinery’s guidelines. Use only the lubricant recommended by the manufacturer. Apply lubricant at the intervals specified in the manual. Make sure the lubricant reaches the inner surfaces between the chain links.

Avoid using too much grease, as excess can attract dust and debris. Inspect the chain and hook for wear, distortion, or damage. Look for elongated links, nicks, or cracks. Replace any part that shows significant wear or damage immediately.

Lubricate the load chain regularly for smooth operation.

Inspect the chain and hook for damage or distortion.

Replace worn or damaged components without delay.

Tip: Proper lubrication and inspection help you avoid costly repairs and keep your hoist running smoothly.

Common Issues and Solutions

You may encounter several common issues when operating your electric chain hoist. The table below lists frequent problems and recommended troubleshooting steps:

Issue Description | Troubleshooting Steps |

|---|---|

Hoist Not Responding When Switch is Pressed | Check the power supply connection. Inspect the switch circuit for damage. Measure voltage for the proper range. |

Hoist Fails to Stop After Operation | Shut off the main power. Inspect or replace the contactor if welded. |

Hoist Slips After Stopping | Adjust the brake nut. Replace worn parts. Inspect for contamination affecting braking. |

Gearbox Oil Leakage | Replace worn seals. Tighten loose bolts on the gearbox. |

Motor Malfunction | Check for overheating, blown fuses, or incorrect wiring. Repair or replace as needed. |

Note: Address issues promptly to maintain safety and prevent downtime.

Routine maintenance and troubleshooting keep your electric chain hoist reliable and safe. You protect your team and equipment when you follow these best practices.

Conclusion

You ensure reliable and safe operation when you follow every step and safety protocol during electric hoist installation. Regular inspections, proper load chain maintenance, electrical system checks, and hook inspections all help extend equipment lifespan.

You also benefit from verifying limit switches, keeping detailed records, and providing operator training. Adhering to workplace safety standards protects your team and equipment. Choose Powerful Machinery’s certified solutions for your lifting needs.

Consult professionals for complex projects. A well-installed and maintained hoist improves workplace safety, efficiency, and equipment longevity.

FAQ

What is the most important safety step before installing an electric hoist?

You must inspect the installation site and equipment for damage or defects. Always verify that the structure can support the hoist’s load. Review the manufacturer’s manual and follow all safety protocols before you begin.

How often should you inspect your electric hoist?

You should inspect your electric hoist before each use and schedule professional inspections at regular intervals. Routine checks help you catch wear, damage, or electrical issues early.

Can you install an electric hoist outdoors?

Yes, you can install an electric hoist outdoors. Choose a model with a high IP rating for dust and water resistance. Always protect electrical components from weather exposure.

What should you do if your hoist stops working during operation?

First, stop using the hoist immediately. Check the power supply and inspect for visible damage. If you cannot resolve the issue, contact a qualified technician for further assistance.