You want your lever chain hoist to deliver reliable performance and last for years. Regular lever chain hoist maintenance makes a big difference in safety and longevity.

Industry studies show that you should inspect your hoist daily, follow the manufacturer’s schedule, lubricate the chain, and get yearly inspections by a qualified technician. Operator training also plays a key role. Powerful Machinery offers certified lever chain hoist solutions trusted by professionals worldwide.

Key Takeaways

Regular inspections are crucial. Check your lever chain hoist daily and follow a detailed monthly schedule to catch issues early.

Use the right lubricants. Apply light machine oil to the load chain and grease to gears to reduce friction and extend equipment life.

Operator training is essential. Ensure all users are certified and understand safety protocols to prevent accidents and equipment failure.

Document all maintenance activities. Keep accurate logs of inspections, repairs, and lubrication to track wear and ensure compliance with safety standards.

Follow safety protocols strictly. Always wear appropriate PPE and respect load limits to protect yourself and your team.

Safety Protocols for Lever Chain Hoist

PPE and Safe Operation

You must follow strict safety protocols every time you use a lever chain hoist. Personal protective equipment (PPE) keeps you safe from common hazards. Heavy-duty gloves protect your hands from pinch points and sharp edges. Steel-toed boots with slip-resistant soles shield your feet.

Hard hats guard your head when you work near overhead loads. Safety glasses or goggles prevent eye injuries from flying particles. High-visibility clothing helps others see you in busy areas.

Fire-resistant clothing is necessary for welding or flame cutting. Tear-resistant and anti-static clothing protects you from sharp steel and electrical risks. Always choose clothing that matches the temperature at your worksite. These protocols support maintenance and safe operation.

Type of PPE | Purpose |

|---|---|

Hand protection | Heavy-duty gloves to protect against pinch points, sharp edges, and abrasion |

Foot protection | Steel-toed boots with slip-resistant soles |

Head protection | Hard hats where overhead hazards exist |

Eye protection | Safety glasses or goggles to shield against flying particles |

High-visibility clothing | When working in areas with moving equipment or traffic |

Powerful Machinery’s lever chain hoist meets CE and ISO standards, showing a strong commitment to safety protocols and international certifications.

Operator Training and Certification

Operator training forms the foundation of safe hoist use. You need comprehensive training before you operate any lifting device. Chain Hoist Technician Certification takes three days and covers different brands.

Overhead Crane Operator Certification, offered by NCCCO, teaches you operational guidelines and safety. Inspection certification programs last two days and focus on maintenance and safety protocols.

LEEA-accredited training is recognized across the industry. CMAA publishes guides for lifting devices. These programs help you understand safety protocols and proper maintenance.

Training Program | Duration | Description |

|---|---|---|

Chain Hoist Technician Certification | 3 Days | Comprehensive training and testing on various hoist brands, leading to certification. |

Overhead Crane Operator Certification | N/A | Certification through NCCCO includes operational guidelines and safety training. |

Overhead Crane & Hoist Inspection Certification | 2 Days | Training on inspection and safety standards applicable to all cranes and hoists. |

LEEA Accredited Safety & Rigging Training | N/A | Industry-recognized training programs for safety and rigging. |

Load Limits and Prohibited Actions

You must respect load limits at all times. Exceeding rated capacity can cause equipment failure, snapping chains, or broken gears. Serious injuries or fatalities may occur if you ignore safety protocols. Legal consequences include fines and criminal charges. Insurance may not cover accidents caused by improper use.

Always check the load rating before lifting. Never use the hoist for loads that exceed its capacity. These protocols protect you and your equipment. Regular maintenance and strict safety protocols keep your worksite safe.

Organization | Standard | Description |

|---|---|---|

ASME | ASME B30.21 | Covers construction, inspection, testing, and maintenance of lever hoists. |

OSHA | N/A | Sets and enforces safety standards for workplace operations, including hoisting equipment. |

ANSI | N/A | Provides voluntary consensus standards for lifting devices, ensuring reliability and safety. |

Tip: Always follow manufacturer guidelines and safety protocols. Powerful Machinery’s certified products help you meet international safety standards.

Lever Chain Hoist Maintenance Inspections

Routine inspections form the backbone of lever chain hoist maintenance. You need to check your equipment regularly to keep it safe and reliable. Powerful Machinery designs lever chain hoists to meet strict international standards, but only regular inspections and proper maintenance can ensure long-term performance.

Daily Visual and Functional Checks

You should always start your workday with pre-use inspections. These quick checks help you spot obvious problems before they become serious. Look for signs of damage, unusual wear, or anything that seems out of place.

Test the hoist’s operation by lifting and lowering a light load. Listen for strange noises and feel for rough movement. Make sure the hooks latch securely and the chain moves smoothly.

Tip: Pre-use inspections catch small issues early, reducing the risk of accidents and costly repairs.

Industry guidelines recommend different inspection frequencies based on service conditions. Use this table to guide your lever chain hoist maintenance schedule:

Service Condition | Daily | Weekly | Monthly | Semiannually | Yearly | Quarterly |

|---|---|---|---|---|---|---|

Normal | N/A | N/A | Yes | N/A | Yes | N/A |

Heavy | N/A | Yes | Yes | Yes | N/A | N/A |

Severe | Yes | Yes | N/A | N/A | N/A | Yes |

You should always follow the manufacturer’s recommendations for routine inspections. Powerful Machinery’s lever chain hoists are built for reliability, but daily checks remain essential.

Chain and Component Inspection

Chain and component inspection is a critical part of lever chain hoist maintenance. You need to look for common wear indicators that signal when parts need attention or replacement.

Use a flashlight to examine the entire length of the chain. Rotate the chain to check every link. Inspect the hooks, latches, and body for cracks or deformation.

Here are the most common wear indicators you should watch for:

Wear Indicator | Description |

|---|---|

Nicks, gouges, and cracks | Stress points that can cause the chain to break under load, especially at the interlink area. |

Chain elongation | Permanent stretching that weakens the chain; compare to the manufacturer’s specifications. |

Twisted or bent links | Prevent proper seating in the sprocket, leading to rapid wear and unsafe operation. |

Weld spatter | Creates hard, brittle spots that can start cracks and weaken the chain. |

Wear exceeding 10% of the dimension | If wear exceeds 10% of the original size, replace the part immediately. |

Cracks, nicks, or gouges on the hook | These defects can cause fatigue failure and require immediate removal from service. |

You should never ignore these signs. Replace any damaged parts right away. Powerful Machinery supplies certified replacement components to keep your lever chain hoist operating safely.

Annual Professional Inspection

Annual professional inspection is a key part of lever chain hoist maintenance. You need a qualified technician to perform a detailed check at least once a year. This inspection goes beyond daily and monthly checks.

The technician will partially disassemble the hoist to inspect internal parts, measure wear, and test the brake system.

Industry standards recommend two main types of inspections:

Inspection Type | Frequency | Typical Findings |

|---|---|---|

Frequent Inspection | Weekly to Monthly | Operational issues with components like chains and hooks |

Periodic Inspection | Monthly to Annually | In-depth issues requiring partial disassembly for internal checks |

Frequent inspections focus on operational components and should happen before each use or weekly.

Periodic inspections involve more detailed checks, often monthly or quarterly.

Annual inspections require a professional and include internal parts.

Regular inspections and annual professional inspections help you catch hidden problems. Powerful Machinery’s lever chain hoists are certified for quality and safety, but only proper maintenance ensures peak performance year after year.

Note: Keep a record of all inspections and maintenance. This helps you track wear, schedule replacements, and prove compliance with safety standards.

Lubrication and Cleaning

Recommended Lubricants and Methods

You need to use the right lubricants to keep your lever chain hoist running smoothly. Lubrication helps reduce friction, protects against corrosion, and extends the life of your equipment. When you clean and lubricate the load chain, you improve chain life by two to four times.

You also reduce energy use by up to 10 percent and cut lubricant use in half. Smoother operation and less wear are clear signs of good lubrication and chain maintenance.

Usage | Type | Container Size |

|---|---|---|

Hoist Gears | Grease | 1/2 lb, 1 lb, 4 lb |

Spine on Drive Shaft End | Oil-Graphite Mix | 1 pint |

Load Chain | Oil | 1 pint, 1 gallon |

Limit Switch Shaft Threads | Light Machine Oil | N/A |

You should apply oil to the load chain and grease to the gears. Use a light machine oil for small moving parts. Always follow the manufacturer’s recommendations for lubrication intervals. Regular lubrication and chain maintenance keep your hoist safe and reliable.

Cleaning Procedures

You must keep your lever chain hoist clean to prevent dirt and debris from causing damage. Start by wiping down the exterior with a clean, dry cloth. For stubborn grime, use a mild detergent and water, but avoid soaking any parts. After cleaning, dry all surfaces completely.

Always clean and lubricate the chain before and after heavy use. This step helps prevent rust and ensures smooth operation. Cleaning and inspection go hand in hand, so check for wear while you clean.

Tip: Never use harsh chemicals or high-pressure water. These can damage seals and remove essential lubrication.

Environmental Considerations

Your work environment affects how often you need to perform maintenance. Dust and moisture can increase the need for cleaning and lubrication. In humid or dirty areas, you should clean and lubricate your hoist more often. Moisture can cause rust, while dust can lead to extra wear.

Always store your hoist in a dry, clean place when not in use. Adjust your maintenance schedule based on your environment to keep your lever chain hoist in top condition.

Troubleshooting Lever Chain Hoist Issues

When your lever chain hoist does not work as expected, you need a clear troubleshooting process. You can solve many problems with careful inspection and basic maintenance. You must always follow manufacturer guidelines and use certified parts from Powerful Machinery to keep your equipment safe and reliable.

Common Symptoms and Causes

You may notice several symptoms when your lever chain hoist develops issues. Recognizing these signs helps you start troubleshooting quickly. The table below lists the most frequently reported symptoms and their descriptions:

Symptom | Description |

|---|---|

Wear | Interlink wear where chain links rub together, detectable by measuring chain pitch. |

Stretching | Overloaded chain elongation, causing rough operation and improper seating in the load sheave. |

Nicks, Gouges, and Cracks | Surface indentations or cracks that can spread under load. |

Twisting and Kinking | Chains that do not hang straight or have kinks, creating stress points. |

Corrosion | Rust that weakens the chain and may hide serious defects. |

Deformation | Bent or twisted hook throat, indicating overload and permanent weakening. |

Latch Malfunction | Safety latch fails to close securely or lacks spring force. |

You may also hear unusual noises or notice the load drifting. These symptoms often point to worn bearings, gears, or brake malfunctions. Neglected maintenance is a leading cause of brake failure and noisy operation. A brake system malfunction can create dangerous situations and must be addressed immediately.

Tip: Early detection of symptoms makes troubleshooting and repair easier and helps prevent costly downtime.

Step-by-Step Troubleshooting

You can follow a step-by-step troubleshooting process to identify and fix most lever chain hoist problems. Always start with safety in mind and use manufacturer-approved tools and parts.

Safety Preparations: Make sure the hoist is not under load. Disconnect any power sources if present.

Initial Diagnosis: Review the operation manual to understand the problem.

Gathering Necessary Tools and Parts: Collect all tools and ensure you have certified replacement parts.

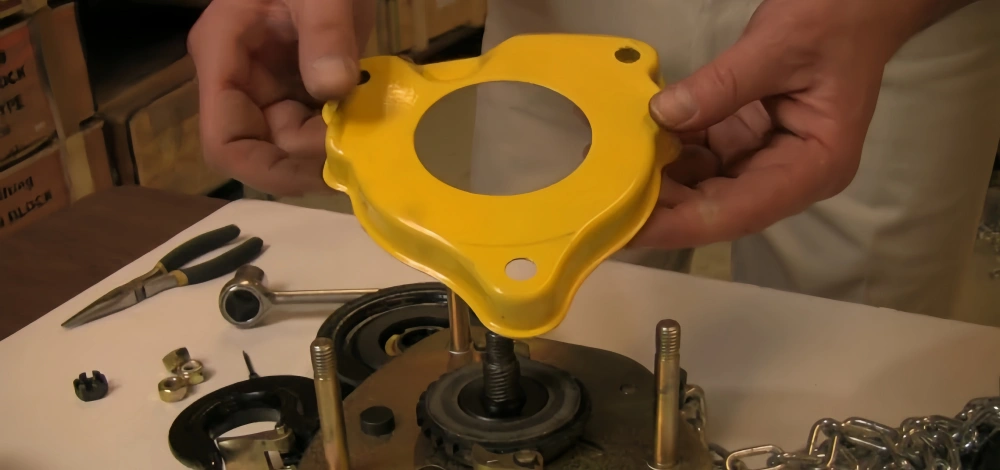

Disassembly Process: Carefully take apart the hoist. Inspect each part for damage or wear.

Cleaning and Inspection: Clean all components. Look for signs of wear, corrosion, or deformation.

Replacing Worn or Damaged Parts: Swap out any damaged parts with manufacturer-recommended replacements.

Reassembly and Lubrication: Put the hoist back together. Lubricate moving parts as specified in the manual.

Testing and Adjustment: Test the hoist without a load. Make adjustments as needed.

Operational Testing: Run the hoist through all functions to check for smooth operation.

Load Testing: Lift a test load to confirm the hoist can handle its rated capacity.

Maintenance Review: Update your maintenance records after repairs.

Continuous Monitoring: Watch the hoist’s performance after repairs to catch any recurring issues.

Note: Always use manufacturer guidelines for troubleshooting and repair. Powerful Machinery offers support and certified parts to ensure safety and reliability.

When to Call a Professional?

Some troubleshooting and repair tasks require specialized knowledge or tools. You should call a professional when you face complex repairs, especially those involving critical components like the brake system or load-bearing parts.

Professional technicians have the training and equipment to handle these repairs safely.

If you notice severe deformation, extensive corrosion, or repeated brake malfunctions, do not attempt repairs yourself. Professional service ensures your lever chain hoist meets safety standards and operates reliably. You protect yourself and your team by seeking expert help for complicated issues.

Safety first: When in doubt, trust certified professionals for troubleshooting and repair. Powerful Machinery provides expert support and certified parts for all maintenance needs.

Essential Maintenance Practices

Chain Care and Replacement

You need to follow essential maintenance practices to keep your lever chain hoist in top condition. Regular chain care helps prevent breakdowns and extends the life of your equipment. Start with a proactive maintenance schedule. Check the chain for wear and damage based on time and usage.

Lubricate the chain according to the manufacturer’s specifications. This reduces friction and prevents rust. Always document your maintenance activities in a logbook. Tracking wear helps you predict when to replace the chain.

Store your hoist properly to protect it from moisture and dust. These maintenance tips ensure your chain stays strong and reliable.

Perform regular service and adjustments.

Lubricate the chain as recommended.

Record all maintenance in a logbook.

Store the hoist in a clean, dry place.

Tip: Replace the chain if you notice stretching, cracks, or wear exceeding 10% of the original size.

Brake and Hook Maintenance

Brake and hook maintenance practices are vital for safe operation. You should inspect these parts every day. Look for visible signs of wear or damage. Check the chain and operational controls for smooth movement.

Lubricate the load chain to prevent corrosion. Inspect the braking system and hooks for mechanical integrity. Make sure the brake engages smoothly and the hook closes securely. These maintenance tips help you avoid accidents and keep your hoist working safely.

Check for wear or damage daily.

Lubricate the load chain regularly.

Inspect brakes and hooks for proper function.

Component | Maintenance Tips |

|---|---|

Brake System | Inspect for smooth engagement |

Hook | Check for secure closure |

Chain | Lubricate and inspect daily |

Storage and Handling

Proper storage and handling protect your lever chain hoist from damage. You should hang the hoist by its suspension hook when possible. If you use shelf storage, support the hoist fully to prevent distortion. Never place heavy items on top of the hoist.

Coil the chain neatly to avoid kinks and tangles. Apply a thin film of rust-preventative oil to exposed surfaces. Use vapor-corrosion inhibitors or desiccant packs for long-term storage. Clean and dry the hoist before storing it. Choose a dry, climate-controlled environment.

Avoid temperature extremes and use waterproof covers if needed. These maintenance tips keep your hoist ready for use and extend its service life.

Hang by suspension hook or fully support on a shelf.

Keep chains coiled and free of tangles.

Apply rust-preventative oil before storage.

Store in a dry, climate-controlled area.

Note: Following these essential maintenance practices helps you maximize the longevity and safety of your lever chain hoist.

Maintenance Records and Compliance

Keeping Logs and Documentation

You need to keep accurate records for every lever chain hoist you use. Good documentation helps you track the history of inspections, repairs, and maintenance. When you record each activity, you make it easier to spot patterns and prevent future problems.

You also create a reliable reference for troubleshooting. Follow manufacturer recommendations and update your logs after every inspection or repair.

Here are effective ways to document your maintenance activities:

Write down every inspection date and the findings.

Record all repairs, including replaced parts and the technician’s name.

Note lubrication schedules and cleaning routines.

Keep copies of manufacturer guidelines and inspection checklists.

Store records in a safe place, either digitally or in a physical binder.

Tip: Detailed logs help you prove compliance with safety standards and support warranty claims.

Meeting Safety Standards

You must meet strict safety standards to keep your lever chain hoist in top condition. These standards protect you and everyone on your team. ASME B30.21 sets the main rules for lever hoists, covering design, inspection, and maintenance. Regular inspections must follow manufacturer guidelines and industry protocols.

Standard | Description |

|---|---|

ASME B30.16 | Specifies materials, load tests, and markings for under-hung hoists. |

Certified Lever Hoist | Confirms the hoist meets recognized safety and performance standards. |

Inspection Protocols | Requires inspections that match manufacturer and ASME recommendations. |

You should follow a clear inspection schedule:

Initial inspection before first use or after repairs.

Frequent inspection every day for damage or malfunction.

Periodic inspection at set intervals based on usage and manufacturer advice.

Note: Meeting these standards ensures your equipment stays safe and reliable. Powerful Machinery’s certified lever chain hoists help you comply with international safety requirements.

Lever Chain Hoist Repair Steps

Safety Preparation

You must prepare for lever chain hoist repair by following strict safety steps. Begin with a pre-operational safety inspection. Check that all markings and labels are clear and readable. Test the hoist controls for quick response. Inspect hooks for wear or bending.

Operate the hoist without a load to confirm smooth movement. Examine the chain for signs of damage. You should perform these inspections daily or before each use. Document every inspection to maintain safety standards. Understand and follow all safety regulations before you start any repair.

Check markings and labels

Test controls for responsiveness

Inspect hooks for wear or deformation

Operate the hoist without a load

Examine the chain for damage

Document inspections

Diagnosis and Disassembly

You need to diagnose the problem before you begin the repair. Listen for abnormal noises and watch for rough movement. Review the manufacturer’s manual to identify possible causes. Gather all necessary tools and certified replacement parts from Powerful Machinery.

Take clear notes and photos during disassembly. Remove the outer casing and separate the chain, brake system, and control lever. Inspect each part for wear, cracks, or corrosion. Careful diagnosis helps you target the exact repair needed.

Part Replacement and Reassembly

Replace damaged or worn parts during the repair process. The brake system, load chain, and control lever are the most common parts you will need to change. Use only certified parts to ensure safety and reliability. Follow the manufacturer’s guidelines for reassembly.

Refer to your notes and photos to put each part back in the correct position. Lubricate all moving parts before closing the casing. Proper reassembly prevents future breakdowns and keeps your lever chain hoist working smoothly.

Replace brake system, load chain, or control lever as needed

Use certified parts for every repair

Follow the manufacturer’s reassembly instructions

Lubricate moving parts

Testing and Final Checks

You must test the lever chain hoist after every repair. Start with no load to check the chain and brake system. Use a light load for the next test. Raise and lower the load to confirm smooth operation. Listen for strange noises or movements. Test the brake at different points.

Finish with a load close to the hoist’s rated capacity. Conduct operational testing as recommended by the manufacturer. Verify that the hoist can lift and hold its rated load safely. If you do not have proper testing equipment, consider hiring a professional. Document all results and update your maintenance records.

Tip: Operational testing after repair ensures your lever chain hoist is safe and ready for use.

Conclusion

You protect yourself and your team when you follow a structured maintenance and repair checklist for your lever chain hoist. Regular inspections, cleaning, and chain care boost safety and improve performance. The table below highlights practices that help you avoid accidents and extend equipment life:

Maintenance Practice | Benefit |

|---|---|

Regular Inspection | Increases safety |

Cleaning and Lubrication | Improves performance |

Chain Care | Extends longevity |

Operator Training | Prevents malfunctions |

Ongoing training and strict adherence to manufacturer guidelines help you meet safety standards and avoid costly fines. You also ensure your hoist delivers reliable performance every day. Powerful Machinery supports you with certified lifting solutions trusted by professionals worldwide.

FAQ

How often should you inspect your lever chain hoist?

You should inspect your lever chain hoist before each use. Perform a more detailed inspection monthly. Schedule a professional inspection every year. Regular checks help you catch problems early and keep your equipment safe.

What lubricant works best for lever chain hoists?

Use light machine oil for the load chain. Apply grease to gears and moving parts. Always follow the manufacturer’s recommendations for the best results. Proper lubrication reduces friction and prevents rust.

When do you need to replace the chain?

Replace the chain if you see stretching, cracks, or wear that exceeds 10% of the original size. Damaged chains can fail under load. You protect yourself and your team by replacing worn chains promptly.

Can you repair a lever chain hoist yourself?

You can handle basic repairs like cleaning, lubrication, and replacing minor parts. For brake systems or severe damage, call a certified technician. Professional help ensures your hoist meets safety standards.

What records should you keep for maintenance?

Keep a log of all inspections, repairs, and lubrication schedules. Record the date, findings, and actions taken. Good documentation helps you track wear, plan replacements, and prove compliance with safety standards.