You rely on electric chain hoist maintenance to keep your equipment running safely and efficiently. Industry studies show that 70% of hoist failures result from poor maintenance, while 80% of downtime is preventable. The cost of just one hour of hoist downtime can exceed $1,000.

Statistic | Value |

|---|---|

Percentage of hoist failures due to poor maintenance | 70% |

The percentage of hoist downtime that is preventable | 80% |

Cost of one hour of hoist downtime | $1,000+ |

Powerful Machinery, a trusted provider of electric chain hoists, helps you meet strict safety standards and extend equipment life. This checklist guides you in protecting your investment and supporting smooth operations.

Key Takeaways

Regular maintenance is crucial. Daily inspections can prevent 80% of downtime and save over $1,000 per hour in costs.

Follow manufacturer guidelines for maintenance. This ensures safety and extends the life of your electric chain hoist.

Keep detailed maintenance logs. Accurate records help track equipment condition and support compliance with safety regulations.

Use the right lubricant for your hoist. Proper lubrication prevents wear and keeps your equipment running smoothly.

Train operators thoroughly. Knowledgeable users can spot hazards and operate hoists safely, reducing the risk of accidents.

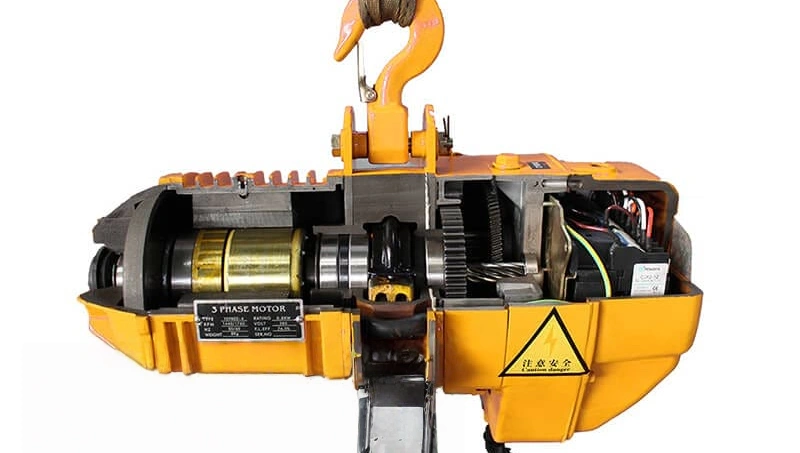

Electric Chain Hoist Components

Main Parts Overview

Powerful Machinery stands out as a trusted leader in electric chain hoist technology. You benefit from their commitment to safety and reliability every time you use their lifting solutions. Understanding the main parts of your electric chain hoist helps you maintain it properly and spot issues before they become serious.

Here are the essential components and their functions:

Motor: Powers the hoist and lifts the load by turning electrical energy into motion.

Chain: Connects the load hook to the hoist body. Made from high-strength alloy steel for durability.

Load Hook: Attaches directly to the load. The safety catch prevents accidental release.

Hoist Body or Frame: Houses the motor and gearbox. Built for strength and long-term use.

Gearbox: Reduces motor speed and increases torque for heavy lifting.

Brake: Holds the load securely when not lifting.

Control Panel: Contains the electrical controls for operating the hoist.

Chain Container: Stores unused chain and keeps your workspace organized.

Push Button Pendant or Remote Control: Lets you operate the hoist safely from a distance.

Limit Switches: Stops the hoist at the correct position and prevents overtravel.

Tip: Regularly check each part for signs of wear or damage. Early detection keeps your electric chain hoist running safely.

Manufacturer Guidelines

You must always follow the manufacturer’s guidelines when maintaining or repairing your electric chain hoist. These instructions help you avoid mistakes and keep your equipment in top condition.

Inspect and lubricate the chain regularly.

Test limit switches and brakes to ensure proper function.

Check electrical components for safe operation.

Replace worn parts right away.

Train operators on safe usage.

Keep detailed records of inspections and repairs.

Following the manufacturer’s guidelines protects your investment and ensures safe lifting every day.

Daily Electric Chain Hoist Maintenance

Inspection Checklist

You need to perform daily pre-operational inspections to keep your electric chain hoist safe and reliable. Start with a visual inspection. Look for damage on the hoist body, clear the path of any obstacles, and check for frayed power cords. Examine the hook and latch assembly for bending or twisting.

Make sure the safety latch works properly. Inspect the load chain for wear, twists, or kinks. Lubricate the chain if needed. Test the control systems, including the pendant and remote controls, to confirm they respond as expected.

Routine inspections help you catch problems early. Common issues include frayed cables, damaged chains, and malfunctioning electrical systems. You might see elongated chain links or cracks on the hook.

Check for deformed or worn hooks and make sure the safety latch is secure. Test the limit switches to prevent over-travel. If you notice any of these problems, stop using the hoist and report the issue right away.

Note: A comprehensive inspection each day reduces the risk of accidents and extends the life of your equipment.

Operator Training

Proper training is essential for safe electric chain hoist maintenance. You must learn how to conduct daily pre-operational inspections before using the hoist. Check the control pendant, wire rope or chain, hooks, load path, and limit switches.

Understand load dynamics and rigging. Assess the weight, find the center of gravity, and use correct sling angles and hitch techniques.

Safe operating procedures include clear communication, lift planning, and trial lifts. Operate the hoist smoothly and stay clear of suspended loads. Prepare for emergencies such as power failures, mechanical malfunctions, or swinging loads. Secure the area if something goes wrong.

You build a culture of safety by attending refresher courses and reporting unsafe conditions. Management should lead safety initiatives and encourage everyone to follow best practices. Training empowers you to spot hazards and take action quickly.

Reporting and Documentation

You must keep detailed records of all maintenance activities, inspections, and repairs. Document lubrication, replacement of worn-out parts, and periodic load testing. Follow the manufacturer’s maintenance guidelines to keep your electric chain hoist in optimal condition.

Daily inspections and routine inspections should include chain lubrication, checking for wear, and testing limit switches and brakes. Train operators on safe usage and replace worn parts immediately. Regular maintenance extends the life of your electric chain hoist and ensures safe operation.

Tip: Accurate documentation helps you track the hoist’s maintenance history and supports predictive maintenance. You also meet regulatory requirements and improve workplace safety.

Preventative Maintenance for Electric Hoists

Cleaning and Lubrication

You need to keep your electric chain hoist clean and well-lubricated to ensure safe and efficient operation. Cleaning and maintenance start with removing dust and debris from the hoist’s surface after each use. Dust can cause corrosion and damage if left unchecked.

Use a solvent and a stiff brush to clean the chain thoroughly, then let it dry completely. This step prevents buildup that can lead to mechanical problems.

Follow these steps for proper lubrication:

Clean the chain first to remove any dirt or old lubricant.

Apply lubricant to the articulating points between the outer and inner plates of each chain link as you run the chain out.

Operate the hoist up and down its full range without a load. This action helps distribute the lubricant evenly.

Wipe off any excess lubricant with a clean, dry rag. Too much lubricant can attract dust and cause further issues.

Lubricate according to the manufacturer’s recommendations to avoid early damage. Regular cleaning and lubrication prevent the lack of lubrication, which often leads to chain wear and operational failures. You should also check for rust and apply anti-rust treatments if you notice any signs of corrosion.

These preventive measures help extend the life of your equipment and reduce the risk of breakdowns.

Tip: Always use the recommended lubricant for your Powerful Machinery electric chain hoist. This practice ensures optimal performance and protects against unnecessary wear.

Scheduled Maintenance Intervals

You should follow a comprehensive schedule for electric chain hoist maintenance. Daily visual inspections and lubrication are essential. These quick checks help you spot problems before they become serious.

For most environments, service your hoist at least once a year. If you use your hoist in high-usage or harsh environments, increase the frequency to every six months.

Here is a simple maintenance and inspection suggestions table:

Interval | Task |

|---|---|

Daily | Visual inspection, chain lubrication |

Monthly | Check the electrical system, test the brakes |

Every 6 months | Full inspection in harsh environments |

Annually | Comprehensive service by a technician |

Regular maintenance helps you identify wear and damage before they lead to failures. Lubrication prevents the lack of lubrication, which can make the chain dry and brittle. Inspect the electrical system to ensure all connections and components work correctly.

These maintenance tips keep your hoist running smoothly and safely.

Environmental Considerations

The environment where you use your electric chain hoist affects its durability and reliability. Outdoor hoists face rain, dirt, and temperature changes, which can reduce efficiency and lifespan. High humidity can cause rust and corrosion. Extreme temperatures may lead to overheating or other mechanical issues.

You should control dust concentration in your workspace. Before lifting, check the dust content in the area. If it is excessive, move the hoist to a cleaner location. After each operation, clean dust from the hoist’s surface to prevent internal damage and corrosion.

For hoists used outdoors or in harsh conditions, consider models with higher protection ratings to withstand moisture and temperature swings.

Note: The physical environment plays a big role in how often you need to perform preventative maintenance. Adjust your schedule if you notice more wear or if your hoist operates in tough conditions.

Powerful Machinery designs electric chain hoists for durability, but you must still follow a regular maintenance plan. Preventive maintenance reduces the risk of costly failures and keeps your equipment in top shape. By following these preventive measures, you protect your investment and ensure safe lifting every day.

Safety Procedures in Electric Hoist Maintenance

Lockout/Tagout (LOTO)

You must always disconnect the power before starting any work on your electric hoist. Lockout/Tagout (LOTO) procedures protect you from accidental startup and electrical hazards.

Begin by switching off the main power supply. Attach a lock and tag to the disconnect switch so no one can turn it on while you work. Verify that the hoist cannot operate by testing the controls. Never remove the lock or tag until you finish all tasks and confirm the area is safe.

Tip: LOTO procedures prevent injuries and keep your team safe during maintenance.

PPE and Work Area Safety

Personal protective equipment (PPE) keeps you safe from harm. Wear safety gloves, hard hats, and eye protection when working with electric hoists. Use steel-toed boots to protect your feet from falling objects. Inspect your PPE before each use to ensure it works properly.

Keep your work area clean and free of clutter. Mark off the area with warning signs or cones to prevent unauthorized access. Remove any obstacles that could cause trips or falls. Always stay alert and communicate with your team.

Safety gloves

Hard hats

Eye protection

Steel-toed boots

A clean and secure workspace reduces the risk of accidents and supports a culture of safety.

Compliance Standards

You must follow strict standards when performing electric hoist maintenance. Powerful Machinery designs electric hoists to meet international safety standards, including ISO, CE, and OSHA. These certifications show that each product passes rigorous tests for quality and reliability.

The company verifies certification legitimacy, manufacturer credibility, and material specifications for every hoist. This process ensures compliance with safety regulations in Europe, the Americas, and other regions.

Inspection Type | Description | Requirements |

|---|---|---|

Frequent Inspections | Conducted at the start of every shift to ensure the hoist is in safe working order. | No record-keeping required. |

Periodic Inspections | Thorough inspections that may require complete disassembly of the hoist, based on usage and environment. | Must be documented and kept on file; required by OSHA, ASME, and manufacturers. |

You protect yourself and your equipment by following these standards. Compliance helps prevent accidents and supports safe lifting operations.

Troubleshooting Electric Chain Hoist Issues

You encounter common problems with electric chain hoists during daily operations. Troubleshooting helps you identify issues quickly and apply step-by-step solutions. This guide covers the most common problems faced by electric hoists and gives you practical troubleshooting steps for repairs.

Power and Motor Problems

Power and motor issues often stop your electric chain hoist from working. You may notice the hoist does not respond, the motor overheats, or you hear unusual noises. Use the table below to match symptoms with troubleshooting steps and solutions:

Problem | Symptoms | Troubleshooting Steps |

|---|---|---|

Hoist Does Not Operate | Hoist doesn’t respond to controls | Check power source, inspect control pendant, verify emergency stop button |

Hoist Motor Overheats | Motor feels hot or shuts off | Allow cooling, ensure no overload, check ventilation |

Unusual Noises | Grinding or squeaking sounds | Lubricate the chain, inspect for wear, and check gearbox oil level |

Follow these troubleshooting steps:

Check the power source and wiring.

Verify voltage and frequency match specifications.

Inspect the control pendant and emergency stop button.

Allow the motor to cool if overheated.

Lubricate moving parts to reduce noise.

These step-by-step solutions help you resolve common problems and keep your equipment running.

Chain and Brake Issues

Chain and brake problems can cause chain jamming, slipping, or load drift. You need to inspect the load chain for twisted or damaged links. Adjust the brake settings according to the manufacturer’s instructions.

Make sure the chain sits correctly in the sprocket. If the load drifts or creeps, check the braking system for wear and lubricate the chain. Verify the hoist is not overloaded.

Symptoms | Troubleshooting Steps |

|---|---|

Chain Jamming or Slipping | Inspect the chain, replace damaged links, adjust the brake, and seat the chain in the sprocket |

Load Drift or Creep | Check brakes, lubricate chain, verify load, adjust or replace brake as needed |

Apply these troubleshooting steps to prevent further damage and ensure safe repairs.

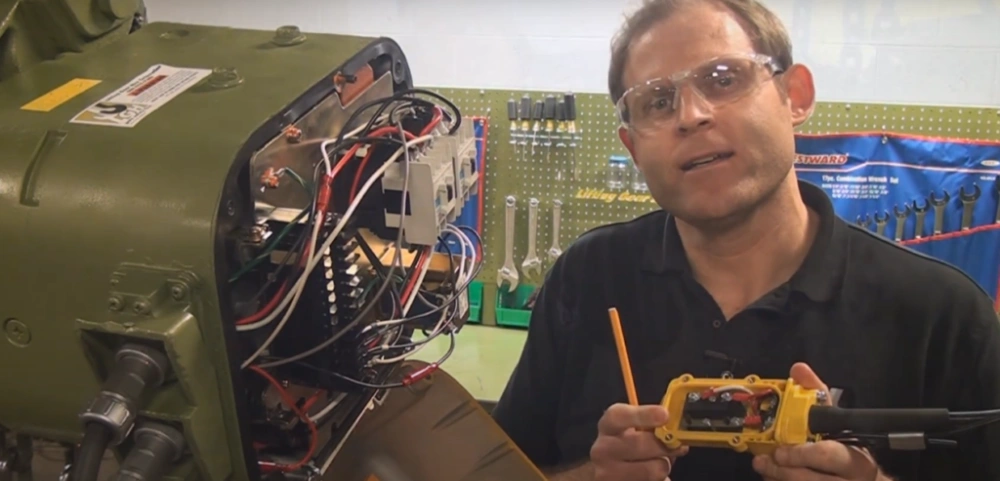

Electrical and Control Faults

Electrical and control faults require careful troubleshooting. Start with a visual inspection for wear and tear on chains, hooks, and gears. Check the pendant, emergency stop button, and cable for damage.

Inspect the control panel for overheating and loose connections. Use a multimeter to test voltage at different points.

Always de-energize the hoist system at the main disconnect before opening any control panels.

Follow these troubleshooting steps:

Inspect the pendant and emergency stop.

Check the control panel and terminal connections.

Perform systematic electrical testing with a multimeter.

Conduct load testing to verify performance.

These step-by-step solutions help you identify electrical faults and complete repairs safely. Troubleshooting common problems faced by electric hoists keeps your equipment reliable and extends its lifespan.

Electric Chain Hoist Repair Guide

Motor and Electrical Repairs

You need a systematic approach when repairing the motor and electrical systems of your electric chain hoist. Always start by disconnecting the hoist from the power source. This step keeps you safe. Remove the motor housing cover to access the motor.

Carefully disconnect the motor’s electrical connections, making notes for reassembly. Unbolt the motor and remove it from the hoist. Install the new motor, secure it with bolts, and reconnect the wires using your notes or the wiring diagram.

Replace the housing cover, reconnect the power, and test the motor before returning the hoist to service.

For electrical repairs, disconnect the power first. Use a multimeter to check for continuity and proper voltage in the control circuit and motor. Inspect all wiring and connections for wear or damage.

Replace any faulty components. Reconnect the power and test the hoist’s operation. Using official Powerful Machinery parts and manuals ensures reliable repairs and maintains safety standards.

Chain and Brake Replacement

You must inspect the load chain and brake system regularly. Replace chains showing signs of wear, twisting, or elongation. Remove the old chain and install a new one, making sure it seats correctly in the sprocket. For brake repairs, check for wear or loss of braking power.

Replace worn brake pads or adjust the brake mechanism as needed. Always follow the manufacturer’s repair guide for these tasks to guarantee safe operation.

Gearbox and Mechanical Repairs

Mechanical repairs often involve the gearbox and moving parts. Begin by disconnecting the power. Remove the gearbox cover and inspect gears for wear or damage. Replace worn gears with official parts. Lubricate all moving components before reassembly.

Check the alignment of the gearbox and ensure all bolts are tight. Timely repairs prevent further damage and extend the life of your equipment.

Post-Repair Testing

After completing repairs, you must test the electric chain hoist to confirm safety and performance. Inspect all electrical connections and wiring for looseness. Test the motor and brake system for efficiency. Check limit switches to prevent over-travel and verify brake engagement.

Maintain a detailed log of inspections and repairs. Ensure all safety devices work properly. Store the hoist in a clean, dry place. Schedule annual inspections by a professional technician to catch hidden issues.

Tip: Careful post-repair testing keeps your hoist reliable and safe for every lift.

When to Call a Professional for Hoist Maintenance?

Certified Technician Services

You should call a certified technician when you face complex repairs with your electric chain hoist. Some tasks need special skills and tools. If you see major electrical faults, brake failures, or structural damage, do not try to fix these problems yourself.

Certified technicians know how to handle these repairs safely. They use official parts and follow strict procedures.

Here is a table showing repairs that need expert attention:

Type of Repair | Description |

|---|---|

Chain Replacement | Swapping out broken or old chains with high-quality certified parts. |

Lever Adjustment | Making necessary and precise adjustments to ensure the levers work correctly. |

Hook Maintenance | Inspecting and replacing hooks that show signs of damage or wear. |

You protect yourself and your equipment by letting professionals handle these repairs.

Warranty and Compliance

You keep your warranty valid when you use Powerful Machinery’s authorized service centers. If you try to repair your electric chain hoist without proper training, you risk losing warranty coverage.

Authorized technicians follow manufacturer guidelines and use certified parts. This process helps you meet safety standards and legal requirements. You also avoid costly mistakes and keep your equipment running longer.

Tip: Always check your warranty terms before starting any repairs. Using official service centers protects your investment.

Accessing Official Manuals

You can find official service manuals and technical drawings through Powerful Machinery’s support resources. These manuals help you understand your equipment and guide you through basic maintenance.

If you need more information or genuine parts, contact an authorized dealer. Service centers provide expert advice and access to the latest updates.

Visit the support site for service manuals and parts lists.

Request information from authorized dealers about genuine parts and service.

Ask service centers for technical bulletins and maintenance tips.

You get reliable support and accurate information when you use official resources. This step helps you keep your electric chain hoist safe and efficient.

Maintenance Records and Compliance

Maintenance Logs

You need to keep detailed maintenance logs for your Powerful Machinery electric chain hoist. These records help you track the condition of your equipment and plan future maintenance activities. A well-kept log allows you to spot wear patterns and address issues before they become serious problems.

A good maintenance log should include:

Dates of inspections

Findings from each inspection

Repairs or replacements made

Notes on lubrication and adjustments

Keeping a record of inspections, repairs, and part replacements is crucial for effective electric chain hoist maintenance. This practice helps you plan preventive maintenance and troubleshoot unexpected issues. When you document every step, you make it easier to predict when parts might need attention.

Tip: Accurate logs support compliance and help you avoid costly downtime.

Predictive Maintenance

Predictive maintenance uses data to help you prevent equipment failures before they happen. You can monitor your electric chain hoist and use the information to predict when a part might fail. This proactive approach lets you fix problems early and avoid unplanned outages.

You benefit from predictive maintenance in several ways:

It reduces downtime and maintenance costs.

It improves reliability for critical machinery.

It uses data-driven techniques to foresee equipment failures.

Many companies use advanced analytics to improve their maintenance strategies. This leads to fewer breakdowns and lower costs. For electric chain hoists, predictive maintenance helps you avoid expensive repairs and keeps your operations running smoothly.

Regulatory Requirements

You must follow strict rules when keeping maintenance records for your electric chain hoist. Organizations like OSHA, ASME, and ISO require proper documentation of periodic inspections. These records help you show compliance and identify patterns of wear or recurring issues.

To meet regulatory requirements:

Store dated inspection reports where authorized personnel can access them.

Keep records of examinations for ropes or chains removed from service.

Follow manufacturer and industry guidelines for documentation.

Proper documentation not only supports compliance but also helps you maintain a safe and efficient workplace. By keeping accurate records, you protect your investment and meet legal standards.

Conclusion

You play a vital role in keeping your electric chain hoist reliable and safe. Regular maintenance boosts equipment lifespan and workplace safety.

Professional inspections catch wear early.

Lubrication prevents friction and damage.

Testing electrical systems ensures proper function.

Powerful Machinery’s certified products meet top industry standards:

Certification/Standard | Description |

|---|---|

CE | Meets EU safety standards. |

ISO9001:2000 | Ensures quality management. |

ASME 30.5 | Mobile crane safety. |

ASME 30.4 | Pedestal and portal crane safety. |

ANSI/ASME 30.2 | Overhead and gantry crane safety. |

OSHA 1926.1400 | Construction crane safety. |

Adopt the checklist and build a proactive maintenance culture. Consult Powerful Machinery for expert support and official resources.

FAQ

How often should you inspect your electric chain hoist?

You should inspect your electric chain hoist daily before use. Perform a more detailed inspection every month. Schedule a full service by a professional at least once a year.

What lubricant should you use for the chain?

Use only the lubricant recommended by the manufacturer. This ensures smooth operation and prevents unnecessary wear. Check your Powerful Machinery manual for the correct product.

Can you repair an electric chain hoist yourself?

You can handle basic maintenance, such as cleaning and lubrication. For electrical repairs or major part replacements, always contact a certified technician. This keeps your equipment safe and your warranty valid.

What are common signs of chain wear?

Look for these signs:

Elongated or twisted links

Rust or corrosion

Cracks or sharp edges

Replace the chain immediately if you see any of these issues.

Where can you find official manuals and support?

Visit the Powerful Machinery website for manuals, parts lists, and technical support. You can also contact authorized dealers for expert help and genuine parts.