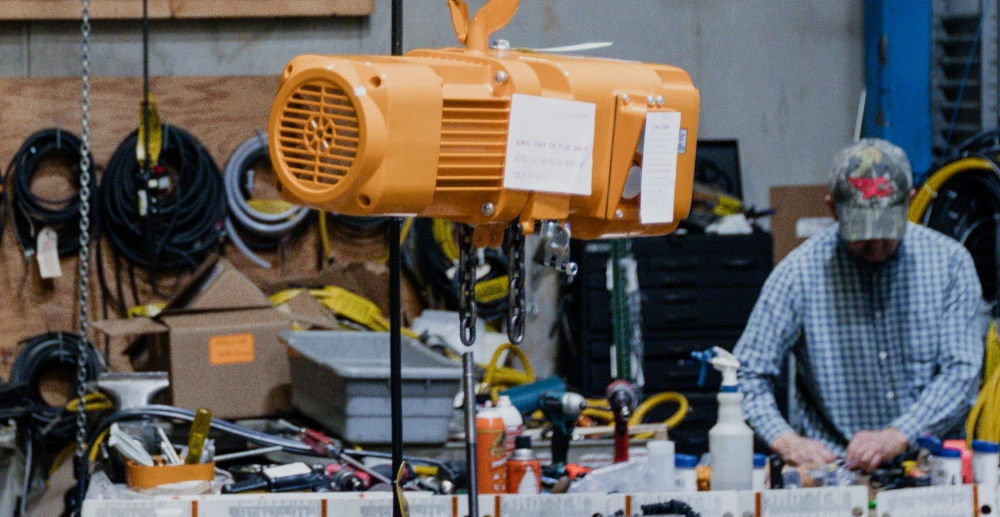

You play a key role in keeping your electric chain hoist working safely and efficiently. Regular electric chain hoist maintenance helps you prevent accidents and avoid equipment failure. Inspections and proper care boost reliability and extend the life of your hoist.

Powerful Machinery delivers trusted products for your lifting needs.

Tip: Stay proactive with maintenance to protect your equipment and keep your workplace safe.

Key Takeaways

Conduct daily inspections to catch wear and damage early. This habit keeps your hoist safe and reliable.

Follow manufacturer guidelines for maintenance. Using approved parts and lubricants extends the life of your hoist.

Keep a detailed maintenance logbook. Documenting inspections and repairs helps track performance and supports warranty claims.

Train operators are regularly trained on safety protocols. Ongoing training ensures everyone understands how to use the hoist safely and effectively.

Replace worn parts immediately to prevent accidents. Quick action protects your team and maintains equipment reliability.

Essential Electric Chain Hoist Maintenance Practices

Importance of Regular Inspections

You need to make regular inspections a core part of your maintenance program. These inspections help you spot problems before they become serious. When you check your electric chain hoist every day, you can find signs of wear, corrosion, or damage early. This habit keeps your equipment safe and reliable.

Industry experts recommend several maintenance practices to keep your hoist in top condition. The table below shows the most effective steps you should include in your routine:

Maintenance Practice | Description |

|---|---|

Daily Inspections | Conduct visual checks for wear, corrosion, and functionality tests before operation. |

Lubrication | Regularly lubricate the chain with the recommended lubricant to reduce friction and prevent rust. |

Periodic Maintenance | Schedule comprehensive inspections to check all components, including electrical and brake systems. |

Load Testing | Perform static and dynamic load tests to verify lifting capacity and ensure safety. |

You should always perform daily inspections before you use your hoist. Look for any signs of chain elongation, unusual noises, or loose connections. If you notice anything unusual, stop using the hoist and report the issue.

Scheduled maintenance and comprehensive inspections help you catch hidden problems that daily checks might miss. These steps protect your investment and support workplace safety.

Tip: Keep a checklist for your daily and periodic inspections. This habit helps you stay organized and ensures you never miss a step.

Following Manufacturer Guidelines

You must follow the manufacturer’s guidelines for electric chain hoist maintenance. These guidelines give you specific instructions for your equipment. When you stick to these rules, you help extend the life of your hoist and keep it running smoothly.

Powerful Machinery provides detailed manuals for every electric chain hoist. These manuals explain how to perform each inspection and what to look for during maintenance. You should use only approved lubricants and replacement parts. This practice ensures the reliability and safety of your hoist.

A strong maintenance program includes regular inspections, scheduled maintenance, and careful record-keeping. You should always monitor your equipment and follow the recommended maintenance practices. This approach helps you avoid unexpected breakdowns and keeps your lifting operations efficient.

Note: If you have questions about your hoist or need help with monitoring and maintenance, contact Powerful Machinery’s support team for expert advice.

Regular Inspections for Electric Chain Hoists

Routine inspections help you keep your electric chain hoist safe and reliable. You need to follow a schedule that includes daily checks, monthly inspections, and annual servicing. Powerful Machinery recommends inspection frequencies that match industry standards.

Frequent inspections before each use and detailed checks at set intervals protect your equipment and your team.

Daily Inspection Checklist

You should start every shift with pre-use checks. These daily checks help you spot problems early and prevent accidents. Safety organizations recommend a simple checklist for daily inspections:

Inspect the hook and latch assembly. Look for bending, twisting, or stretching. Make sure the safety latch works.

Examine the load chain. Check for nicks, gouges, cracks, twists, or kinks. Look for corrosion and confirm proper lubrication.

Test the control systems. Make sure the controls respond quickly and reliably.

Check the brakes. Listen for unusual noises and confirm smooth operation.

Tip: Use a written checklist for daily checks. This habit helps you stay organized and ensures you never miss a step.

Daily checks keep your electric chain hoist in top condition. You improve safety and reduce downtime when you catch issues early.

Monthly and Annual Inspections

Monthly inspections go deeper than daily checks. You need to look at every part of the hoist. Monthly inspections include:

Inspecting the entire chain for wear and elongation.

Checking the motor and electrical connections.

Testing the brake system.

Reviewing the hook and latch for signs of fatigue.

Annual inspections require even more attention. You should schedule a professional inspection and load testing once a year. Certified technicians use specialized tools and follow strict procedures. They check every component, including gears, motors, brakes, and wiring diagrams.

Annual servicing helps you meet safety standards and maintain reliability.

Benefit Type | Description |

|---|---|

Safety | Inspections identify safety hazards and ensure compliance with safety standards. |

Maintenance | Regular checks help in identifying maintenance issues and areas needing service. |

Operational Efficiency | Documentation from inspections aids in developing strategic maintenance plans to prolong hoist life. |

Monthly inspections and annual servicing help you avoid costly repairs and keep your equipment running smoothly.

Professional Servicing by Powerful Machinery

Professional servicing gives you peace of mind. Powerful Machinery offers expert technicians who have hands-on training and deep knowledge of electric chain hoist maintenance. These technicians know how to identify different types of hoists, read wiring diagrams, and troubleshoot electrical systems.

They inspect load chains, maintain brakes, and review industry standards.

Course Topics | Description |

|---|---|

Hoist identification | Understanding different types of hoists |

Basic air and electrical theory | Fundamental concepts necessary for servicing hoists |

Reading a wiring diagram | Skills needed to interpret electrical schematics |

Understanding and troubleshooting the hoist’s electrical system | Techniques for diagnosing electrical issues |

Mechanical brake maintenance | Knowledge required for maintaining brakes |

Load chain inspection | Procedures for inspecting load chains |

Gearing | Understanding gear systems in hoists |

Motor and load brake inspection | Skills for inspecting motors and brakes |

Review of applicable industry standards | Familiarity with industry regulations and standards |

Frequent and periodical maintenance and inspection procedures | Best practices for ongoing maintenance |

Hands-On Training | Description |

|---|---|

Complete disassembly, inspection, and rebuild of over 18 electric, ai,r and manual hoists | Practical experience in servicing various hoist types |

You should always use certified technicians for annual servicing and load testing. Professional inspection ensures your equipment meets safety standards and operates at peak performance.

Note: Schedule professional servicing with Powerful Machinery to keep your electric chain hoist safe, efficient, and reliable.

Load Chain Care and Inspection

Lubrication and Cleaning

You need to keep the load chain clean and well-lubricated to ensure electric chain hoist maintenance delivers the best results. Dirt and old grease can hide signs of wear, making inspection difficult. When you hear a creaking sound as the chain lifts a load, this means the chain needs lubrication.

Use a lubricant like 10R oil from Lubriplate or any oil with an EP additive. This type of oil protects the chain under heavy loads and reduces friction.

Follow these steps for proper lubrication and cleaning:

Remove the chain from the hoist and drop it into a bucket.

Pour the recommended lubricant over the chain, making sure each link is separated.

Hang the chain to let excess oil drip off.

Wipe the chain with a clean cloth to remove extra oil.

Regular cleaning helps you spot signs of wear such as nicks, cracks, or corrosion. Clean chains also improve reliability and reduce the risk of sudden failure.

Wear, Elongation, and Replacement

You must inspect the load chain for signs of wear every time you use your electric chain hoist. Look for elongation, which means the chain has stretched beyond its normal length. This can cause the chain to fail during lifting. Check for cracks, gouges, twists, and corrosion.

If you see any of these signs of wear, replace the chain immediately.

A table can help you track common signs of wear:

Signs of Wear | What to Look For |

|---|---|

Elongation | Stretched links |

Cracks | Visible breaks in metal |

Gouges | Deep scratches or dents |

Twists | Links out of alignment |

Corrosion | Rust or pitting on the surface |

You protect your team and equipment when you replace chains at the first sign of trouble.

Using OEM Chains from Powerful Machinery

You should always use original equipment manufacturer (OEM) chains from Powerful Machinery for your electric chain hoist. These chains meet strict safety standards and resist signs of wear better than generic options. OEM chains ensure reliability and help you avoid unexpected breakdowns.

Powerful Machinery’s certified chains fit your hoist perfectly and support safe lifting operations.

Tip: Using certified chains from Powerful Machinery increases safety and extends the life of your equipment.

Regular inspection, cleaning, and replacement of worn chains keep your electric chain hoist working safely. You maintain reliability and protect your investment with proper maintenance.

Electrical System Checks for Electric Chain Hoists

Motor and Control Testing

You need to test the motor and control systems regularly to keep your electric chain hoist running smoothly. Start by operating the hoist through its full range of motion. Listen for unusual sounds or delays. If the controls do not respond quickly, check the control circuit for damage or loose connections.

Sometimes, control failures happen because of issues in the control circuit or a damaged controller. You can solve these problems by checking the circuit’s integrity and making sure all connections are secure. Reliable controls help you avoid unexpected stops and keep your lifting operations safe.

Wiring and Connection Inspection

Wiring and connection inspection is a key part of electric chain hoist maintenance. Faulty wiring can cause the hoist to stop working or even create safety hazards. During your inspection, look for broken wires, loose connections, or signs of overheating. Use the table below to help identify and solve common wiring issues:

Issue Description | Solution |

|---|---|

The incorrect connection of the electrical line phases is causing operational failure | Swap the power cords of the two phases with each other. |

Broken or improperly connected power cord or control circuit wire | Repair or replace the broken or poorly contacted wire. |

Power supply voltage is too low | Measure if the voltage is lower than 10% of the standard supply. |

Bad contactor causing operational issues | Check for poor contact in the control coil or wire; replace if needed |

Short circuit in the contactor coil | Replace the contactor. |

If you find a short-circuited contactor coil, replace it right away to restore proper function. Careful attention to wiring and connections increases reliability and helps you follow safety guidelines.

Immediate Replacement of Faulty Parts

You must replace any faulty electrical parts as soon as you find them. Do not use the hoist if you see signs of wear, damage, or malfunction. Using a damaged hoist can lead to equipment failure or injury. If you notice significant wear or damage on any part of the chain or hook, replace it immediately.

Quick action keeps your equipment safe and supports long-term reliability. Following these guidelines protects your team and ensures your electric chain hoist works when you need it most.

Tip: Always keep spare parts on hand so you can make repairs quickly and avoid downtime.

Hook, Latch, and Limit Switch Inspection

Hook and Latch Safety

You need to inspect the hook and latch on your electric chain hoist before every use. These parts carry the load and keep it secure. If you miss a problem, you risk dropping the load or causing an accident. Always check for deformation, wear, corrosion, and damage.

Look for cracks, bends, or twists in the hook. If you see more than 10% wear or corrosion, remove the hook from service. Run your finger along the hook. If you feel a gouge deep enough to fit your fingernail, replace the hook right away.

Safety devices like latches must work smoothly. The latch should close fully and bridge the hook’s throat. If the latch sticks or fails to close, fix it before using the hoist. Reliable safety devices help prevent dropped loads and protect your team.

Inspection Criteria | Description |

|---|---|

Deformation | Visible bending, twisting, or cracking indicates potential overload or misuse. |

Wear and Corrosion | More than 10% wear or corrosion compromises safety; hooks must be removed from service. |

Nicks and Gouges | Any damage deep enough to fit a fingernail requires immediate removal from service. |

Latches and Safety Devices | Must operate properly and securely bridge the hook’s throat when closed; malfunctions need urgent attention. |

Tip: Always test safety devices before lifting. A working latch keeps the load secure.

Limit Switch Functionality

Limit switches act as safety devices that stop the chain from moving too far up or down. You need to test these switches before lifting any load. Start with an operational test. Run the hoist through its full range of motion without a load. Listen for odd noises.

Check that the upper and lower limit switches stop the chain at the right points. If the chain moves past the limit, fix the switch before using the hoist.

Step | Description |

|---|---|

1 | Perform an operational test before using the hoist to lift any load. |

2 | Run the hoist through its full range of motions, including lifting and lowering without a load. |

3 | Listen for any unusual noises that could indicate internal problems. |

4 | Test the upper and lower limit switches to confirm they prevent the chain from over-traveling. |

Limit switches and other safety devices protect your equipment and your team. Regular testing helps you catch problems early and avoid accidents.

Note: If you find a faulty limit switch, replace it immediately. Never operate the hoist with broken safety devices.

Braking System Maintenance

Brake Testing Procedures

You must keep the braking system of your electric chain hoist in top condition. The brakes help you control heavy loads and prevent accidents. Safety standards recommend that you test the brakes regularly. You should follow these steps to check brake performance:

Check the brakes for signs of wear. Look for thinning pads or uneven surfaces.

Make sure the brakes engage as soon as you release the control button. The hoist should stop quickly and smoothly.

Address any braking issues right away. If you notice slipping or delayed stopping, stop using the hoist until you fix the problem.

Tip: Always test the brakes before each shift. Reliable brakes protect you and your team from dropped loads.

A simple table can help you track your brake tests:

Test Step | What to Look For |

|---|---|

Visual inspection | Pad thickness, surface condition |

Engagement test | Immediate stopping |

Response to issues | Quick repairs or adjustments |

Adjustment and Replacement

You need to inspect and adjust the brakes often. Monthly checks help you spot problems early. Look for these signs that show the brakes need adjustment or replacement:

Inspect brake pad wear. If the pads are less than one-third of their original thickness, replace them.

Watch for abnormal braking, such as burning smells or strange noises.

Check the brake drum or disc for cracks, deformation, or heavy wear.

Test the brake’s response time and force. Slow or weak braking means you need to adjust or replace parts.

If you find any of these issues, replace the worn components with certified parts from Powerful Machinery. Using high-quality replacements keeps your hoist safe and reliable.

Note: Document every brake inspection and replacement. Good records help you track performance and support warranty claims.

Documentation and Record Keeping

Maintenance Logbook Best Practices

You need to keep a maintenance logbook for your electric chain hoist. This record helps you track every inspection, repair, and replacement. A good logbook improves safety and supports efficient maintenance. You can use a notebook, spreadsheet, or digital app. Choose a format that works best for your team.

Tip: Write down every maintenance activity right after you finish it. This habit helps you avoid missing important details.

A clear logbook should include these items:

Date of inspection or service

Name of the person who performed the task

Type of maintenance (inspection, lubrication, repair, replacement)

Parts checked or replaced

Notes about findings or issues

Next scheduled maintenance

Here is a sample logbook table:

Date | Technician | Task | Parts Checked/Replaced | Notes | Next Service |

|---|---|---|---|---|---|

2024-06-01 | Alex Chen | Inspection | Chain, Hook | No issues found | 2024-07-01 |

2024-06-15 | Jamie Lee | Lubrication | Chain | Lubricated links | 2024-07-15 |

2024-06-20 | Alex Chen | Replacement | Hook | Replaced worn hook | 2024-07-20 |

A well-kept logbook helps you spot patterns and plan future maintenance.

Tracking and Warranty Support

You need to track all maintenance and repairs for warranty support. Powerful Machinery offers warranties on electric chain hoists. If you keep detailed records, you can prove that you followed recommended maintenance steps. This proof helps you get warranty service quickly.

Note: Always keep receipts and service reports with your logbook. These documents help you when you need warranty support.

Tracking maintenance also helps you:

Identify recurring problems

Schedule preventive maintenance

Meet safety standards

Increase equipment lifespan

You protect your investment when you keep good records. You also make it easier to work with Powerful Machinery’s support team if you need help.

Operator Training and Safety Protocols

Training Requirements for Powerful Machinery Hoists

You need proper operator training before you use any Powerful Machinery electric chain hoist. Training helps you understand how the equipment works and how to spot hazards. You learn to recognize signs of wear and know the limits of your hoist. Ongoing training keeps you updated on new standards and workplace safety practices.

Refresher courses help you remember important safety protocols and equipment use. Hands-on training with new hoists gives you practical experience and builds your confidence.

You must complete training in hoist operation.

You should learn to identify hazards and equipment limits.

You need ongoing training to stay current with workplace safety standards.

Refresher courses help you keep up with safety protocols and guidelines.

Hands-on training with new equipment is essential.

Tip: Regular training and evaluation help you avoid mistakes and keep your workplace safe.

Safe Operation Guidelines

You must follow clear guidelines to keep your electric chain hoist safe and reliable. Proper load handling is important. Always balance loads and attach them securely to prevent swinging or overloading. Lift loads vertically to avoid side pulling, which can damage the hoist and create hazards.

Use limit switches as a backup, not for routine stopping. Communicate with your team using signals or radios to maintain workplace safety during operations.

A simple table can help you remember key safety protocols:

Safety Protocol | What You Should Do |

|---|---|

Load Handling | Balance and secure loads |

Vertical Lifting | Avoid side pulling |

Limit Switch Use | Use as a backup, not for routine stopping |

Communication | Use clear signals or radios |

You should also check the chain, hook, brakes, and electrical systems often. Lubricate the chain to reduce wear. Inspect for damage before each use. Test the brakes for proper engagement. Look for frayed wires and loose connections.

Continuous training and regular drills help you respond quickly to emergencies and keep workplace safety a top priority.

Note: Following these guidelines protects you, your team, and your equipment every day.

Troubleshooting Common Electric Chain Hoist Issues

Electric chain hoists can face problems that affect safety and performance. You need to know how to spot these issues and fix them quickly. This section helps you identify common problems and gives you practical steps to solve them.

Power and Electrical Problems

Power and electrical issues can stop your hoist from working. You might notice the hoist does not respond or the motor overheats. Sometimes, you hear strange noises or the chain slips. Use the table below to help with troubleshooting:

Problem | Symptoms | Troubleshooting Steps |

|---|---|---|

Hoist Does Not Operate | The hoist doesn’t respond to control commands. | Check the power source, inspect the control pendant, and verify the emergency stop button. |

Hoist Motor Overheats | The motor feels hot or shuts off during use. | Allow cooling, ensure no overload, check ventilation. |

Unusual Noises | Grinding or squeaking sounds during operation. | Lubricate the chain, inspect for wear, and check gearbox oil level. |

Chain Jamming or Slipping | The chain does not move smoothly or slips under load. | Inspect the load chain, adjust brake settings, and ensure correct seating in the sprocket. |

Load Drift or Creep | The load moves slightly when the hoist is stopped. | Check the braking system, lubricate the load chain, and verify no overload. |

Control Issues | Hoist does not respond accurately to inputs. | Examine the control mechanism, check wiring, and consult the manufacturer’s manual for calibration. |

Tip: Always start with a visual inspection before you troubleshoot electrical problems.

Chain and Lubrication Issues

Chain and lubrication problems can cause noise or make the hoist work poorly. You need to check the chain and keep it clean and lubricated. Here are steps you can follow:

Lubricate the chain as recommended by the manufacturer.

Inspect the chain and sprockets for signs of wear.

Check the gearbox oil level.

Look for damage if the chain jams or slips.

Adjust brake settings and make sure the chain sits correctly in the sprocket.

If the load drifts or creeps, check the braking system and confirm proper lubrication.

Regular inspections help you catch these problems early and keep your hoist running smoothly.

Limit Switch and Brake Malfunctions

Limit switches and brakes protect your equipment and team. You need to test and calibrate limit switches often to prevent over-traveling. If you find a problem, follow the manufacturer’s instructions to set the switches. Use lockout/tagout procedures during adjustments for safety.

Test limit switches regularly.

Calibrate switches to make sure they stop the chain at the right points.

Inspect the brake mechanism, especially if loads stay suspended for long periods.

Replace worn brake parts to prevent failure.

Note: Frequent inspections of limit switches and brakes help you avoid accidents and keep your hoist reliable.

Cleanliness and Environmental Care

Cleaning After Use

You need to clean your electric chain hoist after every use. Dust, grease, and debris can build up on the chain and housing. These materials can hide signs of wear and cause damage over time.

Start by wiping down the exterior with a clean, dry cloth. Remove any dirt or oil from the load chain and hooks. Use a soft brush to clean hard-to-reach areas. If you notice stubborn grime, use a mild detergent and water, but make sure all parts are dry before storing the hoist.

Regular cleaning helps you spot problems early. You can see cracks, corrosion, or other damage that might need attention. Clean equipment also works better and lasts longer. Make cleaning part of your daily routine to keep your hoist in top condition.

Tip: Always inspect the chain and hooks during cleaning. Early detection of wear prevents accidents.

Storage and Corrosion Prevention

Proper storage protects your electric chain hoist from environmental damage and corrosion. You should always store the hoist in a clean, dry place. Moisture can cause rust and weaken electrical components.

Avoid damp conditions. Choose a storage area that is cool, dry, and well-ventilated. This prevents humidity from building up and damaging your equipment.

Extreme temperatures can harm electrical parts. Keep your hoist in a temperature-controlled environment, ideally between 50–86°F (10–30°C). If you work in harsh environments, increase the frequency of maintenance checks. This helps you catch problems before they become serious.

Here are the best practices for storing your electric chain hoist:

Store in a clean, dry environment.

Avoid damp conditions.

Ensure good ventilation in the storage area.

Keep the temperature between 50–86°F (10–30°C).

Increase maintenance checks in harsh environments.

Storage Tip | Why It Matters |

|---|---|

Dry environment | Prevents rust and corrosion |

Good ventilation | Reduces humidity buildup |

Temperature control | Protects electrical components |

Frequent checks | Catches early signs of damage |

Note: Proper storage and regular cleaning extend the life of your electric chain hoist and keep it safe for every lift.

Energy Efficiency and Busbar Systems

Benefits for Electric Chain Hoist Operations

You can boost the efficiency of your electric chain hoist by using busbar systems. These systems supply power along the crane’s track or bridge. Busbars use steel or copper conductor bars. A collector arm transfers current to moving parts, such as motors and hoists.

This setup gives you reliable power distribution for all components.

Busbar systems offer several advantages for your operations:

Reliable power supply to motors, hoists, and winches.

Easy maintenance and quick repairs.

Adaptability to harsh environments.

Use in industrial, manufacturing, and construction settings.

You get improved energy efficiency because busbars reduce power loss and keep your equipment running smoothly. You also lower the risk of downtime since repairs are simple and fast. Busbar systems work well in tough conditions, so you can trust them in demanding workplaces.

Tip: Choose busbar systems if you want consistent power and less maintenance for your electric chain hoist.

Implementation and Maintenance

You need to install busbar systems correctly to get the best results. Start by selecting the right type of conductor bar for your workspace. Make sure the collector arm fits your hoist and moves freely along the track. You should check all connections before turning on the power.

Regular maintenance keeps your busbar system working at its best. Inspect the conductor bars for wear or corrosion. Clean the collector arm to prevent dust buildup. Replace damaged parts right away to avoid power interruptions.

Here is a simple table to help you remember key maintenance steps:

Maintenance Task | What You Should Do |

|---|---|

Inspect conductor bars | Check for wear and corrosion |

Clean the collector arm | Remove dust and debris |

Check connections | Ensure tight and secure fittings |

Replace damaged parts | Swap out worn or broken pieces |

You keep your electric chain hoist safe and efficient when you follow these steps. Good maintenance supports long-term reliability and helps you avoid costly repairs.

Note: Regular checks and cleaning help your busbar system deliver steady power and support safe lifting operations.

Conclsuion

You keep your workplace safe and your equipment reliable when you follow electric chain hoist maintenance best practices. Regular inspections, proper care, and using manufacturer guidelines help you avoid problems. Choose Powerful Machinery’s certified products and services for the best results.

Keep a detailed logbook.

Train operators often.

Replace worn parts quickly.

Stay proactive with your electric chain hoist to ensure long-term performance.

FAQ

How often should you inspect your electric chain hoist?

You should inspect your electric chain hoist before each use. Complete a deeper inspection every month. Schedule a professional inspection and load test once a year for maximum safety.

What lubricant works best for electric chain hoist chains?

Use a high-quality oil with EP additives, such as 10R oil from Lubriplate. This oil protects the chain under heavy loads and reduces friction.

Can you use non-OEM chains with Powerful Machinery hoists?

You should always use OEM chains from Powerful Machinery. Certified chains fit your hoist perfectly and meet strict safety standards.

What should you do if your hoist stops working suddenly?

Check the power supply.

Inspect the control pendant.

Look for loose wires.

Contact a certified technician if you cannot find the problem.