When you compare fiber core vs steel core wire rope, you see clear differences that impact your project’s safety and efficiency. Your choice affects flexibility, temperature resistance, load capacity, and cost.

Powerful Machinery provides certified wire rope solutions trusted by professionals worldwide. The table below highlights the main differences between these two core types:

Aspect | Fiber Core Wire Rope | Steel Core Wire Rope |

|---|---|---|

Flexibility | Excellent, easy to bend | Poor, requires a larger bending radius |

High-Temperature Resistance | Poor (fibres prone to carbonization) | Excellent (steel wires withstand heat) |

Load Capacity | Lower, for light-to-medium loads | Higher, ideal for heavy lifting |

Crush Resistance | Poor, prone to deformation | Excellent, resists extrusion and impact |

Self-Weight | Light | Heavy |

Key Takeaways

Choose fiber core wire ropes for flexibility and shock absorption in light-to-medium load applications.

Select steel core wire ropes for maximum strength and durability in heavy lifting and high-tension tasks.

Consider environmental factors like temperature and moisture when selecting the core type for your wire rope.

Regular maintenance, including lubrication and inspections, significantly extends the lifespan of wire ropes.

Evaluate both initial costs and long-term maintenance needs to make the most cost-effective choice for your projects.

Wire Rope Construction Overview

Core Types and Functions

You encounter two main core types in wire rope construction: fiber core and steel core. Each core type plays a vital role in how the rope performs under load and in different environments.

Fiber cores use natural or synthetic fibers. These provide extra flexibility and absorb shock well. Steel cores use strands of steel wire. These offer higher strength and resist crushing forces.

The table below shows how core types affect durability and safety:

Feature | Fiber Core | Steel Core |

|---|---|---|

Load Capacity | Lower | Higher |

Fatigue Resistance | High | Moderate |

Tip: Choose a core type that matches your application’s load and fatigue requirements. This decision impacts the safety and lifespan of your wire ropes.

Common Structures and Materials

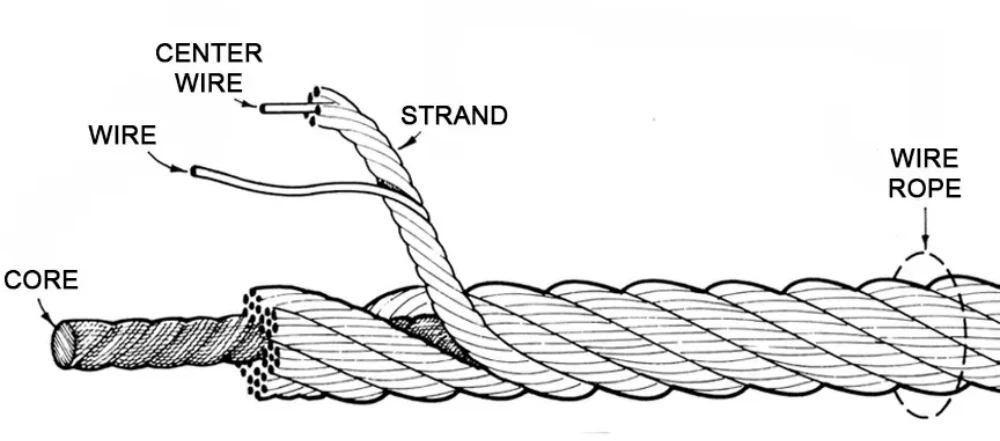

Wire ropes consist of several key components. Each part influences the rope’s flexibility, strength, and durability. You should understand these elements before selecting a rope for your project.

Wires: These form the basic building blocks. Thinner wires increase flexibility. Thicker wires boost strength.

Strands: Multiple wires twist together to create strands. The number and arrangement of wires in each strand affect the rope’s balance between strength and flexibility. For example, a 6×19 construction balances both, while a 6×37 structure offers more flexibility.

Core: The core supports the strands and maintains the rope’s shape under load. Fiber cores provide flexibility. Steel cores deliver strength and resist deformation.

You also find lubrication in many wire ropes. Lubrication reduces friction and protects against corrosion, which extends the rope’s service life.

Understanding these components helps you select the right wire rope construction for your specific needs.

Fiber Core Wire Rope

Materials and Features

You often see fiber core wire rope made with either natural or synthetic fibers. These materials give the rope its signature flexibility and shock absorption. Natural fibers, such as sisal or jute, offer a high strength-to-weight ratio and excellent fatigue life.

Synthetic fibers, like polypropylene, provide similar flexibility but may have lower crush resistance. Fiber core wire ropes remain popular because they bend easily and handle repeated movement well.

Here is a quick overview of the materials and their mechanical properties:

Material Type | Mechanical Properties |

|---|---|

Natural Fibers | High flexibility, high strength-to-weight ratio, superior breaking load, good fatigue life |

Synthetic Fibers | Similar properties to natural fibers, but with lower crush resistance and lower strength than steel in some applications |

General Properties | Susceptible to crushing, unsuitable for high-heat or open flame environments |

You should avoid using fiber core wire ropes in high-temperature settings. The fibers can break down or carbonize when exposed to heat or open flames. Fiber core also tends to deform under heavy pressure, so it works best in applications where crushing is not a concern.

Performance and Applications

Fiber core wire rope delivers reliable performance in many industries. You benefit from its flexibility and ability to absorb shock, which makes it ideal for jobs that require frequent bending or movement. Fiber core wire ropes excel in light-to-medium load tasks and environments where you need easy handling.

You will find fiber core wire ropes used in the following areas:

Cranes and hoists for lifting operations that demand flexibility

Construction and infrastructure projects, such as suspending bridges or supporting machinery

Marine and shipping for mooring, towing, and rigging in wet or harsh weather

Mining and drilling for underground lifting and supporting drilling rigs

Elevators and lifts where controlled movement and strength matter

Logging and forestry for pulling logs and securing heavy loads

Fiber core wire ropes offer smooth operation and reduce wear on pulleys and sheaves. You should choose a fiber core when your project values flexibility and fatigue resistance over maximum strength or crush resistance.

Steel Core Wire Ropes

Structure and Benefits

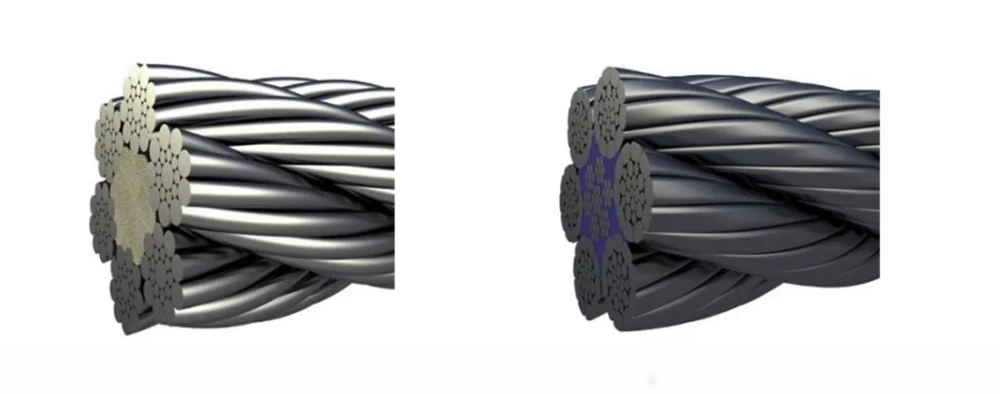

You rely on steel core wire ropes when you need maximum strength and rigidity. The steel core sits at the center, made from steel wires or strands. This structure gives the rope exceptional load-bearing capacity and resistance to crushing. The table below shows how steel core wire ropes differ from fiber core options:

Type | Core Material | Characteristics |

|---|---|---|

Fiber Core | Natural or synthetic fibres | Soft, can store oil for lubrication of steel wires |

Steel Core | Steel wires or strands | High strength and rigidity |

Steel core wire ropes deliver several key benefits in heavy-duty applications:

Exceptional strength and load-bearing capacity

Resistance to wear and environmental damage

Safety and reliability

Longevity and cost-effectiveness

Versatility in wire rope applications

You choose steel core wire rope for demanding tasks where safety and durability matter most.

Product Features and Configurations

Powerful Machinery’s steel wire rope core products set the standard for quality and performance. You get certified wire ropes engineered for stability and safety. The non-rotating design prevents twisting and kinking, which protects your equipment and crew.

You can select from multiple configurations, such as 35W×7, 18×19, and 8×55SWS, each tailored for specific wire rope applications and load requirements. The steel core resists abrasion and corrosion, making it ideal for harsh environments.

You benefit from high tensile strength and extended service life, which reduces downtime and maintenance costs.

Tip: Choose a steel core wire rope when you need reliable performance in heavy-duty applications or when working in harsh environments.

Industrial Applications

You see steel core wire ropes used across many industries because of their strength and reliability. Common applications include:

Construction: Lifts, window cleaning equipment, and securing shafts

Lifting: Cranes and hoists for moving heavy loads

Mining: Extracting minerals and supporting mining operations

Manufacturing: Assembly lines and moving goods efficiently

Transportation: Automotive, aerospace, and rail industries for mechanical functions

You depend on steel wire rope core products for projects that demand safety, longevity, and consistent performance. Powerful Machinery’s certified wire ropes meet international standards, making them a trusted choice for critical wire rope applications.

Fiber Core vs Steel Core Wire Rope: Direct Comparison

Strength and Load Capacity

When you compare fiber core vs steel core wire rope, you see clear performance differences in strength and load-bearing capacity. Steel core wire ropes, often called IWRC (Independent Wire Rope Core), deliver higher tensile strength and better load capacity.

You rely on these ropes for demanding applications, such as crane wire ropes, where heavy lifting is routine. Fiber core ropes, on the other hand, suit lighter applications and offer enough strength for typical application scenarios that do not require maximum capacity.

Wire Rope Type | Tensile Strength | Load Capacity |

|---|---|---|

IWRC | Higher | Better |

FC | Less | Suitable for lighter applications |

You should select steel core wire ropes when your application demands superior load-bearing capacity and safety. Fiber core ropes work well in less intense applications, where flexibility and fatigue resistance matter more than raw strength.

Flexibility and Handling

You notice significant differences in flexibility and handling when you evaluate fiber core vs steel core wire rope. Fiber core ropes are more flexible and easier to handle, making them ideal for applications that require frequent bending or movement.

You benefit from their ability to cushion bends and reduce internal friction, which enhances flexibility and extends service life.

Fiber core ropes are more flexible and easier to handle, making them ideal for applications requiring frequent bending.

Fiber core ropes cushion bends and reduce internal friction, enhancing flexibility.

Steel core ropes provide higher strength and durability but are less flexible and harder to handle.

Steel core ropes add strength but reduce flexibility and increase the minimum bend radius.

You should choose fiber core ropes for applications where you need smooth operation and easy handling, such as crane wire ropes in construction or marine environments. Steel core ropes suit applications where strength is the priority, even if handling becomes more challenging.

Tip: For applications with tight bends or frequent movement, fiber core ropes offer superior flexibility and handling.

Crush and Temperature Resistance

You encounter notable performance differences in crush and temperature resistance when comparing fiber core vs steel core wire rope. Steel core ropes and compacted strand ropes demonstrate better resistance to crushing and deformation.

You rely on steel core wire ropes in application scenarios where ropes face heavy pressure or impact, such as mining or industrial lifting.

Steel core ropes and compacted strand ropes have better resistance to crushing and deformation.

Steel core wire ropes have superior high-temperature resistance compared to fiber core ropes.

Steel wire ropes can endure temperatures up to 200°C.

Fiber core steel wire ropes should be limited to temperatures below 100°C.

High temperatures can cause the fiber core and plastic coating of steel wire ropes to soften, leading to structural damage. The loss of lubricating oil due to heat accelerates wear on wire ropes.

You should select steel core ropes for applications exposed to high temperatures or crushing forces, such as heavy-duty lifting or manufacturing.

Note: Always consider the temperature and pressure conditions of your application before choosing between fiber core vs steel core wire rope.

Weight and Cost

You see differences in weight and cost when you compare fiber core vs steel core wire rope for similar specifications. Steel core ropes are heavier, which can affect handling and installation in certain applications. Fiber core ropes are lighter, making them easier to transport and install in typical application scenarios.

Type | Initial Cost | Maintenance Needs | Total Cost of Ownership |

|---|---|---|---|

Steel Core | Lower | Higher due to checks and oiling | Higher over time |

Fiber Core | Higher | Lower, less frequent maintenance | Lower over time |

You should consider both the initial cost and long-term maintenance when selecting wire ropes for your application. Steel core ropes may have a lower upfront cost, but they require more frequent checks and oiling, which increases the total cost of ownership.

Fiber core ropes, while higher in initial cost, need less maintenance and offer lower total costs over time.

Tip: Evaluate your budget and maintenance resources before choosing between fiber core vs steel core wire rope for your applications.

Advantages and Disadvantages

Fiber Core Pros and Cons

You often choose fiber core wire ropes when flexibility matters most. These ropes bend easily and absorb shock, which helps in applications that require frequent movement. You benefit from their high strength-to-weight ratio and superior breaking load.

Fiber core wire ropes also offer good fatigue life, so you see longer service intervals in many projects.

Here is a table that summarizes the main advantages and disadvantages:

Advantages of Fiber Core Wire Ropes | Disadvantages of Fiber Core Wire Ropes |

|---|---|

High flexibility | Lower crush resistance |

High strength-to-weight ratio | Lower strength than steel in some applications |

Superior breaking load | Cannot be used in high-heat environments |

Good fatigue life | N/A |

Note: You should avoid fiber core wire ropes in high-temperature or high-pressure environments. The fibers can break down or deform, which reduces safety and performance.

Steel Core Pros and Cons

You rely on steel core wire ropes for heavy-duty tasks. These ropes provide excellent strength and resist crushing forces, making them ideal for demanding industrial settings.

Steel core wire ropes maintain their shape under load and offer low stretch, which helps you achieve precise positioning. You also see lower initial costs, but you need to plan for regular maintenance to prevent rust and wear.

The table below highlights the main pros and cons:

Aspect | Steel Core Wire Ropes | Synthetic Ropes |

|---|---|---|

Weight | Heavier, increasing handling effort, and costs | Lighter, reducing handling and transportation costs |

Corrosion | Susceptible to rust and requires protective measures | Resistant to rust, but UV exposure can degrade |

Stretch | Low elasticity, good for precise positioning | High elasticity, absorbs shock, but can sag |

Cost | Lower initial cost, but higher maintenance over time | Higher upfront cost, but lower total ownership cost |

Tip: You should select steel core wire ropes for applications that demand maximum strength and crush resistance. Regular inspection and lubrication help you extend their lifespan and maintain safety.

How to Choose the Core?

Selecting the correct wire rope for your project starts with understanding your operational needs and the environment in which you work. You must evaluate several criteria to ensure safety, efficiency, and long-term value.

Powerful Machinery offers custom-engineered solutions and expert consultation to help you make the right choice for your application.

Load and Application Needs

You should begin by assessing the load requirements and the nature of your application. The core type directly impacts the wire rope’s strength, durability, and flexibility. Consider these factors:

Fiber core ropes provide more flexibility, making them suitable for applications where frequent bending or shock absorption is necessary.

Steel core ropes offer greater strength and are ideal for heavy lifting, high-tension tasks, and situations where maximum load capacity is required.

The choice of core affects the overall performance and safety of the wire rope sling.

Tip: For demanding lifting operations or environments with high mechanical stress, select steel core wire ropes. For lighter loads or applications needing frequent movement, fiber core ropes deliver the flexibility you need.

Environmental Factors

Environmental resistance plays a crucial role in selecting the correct wire rope. You must consider exposure to moisture, saltwater, chemicals, and extreme temperatures. These factors can accelerate wear and corrosion, reducing the lifespan and reliability of your wire rope.

Saltwater and corrosive chemicals increase the risk of metal degradation and failure.

Environmental exposure can decrease wire rope durability by up to 30%, especially if the rope lacks protective coatings or proper lubrication.

Protective coatings and high-performance alloys can extend lifespan by up to 40%, which is vital for safety in harsh conditions.

In marine, wastewater, or chemical processing applications, galvanized or stainless steel ropes are recommended for superior environmental resistance.

Note: Powerful Machinery provides wire ropes with advanced coatings and materials designed for challenging environments. You can consult their experts to select the best option for your specific conditions.

Flexibility and Equipment Compatibility

You must match the wire rope’s flexibility to your equipment and operational requirements. The core type influences how easily the rope bends and how well it fits with pulleys, sheaves, and other hardware.

Fiber core (FC) ropes offer high flexibility but lower strength, making them ideal for applications with tight bends or frequent movement.

Independent Wire Rope Core (IWRC) ropes provide maximum strength and durability, suitable for heavy-duty equipment and high-load scenarios.

Wire Strand Core (WSC) ropes are commonly used in smaller diameter ropes for specialized tasks.

Synthetic cores offer moderate flexibility and are best for lightweight, specialized applications.

Core Type | Flexibility | Strength |

|---|---|---|

Steel core (IWRC) | Low | Maximum strength |

Fiber core (FC) | High | Lower strength |

Synthetic core | Moderate | Varies based on design |

Tip: Always check your equipment specifications and operational needs before selecting the correct wire rope. Powerful Machinery’s team can help you evaluate compatibility and recommend the optimal configuration.

Cost and Maintenance

You must balance initial investment with long-term maintenance and operational costs. The core type influences both the upfront price and the frequency of inspections, lubrication, and replacements.

Steel core ropes may have a lower initial cost but require regular maintenance to prevent corrosion and ensure safety.

Fiber core ropes often cost more initially but need less frequent maintenance, which can lower total ownership costs over time.

Consider your budget, maintenance resources, and the expected lifespan of the wire rope in your application.

Tip: Powerful Machinery offers consultation services to help you analyze cost and maintenance factors, ensuring you select the most cost-effective and reliable solution for your needs.

If you want expert guidance on how to choose the core for your wire rope, Powerful Machinery’s specialists are ready to assist. Their custom solutions and certified products guarantee safety, performance, and value in every application.

Maintenance Tips for Wire Ropes

Lubrication and Lifespan

You extend the lifespan of wire ropes by following a consistent maintenance routine. Lubrication plays a critical role in reducing friction and preventing rust. When you lubricate wire ropes properly, you see dramatic improvements in service life.

For example, at a South African mine, the replacement rate for four 44-mm ropes increased from 18.5 months to 43 months with regular lubrication. Another study showed that the life cycle of four 43-mm x 2073-meter ropes rose from 8 months to 12 months.

Overhead crane operators also doubled the average life of their ropes by using lubricants that displace water and contaminants.

You should combine lubrication with other maintenance practices to maximize safety and durability. The table below outlines recommended steps:

Maintenance Practice | Description |

|---|---|

Lubrication | Regularly lubricate wire ropes to reduce friction and prevent rust. |

Load Rotation | Rotate equipment to distribute wear evenly and extend lifespan. |

Protective Measures | Use padding or edge protectors to minimize damage when lifting sharp materials. |

Cleaning | Remove contaminants after each use to prevent material degradation. |

Scheduled Servicing | Follow manufacturer guidelines for periodic servicing and replacement of components. |

Comprehensive Inspection | Conduct thorough inspections to identify potential hazards before use. |

Tip: You increase safety and reduce costs when you schedule inspections and keep wire ropes clean and lubricated.

Modern Enhancements

You benefit from new technologies and materials that improve wire rope durability and safety. Manufacturers now use synthetic fiber cores, such as high-density polyethylene, to boost strength-to-weight ratios and compression resistance. Zinc-aluminum alloy coatings offer better protection against rust than older methods.

Some wire ropes feature embedded sensors for real-time condition monitoring, which helps you spot problems early and avoid unexpected failures.

The table below highlights recent advancements:

Enhancement Type | Description |

|---|---|

Synthetic Fiber Cores | Use of high-density polyethylene (HDPE) for better strength-to-weight ratios and compression resistance. |

Corrosion Resistance | New zinc-aluminum alloy coatings provide superior protection against rust compared to traditional methods. |

Smart Monitoring | Embedded sensors for real-time condition monitoring, enhancing safety, and extending operational life. |

Advanced Manufacturing Processes | Precision-controlled stranding for consistent tension and reduced internal stresses. |

High-Performance Alloys | Specialized alloys for optimal strength, flexibility, and wear resistance in high-stress applications. |

Sustainability Initiatives | Incorporation of recycled materials and biodegradable lubricants to minimize environmental impact. |

Note: You improve reliability and reduce downtime when you choose wire ropes with modern enhancements and follow best maintenance practices.

Industry Trends and Certifications

Manufacturing Practices

You see rapid advancements in wire rope manufacturing as the industry responds to higher safety and performance demands. Modern factories use strict inspection protocols at every stage of production. This ensures that each wire rope meets the highest standards for strength, flexibility, and durability.

Inspection Stage | Inspection Items | Testing Standards / Purpose | Result & Qualification |

|---|---|---|---|

Raw Material Inspection | Chemical composition, Mechanical properties, Surface quality | Ensure steel wire rods meet composition, tensile strength, and cleanliness standards before production | Only qualified wire rods are approved for drawing and processing |

Wire Inspection (Semi-finished & Finished) | Breaking load test, 360° torsion test, 180° bending test, Zinc coating weight & adhesion test | Verify wire strength, flexibility, and coating durability | All wires must pass 100% inspection to ensure uniform mechanical performance |

Final Rope Inspection | Breaking load test, Tensile strength test, Structural integrity check | Confirm final rope performance under working load and compliance with technical standards | Only ropes meeting all required specifications are released for shipment |

You benefit from these rigorous controls. Manufacturers use non-destructive testing, such as magnetic flux leakage, to detect hidden flaws. This technology helps you trust the rope’s integrity before it reaches your site.

Quality assurance in wire rope manufacturing involves comprehensive material testing, strict production controls, and thorough performance verification. These steps guarantee that you receive products that meet demanding industrial requirements.

Industry trends also shape your choices. You notice a growing demand for fiber core wire ropes in vertical infrastructure and green building projects. Regulatory changes, such as elevator modernization mandates in Europe, push building owners to select safer and more sustainable options.

Many companies now prefer fiber core ropes for their lighter weight and energy efficiency. The integration of AI-driven maintenance and IoT-enabled tension monitoring is also driving the adoption of advanced wire rope solutions.

International Standards

You rely on international standards to ensure the safety and reliability of your wire ropes. These standards guide manufacturers in every step, from material selection to final inspection. They also help you compare products from different suppliers with confidence.

Standard Name | Description |

|---|---|

ISO 2408:2017 | Specifies requirements for the manufacture, testing, acceptance, packing, marking, and issuing of a certificate of quality of wire ropes. |

ASTM A1023/A1023M-21 | Standard Specification for Carbon Steel Wire Ropes for General Purposes. |

AS9100 Rev. D | Quality management system standard for the aerospace industry. |

IMO Rules | Requirements for the manufacture, testing, and certification of steel wire ropes for marine purposes. |

Certifications play a key role in global markets. You often look for these marks to ensure compliance and quality:

Certification | Description | Market Relevance |

|---|---|---|

CE | Indicates compliance with EU health and safety requirements. | Essential for selling in the European market. |

ISO 9001 | Quality management system standard ensuring systematic quality control. | Demonstrates quality assurance globally. |

ASME | Standards for safety requirements in overhead and gantry cranes. | Crucial for targeting the North American market. |

UL | Focuses on electrical safety standards for components. | Highly regarded in the US and Canada. |

Tip: Always check for these certifications when selecting wire ropes. They help you meet regulatory requirements and ensure the safety of your operations.

You see that industry trends and strict certifications work together to deliver safer, more reliable wire rope solutions for your projects.

Conclusion

You must select the right wire rope core to ensure safety and efficiency in your operations. Consider these key points:

Exceed minimum breaking strength by 20% for dynamic loads.

Match core material to environmental extremes like heat or moisture.

Consult regulatory guidelines for core type requirements.

Choosing the correct core prevents equipment failure and reduces downtime.

Steel cores deliver strength for heavy loads, while fiber cores offer flexibility.

Service Type | Description |

|---|---|

Custom Tooling Development | Work with expert engineers for tailored wire rope solutions. |

Free Consultation | Receive guidance to match products to your project’s specifications. |

Powerful Machinery stands ready to support your next project with certified, custom-engineered wire rope solutions.

FAQ

What is the main difference between fiber core and steel core wire ropes?

You will notice that fiber core ropes offer more flexibility, while steel core ropes provide higher strength and crush resistance. Your application requirements will determine which core type works best for you.

When should you choose a steel core wire rope?

You should select steel core wire ropes for heavy lifting, high-tension tasks, or environments with high temperatures and crushing forces. These ropes deliver superior strength and durability.

Are fiber core wire ropes suitable for outdoor use?

You can use fiber core wire ropes outdoors, but you must avoid high-temperature or high-pressure environments. Moisture and chemicals may reduce their lifespan, so always check your application’s environmental conditions.

Does Powerful Machinery offer custom wire rope solutions?

Yes! You can work with Powerful Machinery’s experts to design custom-engineered wire ropes. Their certified products meet international standards and fit your unique project needs.

How often should you inspect and maintain your wire rope?

You should inspect your wire rope before each use. Regular lubrication and cleaning help extend its lifespan. Schedule comprehensive inspections based on your application’s load and frequency of use.