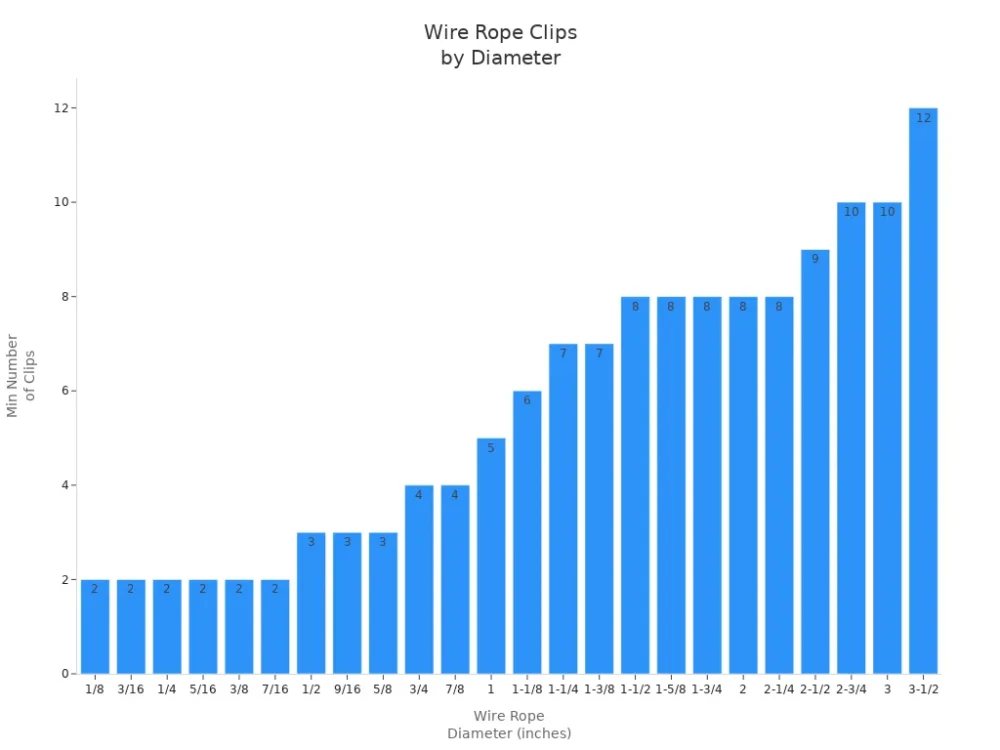

You need to know how many wire rope clips to use for each wire rope diameter. For example, industry standards recommend two clips for ropes up to 3/8 inch, three clips for 1/2 inch, and up to twelve clips for larger diameters. Using the correct number keeps your connections strong and safe.

Workplace injuries can reach 2.6 million cases each year, with rigging failures leading to 60% of crane-related fatalities. Following safety guidelines is critical. Powerful Machinery provides certified wire rope clips and steel wire rope that meet strict standards, helping you protect your team and equipment.

Key Takeaways

Use the correct number of wire rope clips based on the diameter of the wire rope. For ropes up to 3/8 inch, use at least two clips; for larger diameters, follow the recommended guidelines.

Always check the manufacturer’s instructions and safety standards before starting your project. This ensures safe and effective wire rope connections.

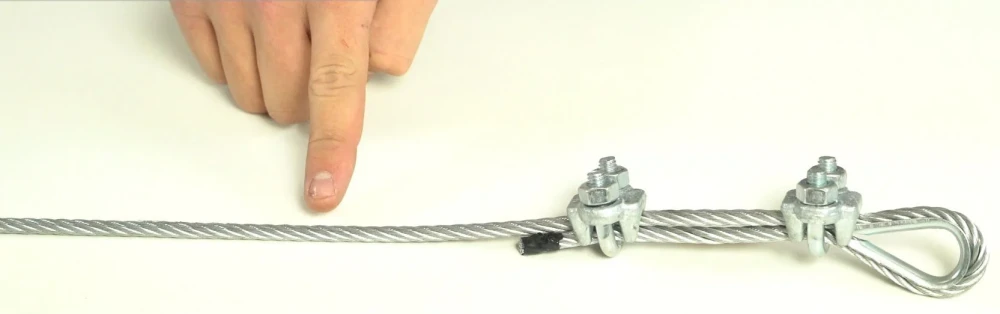

Install wire rope clips properly by placing the saddle on the live end and the U-bolt on the dead end. This prevents slippage and maintains the strength of your wire rope assembly.

Regularly inspect and re-tighten wire rope clips after installation. This helps maintain safety and prevents accidents due to loosening under load.

Choose certified wire rope clips from reputable suppliers like Powerful Machinery. Certified products meet strict safety standards and provide reliable performance.

How Many Wire Rope Clips to Use for Each Size?

Standard Guidelines by Diameter

You need to know how many wire rope clips to use for each wire rope diameter. Industry standards, such as those from OSHA and ASME, recommend following the manufacturer’s instructions for every application.

Powerful Machinery provides clear guidance for its Stainless Steel Wire Rope Clips, helping you make safe choices.

Tip: Always check the official tables and manufacturer recommendations before starting your project. This ensures you use the correct number of wire rope clips for each wire rope size.

The number of wire rope clips depends on the diameter of your wire rope. Using the right amount keeps your connections secure and prevents accidents. If you use too few clips, the wire rope can slip or fail under load. This puts people and equipment at risk. You should always follow the guidelines to avoid these dangers.

Here are some key points from safety standards:

OSHA regulations require you to use the number of wire rope clips specified by the manufacturer for each wire rope diameter.

At least two or three wire rope clips are necessary for smaller diameters to prevent slippage.

Larger diameters need more wire rope clips to maintain safety and reliability.

Wire Rope Clip Chart

The chart below shows how many wire rope clips to use for each wire rope diameter. These recommendations follow Powerful Machinery’s standards for Stainless Steel Wire Rope Clips and align with industry safety requirements.

Wire Rope Diameter (inches) | Minimum Number of Wire Rope Clips |

|---|---|

1/8 | 2 |

3/16 | 2 |

1/4 | 2 |

5/16 | 2 |

3/8 | 2 |

1/2 | 3 |

5/8 | 3 |

3/4 | 4 |

7/8 | 4 |

1 | 5 |

1-1/8 | 6 |

1-1/4 | 6 |

1-3/8 | 7 |

1-1/2 | 8 |

1-5/8 | 8 |

1-3/4 | 9 |

2 | 10 |

You should use this chart every time you ask yourself how many wire rope clips to use. The chart helps you avoid mistakes and keeps your wire rope assemblies strong.

Why Using the Correct Number Is Critical?

When you use the right number of wire rope clips, you protect your team and your equipment. If you use fewer clips than recommended, you decrease the efficiency of your wire rope assembly. This can cause the wire rope to slip through the clips, leading to failure.

You must install wire rope clips properly to support the intended load safely.

Wire rope clips secure the loose ends of wire ropes. At least two or three clips are necessary to prevent slippage and damage.

Incorrect fitting or using too few wire rope clips can reduce the effectiveness of your wire rope terminations.

Proper installation, including the correct number of wire rope clips, ensures your wire rope can handle the load and keeps everyone safe.

Note: Always inspect your wire rope clips after installation. Re-tighten them as needed to maintain safety.

You can trust Powerful Machinery’s Stainless Steel Wire Rope Clips for reliable performance. The company’s products meet strict safety standards and provide clear instructions for how many wire rope clips to use. Following these guidelines helps you avoid accidents and ensures your wire rope connections stay secure.

Choosing and Installing Wire Rope Clips from Powerful Machinery

Selecting the Right Clip

You need to select wire rope clips that match your application and wire rope diameter. Powerful Machinery offers several types of wire rope clips, including cast, malleable, and drop forged designs. Each type suits different load requirements. The table below helps you choose the right clip for your project:

Type of Clip | Application Use Cases | Load Capacity |

|---|---|---|

Cast and Malleable Clips | Handrails, fencing, light-duty tasks | Light loads |

Drop Forged Clips | Scaffolding, guy lines, overhead lifting | Heavy loads |

When choosing wire rope clips, consider these factors:

Manufacturer’s reputation for quality and safety.

Instruction manual with installation and load details.

Expert advice for special applications.

Correct size for your wire rope diameter.

Weather resistance for outdoor or marine use.

Regular inspection and maintenance.

Proper storage in a dry, cool place.

Proper Clip Placement and Spacing

Placing wire rope clips correctly ensures safety and reliability. You must turn back the specified amount of rope from the thimble or loop. Place the first clip one base width from the dead end. Position the U-bolt over the dead end, and the saddle on the live end.

Space additional clips evenly between the first two. Improper spacing can decrease efficiency and may cause wire rope assemblies to fail. Correct spacing allows for even load distribution and secure holding.

Tip: Always use a torque wrench to tighten nuts evenly and alternate between nuts for balanced tension.

Installation Steps for Safety

Follow these steps to install wire rope clips safely:

Select the correct size for your wire rope.

Determine the number of clips needed and the amount of rope to turn back.

Check torque specifications for tightening.

Use at least three clips for loop or thimble-eye terminations.

Install all clips with the saddle on the live end.

Remember: “Never saddle a dead horse”—the U-bolt goes on the dead end.

Tighten nuts with a calibrated torque wrench, alternating between nuts.

Apply a load to the wire rope and retorque the nuts to ensure proper seating.

You can rely on Powerful Machinery’s wire rope clips for secure and long-lasting connections. Proper installation keeps your wire rope assemblies safe and effective.

Common Mistakes with Wire Rope Clips

Wire rope clips play a vital role in keeping wire rope assemblies secure. You must avoid common mistakes to ensure safety and reliability. Powerful Machinery provides clear guidelines to help you prevent errors and protect your equipment.

Using Too Few Clips

Many people use fewer wire rope clips than recommended. This mistake can cause the rope to slip or fail under load. You should always check the chart and follow the manufacturer’s instructions for the correct number of clips. Using the right amount keeps your wire rope strong and reduces the risk of accidents.

Common errors include:

Using fewer clips than the chart suggests

Choosing the wrong size for your wire rope

Incorrect spacing between clips

You need to select the proper types of wire rope clips for your application. Each type has a specific load rating and fits certain rope diameters. Always match the clip to your wire rope and use the minimum number required.

Incorrect Installation

Improper installation of wire rope clips can weaken your wire rope by up to 40%. You must place the saddle on the live end and the U-bolt on the dead end. If you install the clips backwards, the rope strands may crush, leading to slippage or failure.

Position each clip at least six times the rope diameter from the rope tail, and space them evenly.

Tip: Remember the saying, “Never saddle a dead horse.” The saddle goes on the live end, and the U-bolt goes on the dead end.

You should use the correct types of wire rope clips for your project. Powerful Machinery recommends drop forged clips for heavy loads and malleable clips for lighter tasks. Always follow the installation steps and torque specifications.

Skipping Re-Tightening

After you install wire rope clips, the rope may adjust under pressure or weight. This can cause the clips to loosen. You must re-tighten the nuts before applying a full load. Regular inspections and retightening are essential, especially in environments with vibration or frequent use.

Key steps to avoid mistakes:

Inspect clips for wear or cracks

Re-tighten nuts after initial load

Replace any damaged clips immediately

Following Powerful Machinery’s guidelines helps you avoid these common mistakes. You keep your wire rope assemblies safe and extend their lifespan.

Powerful Machinery’s Commitment to Quality and Safety

Certified Wire Rope Clips and Steel Wire Rope

You want products that meet the highest safety standards. Powerful Machinery delivers certified wire rope clips and steel wire rope for demanding environments.

You benefit from certifications like ISO 9001, TUV Rheinland, and OSHA, which guarantee consistent quality and safety. These certifications mean you get wire rope clips that perform reliably and help prevent accidents.

You gain several advantages when you choose certified wire rope clips:

Certifications ensure every product meets strict quality management standards.

Compliance with international regulations increases safety during lifting and rigging.

You receive assurance that your wire rope clips will perform as expected.

Powerful Machinery offers a wide range of wire rope clips, including stainless steel, simplex, duplex, and DIN741 designs. You also find steel wire rope in multiple configurations for different load requirements.

Each product undergoes rigorous testing, including chemical analysis and proof-load testing. You can trace every item from raw steel to shipment, which guarantees reliability.

Why Choose Powerful Machinery

You want a supplier you can trust for your wire rope clips and steel wire rope. Powerful Machinery earns customer trust through quality and service. You see this in reviews from professionals who rely on these products for large construction projects and marine applications.

“For our large-scale construction projects, we need a supplier we can trust. PowerFul Machinery delivers every time with their high-strength wire ropes and custom fittings. Their products withstand extreme conditions, and their professional service is second to none. Highly recommended.”

Customers praise Powerful Machinery for excellent product quality and reliable certifications. You benefit from a team that supports you throughout the procurement process. You also find friendly service and knowledgeable staff who help you select the right wire rope clips for your needs.

Powerful Machinery inspects raw materials with care.

Every batch receives comprehensive testing for strength and safety.

You get full traceability, so you know your wire rope clips are certified and dependable.

You can count on Powerful Machinery for wire rope clips and steel wire rope that meet your safety standards and project requirements.

Conclusion

You keep your wire rope assemblies safe when you use the correct number of clips.

Two or three clips secure most wire rope applications.

Always follow manufacturer guidelines for placement and quantity.

Certified products from Powerful Machinery add reliability to your projects:

Key Aspect | Description |

|---|---|

Minimum Breaking Strength | Ropes meet required load capacities for safety-critical tasks. |

Fatigue Resistance | Durable under repeated bending and stress. |

Corrosion Protection | Coatings extend lifespan in harsh environments. |

Quality Control and Traceability | Inspection and certification ensure consistent performance. |

Follow these best practices for every project:

Assign a competent person for daily inspections.

Avoid placing the saddle on the dead end.

Select the correct clip model for your application.

Use the right number of clips for your rope size.

Tighten nuts to the recommended torque.

Explore Powerful Machinery’s wire rope clips and steel wire rope solutions to ensure safety and reliability in your next project.

FAQ

How do you choose the right wire rope clip size?

You match the clip size to your wire rope diameter. Check the manufacturer’s chart for guidance. Powerful Machinery provides clear sizing information for each product.

Can you reuse wire rope clips?

You should not reuse wire rope clips for safety-critical applications. Clips may lose strength after use. Always inspect clips before each installation.

How often should you inspect wire rope clips?

You inspect wire rope clips before each use and after heavy loads. Look for signs of wear, corrosion, or loose nuts. Regular checks keep your assemblies safe.

What is the difference between simplex and duplex wire rope clips?

Simplex clips have one saddle. Duplex clips have two saddles for extra grip. Duplex clips provide more security for heavy-duty tasks.

Are Powerful Machinery’s wire rope clips suitable for marine environments?

Yes. Powerful Machinery’s stainless steel wire rope clips resist corrosion and rust. You can use them in marine, outdoor, and industrial settings.