You want lifting equipment that delivers measurable results. Wire rope hoists stand out for five key reasons: high load capacity, durability, smooth operation, versatility, and enhanced safety. The market recognizes the advantage wire rope hoist brings, with 55% preference for heavy-duty tasks compared to other solutions:

Lifting Solution | Market Share | Application Type |

|---|---|---|

Wire Rope Hoists | 55% | Heavy-duty applications, versatile and durable. |

Chain Hoists | 40% | Standard applications, cost-effective and portable. |

When you choose wire rope hoists, you gain time savings, reduced fatigue, consistent performance, precise load control, better ergonomics, and fewer accidents. These features make your lifting operations safer and more efficient.

Key Takeaways

Wire rope hoists offer high load capacity, making them ideal for heavy-duty tasks. This allows you to handle larger projects with confidence.

Durability is a key feature of wire rope hoists. Regular maintenance and inspections can extend their lifespan and ensure reliable performance.

Smooth operation and precise control enhance efficiency. These hoists minimize vibrations and lateral movement, making lifting easier and safer.

Versatility in application allows wire rope hoists to adapt to various industries. They can be customized for specific environments and tasks.

Enhanced safety features protect your team and equipment. Built-in systems like overload protection and emergency stops help prevent accidents.

High Load Capacity Advantage Wire Rope Hoist

Heavy Lifting Power

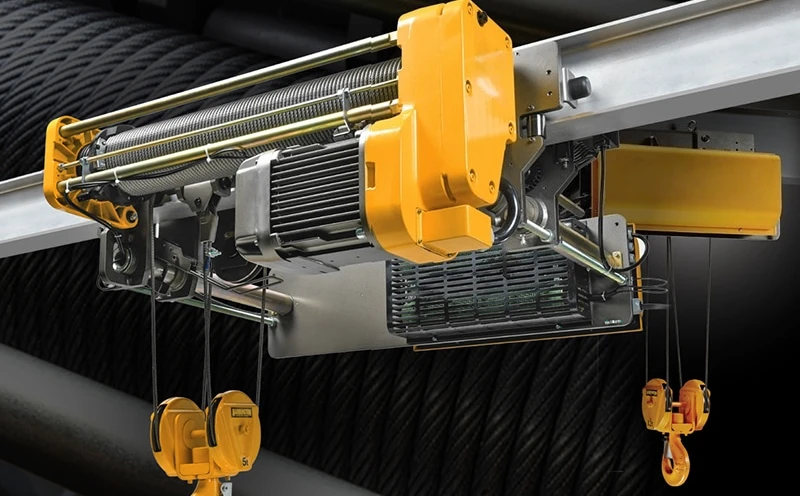

You need equipment that handles the toughest jobs. The advantage wire rope hoist stands out for its unmatched lifting capacity. Powerful Machinery designs wire rope hoists that deliver reliable performance for lifting heavy loads in demanding environments.

You can trust these machines to move everything from steel beams to massive turbines.

Take a look at how leading wire rope hoist models compare in terms of maximum load capacity:

Hoist Model | Maximum Load Capacity |

|---|---|

Demag DVR rope hoist | 80 tons (160,000 lbs) |

Demag DH wire rope hoist | 220,000 lbs |

tirak® Standard Man-Riding X-Series | 700 lbs to 4,400 lbs |

You see that wire rope hoists offer far greater lifting capacity than chain hoists. This means you can tackle larger projects and heavier materials with confidence. Powerful Machinery’s wire rope hoists meet strict international certifications, so you know your equipment is built for safety and reliability.

Wire Rope Crane Hoist for Demanding Jobs

When your operation requires lifting heavy loads day after day, you need a wire rope crane hoist that performs without compromise. Powerful Machinery’s products excel in industries where strength and durability matter most.

Here are some common applications for high-capacity wire rope hoists:

Manufacturing and assembly: Move raw materials and position heavy assemblies.

Warehousing and logistics: Stack cargo and load pallets efficiently.

Construction and infrastructure: Hoist steel beams and concrete blocks to elevated platforms.

Mining and heavy industries: Shift large ore containers and machine parts.

Energy and power plants: Lift generators and turbines for maintenance.

Wire rope hoists outperform alternatives in harsh environments. You benefit from superior lifting heights, advanced speed control, and excellent resistance to abrasion. The advantage wire rope hoist gives you the power to handle the most demanding jobs, ensuring your lifting operations run smoothly and safely.

Durability and Longevity

Robust Build Quality

You expect your lifting equipment to perform reliably, even in the harshest environments. Powerful Machinery wire rope hoists deliver exceptional durability and strength through advanced engineering and premium materials.

The flexible steel cable wound around a grooved drum ensures a smooth, steady lift and true vertical movement. This design minimizes jarring and protects sensitive loads. You benefit from higher lifting speeds, which are essential for high-volume production.

Powerful Machinery meets strict international standards, including ISO 4301-1, ISO 4309, ASME B30.16, and EN 13157. These certifications guarantee that every advantage wire rope hoist you use is built for safety and long-term reliability.

Standard | Description |

|---|---|

ISO 4301-1 | General design requirements for hoists, including load capacity and safety. |

ISO 4309 | Hook design standards for strength in load handling. |

ASME B30.16 | Safety requirements for overhead and gantry cranes. |

EN 13157 | Technical and safety standards for manual chain hoists in Europe. |

Regular inspections and proper maintenance play a key role in extending the life of your hoist. You should check for signs of wear, damage, or corrosion, and lubricate moving parts as recommended by the manufacturer.

Electric Wire Rope Hoist Lifespan

You want equipment that lasts. The average operational lifespan of an electric wire rope hoist ranges from 2 to 5 years under typical industrial use. With proper care, you can maximize this lifespan and reduce downtime.

Daily visual checks, frequent lubrication, and annual comprehensive inspections help you catch issues early and keep your hoist running smoothly.

Lubricate wire ropes to reduce friction and wear.

Store your hoist in a clean, dry environment to prevent moisture damage.

Keep a maintenance log to track inspections and repairs.

Customer testimonials highlight the reliability of Powerful Machinery hoists in extreme conditions. For example, a furnace charging hoist operated flawlessly in high temperatures, while a twin hook hoist at a truck manufacturer proved effective for heavy-duty tasks.

These stories show that with regular upkeep, your electric wire rope hoist will deliver consistent performance year after year.

Tip: Following manufacturer’s maintenance instructions and scheduling regular inspections ensures your equipment’s durability and strength, keeping your operations safe and efficient.

Smooth Operation and Precision

Ease of Use and Versatility

You want lifting equipment that delivers consistent results with minimal effort. Powerful Machinery’s wire rope hoists provide smooth operation, which helps you achieve high efficiency in every lift. These hoists minimize lateral movement, so you can position loads exactly where you need them.

The wire rope mechanism reduces vibrations, making each lift steady and controlled. You experience less fatigue and more confidence on the job.

Wire rope hoists stand out for their ease of use and versatility. You can adapt them to a wide range of industries, from construction to marine and transportation. Powerful Machinery offers custom-engineered solutions, so you get equipment tailored to your unique requirements.

Take a look at how wire rope hoists compare to other options:

Hoist Type | Lifting Capacity | Ease of Use | Operator Control | Maintenance Costs |

|---|---|---|---|---|

Wire Rope Hoist | High | Moderate | High | Higher |

Chain Hoist | Moderate | High | Moderate | Lower |

Pneumatic Hoist | Moderate | High | High | Moderate |

You see that wire rope hoists offer higher lifting capacity and precise control, which boosts operational efficiency in demanding environments.

Accurate Lifting Control

You need precise control when handling heavy or sensitive loads. Powerful Machinery’s wire rope hoists use advanced features to ensure accuracy and safety. The 6:1 ratio in the hoist design allows you to move loads by just a fraction of an inch, giving you unmatched precision.

Continuous load monitoring and automatic load control prevent spikes and keep your operation safe. If the system detects an overload, it shuts down immediately to protect both the equipment and your team.

Minimized lateral movement for accurate load placement

Reduced vibrations for smooth lifting and lowering

Advanced safety features like overload protection and limit switches

These technologies help you maintain operational efficiency and reduce the risk of accidents. You can trust Powerful Machinery’s wire rope hoists to deliver the efficiency and reliability you need for every project.

Versatility in Application

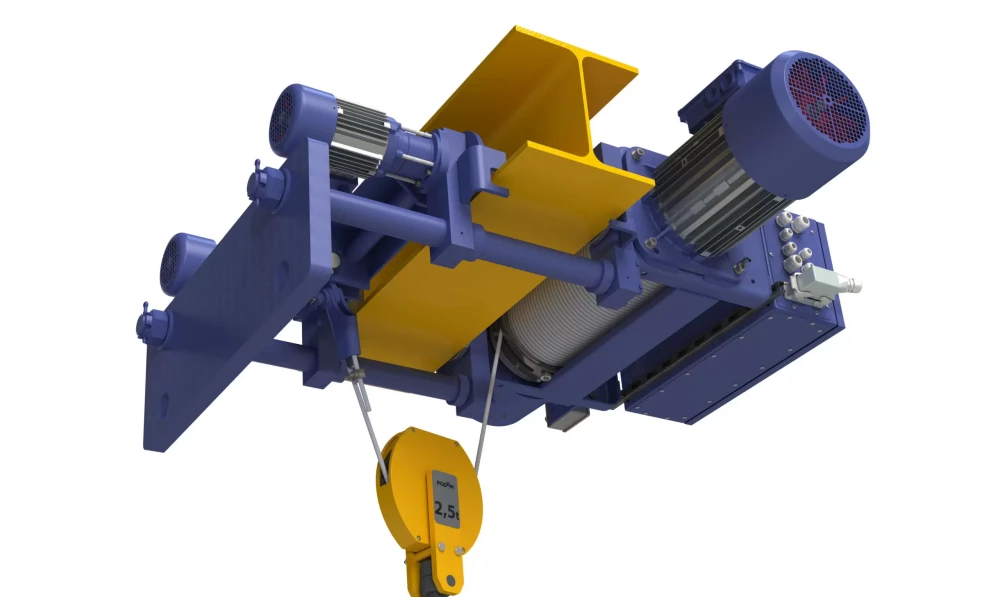

Adaptable Wire Rope Crane Hoist

You need lifting equipment that adapts to your unique job site. Powerful Machinery offers a wide range of wire rope hoists, each engineered for specific environments and tasks. You can select from manual or powered models, choose different rope lengths, and even request custom-engineered solutions for challenging conditions.

For example, you may need a hoist that handles high temperatures in steel mills or one that fits tight spaces in paper plants. Powerful Machinery delivers tailored solutions for every scenario.

Here are some examples of custom-engineered wire rope hoist solutions for unique environments:

Application Environment | Description |

|---|---|

Steel Mills | Custom electric wire rope hoists for steel coils and high-capacity lifting. |

Paper Plants | Hoists designed for strict clearance limits and workflow needs. |

High-Heat Operations | Hot metal hoists with redundant braking for extreme temperatures. |

Power Generation | Reliable hoists for demanding power facility applications. |

High-Capacity Manufacturing | Tailored hoists for unique operational requirements. |

You can rely on the advantage wire rope hoist to operate in vertical, horizontal, or angled positions. This adaptability means you can use the same equipment for lifting, pulling, or positioning loads in a variety of applications.

Mobility and Multi-Industry Use

You want equipment that moves with you from one project to the next. Wire rope hoists from Powerful Machinery are lightweight and easy to install, so you can set them up quickly on any job site.

Their robust design allows you to use them in both stationary and mobile applications, making them ideal for warehouses, construction sites, and even emergency rescue operations.

Wire rope hoists excel in many industries. The table below shows how different sectors benefit from their use:

Industry | Benefit Description |

|---|---|

Industrial | Handles heavy loads efficiently. |

Construction | Lifts materials safely on-site. |

Energy | Supports maintenance and installation tasks. |

Telecoms | Installs and repairs equipment with precision. |

Infrastructure | Manages construction and maintenance work. |

You can use wire rope hoists in marine, transportation, and cargo handling applications as well.

Features like intelligent control systems and dynamic lift speed adjustment help you match the hoist’s performance to your specific needs. You also benefit from galvanized or stainless steel wire ropes, which withstand harsh environments such as high humidity or corrosive conditions.

Tip: Choose wire rope hoists for their versatility and reliability in a wide range of applications. You gain efficiency, safety, and peace of mind on every project.

Enhanced Safety Features

Built-In Safety

You need lifting equipment that puts safety first. Powerful Machinery wire rope hoists come with advanced safety features that protect both your team and your investment. These hoists include multiple built-in systems that help you avoid accidents and keep operations running smoothly.

You can see how these features work together in the table below:

Safety Feature | Description |

|---|---|

Load Limiters | Stop the hoist if the load exceeds safe limits, protecting people and equipment. |

Emergency Stop Button | Let you halt operations instantly in case of danger. |

Control Systems | Give you precise control for safe and accurate lifting. |

Anti-Friction Brakes | Hold the load securely, preventing sudden drops. |

Limit Switches | Stop movement at set points to avoid over-travel and collisions. |

Safety Latches | Keep the load attached to the hook during lifting. |

Anti-Collision Systems | Use sensors to prevent accidents between loads or hoists. |

Thermal Protection Mechanisms | Monitor temperature to prevent overheating. |

LED Status Indicators | Show real-time operational status for quick checks. |

Phase Failure Protection | Stop the hoist if there is a power imbalance, preventing damage. |

Powerful Machinery wire rope hoists meet strict international safety certifications, including CE, ISO, ASME, and UL. These certifications prove that your equipment meets the highest standards for quality and safety.

Overload Protection and Emergency Systems

You want to avoid risks on every lift. Overload protection systems in wire rope hoists prevent you from lifting loads that exceed the rated capacity. This system acts as your first line of defense, stopping the hoist before an unsafe lift can happen.

Emergency stop buttons and fail-safe brakes give you extra control in critical moments.

In 2023, a crane operator in Dubai tried to lift a panel that unknowingly exceeded the hoist’s rated capacity. The overload protection system detected the excess weight, sounded an alarm, and stopped the lift before any damage occurred. The site manager later confirmed that this system prevented a possible accident.

Powerful Machinery designs hoists with redundancy in mind. Multiple strands of high-strength wire ensure that if one strand fails, others still support the load. This enhanced safety design goes beyond standard practice, giving you peace of mind on every job.

When you choose Powerful Machinery, you get equipment that not only meets but exceeds industry standards for safety. You can trust these hoists to protect your team and your projects every day.

Conclusion

You have seen how the advantage wire rope hoist delivers high load capacity, durability, smooth operation, versatility, and enhanced safety. Powerful Machinery stands out as your trusted partner for lifting solutions. The table below highlights why you can rely on this brand:

Strengths & Features | Description |

|---|---|

Direct-from-manufacturer pricing | Saves you money |

Custom-engineered solutions | Fit your unique project requirements |

Strict quality control | Meets or exceeds international standards |

Advanced manufacturing equipment | Guarantees consistent quality |

Industry certifications | Ensures safety and compliance |

To choose the right hoist for your needs, follow these steps:

Assess your load weight and dimensions.

Match the hoist’s duty cycle to your operation.

Evaluate your environment for temperature and corrosives.

Prioritize comprehensive safety features.

Consider the total cost of ownership.

Select a reputable supplier with strong support.

Ensure compatibility with your existing systems.

Take the next step with Powerful Machinery and experience reliable lifting performance on every project.

FAQ

What certifications do Powerful Machinery wire rope hoists carry?

You receive wire rope hoists certified to ISO, CE, ASME, and UL standards. These certifications guarantee safety, reliability, and compliance with global industry requirements.

How often should you inspect your wire rope hoist?

You should perform daily visual checks and schedule comprehensive inspections annually. Regular maintenance helps you catch wear early and ensures safe operation.

Can you customize wire rope hoists for specific projects?

You can request custom-engineered wire rope hoists. Powerful Machinery tailors solutions to your load requirements, environment, and operational needs.

What industries benefit most from wire rope hoists?

You see wire rope hoists used in construction, marine, transportation, energy, and manufacturing. These industries rely on high load capacity and durability for demanding tasks.