Wire rope clamp strength refers to the ability of wire rope clamps to retain the original breaking strength of the wire rope after installation. In most cases, properly installed wire rope clamps can retain 80% to 90% of the rope’s breaking strength.

You need to consider termination efficiency and working load limit when selecting hardware for rigging. Certified wire rope clips from Powerful Machinery help you maintain safety and reliability in demanding environments. You will learn practical ways to maximize strength and avoid common mistakes in your projects.

Key Takeaways

Properly installed wire rope clamps retain 80% to 90% of the rope’s breaking strength, ensuring safety and reliability in rigging.

Choose the right type of wire rope clip—prefer forged clips for heavy-duty tasks and stainless steel for corrosion resistance in harsh environments.

Always follow installation best practices: space clips six rope diameters apart, tighten before and after loading, and ensure correct attachment methods.

Regularly inspect wire rope and hardware for wear, corrosion, or damage to maintain strength and prevent failures.

Understand the working load limit and avoid exceeding it to prevent sudden failures and ensure safe lifting operations.

Wire Rope Clamp Strength Limits

Wire rope clamp strength measures how much of the original breaking strength of a wire rope you can retain after installing clamps. Industry standards show that most wire rope clamps, when installed correctly, allow you to keep about 80% to 90% of the rope’s strength.

This percentage is called termination efficiency. You need to understand this value because it directly impacts the safety and reliability of your rigging setup. If you use clamps that do not meet these standards, you risk equipment failure and safety hazards.

What Affects Clamp Strength?

Many factors influence wire rope clamp strength. The material grade, rope construction, and installation method all play a role. You must also consider the environment and the type of load applied. The table below summarizes the most common factors that affect clamp strength:

Factor | Description |

|---|---|

Material Grade and Composition | The type of stainless steel affects mechanical strength and corrosion resistance. |

Rope Construction Type | The number of strands and wires per strand impacts strength and flexibility. |

Core Type | The core supports the strands and affects strength and shape maintenance. |

Diameter of the Rope | Strength is proportional to the cross-sectional area; larger diameters increase breaking strength. |

Lay Direction and Type | Determines the twist direction and affects flexibility and resistance to crushing. |

Method of Termination | The way the rope is terminated can significantly reduce usable strength if not done correctly. |

Loading Conditions | Static, dynamic, and shock loads affect the rope’s strength and durability. |

Bending Over Sheaves | Frequent bending can weaken the rope, especially with small sheave diameters. |

Environmental Conditions | Factors like salt exposure and chemicals can degrade wire rope strength over time. |

Wear, Abrasion, and Corrosion | Mechanical wear and corrosion can reduce strength; regular inspections are necessary. |

Manufacturing Quality | Compliance with international standards ensures the rope meets safety and strength requirements. |

You should always select hardware that matches your application and environment. Powerful Machinery’s certified wire rope clips use high-grade materials and precise manufacturing. This ensures you get consistent wire rope clamp strength, even in harsh conditions.

Termination Efficiency Explained

Termination efficiency tells you how much strength you keep after forming an eye or loop with a clamp. For example, if your wire rope has a breaking strength of 10,000 pounds and the termination efficiency is 85%, your assembly can safely handle up to 8,500 pounds before failure.

No clamp can provide 100% efficiency. Only a properly attached spelter socket achieves full strength retention. Most wire rope clamps, including those from Powerful Machinery, retain 80% to 90% of the original strength. This matches the best industry standards.

You measure wire rope clamp strength by testing the assembly until it breaks. The ratio of the breaking load to the original rope strength gives you the efficiency. You must always consider the working load limit, which is the maximum load you should apply under ideal conditions.

Exceeding this limit, especially with shock loads, can cause sudden failure. The table below highlights key safety aspects:

Safety Aspect | Description |

|---|---|

Working Load Limit (WLL) | The maximum load that should be applied to the product, even when new and under ideal conditions. |

Shock Loads | Loads resulting from rapid changes in movement, which can exceed the WLL and pose safety risks. |

Avoiding Shock Loads | Important to prevent exceeding the WLL, as shock loads can be significantly greater than static loads. |

You should always follow manufacturer guidelines and use certified hardware. Powerful Machinery’s wire rope clips undergo strict testing and certification. This gives you confidence that your wire rope clamp strength meets or exceeds industry expectations.

When you use the right hardware and proper installation, you maximize safety and performance in every application.

Types of Wire Rope Hardware

Forged vs Malleable Clips

You need to choose the right type of wire rope clip for your application. Forged and malleable clips look similar, but they perform very differently. Forged clips use a single piece of steel shaped under high pressure. This process gives them high strength and reliability.

Malleable clips use cast iron, which can have inconsistent strength. You should know that industry standards, such as ASME B30.5 and B30.26, do not allow malleable clips in critical lifting or load-bearing applications.

Forged clips provide:

Superior strength for heavy-duty tasks

Consistent performance under high loads

Reliable use in safety-critical environments

Malleable clips offer:

Lower cost for light-duty or temporary jobs

Less strength and reliability than forged clips

Tip: Always use forged wire rope clips for lifting, hoisting, or any application where safety matters most.

Stainless Steel Wire Rope Clips

Stainless steel wire rope clips give you excellent corrosion resistance and long-term durability. You should select AISI 316 stainless steel clips for marine, coastal, or outdoor environments.

These clips resist rust and chemical damage, making them ideal for harsh conditions. Regular inspections and re-tightening help maintain their holding power and overall strength.

Stainless steel clips provide:

Outstanding protection against corrosion

Reliable performance in wet or salty environments

Easy maintenance and long service life

Powerful Machinery offers a full range of wire rope clip materials, including forged steel and stainless steel options. All products meet or exceed international safety standards, such as ISO9001, TUV Rheinland, and OSHA.

You can trust Powerful Machinery’s certified hardware for demanding construction, marine, and transportation projects.

Factors Affecting Wire Rope Clamp Strength

Installation Quality and Number of Clips

You must focus on installation quality to achieve the minimum breaking strength required for your application. The way you space and tighten wire rope clips directly impacts holding power. Clips should be spaced about six wire rope diameters apart.

You need to tighten each clip before and after loading to maintain the minimum breaking strength. Always attach the U-bolt to the dead end and the saddle to the live end for proper installation. The table below highlights key installation practices:

Practice | Description |

|---|---|

Proper spacing of clips | Space clips six rope diameters apart for best grip. |

Tightening clips | Tighten before and after loading to maintain strength. |

Correct attachment method | Place saddle on live end, U-bolt on dead end to prevent failure. |

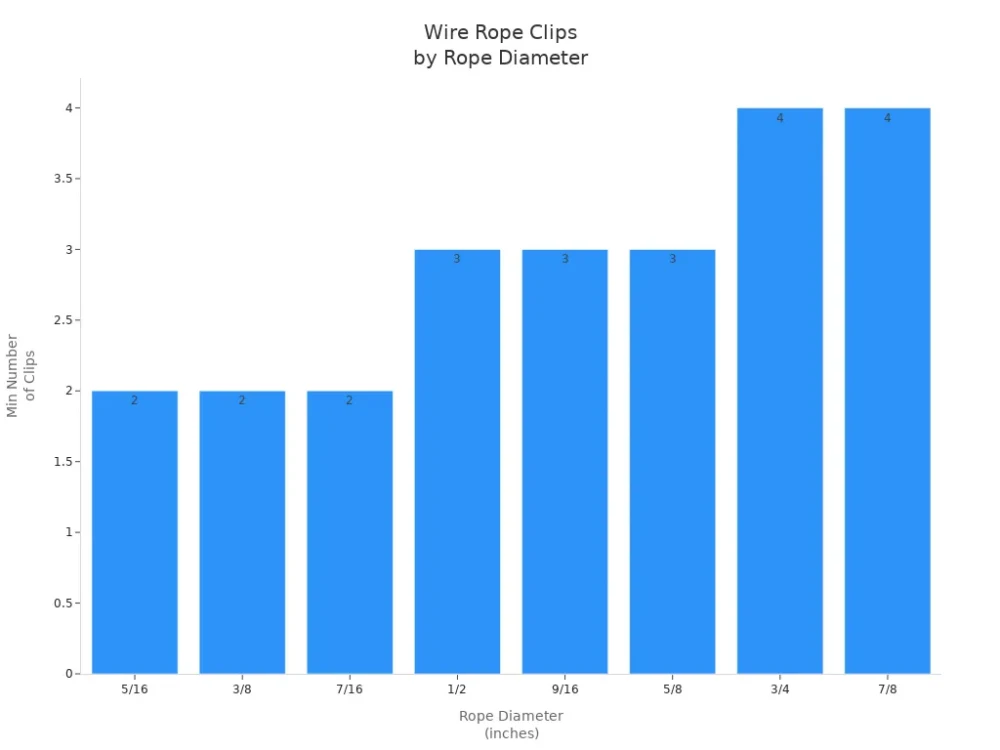

The number of clips you use also determines the minimum breaking strength of your assembly. Industry guidelines recommend at least three clips for most diameters. The chart below shows the minimum number of clips needed for different rope sizes:

Tip: For a 1/2-inch wire rope, use at least three clips to reach the minimum breaking strength and ensure safety.

Rope Size and Material Compatibility

You must match the wire rope clamp size to the rope diameter. This step is essential for achieving the minimum breaking strength. Always check that the Working Load Limit meets or exceeds your application’s demands. Using clamps that comply with standards like ASME B30.26 ensures reliability.

A compatible clamp fits both the rope and the material, which is crucial for maintaining the minimum breaking strength. Stainless steel wire rope clips resist corrosion and perform well in harsh environments, helping you maintain strength over time.

Proper sizing of the clamp to the rope diameter secures gripping.

Stainless steel clips provide durability and help you reach the minimum breaking strength in wet or chemical environments.

Common Installation Mistakes

Mistakes during installation can reduce the minimum breaking strength and compromise safety. You must avoid placing the saddle on the dead end, over-tensioning, or under-tensioning the clips. Always inspect the wire rope for damage before installation. The table below lists common mistakes and solutions:

Mistake | Consequence | Solution |

|---|---|---|

Improper Use of Wire Rope Clips | Poor grip, slippage, failure | Saddle on live end, U-bolt on dead end, use at least three clips |

Over-Tensioning or Under-Tensioning | Weakening or sagging | Use calibrated tools, recheck after load cycles |

Neglecting End Termination Integrity | Catastrophic accidents | Correct installation, testing, and inspection |

Ignoring Environmental Factors | Corrosion, stress cracking | Choose a proper stainless steel grade, consider coatings |

Failure to Pre-Inspect Wire Rope | Risk of using damaged rope | Inspect for kinks, corrosion, and broken wires |

Note: After the first load, re-torque the nuts to maintain the minimum breaking strength. Regular inspections and proper installation help you avoid failures.

Practical Tips for Maximizing Holding Power and Safety

Install clips correctly with the saddle on the live end and U-bolt on the dead end.

Use the recommended number of clips for your rope diameter to reach the minimum breaking strength.

Re-torque nuts after initial use to maintain grip.

Inspect wire rope and hardware before every installation.

Choose stainless steel clips for environments with moisture or chemicals.

You can achieve the minimum breaking strength and ensure safety by following these steps and using certified wire rope clips from Powerful Machinery.

Best Practices for Safe Wire Rope Hardware Use

Installation Tips for Maximum Strength

You can maximize the strength of your wire rope clip installation by following proven techniques. Position the wire rope without sharp bends or twists. Secure the ends using the correct fittings and make sure each wire rope clip is tightly fastened. Gradually apply tension to the rope to prevent sudden stress.

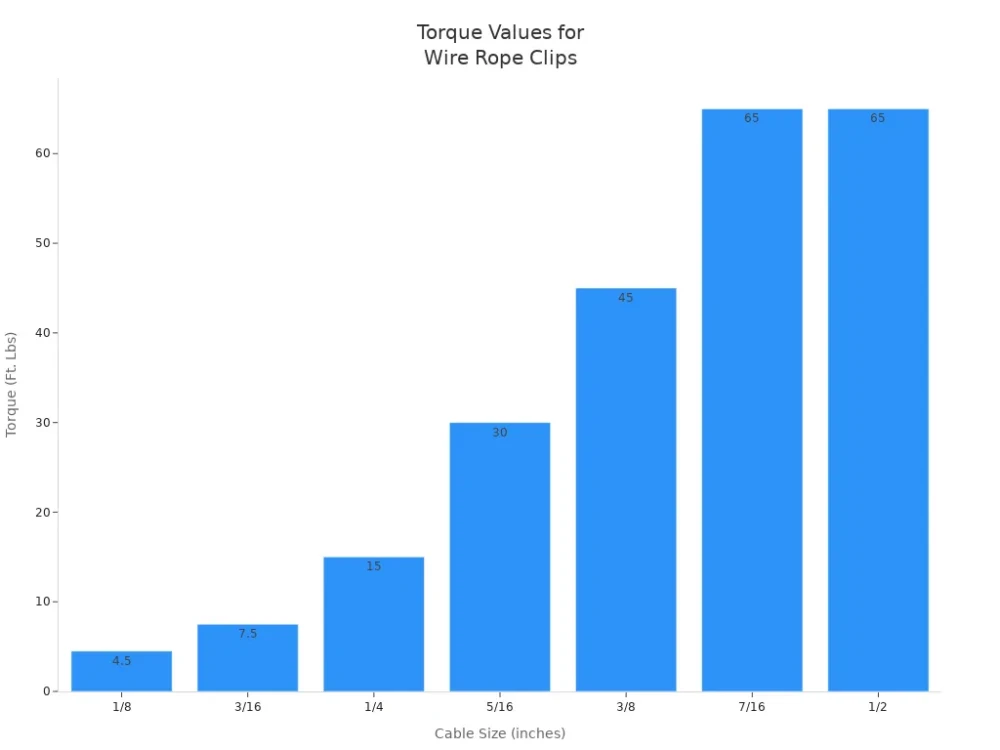

Align the rope so it runs smoothly along pulleys and adjust as needed to reduce friction. Space each wire rope clip evenly, usually six to eight rope diameters apart, to distribute the load. Use a torque wrench to tighten every wire rope clip to the recommended value.

After the first load, recheck and retighten each wire rope clip to maintain grip and safety.

Cable Size (Inches) | Minimum Clips | Rope Turnback (Inches) | Torque (Ft. Lbs) |

|---|---|---|---|

1/8 | 2 | 3-3/4 | 4.5 |

3/16 | 2 | 3-3/4 | 7.5 |

1/4 | 2 | 4-3/4 | 15 |

5/16 | 2 | 5-1/4 | 30 |

3/8 | 2 | 6-1/2 | 45 |

7/16 | 2 | 7 | 65 |

1/2 | 3 | 11-1/2 | 65 |

Tip: Daily visual inspections help you spot hazards like kinking, corrosion, or broken wires. Schedule periodic checks with a qualified person to assess the entire wire rope and every wire rope clip.

Safety Considerations for Lifting

You must select a wire rope clip that can handle more weight than your load. Inspect each wire rope clip for cracks, deformities, or corrosion before use. Train operators on wire rope clip operation and safety protocols. Secure and balance the load before lifting.

Know the weight limit of each wire rope clip and confirm the load’s weight. Keep the lifting area clear and communicate with clear signals. Assess the load’s shape and center of gravity to prevent accidents.

Note: Never exceed the working load limit of any wire rope clip. Overloading can cause sudden failure and serious injury.

When to Use Alternative Terminations

Sometimes you need alternatives to a wire rope clip. Swaged fittings work best for permanent, high-strength terminations. Swageless fittings offer quick installation and easy replacement, making them ideal for projects where you cannot pre-measure wire rope length.

For small jobs, swageless fittings save time and money. For large projects, swaged fittings may be more cost-effective in the long run. Choose the termination that matches your project’s needs and safety requirements.

Tip: Consult Powerful Machinery’s guidelines to select the right wire rope clip or alternative termination for your application.

Conclusion

Wire rope clamps play a vital role in securing wire ropes and forming safe loops. You should select the right clamp type—stainless steel, malleable, or drop forged—based on your application and load requirements.

Certified wire rope clips from Powerful Machinery withstand heavy loads and meet strict safety standards, reducing the risk of failure.

Always follow manufacturer instructions, inspect regularly, and consult a rigging specialist for critical projects. By choosing high-quality hardware and expert guidance, you maximize safety and performance in every lifting operation.

FAQ

How do you choose the right wire rope hardware for your project?

You should match wire rope hardware to your rope diameter and load requirements. Always check certifications and manufacturer guidelines. Powerful Machinery provides a wide range of wire rope hardware for construction, marine, and transportation applications.

Can you reuse wire rope hardware after disassembly?

You should avoid reusing wire rope hardware in critical applications. Hardware may show wear or deformation after use. Always inspect for damage before considering reuse. Replace any wire rope hardware that shows signs of corrosion or fatigue.

What maintenance does wire rope hardware require?

You need to inspect wire rope hardware regularly for signs of wear, corrosion, or loose fittings. Clean hardware to remove debris. Retighten nuts and bolts after initial loading. Schedule periodic checks to ensure wire rope hardware maintains its strength and reliability.

Is stainless steel wire rope hardware suitable for marine environments?

You can use stainless steel wire rope hardware in marine settings. Stainless steel resists corrosion from saltwater and moisture. Powerful Machinery offers stainless steel wire rope hardware designed for long-term durability in harsh environments.

How many wire rope hardware clips do you need for safe installation?

You should use at least three wire rope hardware clips for most rope diameters. Space each clip six rope diameters apart. Follow manufacturer recommendations to maximize holding power and safety. Proper installation of wire rope hardware ensures reliable performance.