When you face the decision of wire rope vs cable, you need to understand the distinct roles each plays in your project. Wire rope stands out for its strength and flexibility, made from multiple steel wires twisted together for heavy-duty tasks like lifting and hoisting.

In contrast, cable serves as a broad term for various structures, including electrical and communication lines. Powerful Machinery brings decades of expertise in certified lifting solutions, ensuring you get the right product for your toughest applications.

Quick Comparison Table:

Aspect

Wire Rope

Cable

Construction

Multiple metal wires twisted together for strength and flexibility

General term for many structures, including electrical and data cables

Materials

Steel, stainless steel, or alloys

Materials vary: steel, copper, and more, depending on use

Applications

Lifting, hoisting, structural support

Power lines, data transfer, structural support

Key Takeaways

Wire rope is ideal for heavy-duty tasks due to its strength and flexibility, making it perfect for lifting and hoisting.

Cable refers to a broader category, often used for electrical and communication purposes, and is suitable for lighter applications.

When selecting between wire rope and cable, consider load capacity, environmental conditions, and required flexibility to ensure safety and performance.

Regular maintenance and inspections are crucial for both wire rope and cable to extend their lifespan and ensure safe operation.

Consulting with experts can provide valuable insights to help you choose the right product for your specific application needs.

Wire Rope vs Cable: Key Definitions

What Is Wire Rope?

You encounter wire rope in many heavy-duty applications. Industry standards, such as those from ASTM and ISO, define wire rope by several attributes. These include length, diameter, construction, lay, grade, finish, core, and lubrication.

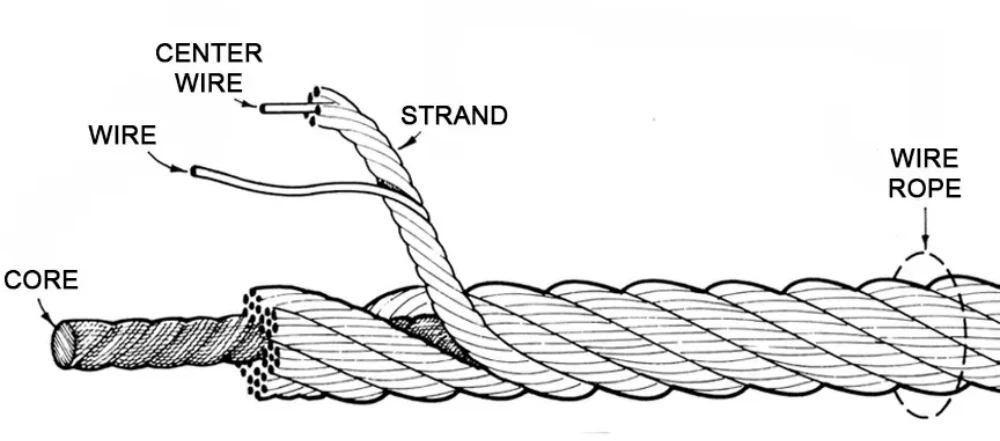

Wire rope consists of multiple wires twisted into strands, which are then twisted around a central core. This design gives you high strength, flexibility, and resistance to fatigue. You often use wire rope for lifting, hoisting, and structural support in construction, marine, and industrial settings.

Note: The construction of wire rope allows it to handle heavy loads and endure repeated bending without losing integrity.

Attribute | Description |

|---|---|

Length | Total measurement of the rope |

Diameter | Thickness across the rope |

Construction | Number of wires and strands |

Lay | Direction and pattern of twist |

Grade | Strength rating of the steel |

Finish | Surface treatment (e.g., galvanized) |

Core | Central support (fiber or steel) |

Lubrication | Reduces friction and wear |

What Is Cable?

You see the term cable used for a wide range of products. In industrial settings, cable often refers to assemblies made from copper or aluminum conductors. These cables can have single or multiple strands and are built to handle electrical, data, or mechanical loads.

Manufacturers design cables with tough jacketing, insulation, and fillers to withstand harsh environments. Flexible jacketing materials like TPE, PVC, and CPE help prevent cracking. Flat cables work well in tight spaces and offer strong protection against electromagnetic interference.

Instrumentation cables transmit low-level signals in sensitive environments.

Twisted pairs with shielding minimize electromagnetic interference.

Industrial motion cables require flexibility and can bend many times their diameter.

Wire Rope vs Steel Cable

You need to understand the differences between wire rope and steel cable to choose the right product. Wire rope features multiple wires twisted into strands, then formed into a rope.

A steel cable may have a simpler structure, such as a single layer of wires twisted together. This difference affects performance and application.

Feature | Wire Rope | Steel Cable |

|---|---|---|

Structure | Multiple wires and strands | Few wires or a single-layer twist |

Example | 6×19 IWRC | 1×7 or 7×7 cable |

Application | Lifting, rigging, construction | Guy wires, decorative, light-duty |

Strength | High, fatigue-resistant | Lower, suited for lighter use |

Load capacity is higher for wire rope, making it ideal for demanding tasks.

Wire rope offers better abrasion resistance, while steel cable provides more flexibility for lighter applications.

You select wire rope when you need maximum strength and durability. Steel cable works best for lighter, less demanding uses. Both products use high-quality materials to ensure safety and performance.

Construction and Materials

Wire Rope Construction

You rely on wire rope construction for demanding lifting and rigging tasks. Manufacturers twist multiple wires into strands, then lay these strands around a core. This method gives you a product with high strength, flexibility, and resistance to fatigue.

Powerful Machinery’s steel wire rope uses advanced construction techniques, including a non-rotating design. This feature prevents twisting under load, which increases safety and extends the rope’s lifespan. You can choose from several configurations, such as 35W×7 or 18×19, to match your specific application.

Cable Construction

Cable construction varies based on the intended use. In mechanical applications, you often see cables made from a single layer of wires twisted together. This structure offers flexibility and is suitable for lighter loads.

In contrast, wire rope construction uses multiple layers and strands, which increases strength and durability. When you need secure connections, Powerful Machinery’s wire rope clips provide a reliable solution. These clips ensure your cable assemblies remain safe and stable during operation.

Materials and Finishes

You must select the right material and finish for your environment. The most common materials include bright, galvanized, and stainless steel. Each option offers unique benefits:

Material | Description |

|---|---|

Bright | Made from wire without coatings, designed to reduce rotation under loads. |

Galvanized | Offers similar strength to Bright; an economical alternative depending on the environment. |

Stainless Steel | Highest quality, durable in all settings, but not as strong as the other two materials. |

Coatings seal in lubricants and prolong cable life.

Finishes help achieve the desired appearance and prevent dirt from contacting the cable.

Optional plastic coatings, such as FEP or nylon, enhance durability against abrasion and chemicals.

Core Types and Strands

The core type in your wire rope affects its performance. You can choose from fiber core, metal core, or hybrid core options:

Core Type | Characteristics | Suitable For | Performance Characteristics |

|---|---|---|---|

Fiber Core | Enhances flexibility and elasticity | High-flexibility applications | Offers flexibility but lower strength |

Metal Core | Provides greater strength and resistance to crushing | High-load scenarios | Used in smaller diameters |

Hybrid Core | Combines fiber and metal for flexibility and strength | Dynamic environments like offshore winching | Best strength and structural stability |

Different core types allow you to balance flexibility and strength based on your needs. Fiber cores suit light-duty tasks, while metal cores handle heavy loads and resist crushing. Hybrid cores give you both flexibility and structural stability, making them ideal for dynamic environments.

Mechanical Properties

Strength and Load

You need to consider strength and load capacity when choosing between wire rope and cable. Wire rope offers superior strength due to its multi-strand construction. This design allows you to handle higher loads with confidence.

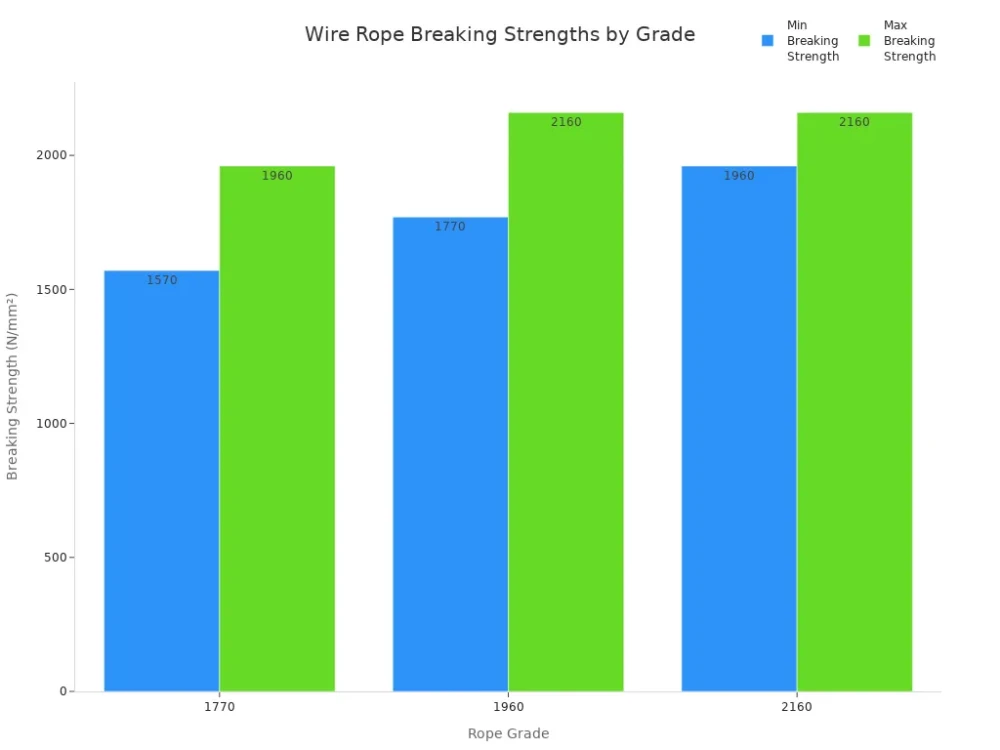

The steel wire rope from Powerful Machinery uses high-grade materials, ensuring consistent performance in demanding environments. You can refer to the following table to compare typical tensile strengths for different wire rope grades:

Rope Grade | Wire Tensile Strength Guide (N/mm²) |

|---|---|

IPS (Improved Plow Steel) | 1570 to 1960 |

EIPS (Extra Improved Plow Steel) | 1770 to 2160 |

EEIPS (Extra Extra Improved Plow Steel) | 1960 to 2160 |

Wire rope provides a higher load capacity than standard cable, making it the preferred choice for lifting, hoisting, and critical support tasks. You ensure safety by selecting the right grade and construction for your application.

Flexibility and Fatigue

You benefit from the flexibility of wire rope, especially in applications that require repeated bending. The construction of wire rope, such as the 6×37 configuration, distributes stress across many small wires. This feature improves fatigue resistance and extends service life.

The table below highlights the differences in flexibility and fatigue resistance:

Feature | Wire Rope (6×37) | Cable |

|---|---|---|

Flexibility | Highly flexible, suitable for repeated bending | Generally less flexible, may not handle repeated bending as well |

Fatigue Resistance | Better fatigue resistance due to smaller wires distributing stress | May experience fatigue more quickly due to larger wire sizes and fewer strands |

You reduce downtime and maintenance costs by choosing wire rope for dynamic operations.

Abrasion Resistance

You encounter abrasion in many industrial settings. Wire rope resists abrasion well, especially when you select the right material and finish. The outer wires in wire rope protect the inner core, maintaining strength and safety.

Galvanized and stainless finishes add extra protection against wear and corrosion. You can rely on wire rope for long-term durability in harsh environments.

Bending and Stretch

You must evaluate how wire rope and cable respond to bending and stretching. Wire rope bends smoothly around pulleys and sheaves, maintaining its shape and strength. The multi-strand construction minimizes permanent stretch under load, which helps preserve load capacity and safety.

The following chart visually compares the breaking strengths of different wire rope grades:

You achieve reliable performance and consistent results by selecting wire rope with the right construction for your project.

Differences Between Cable and Wire Rope

When you compare wire rope vs cable, you notice important differences that affect your choice for industrial and commercial projects. Understanding these differences between cable and wire rope helps you select the right product for safety, performance, and cost-effectiveness.

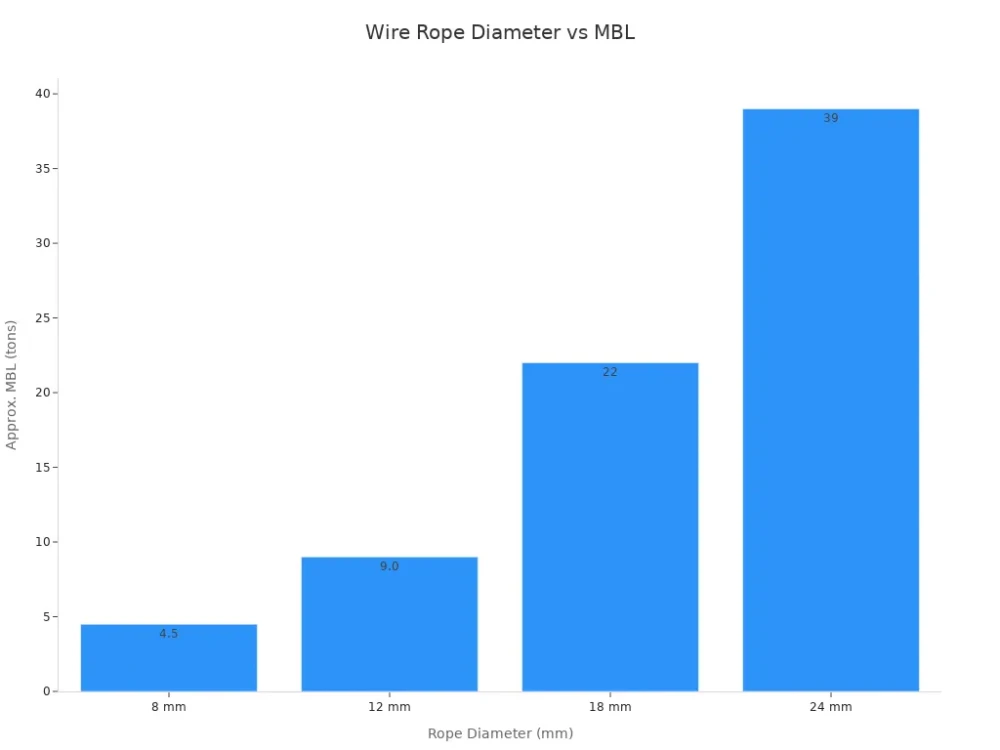

Size and Diameter

You see a wide range of sizes and diameters in both wire rope and cable. Wire rope typically comes in larger diameters and supports heavier loads. Cable, on the other hand, often features smaller diameters for lighter tasks. Choosing the correct size is critical.

If you select the wrong diameter, you risk poor drum winding, increased wear, and load imbalances.

Rope Diameter | Approx. MBL (6×19 IWRC) | Suitable For |

|---|---|---|

8 mm | ~4.5 tons | Light lifting, winches |

12 mm | ~9.0 tons | Hoists, tower cranes |

18 mm | ~22 tons | Deck cranes, ship loading |

24 mm | ~39 tons | Offshore winches, large cranes |

You should follow the guideline that the rope diameter should be about 1/40 of the drum diameter, or use the original equipment manufacturer’s recommendations. This ensures proper fit and safe operation.

Powerful Machinery’s steel wire rope offers a variety of diameters and configurations, making it easy for you to match the right rope to your application, whether you need high load capacity or flexibility for winching.

Construction Complexity

You find that the wire rope has a more complex construction than the cable. Manufacturers design wire rope with multiple layers of strands twisted around a core. This intricate structure gives you better flexibility and distributes loads more evenly.

In contrast, cable usually has a simpler design, often with just one layer of wires twisted together. This simplicity makes cable more cost-effective for light-duty tasks but less suitable for high-stress environments.

Wire rope’s complex design allows it to handle dynamic loads and repeated bending.

Cable’s straightforward construction works well for static or low-load applications.

The difference between wire rope and cable becomes clear when you need performance in demanding conditions. Powerful Machinery’s wire rope, with its non-rotating and abrasion-resistant features, stands out for heavy lifting and critical operations.

Application Suitability

You must consider the intended use when deciding between wire rope vs cable. Wire rope excels in applications that require strength, durability, and flexibility. You see wire rope in cranes, hoists, marine operations, and construction sites.

Cable, with its lighter build, fits best in home projects, light rigging, and some automotive uses.

Application | Features and Suitability |

|---|---|

Cranes and Hoists | Handles significant weight while maintaining flexibility for smooth movement. |

Construction and Infrastructure | Supports structures and operates machinery in building projects. |

Marine and Shipping | Withstands exposure to water and harsh weather for mooring and towing operations. |

Mining and Drilling | Lifts materials and supports drilling rigs in underground operations. |

Elevators and Lifts | Provides strength and controlled movement for vertical transportation systems. |

Home | Cost-effective and easy to install for various home maintenance tasks. |

You benefit from the wire rope’s strength and fatigue resistance in heavy-duty environments. For lighter, less demanding tasks, cable offers a practical and affordable solution.

Powerful Machinery’s product range, including wire rope clips, ensures you have the right accessories for secure and reliable connections in any setting.

Cost and Maintenance

You need to weigh cost and maintenance when comparing wire rope vs cable. Wire rope requires more raw materials and a complex manufacturing process, which increases its cost. Coatings and finishes add to the price but extend the rope’s lifespan.

Cable, with fewer wires and simpler construction, costs less if your application does not demand high strength or flexibility.

Aspect | Wire Rope | Cable |

|---|---|---|

Cost Factors | More wires needed increases raw material and manufacturing complexity. | Fewer wires can lead to cost savings if flexibility and strength are met. |

Coating Requirements | Coatings add to the cost but improve durability and lifespan. | Similar coatings can be applied, affecting overall cost and maintenance. |

Maintenance Requirements | Requires periodic inspections based on usage and environmental conditions. | Inspections are also necessary, with a focus on wear and operational conditions. |

You should always perform visual inspections before and after operations. Maintenance plans must consider the environment and how often you use the product. Document inspection results and address any defects immediately to ensure safety and reliability.

Cable and Wire Rope: Similarities

Shared Materials

You will notice that wire rope and cable often share many of the same materials. Manufacturers select these materials for their strength, durability, and resistance to environmental factors. Stainless steel stands out for its corrosion resistance and reliability in harsh conditions.

Tungsten and titanium provide high tensile strength, making them suitable for demanding applications. You also see advanced alloys like Inconel® and Vitallium® in specialized environments.

For insulation and protection, PVC, FEP (Teflon®), nylon, polyurethane, polyethylene, and polypropylene are common choices. These coatings help extend the lifespan of both wire rope and cable.

Material | Description |

|---|---|

Stainless Steel | Commonly used for its strength and corrosion resistance. |

Tungsten | Utilized for its high tensile strength and durability. |

Nitinol | Known for shape memory properties in specialized applications. |

Vitallium® | Cobalt-chromium alloy is used in medical devices for biocompatibility. |

Inconel® | Nickel-chromium alloy with high-temperature resistance. |

Titanium | Valued for its strength-to-weight ratio and corrosion resistance. |

Molybdenum | High melting point and strength at elevated temperatures. |

PVC | Provides insulation and protection. |

FEP (Teflon®) | Non-stick properties and chemical resistance. |

Nylon | Durable and flexible for cable applications. |

Polyurethane | Excellent abrasion resistance and flexibility. |

Polyethylene | Used for insulation and protection. |

Polypropylene | Lightweight and chemical-resistant. |

Versatility in Industry

You benefit from the versatility of wire rope and cable across many industries. Both products play essential roles in construction, marine, and offshore operations. You see wire rope and cable used in oil and gas, marine fishing, and mining.

Their adaptability allows you to tackle a wide range of tasks, from lifting heavy loads to securing structures and transmitting signals.

Construction

Marine

Offshore

Oil and Gas

Marine Fishing

Mining

Wire rope and cable help you meet the demands of complex projects, whether you work on land or at sea.

Maintenance and Safety

You must follow strict maintenance and safety practices to ensure reliable performance. Store wire rope and cable in dry environments to prevent corrosion. Protect them from harsh weather when not in use. Maintain a detailed log of inspections and maintenance activities.

Regularly inspect for damage, such as fraying or corrosion. Clean both wire rope and the cable to remove dirt and debris. Lubricate them properly to reduce friction and prevent rust. Always use the correct size and type for your specific job. Maintain proper tension and avoid overloading to prevent slack and kinks.

Tip: Consistent inspection and maintenance extend the life of your wire rope and cable, keeping your operations safe and efficient.

Applications of Wire Rope and Cable

Industrial Uses

You see wire rope and cable in many industrial settings where strength and safety matter most. In crane operations, wire rope plays a vital role in lifting heavy loads and preventing accidents. Offshore cranes rely on specialized wire rope to withstand harsh marine conditions.

In the automotive industry, cable and wire rope support car recovery and safety mechanisms. You also find these products in unique environments, such as entertainment venues, where they provide secondary safety systems for performances.

Real-world projects, like the Galway City Cathedral Bridge, use wire rope assemblies to enhance traveler safety and security.

Crane safety and lifting operations

Offshore and marine cranes

Automotive recovery and safety systems

Entertainment rigging and secondary safety

Bridge and infrastructure security

Engineering and Construction

You depend on wire rope and cable for engineering and construction projects that demand reliability. These products support structures, move materials, and ensure safe operations. Industry standards, such as ASME B30.16, guide the design and use of wire rope hoists.

OSHA regulations require proper training and maintenance to keep your workplace safe. Military projects follow MIL-DTL-83420 to guarantee uniformity and performance. You can trust wire rope to meet strict requirements for strength and durability in every application.

Structural support and lifting in construction

Compliance with ASME B30.16 and OSHA safety standards

Military-grade uniformity with MIL-DTL-83420

Powerful Machinery Solutions

You gain a competitive edge when you choose Powerful Machinery’s steel wire rope and wire rope clips for your toughest applications. These products deliver high strength, a non-rotating design, and abrasion resistance, making them ideal for demanding environments.

Powerful Machinery’s solutions meet or exceed international certifications, including ISO9001, TUV Rheinland, and OSHA. You can rely on these products for consistent performance and safety, whether you work in construction, marine, or transportation.

The wide range of configurations ensures you find the right fit for every project.

Tip: Choose certified steel wire rope and accessories from Powerful Machinery to maximize safety and reliability in your operations.

Selection Guide: How to Choose

Selecting the right product for your application requires a careful look at several factors. You must consider load, environment, flexibility, safety, cost, and expert advice. This guide will help you make an informed decision when comparing steel cable vs wire rope for your project.

Load and Strength

You should always start your selection by evaluating the load and strength requirements. The right choice ensures your equipment operates safely and efficiently. The following table outlines the main factors you need to assess:

Factor | Description |

|---|---|

Resistance to breaking | Choose a product with enough strength to handle the maximum load without failure. |

Resistance to fatigue bending | Select ropes with many small wires if frequent bending occurs around sheaves and drums. |

Resistance to vibrational fatigue | Consider energy absorption at tangent points or end fittings for long-term use. |

Resistance to abrasion | Opt for ropes with fewer, larger wires for better abrasion resistance on hard surfaces. |

Crushing resistance | Ensure the rope can withstand crushing forces to prevent distortion during operation. |

You need to match the capacity of the wire rope or cable to the demands of your application. For heavy lifting, wire rope offers higher strength and durability. In lighter tasks, a steel cable may provide enough capacity at a lower cost.

Always check the manufacturer’s specifications for breaking strength and working load limits.

Environment and Corrosion

Environmental conditions play a major role in your selection process. You must protect your investment from corrosion and degradation. Consider these points:

Exposure to saltwater and chemicals increases the risk of metal degradation.

Hot and humid climates raise corrosion risks.

Saltwater is highly corrosive, especially in marine environments.

Chemicals like acids and bases speed up corrosion.

Humidity and temperature changes can cause rust.

You can improve durability by choosing the right material and finish:

Use epoxy or zinc coatings in humid regions.

Apply corrosion-resistant lubricants in changing temperatures.

Select marine-grade materials for saltwater exposure.

Stainless steel wire rope resists rust and works well in corrosive environments.

Aluminum and copper offer additional corrosion resistance.

In coastal areas, you should choose stainless steel wire rope to ensure long-term safety and reduce replacement frequency. Galvanized steel wire rope provides an economical option for less aggressive environments.

Flexibility Needs

You must match the flexibility of your wire rope or cable to the application. Flexibility depends on construction, core type, and wire arrangement. Applications with frequent bending, such as winches or pulleys, require ropes with more wires per strand. For structural support, less flexible options work best.

Load capacity: Determine the maximum load and select a construction that supports it.

Flexibility: Choose more wires per strand for frequent bending.

Environment: Use stainless or galvanized steel for corrosion resistance.

Abrasion resistance: Thicker wires and steel cores improve durability.

Rotation resistance: For cranes and elevators, use rotation-resistant constructions.

A 7×19 steel cable offers high flexibility and works well in control cables or winches. A 1×19 construction provides less flexibility but excels in structural support and alignment. You must balance flexibility and strength to achieve the best performance.

Safety and Standards

You must follow safety and quality standards to protect your team and equipment. Certified products ensure compliance and reduce risks. Look for these certifications:

CCC Certification: Meets electrical safety standards.

CE Certification: Complies with European safety requirements.

ASME B30.9 Standard: Covers lifting slings, inspection, and safe use.

Certified cables undergo testing to withstand hazards and prevent failures. Using non-certified products can lead to accidents and equipment damage. Safety and quality standards cover attachment, buying, fabrication, inspection, maintenance, and training. You should always verify certifications before making a selection.

Tip: Always document inspections and maintenance to maintain compliance and extend the life of your wire rope or cable.

Cost and Project Specs

Cost and project specifications influence your final decision. You must balance initial investment with long-term durability and performance.

Galvanized steel wire rope is cost-effective but may not last in harsh conditions.

Stainless steel wire ropes cost more but offer superior durability in marine settings.

Simple rigging products are less expensive than custom-engineered solutions.

Specialty cables have higher upfront costs but may reduce labor and replacement expenses.

Core type affects price: Fiber Core is the cheapest, Independent Wire Rope Core is the most expensive but strongest.

Surface treatments, such as polished finishes, add to the cost.

You should review your project’s requirements and budget. Select the product that meets your needs for durability, capacity, and performance.

Expert Consultation

You gain valuable insights by consulting with wire rope and cable experts. These professionals help you understand load requirements, application challenges, and the best options for your project. Experts compare the cost, performance, and longevity of different constructions.

Engaging with suppliers or manufacturers leads to better-informed decisions and ensures your selection matches your safety and operational goals.

Note: Powerful Machinery’s team offers personalized support and certified solutions for all your lifting and rigging needs. You can trust their expertise to guide your selection and maximize safety and durability.

You will notice many similarities in the selection process for steel cable vs wire rope. Both require careful evaluation of properties, construction, and application needs. By following these guidelines, you ensure your equipment delivers reliable performance and long-lasting durability.

Conclusion

You now understand the core differences and similarities between wire rope and cable. Wire rope excels in mechanical strength and load-bearing, while cable often serves electrical or data needs. Review the table below for a quick comparison:

Feature | Wire Rope | Cable (Electrical) |

|---|---|---|

Primary Function | Lifting, pulling, support | Power, signal transmission |

Typical Materials | Steel, stainless steel, alloys | Copper, aluminum, PVC, PTFE |

Common Uses | Cranes, elevators, rigging | Electronics, power grids, networks |

For specialized applications, consider construction, material, and flexibility. Powerful Machinery’s certified solutions and expert team help you select the right product for your industry.

FAQ

What is the main difference between wire rope and steel cable?

You will notice that wire rope uses multiple strands twisted around a core for heavy-duty lifting. Steel cable often refers to a simpler construction with fewer wires. You should choose wire rope for demanding tasks and steel cable for lighter applications.

When should you use a steel cable instead of a wire rope?

You should use a steel cable for tasks that require flexibility and lower load capacity. Steel cable works well for home projects, light rigging, and some automotive uses. You can rely on a steel cable when you do not need the high strength of a wire rope.

How do you maintain steel cable for long-term use?

You should inspect the steel cable regularly for signs of wear, corrosion, or fraying. Clean the steel cable to remove dirt and debris. Lubricate the steel cable to reduce friction and prevent rust. Store steel cable in a dry place to extend its lifespan.

Can you use a steel cable outdoors?

You can use a steel cable outdoors if you select the right material and finish. Galvanized or stainless steel cable resists corrosion and handles harsh weather. You should always check the environment and choose a steel cable designed for outdoor use.

What accessories do you need with a steel cable?

You need accessories like wire rope clips, thimbles, and turnbuckles to secure steel cable connections. These accessories help you create loops, adjust tension, and ensure safety. You should select accessories that match the diameter and type of steel cable for the best results.