You must select a wire rope clamp that matches the exact size of your wire rope or cable. Accurate measurement protects your equipment and ensures reliable performance. Powerful Machinery provides certified products and expert support for secure wire rope connections.

Use sizing charts and double-check your measurements before you purchase. If you ask yourself what size wire rope clamp do I need, precise sizing keeps your installation safe.

Key Takeaways

Always measure the bare steel diameter of your wire rope, not the coating, to ensure a proper fit for the clamp.

Use precision tools like digital or vernier calipers for accurate measurements; avoid tape measures for safety-critical applications.

Refer to sizing charts from trusted sources like Powerful Machinery to match the clamp size directly to your wire rope diameter.

Double-check your measurements and specifications to prevent slippage and ensure a secure connection.

Follow industry standards and guidelines for the number of clips needed based on wire rope diameter to maintain safety.

How to Measure Wire Rope Diameter?

Tools for Measuring

You need the right tools to measure wire rope diameter accurately. A precision caliper is the best choice. You can use a digital caliper for quick readings or a vernier caliper for more detailed measurements. A wire rope gauge also works well for standard sizes.

Avoid using tape measures or rulers, as these tools do not provide the accuracy required for safety-critical applications.

Recommended tools:

Digital caliper

Vernier caliper

Wire rope gauge

Step-by-Step Measurement

Follow these steps to measure your wire rope diameter:

Clean the wire rope. Remove dirt, grease, or debris from the surface.

Select a straight section of the rope. Avoid measuring near bends or kinks.

Place the caliper jaws perpendicular to the rope strands. Do not compress the rope.

Read the measurement at the widest point of the rope.

Repeat the measurement at several points along the rope. Use the largest reading as your final diameter.

Tip: Always measure the rope itself, not the coating. If your wire rope has a plastic or vinyl coating, measure the bare steel diameter for clamp selection.

Tips for Accuracy

You must ensure your measurement falls within industry tolerances. International standards such as EN 12385, DIN 3055, and ASTM A1023 specify acceptable diameter ranges. The actual diameter should not exceed +5% of the nominal size and should not be below the nominal diameter.

For ropes up to 8 mm, EN 12385 allows a maximum of +5%. DIN 3055 typically permits +4%. ASTM A1023 tolerances range from ±2.5% to ±5%, depending on rope type.

Standard | Diameter Size | Tolerance Specification |

|---|---|---|

EN 12385 | Up to 8 mm | Actual diameter should not exceed +5% of nominal; negative tolerance typically 0% |

Over 8 mm | Actual diameter should not exceed +5% and should not be below the nominal diameter | |

DIN 3055 | All sizes | Typically allowed +4% / -0% for nominal diameters |

ASTM A1023 | Varies by type | Diameter tolerances within ±2.5% to ±5% depending on rope type and construction |

You should always double-check your measurements before selecting a wire rope clamp. Accurate sizing helps prevent slippage and ensures a secure connection.

What Size Wire Rope Clamp Do I Need?

Sizing Chart Overview

Choosing the right size for your wire rope clamp starts with understanding the sizing chart. You must match the clamp size directly to the diameter of your wire rope.

Powerful Machinery provides detailed sizing charts for all certified products. These charts list the recommended clamp size for each wire rope diameter, making your selection process straightforward.

Wire Rope Diameter | Recommended Clamp Size | Clamp Type Options |

|---|---|---|

3 mm | 3 mm | Simplex, Duplex, DIN741 |

6 mm | 6 mm | Simplex, Duplex, DIN741 |

10 mm | 10 mm | Simplex, Duplex, DIN741 |

12 mm | 12 mm | Simplex, Duplex, DIN741 |

16 mm | 16 mm | Simplex, Duplex, DIN741 |

You should always refer to the official sizing chart before you purchase a clamp. Powerful Machinery’s charts help you avoid mismatches and ensure a secure connection. If you wonder what size wire rope clamp do I need, start by checking the chart for your specific wire rope diameter.

Note: Sizing charts from Powerful Machinery are based on international standards such as OSHA and ASME B30.5-2004. These standards guarantee that each clamp meets strict safety and performance requirements.

Matching Clamp to Rope Diameter

You must select a clamp that matches the exact diameter of your wire rope. This step is critical for safety and reliability. If your wire rope has a plastic or vinyl coating, measure only the steel core diameter. Do not include the coating in your measurement. The clamp must grip the steel strands directly to prevent slippage.

When you ask yourself what size wire rope clamp do I need, consider these key factors:

The clamp size must match the wire rope diameter for secure holding.

You should verify the specifications of both the wire rope and the clamp before making a selection.

Consult an expert if you have doubts about the type of work or environmental conditions.

Powerful Machinery’s certified clamps come in various sizes to fit every wire rope diameter. You can find simplex, duplex, and DIN741 designs, each with specific advantages for different applications. Always double-check your measurements before you choose a clamp.

Use a precision caliper or wire rope gauge for the most accurate results.

Tip: Double-check your measurements and compare them to the sizing chart. This step helps you avoid common mistakes and ensures a safe installation.

Industry standards require you to select and install wire rope and clamps according to OSHA regulations. You must comply with ASME B30.5-2004 design criteria and specific breaking force requirements. Powerful Machinery’s products meet or exceed these standards, giving you confidence in every connection.

Key factors to consider when selecting the correct wire rope clamp size:

Match clamp size to wire rope diameter.

Verify specifications for both wire rope and clamp.

Consider environmental conditions and type of work.

Follow OSHA and ASME standards for installation.

If you still ask what size wire rope clamp do I need, use Powerful Machinery’s sizing charts and certified products for guidance. You can always contact their expert team for support. Accurate sizing and proper installation keep your wire rope connections safe and reliable.

Wire Rope Clip Types and Features

Stainless Steel Wire Rope Clips

You need wire rope clip solutions that deliver strength and reliability in demanding environments. Powerful Machinery’s stainless steel wire rope clips offer superior corrosion resistance, making them ideal for marine, coastal, and industrial applications.

You can choose from simplex, duplex, and DIN741 designs, each engineered for secure grip and easy installation. The 316 marine-grade stainless steel wire rope clip provides unmatched durability in saltwater and high-humidity conditions.

You benefit from precision manufacturing and a polished finish that protects your wire rope and maintains efficiency.

Material Type | Corrosion Resistance | Applications | Features |

|---|---|---|---|

304 Stainless Steel | Corrosion Resistant | Marine, rigging | 80% efficiency rating |

316 Stainless Steel | Superior Corrosion Resistance | Saltwater, coastal, industrial | U-bolt clamp design, precision |

Tip: For marine or outdoor use, select a stainless steel wire rope clip to maximize longevity and safety.

Malleable vs Drop-Forged Clips

You must understand the differences between malleable and drop-forged wire rope clip types before making your selection. Malleable wire rope clip options suit light-duty, non-critical tasks.

Drop-forged wire rope clip designs handle heavy-duty, critical applications with thicker profiles and greater durability. You should always match the wire rope clip type to your load requirements and working environment.

Type of Clip | Load Capacity | Durability |

|---|---|---|

Malleable Wire Clips | Light-duty, non-critical applications | Thinner material |

Drop-forged Clips | Heavy-duty, critical applications | Thicker profile, durable |

You also find U-bolt clips among the most common wire rope clip designs. U-bolt clips feature a U-bolt, saddle, and nuts, providing a secure connection for various wire rope diameters. Double-saddle wire rope clip designs simplify installation and allow for flexible positioning.

Type | Features |

|---|---|

U-bolt Wire Rope Clips | Common type, forged or malleable, U-bolt, two nuts, saddle |

Forged Wire Rope Clips | Forged steel, heavy-duty, consistent grain structure |

Malleable Wire Rope Clips | Malleable cast iron, light-duty, may fracture under heavy use |

Double Saddle Wire Clips | Two saddles, install in either direction, easy installation |

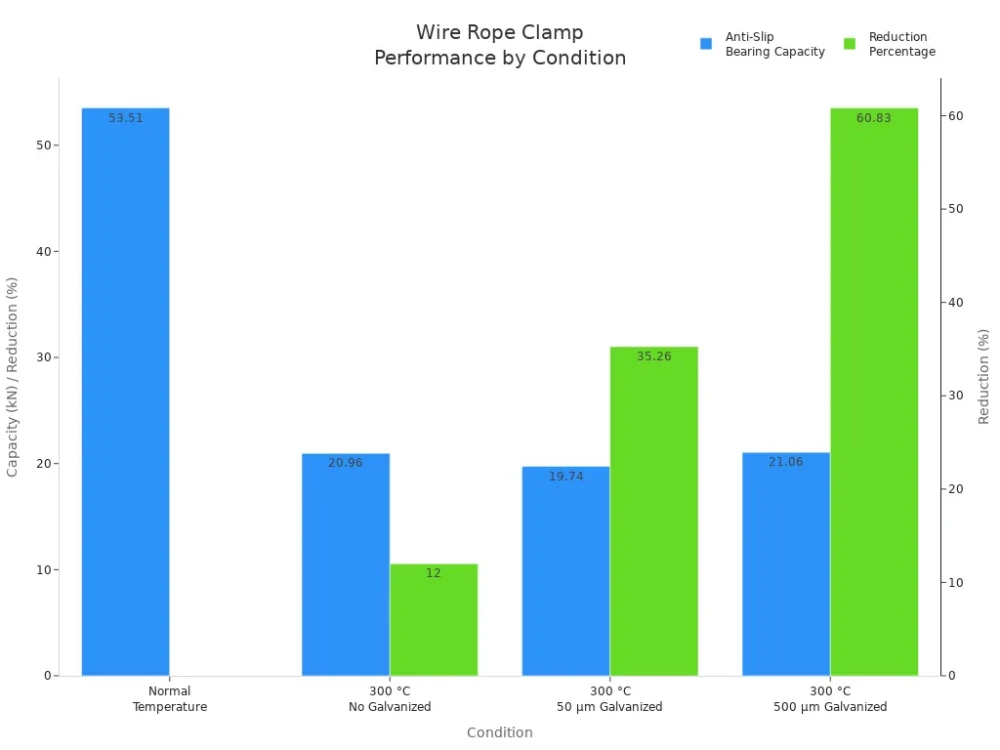

You should consider environmental factors such as temperature and humidity when selecting a wire rope clip. High temperatures and exposure to moisture can reduce anti-slip bearing capacity.

Stainless steel wire rope clips maintain performance in harsh conditions, making them the preferred choice for marine, construction, and industrial projects.

Note: Always select the wire rope clip type and material that matches your application and environment for maximum safety and reliability.

Common Mistakes with Wire Rope Clamps

Wrong Size Selection

You often see problems when the clamp size does not match the wire rope diameter. If you choose a clamp that is too large, it will not grip the rope securely. A clamp that is too small can damage the wire strands and reduce the rope’s strength.

Always measure the wire rope with a precision tool before selecting a clamp. Double-check your measurements against the sizing chart from Powerful Machinery. This step helps you avoid slippage and ensures a safe connection.

Tip: Always use the largest diameter reading from multiple measurements to select your clamp size.

Metric vs. Imperial Confusion

You may encounter confusion between metric and imperial measurements. Wire rope and clamps come in both millimeter and inch sizes. Mixing these units can lead to improper fit and unsafe installations. For example, a 3/16-inch clamp does not fit a 5 mm rope perfectly.

You should always confirm the measurement units on both the wire rope and the clamp packaging. Use a conversion chart if you need to switch between metric and imperial sizes.

Measurement System | Common Rope Sizes | Common Clamp Sizes |

|---|---|---|

Metric | 3 mm, 6 mm, 10 mm | 3 mm, 6 mm, 10 mm |

Imperial | 1/8″, 3/16″, 3/8″ | 1/8″, 3/16″, 3/8″ |

Note: Consistency in measurement units prevents mismatches and keeps your installation safe.

Ignoring Rope Coating

You must pay attention to the rope’s coating when selecting a clamp. Many wire ropes have a plastic or vinyl coating for extra protection. If you measure the coated diameter instead of the steel core, you risk choosing a clamp that does not grip the rope properly.

Neglecting the wire rope coating can result in significant deterioration of the rope due to environmental exposure, which in turn can weaken the clamps that secure it. This degradation can lead to increased risks of slippage or failure when the rope is under load, thereby compromising safety.

Always measure the bare steel diameter and select a clamp that fits the core. This practice supports proper usage of wire rope clips and maintains the integrity of your connection.

Alert: Remove the coating from the measurement area before sizing your clamp for best results.

Installation and Safety Tips

Number of Clips Needed

You must use the correct number of clips for safe application when securing wire rope. The number depends on the diameter of your wire rope. Industry standards, such as OSHA §1926.251 and manufacturer guidelines, help you determine the right amount.

Using too few clips can lead to slippage and unsafe connections. Always check the recommended table before installation.

Diameter of Wire Rope | Recommended Number of Clips |

|---|---|

1/8 inch | 2 |

3/16 inch | 2 |

1/4 inch | 2 |

5/16 inch | 2 |

3/8 inch | 2 |

7/16 inch | 2 |

1/2 inch | 3 |

Tip: For ropes ½ inch and greater, refer to OSHA and manufacturer tables for guidance. Always follow the recommendations for your specific wire rope diameter.

Proper Installation Steps

You need to follow the correct method for attaching u-bolt clips to ensure a secure and reliable connection. Begin by measuring the wire rope diameter accurately. Lay out the rope and plan the turnback length according to the table below. Position the first clip one base width from the dead end of the rope.

Place the saddle on the live end and the U-bolt on the dead end. Tighten the nuts evenly to the specified torque.

Cable Size (Inches) | Minimum Number of Clips | Amount of Rope Turnback (Inches) | Torque (Ft. Lbs) |

|---|---|---|---|

1/8 | 2 | 3-3/4 | 4.5 |

3/16 | 2 | 3-3/4 | 7.5 |

1/4 | 2 | 4-3/4 | 15 |

5/16 | 2 | 5-1/4 | 30 |

3/8 | 2 | 6-1/2 | 45 |

7/16 | 2 | 7 | 65 |

1/2 | 3 | 11-1/2 | 65 |

Follow these steps for installation:

Measure the wire rope diameter with a parallel-jawed caliper.

Unreel the wire rope properly to avoid kinks.

Cut the rope at a straight angle and seize the ends.

Lay out the rope and plan the turnback length.

Attach the first clip one base width from the dead end.

Place the saddle on the live end and the U-bolt on the dead end.

Tighten the nuts evenly to the recommended torque.

Space additional clips evenly along the turnback.

Inspect the installation for secure fit and proper tightening.

Note: Regular inspections, cleaning, and proper storage help maintain the integrity of your wire rope clamps. Lubricate the wire rope periodically and store it in a dry, ventilated area.

Conclusion

You protect your equipment and ensure safety when you match the wire rope clamp size to the exact rope diameter. Powerful Machinery’s certified products and detailed sizing charts help you make the right choice every time.

Double-check your measurements and reach out to experts if you have questions. You can access valuable resources, including:

Comprehensive instructions for selecting and installing wire rope clips

Step-by-step installation guidance

Safety tips to prevent errors

Visit Powerful Machinery’s website for more information and product options.

FAQ

How do you choose the correct wire rope clamp size?

You match the clamp size to the exact diameter of your wire rope. Always measure the bare steel, not the coating. Refer to Powerful Machinery’s sizing charts for precise selection.

Can you reuse wire rope clamps?

You should not reuse wire rope clamps in critical applications. Reusing clamps can reduce grip strength and compromise safety. Always inspect clamps for wear before considering reuse.

What is the difference between simplex and duplex wire rope clips?

Simplex clips have a single saddle. Duplex clips feature two saddles for extra security. Duplex designs provide a stronger grip for heavy-duty or high-vibration environments.

Are stainless steel wire rope clips suitable for marine use?

Yes. Stainless steel wire rope clips from Powerful Machinery resist corrosion and rust. You can use them confidently in marine, coastal, and outdoor environments.